Method for improving breakdown strength and energy storage density of polymer

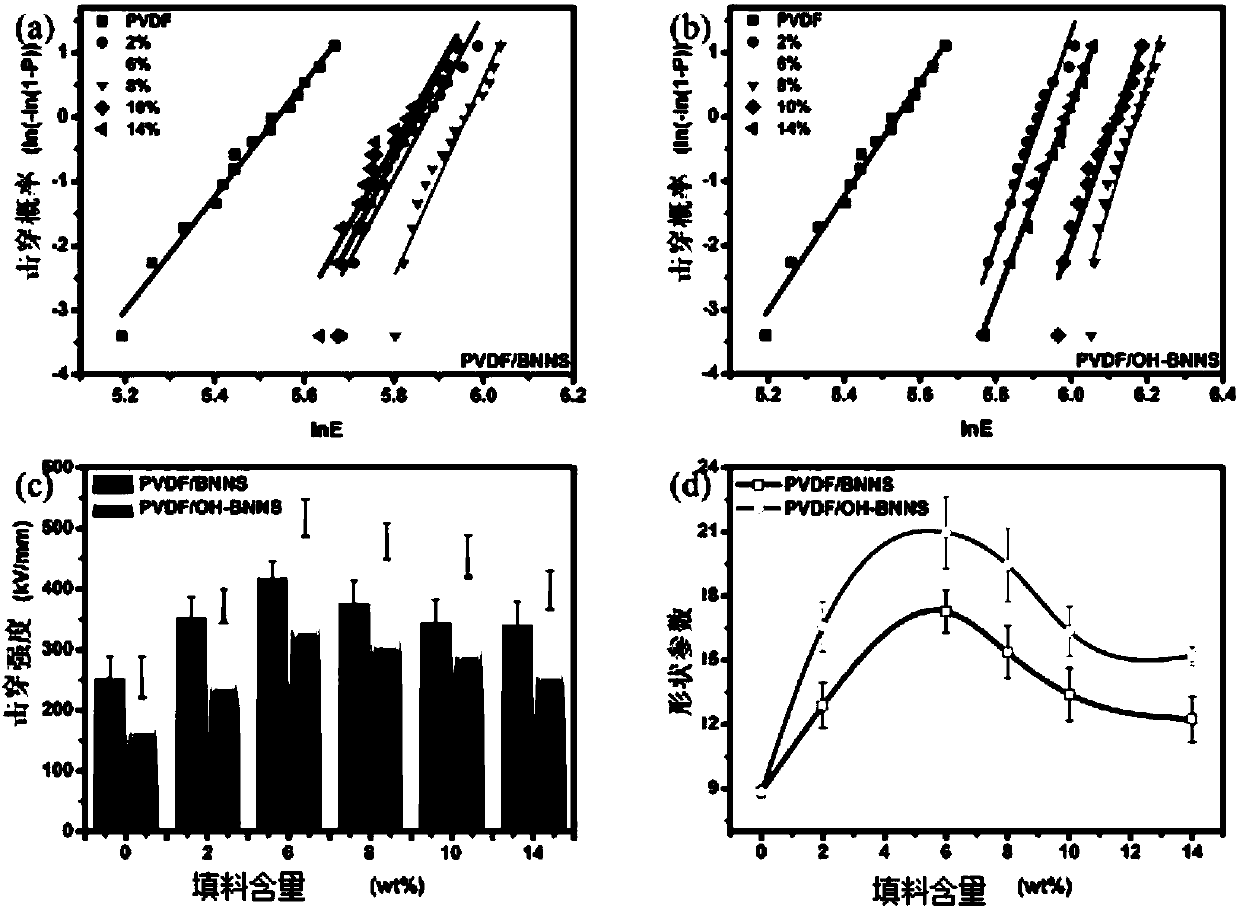

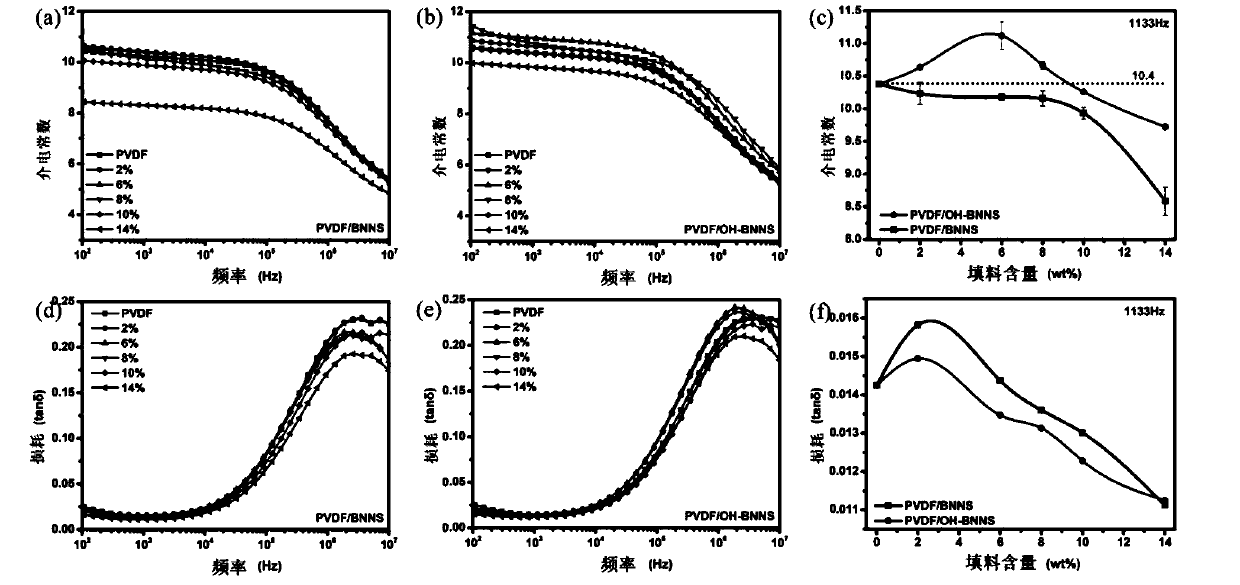

A technology of breakdown strength and energy storage density, applied in the field of energy storage materials, can solve the problems of the decrease of the breakdown strength of the composite, the decrease of the dielectric constant of the composite, the concentration of the electric field, etc., and meet the requirements of reducing microstructure defects and equipment conditions. Low, weakening effect of the tendency to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0042] A method for improving the breakdown strength of a composite by modifying boron nitride nanosheets, prepared by the following steps:

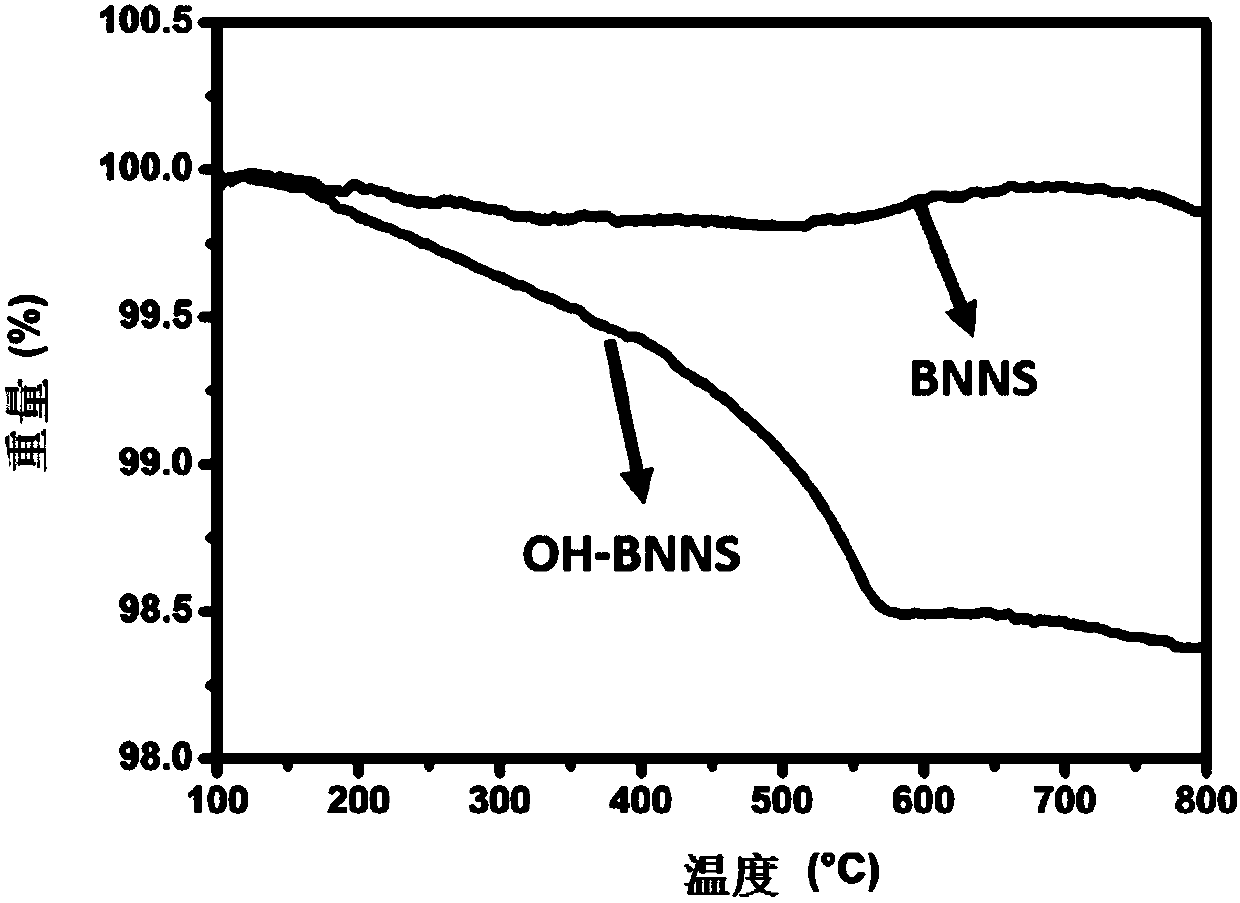

[0043] Step 1: Hydroxylation modification of BNNSs:

[0044] Add 1g of BNNSs to 1000ml of nitric acid, then ultrasonicate for 5h while stirring at room temperature, then add the mixture into a high-pressure reactor, and stir at 150°C for 24h;

[0045] Step 2: Dilute the neutralization mixture and wash the OH-BNNSs:

[0046] Dilute the product of step 1 to 2L with deionized water, and dissolve NaOH in water to obtain an aqueous sodium hydroxide solution. After adjusting the pH of the mixture to neutral, vacuum-assisted suction filtration is used; the product obtained by suction filtration is dispersed in 1L to Ultrasound in ionized water for 15 minutes at room temperature with an ultrasonic power of 100 W, then filter again, and repeat this process 4 times; place the product after multiple washings in a vacuum oven to dry for 24 hours to...

Embodiment 2 and comparative example 2

[0051] A method for improving the breakdown strength of a composite by modifying boron nitride nanosheets, prepared by the following steps:

[0052] Step 1: Hydroxylation modification of BNNSs:

[0053] Add 1.5g of BNNSs to 1500ml of nitric acid, then sonicate for 5h while stirring at room temperature, then add the mixture into a high-pressure reactor, and stir at 150°C for 24h;

[0054] Step 2: Dilute the neutralization mixture and wash the OH-BNNSs:

[0055] Dilute the product of step 1 to 3L with deionized water, and dissolve NaOH in water to obtain an aqueous sodium hydroxide solution. After adjusting the pH of the mixture to neutral, vacuum-assisted suction filtration is used; the product obtained by suction filtration is dispersed in 1.5L Ultrasound in deionized water for 15 minutes at room temperature and with an ultrasonic power of 100 W, then filter again, and repeat this process 4 times; place the product after multiple washings in a vacuum oven to dry for 24 hours ...

example example 3 and comparative example 3

[0059] A method for improving the breakdown strength of a composite by modifying boron nitride nanosheets, prepared by the following steps:

[0060] Step 1: Hydroxylation modification of BNNSs

[0061] Add 0.5g of BNNSs to 500ml of nitric acid, then sonicate for 5h while stirring at room temperature, then add the mixture into a high-pressure reactor, and stir at 150°C for 24h;

[0062] Step 2: Dilute the neutralization mixture and wash the OH-BNNSs:

[0063] Dilute the product of step 1 to 1L with deionized water, and dissolve NaOH in water to obtain an aqueous sodium hydroxide solution. After adjusting the pH of the mixture to neutral, vacuum-assisted suction filtration is used; the product obtained by suction filtration is dispersed in 0.5L Ultrasound in deionized water for 15 minutes at room temperature and with an ultrasonic power of 100W, then filter again, and repeat this process 4 times;

[0064] The product after multiple washings was dried in a vacuum oven for 24 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com