High-performance epoxy resin composition for vacuum infusion molding and preparation method thereof

A technology of vacuum introduction molding and epoxy resin, which is applied in the field of high-performance epoxy matrix resin composition and its preparation, can solve the problems of high viscosity, low mechanical properties and flammability, and achieve uniform performance and good internal compactness , the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

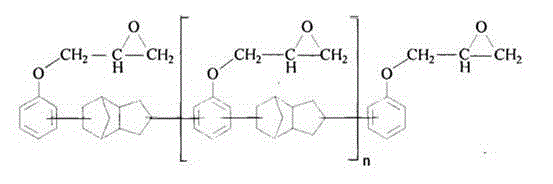

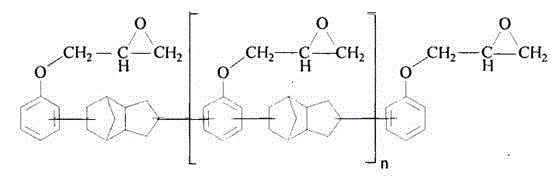

Image

Examples

Embodiment 1

[0024] Embodiment 1: 50g dicyclopentadiene (DCPD) type epoxy resin (purchased from Da Nippon Printing HP-7200H, epoxy equivalent (EEW): 279), 45.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value 0.48-0.54), 5.0g glycidylamine epoxy resin JEh-012 (purchased from Changshu Jiafa Chemical Co., Ltd., Epoxy value is 0.80-0.85) mixed, mechanically stirred and dispersed at 30°C at a speed of 800 rpm for 5 minutes, while stirring, add 0.5g kaolin and 10.0g 1,4-butanediol diglycidyl ether in sequence, Mechanically stir and disperse at a speed of 800 rpm for 10 minutes, then stand at room temperature for use, mechanically stir 40.0 g of phthalic anhydride at room temperature at a speed of 600 rpm, and then add 0.5 g of 2 - Ethyl-4-methylimidazole, mechanically stirred at a speed of 600 rpm for 5-10 minutes at room temperature. Mix the above components at room temperature, mechanically stir and...

Embodiment 2

[0025]Embodiment 2: 60g dicyclopentadiene (DCPD) type epoxy resin (purchased from Da Nippon Printing HP-7200H, epoxy equivalent (EEW): 279), 36.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value 0.48-0.54), 4.0g glycidylamine epoxy resin JEh-012 (purchased from Changshu Jiafa Chemical Co., Ltd., Epoxy value is 0.80-0.85) mixed, mechanically stirred and dispersed at 30°C at a speed of 800 rpm for 5 minutes, while stirring, add 0.5g kaolin and 10.0g 1,4-butanediol diglycidyl ether in sequence, Mechanically stir and disperse at a speed of 800 rpm for 10 minutes, then stand at room temperature for use, and mechanically stir and disperse 40.0 g of phthalic anhydride at room temperature at a speed of 600 rpm for 5 minutes, and then, while stirring, add 0.5 g of 2-ethyl-4-methylimidazole was also mechanically stirred at a speed of 600 rpm for 5-10 minutes at room temperature to disperse. Mi...

Embodiment 3

[0026] Embodiment 3: 70g dicyclopentadiene (DCPD) type epoxy resin (purchased from Da Nippon Printing HP-7200H, epoxy equivalent (EEW): 279), 27.0g bisphenol A type glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value 0.48-0.54), 3.0g glycidylamine epoxy resin JEh-012 (purchased from Changshu Jiafa Chemical Co., Ltd., Epoxy value is 0.80-0.85) mixed, mechanically stirred and dispersed at 30°C at a speed of 800 rpm for 5 minutes, while stirring, add 0.5g kaolin and 10.0g 1,4-butanediol diglycidyl ether in sequence, Mechanically stir and disperse at a speed of 800 rpm for 10 minutes, then stand at room temperature for use, and mechanically stir and disperse 40.0 g of phthalic anhydride at room temperature at a speed of 600 rpm for 5 minutes, and then, while stirring, add 0.5 g of 2-ethyl-4-methylimidazole was also mechanically stirred at a speed of 600 rpm for 5-10 minutes at room temperature to disperse. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com