Halloysite nanotube / epoxy nanocomposite

A technology of halloysite nanotubes and nanocomposites, which is applied in the field of halloysite nanotubes/epoxy resin nanocomposites to achieve good practical value, enhance interface interaction, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

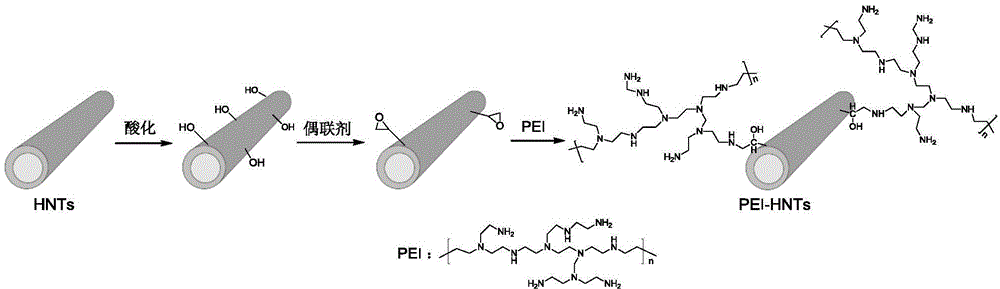

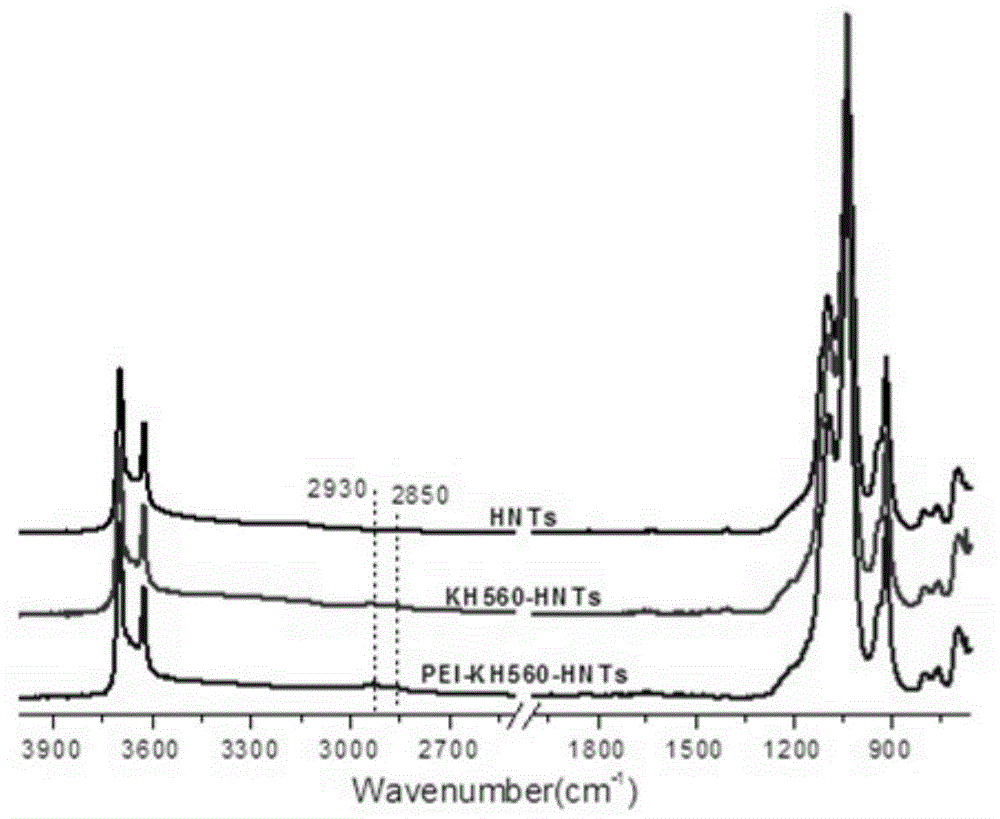

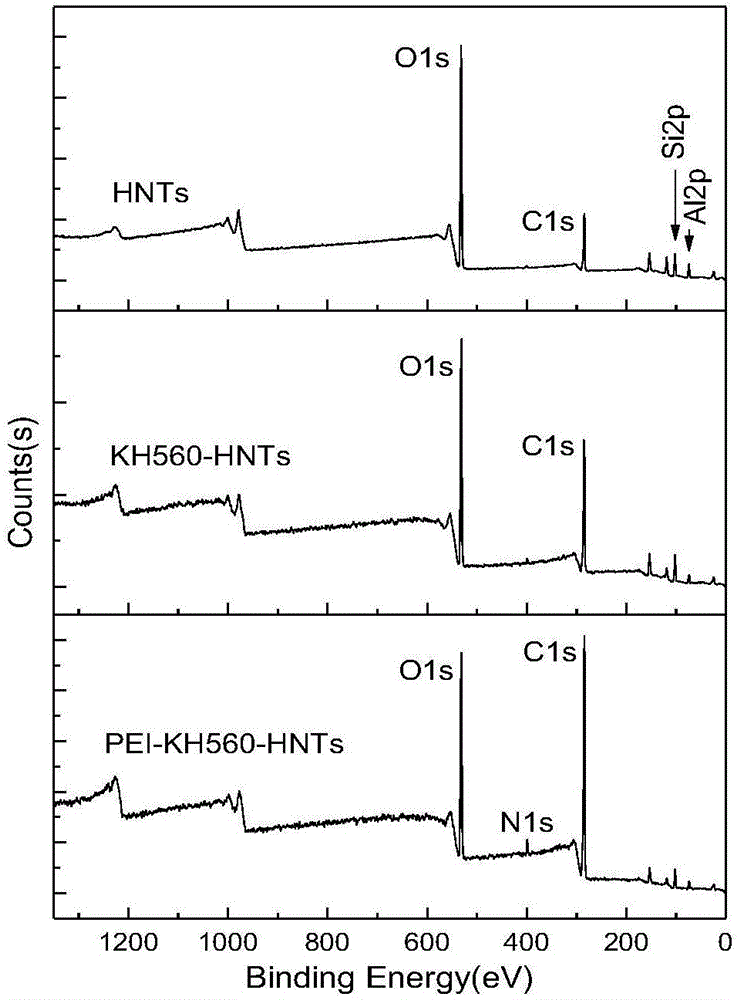

[0051] (1) Acidification of halloysite nanotubes: mix halloysite nanotube particles with 1mol / L hydrochloric acid solution at a mass ratio of 1:20, ultrasonically disperse for 60 minutes, stir for 4 hours, centrifuge, filter, and wash with water until medium properties, acidified halloysite nanotubes were obtained after drying at 110°C for 2 hours;

[0052] (2) Surface modification of halloysite nanotubes by silane coupling agent: prepare a homogeneous suspension with acidified halloysite nanotubes and toluene at a mass ratio of 1:50, and continue ultrasonic treatment for 30 minutes. Add dropwise γ-glycidyl etheroxypropyltrimethoxysilane (KH560) with 20% mass of acidified halloysite nanotubes, and stir and react at 120°C for 4 hours; after the reaction, filter, wash, and dry to obtain surface-modified Halloysite nanotubes with epoxy groups (KH560-HNTs);

[0053] (3) Branched polyethyleneimine grafted halloysite nanotubes: the epoxy group-modified halloysite nanotubes obtained i...

Embodiment 2

[0066] (1) Acidification of halloysite nanotubes: Mix halloysite nanotube particles with 2mol / L sulfuric acid solution at a mass ratio of 1:30, ultrasonically disperse for 30 minutes, stir for 12 hours, centrifuge, filter, and wash with water until neutral ; Import the washed product into a clean container, and dry at 100°C for 3 hours to obtain acidified halloysite nanotubes;

[0067] (2) Surface modification of halloysite nanotubes by silane coupling agent: take halloysite nanotubes by weighing, add 20 times the mass of acetone solution, ultrasonic treatment for 30 minutes; -(3,4-epoxycyclohexyl)ethyltrimethoxysilane (A-186), continue ultrasonic stirring for 30 minutes, add sodium hydroxide solution to make the pH of the mixture neutral, and react at 70°C for 5 hour; after the reaction finishes, filter, wash, dry, obtain the halloysite nanotube that the surface is modified with epoxy group;

[0068] (3) Branched polyethyleneimine grafted halloysite nanotubes: ultrasonically...

Embodiment 3

[0076] (1) Acidification of halloysite nanotubes: halloysite nanotube particles are mixed with 30% hydrogen peroxide at a mass ratio of 1:10, ultrasonically dispersed for 45 minutes to obtain a uniformly dispersed system; transferred to 80°C and stirred for 48 hours, Centrifuge, filter, wash with water until neutral, and dry at 110°C for 2.5 hours to obtain acidified halloysite nanotubes;

[0077] (2) Surface modification of halloysite nanotubes by silane coupling agent: Weigh acidified halloysite nanotubes, add 10 times the mass of ethanol solution (volume ratio of ethanol to water is 95 / 5), and continue ultrasonic treatment for 45 minutes ; The pH value of the solution is adjusted to 4 to 5 with dilute hydrochloric acid, and γ-glycidyl etheroxypropylmethyldimethoxysilane (AC-661) of acidified halloysite nanotube quality 50% is added dropwise, at 80°C The reaction was stirred for 24 hours. After the reaction is finished, filter, wash, and dry to obtain halloysite nanotubes w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com