Preparation method of nanopolyaniline-containing compound anti-corrosion coating auxiliary agent

A nano-polyaniline, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of poor compatibility with epoxy coatings, and the improvement of performance is not better reflected. Achieve the effect of increasing adhesion and avoiding secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

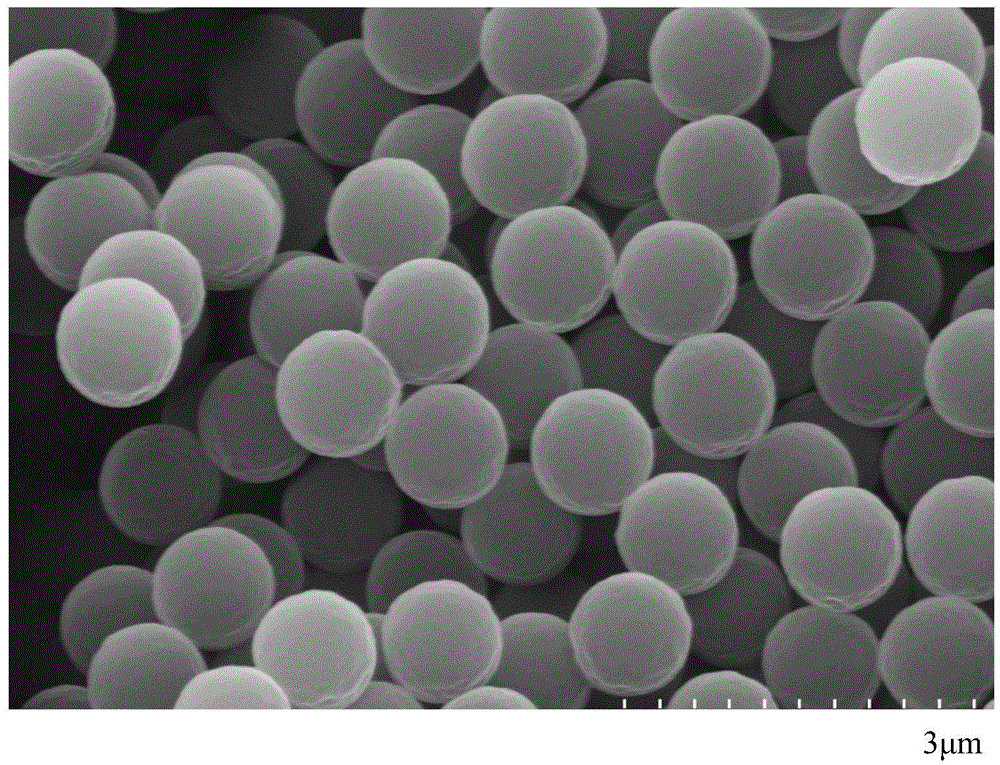

[0029] (1) Add 0.25g polyvinylpyrrolidone, 45mL absolute ethanol, magnetic stirrer to the three-necked flask in turn, turn on the cycle of condensation, magnetic stirring and blow nitrogen to purge and remove oxygen for 15min, and add 5g methacrylic acid to shrink with injection needle. Glycerides, stir fully for 0.5h at a uniform speed at room temperature, and raise the temperature of the system to 70°C.

[0030] (2) Fully dissolve 0.05 g of initiator azobisisobutyronitrile in 5 mL of absolute ethanol. After the temperature of the system in step (1) stabilizes, add it to the system with an injection needle and react for 24 hours.

[0031] (3) Centrifuge the product obtained in step (2) at a speed of 2000r / min for 2 minutes on a centrifuge, pour out the supernatant, add ethanol, and then ultrasonically disperse, repeat the above centrifugation steps, repeat three times, and then repeat the above steps with distilled water. Centrifugal washing three times to wash away the surfactant...

Embodiment 2

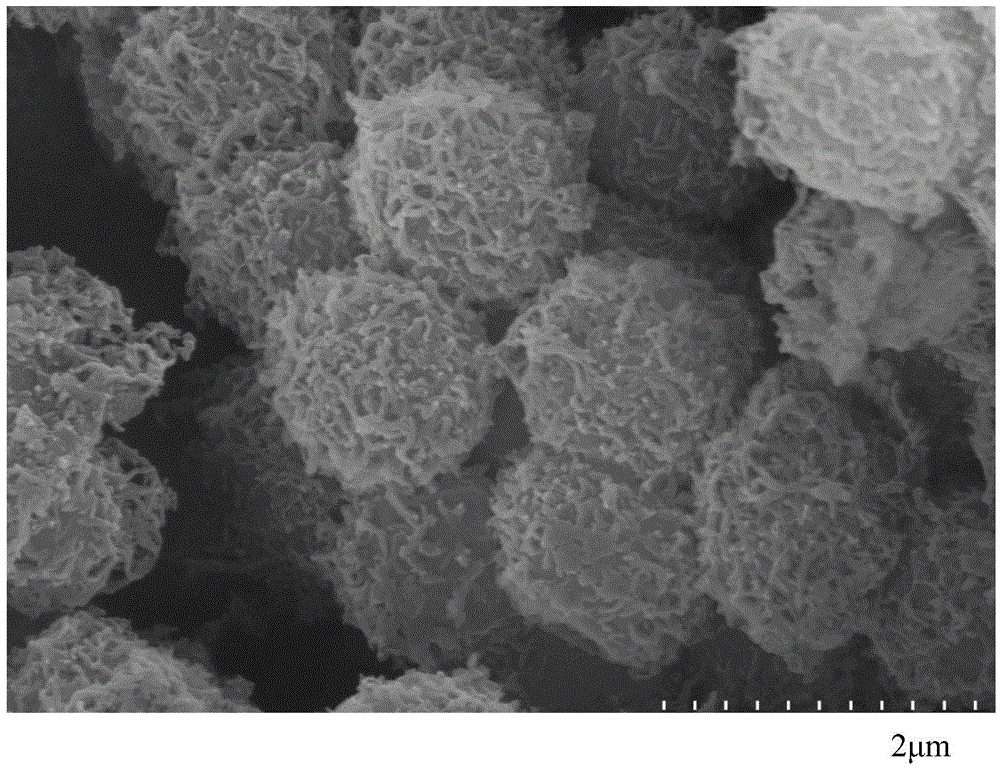

[0036] (1) Adjust the mass of polyvinylpyrrolidone in Example 1 to 0.50g;

[0037] (2)~(6) Same as Example 1.

Embodiment 3

[0039] (1) Adjust the mass of polyvinylpyrrolidone in Example 1 to 0.75g;

[0040] (2)~(6) Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com