Patents

Literature

34results about How to "Reduced reunion tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of teflon composite material

The invention discloses a preparation method of a teflon composite material, comprising the following steps: 1) successively adding teflon and filling materials in the water which contains surfactant, and uniformly stirring, wherein the weight ratio of the surfactant to water is 0.0002-0.1:1, the weight ratio of water to the sum of teflon and filling materials is 0.5-2:1, and the weight of teflon accounts for 84-99% of that of the sum of teflon and filling materials; and 2) filtering the product obtained by the step 1), washing, drying, conducting mold pressing and sintering the solids obtained by filtering to obtain the teflon composite material. The method is simple and green, and the teflon composite material prepared by the method has excellent performance.

Owner:ZHEJIANG UNIV

Method for improving breakdown strength and energy storage density of polymer

ActiveCN107903441AEasy to operateLow equipment requirementsHeat-exchange elementsBreakdown strengthHexagonal boron nitride

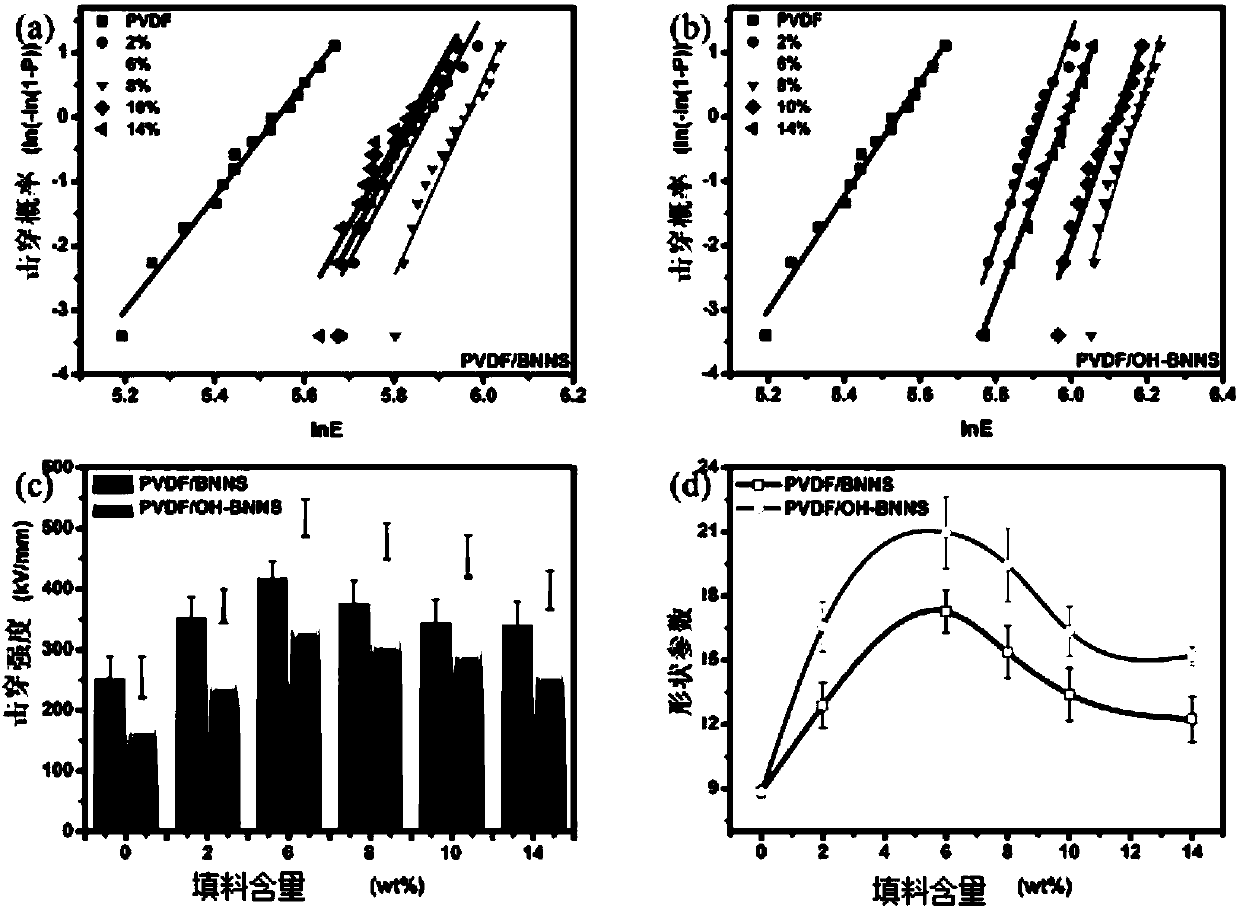

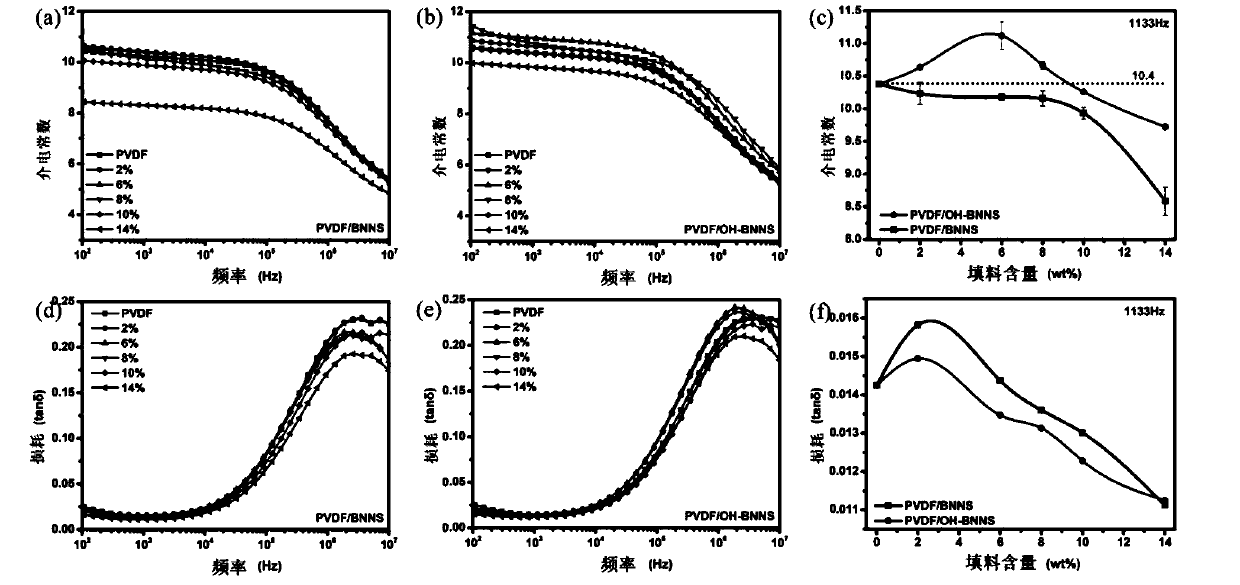

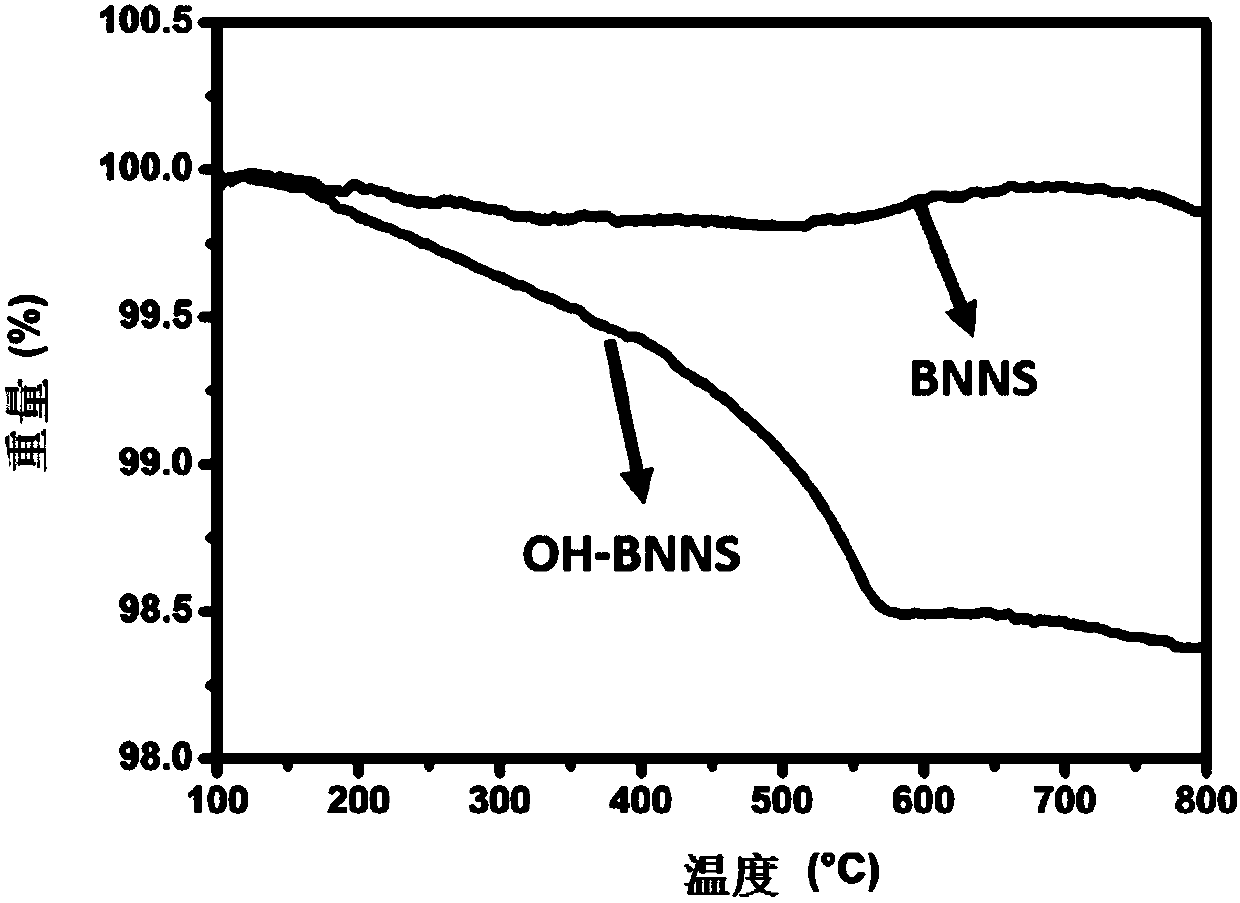

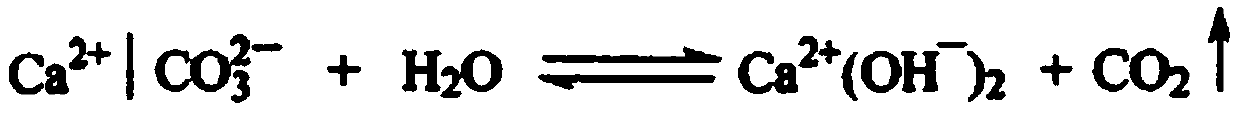

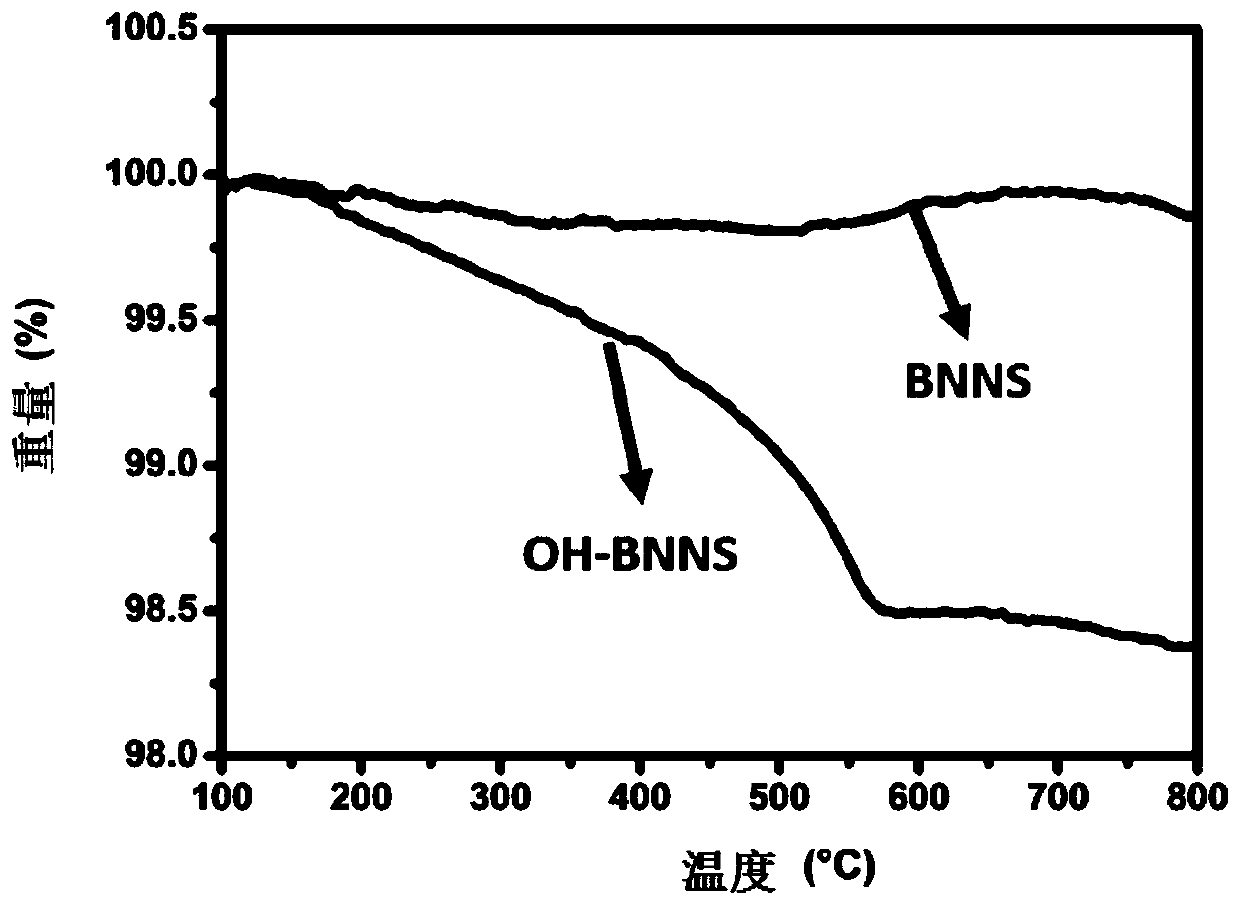

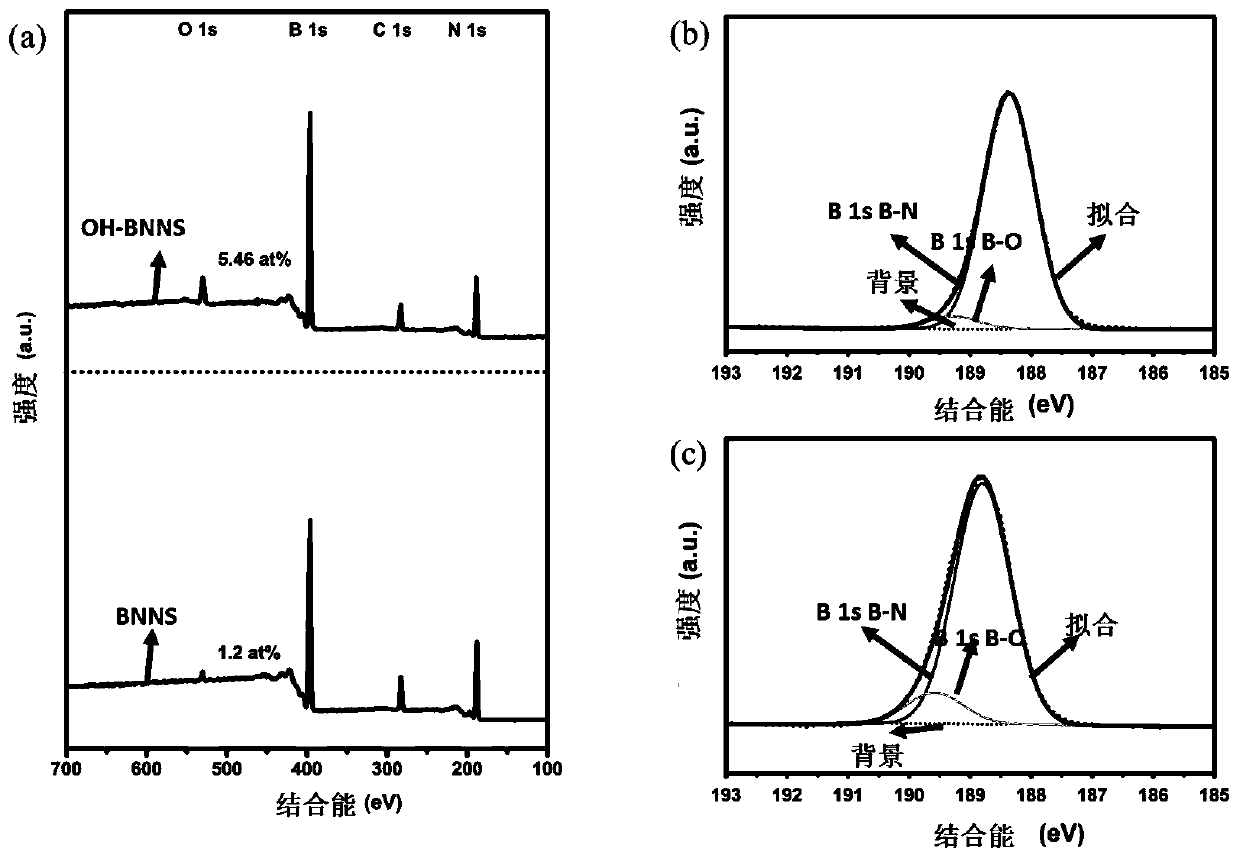

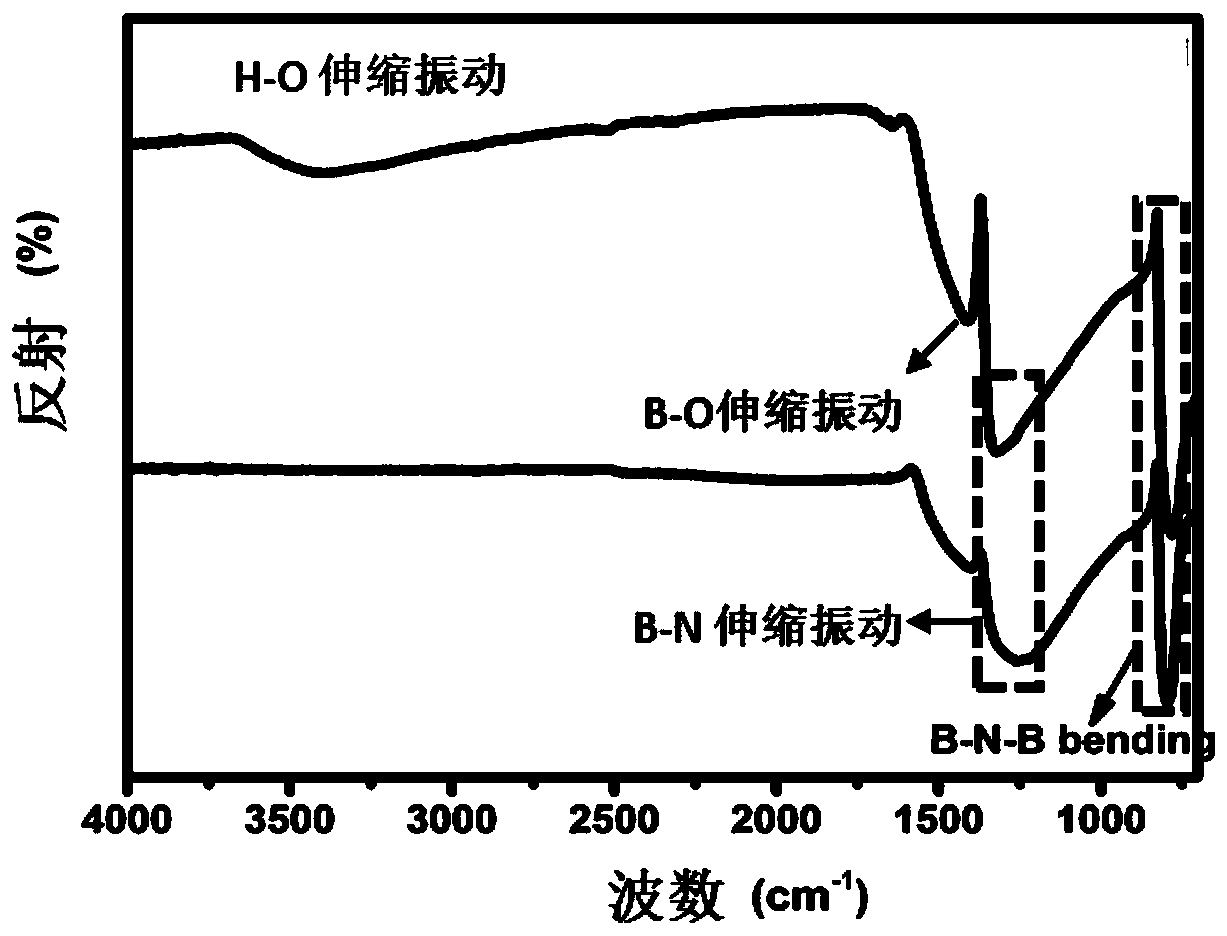

The invention relates to the technical field of energy storage materials, and in particular relates to a method for improving the breakdown strength and energy storage density of a polymer. The methodfor improving the breakdown strength and energy storage density of the polymer comprises the following steps: adding 2-14 parts by weight of hydroxylated hexagonal boron nitride to 100 parts by weight of the polymer. The modified product of BNNSs (hexagonal boron nitride nanosheets) provided by the invention has better dispersion effects in the polymer, so that the agglomeration tendency of the BNNSs in the polymer is greatly weakened, and the method is very beneficial for the improvement of the breakdown strength and energy storage density of a composite capacitor.

Owner:SICHUAN UNIV

Cable for power distribution system

The invention belongs to the field of power distribution, and discloses a cable for a power distribution system. The cable is prepared by wrapping a wire with an insulating outer layer. The insulating outer layer is prepared from graphite, aluminum triphosphate, aluminum hydroxide, triphenyl phosphate, oleamide, zinc borate, glass fiber, borax, palygorskite, stearic acid, aluminum nitride, egg shells, triallyl cyanurate, polypropylene resin, ethylene propylene diene monomer, polyvinyl chloride and hydrogenated acrylonitrile butadiene rubber. The cable for the power distribution system is good in flame retardant property, excellent in mechanical property and good in corrosion resistance, the application range is widened, and the service life of the cable is prolonged.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Temperature memory color-variable insulating material for cable

InactiveCN105504420AHigh strengthImprove insulation performanceRubber insulatorsAcrylonitrilePalygorskite

The invention belongs to the field of electric power materials and discloses a temperature memory color-variable insulating material for a cable. The temperature memory color-variable insulating material is prepared from 1-2 parts by weight of antimonous oxide, 1-2 parts by weight of magnesium hydroxide, 2-3 parts by weight of aluminum hydroxide, 2-3 parts by weight of borax, 2-3 parts by weight of triphenyl phosphate, 2-3 parts by weight of zinc borate, 2-3 parts by weight of glass fibers, 3-4 parts by weight of temperature-sensitive color-variable powder, 3-4 parts by weight of palygorskite, 4-6 parts by weight of stearic acid, 5-7 parts by weight of egg shells, 5-7 parts by weight of kaolin, 8-10 parts by weight of aluminum nitride, 8-10 parts by weight of triallyl cyanurate, 12-15 parts by weight of chlorinated polyethylene, 16-20 parts by weight of an ethylene-propylene-diene monomer and 16-20 parts by weight of hydrogenated butadiene-acrylonitrile rubber. The temperature memory color-variable insulating material can produce different colors based on different temperatures and can provides high temperature early warning.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Method for preparing flame-retardant expandable polystyrene spheres containing delamination graphite

The invention discloses a method for preparing flame-retardant expandable polystyrene spheres containing delamination graphite, relates to a method for preparing flame-retardant expandable polystyrene spheres, and aims at solving the technical problems that the expandable polystyrene containing delamination graphite containing graphite granules prepared by the existing method is polymerized and easily aggregated in a suspension manner, the graphite granules are uneven to disperse in polystyrene, and poor in flame-retardant insulation performance of the expandable polystyrene. The preparation method disclosed by the invention comprises the following steps: 1, weighing raw materials according to parts by weight; 2, preparing a first mixture; 3, preparing a second mixture; 4, adding the second mixture to the first mixture under agitation, adding an emulsifier after reaction, continuing to react, and then adding pentane, charging nitrogen into a reaction kettle, heating up and reacting, naturally cooling after reaction is ended, slowly releasing a gas and discharging until the pressure is zero; washing and drying, so as to obtain the flame-retardant expandable polystyrene spheres containing delamination graphite. The method is applied to the field of preparation of the flame-retardant expandable polystyrene spheres.

Owner:HARBIN INST OF TECH

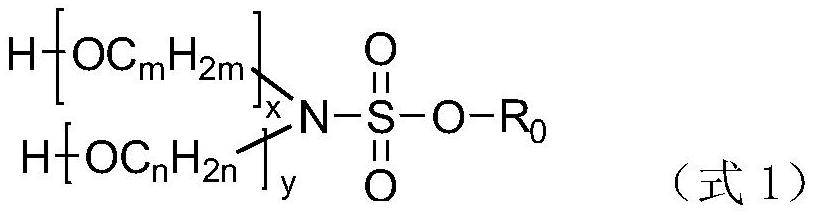

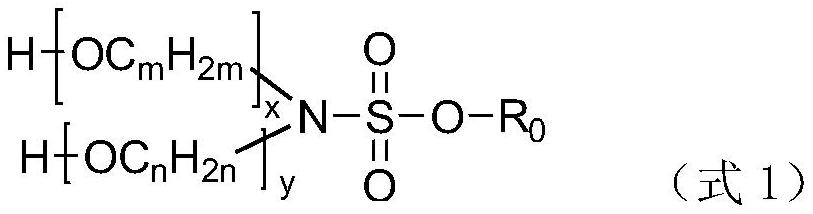

Preparation method and application of N, N-disubstituted sulfamic acid compound

PendingCN114196005AImprove adsorption capacityReduced reunion tendencySulfuric acid amide preparationAlkaneDimer

The invention discloses a preparation method of an N, N-disubstituted sulfamic acid compound, which specifically comprises the following steps: by taking a sulfamic acid compound as a substrate, carrying out addition reaction on the sulfamic acid compound and alkylene oxide to prepare the N, N-disubstituted sulfamic acid compound, and reacting the N, N-disubstituted sulfamic acid compound with the alkylene oxide to prepare the N, N-disubstituted sulfamic acid compound. The N, N-disubstituted sulfamic acid compound is a dihydroxyalkyl sulfamic acid compound or a dimer alkoxy sulfamic acid compound. The invention also discloses an application of the N, N-disubstituted sulfamic acid compound prepared by the method. In the invention, sulfamic acid or salt or ester is used as a substrate and is subjected to addition condensation with alkylene oxide. The method has the advantages of easily available raw materials, low cost, short synthesis route, mild process conditions and simple post-treatment.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

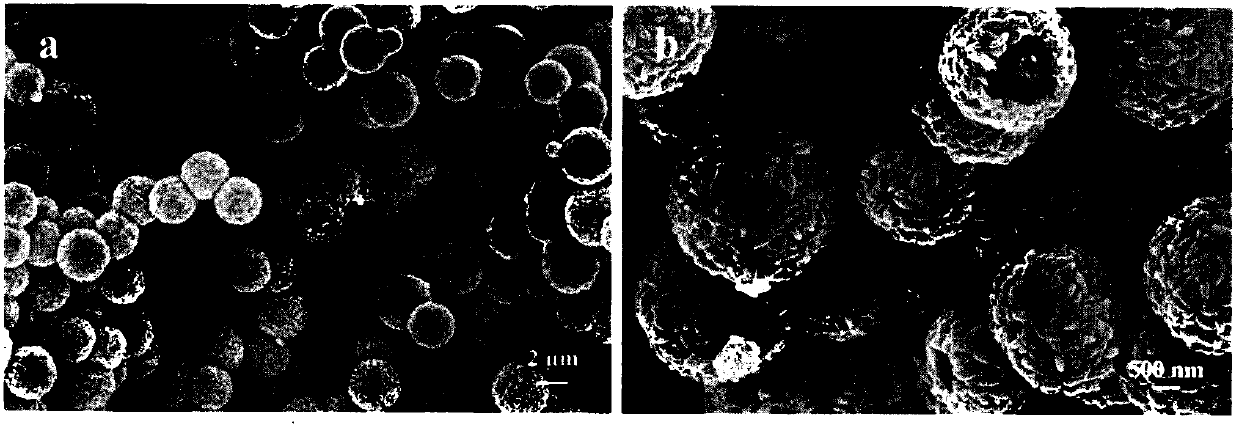

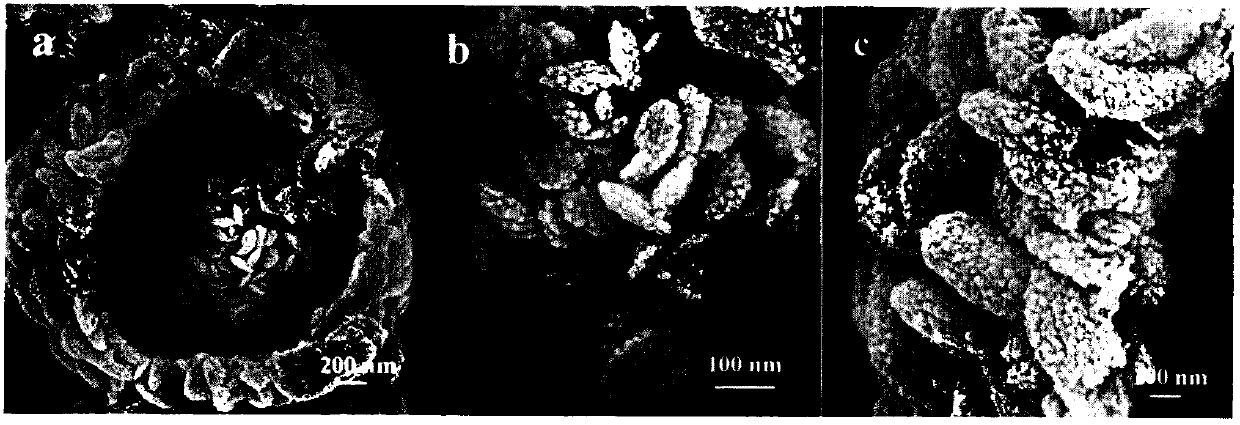

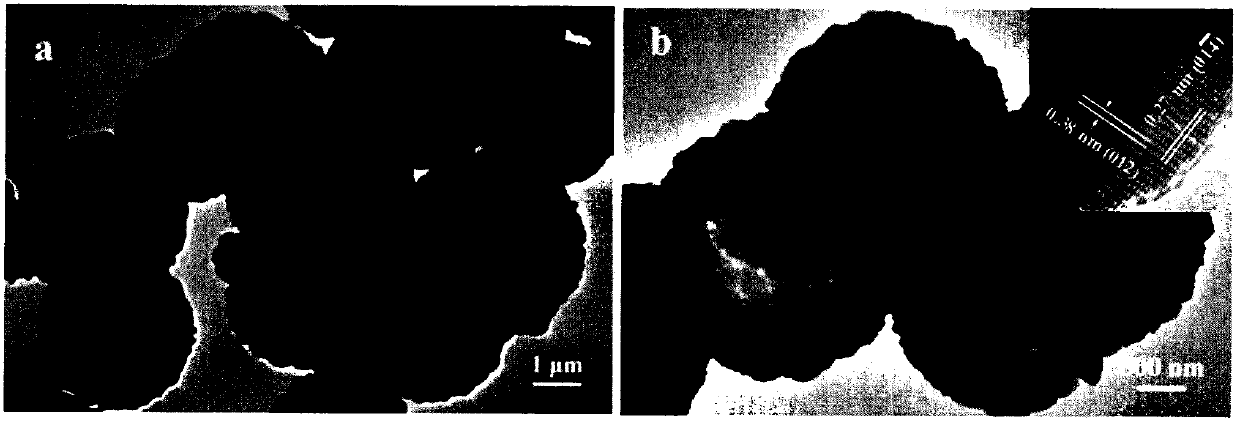

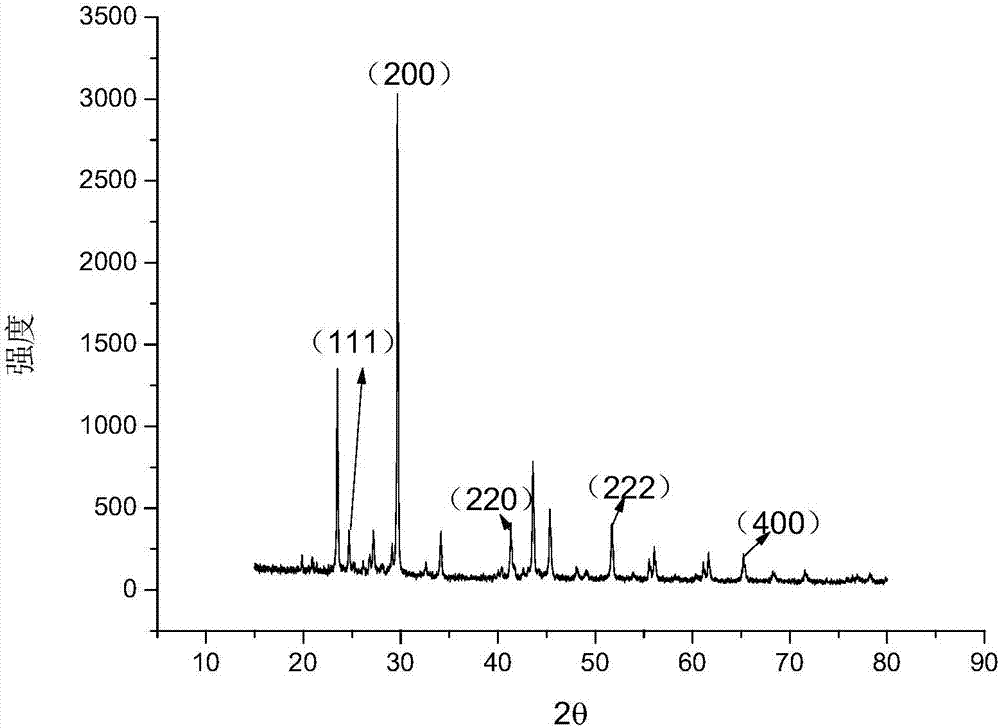

Alpha-Fe2O3 multilayer hollow nanometer spherical structure, preparation method and application

InactiveCN105502510AHigh surfaceIncrease in sizeMaterial nanotechnologyCell electrodesMicrometerNanostructure

The invention discloses an alpha-Fe2O3 multilayer hollow nanometer spherical structure, a preparation method and application and relates to alpha-Fe2O3 hollow nanometer structures, in particular to a alpha-Fe2O3 hollow nanometer spherical structure formed by assembling alpha-Fe2O3 nanometer aggregates. The diameter of the alpha-Fe2O3 multilayer hollow nanometer spherical structure is between 900 nanometers and 5 micrometers, the wall thickness is between 100 nanometers and 500 nanometers, and the number of layers is two or more. Each alpha-Fe2O3 aggregate is a cambiform assembly formed by aggregating alpha-Fe2O3 nanometer particles, wherein the diameter of the aggregate is between 50 nanometers and 200 nanometers, and the length is between 200 nanometers and 500 nanometers. According to the preparation method of the alpha-Fe2O3 hollow nanometer structure, ferric salt and glycine are mixed for a reaction for 6-12 hours on an ethanol-hydrothermal condition at the temperature of 120-200 DEG C. The alpha-Fe2O3 hollow nanometer structure can be used as an electrode material of a lithium ion battery, displays excellent lithium ion battery properties and very good rate capability, and has ultrahigh specific discharge capacity and good cycling stability.

Owner:NANJING UNIV

Method for preparing nanometer toughened inorganic transparent protective coating

ActiveCN109135367AImprove mechanical propertiesGood toughening effectAlkali metal silicate coatingsSanderPhosphate

The invention relates to the field of inorganic coating, and aims to provide a method for preparing nanometer toughened inorganic transparent protective coating. The method includes weighing various raw components according to set weight percentages; adding methyl silicate, phosphate, nanometer fillers, dispersing agents, surfactants and deionized water into ingredient barrels, and stirring the methyl silicate, the phosphate, the nanometer fillers, the dispersing agents, the surfactants and the deionized water to form mixed slurry; injecting the mixed slurry into nanometer ball mills and grinding the mixed slurry; adding water glass and defoaming agents into dispersion machines, stirring the water glass and the defoaming agents and then adding the ground mixed slurry into the dispersion machines; continuing to stir the water glass, the defoaming agents and the ground mixed slurry to obtain the nanometer toughened inorganic transparent protective coating. The method has the advantages that inorganic coating is toughened by nanometer materials, and accordingly good toughening effects can be realized without deterioration of the mechanical properties (such as the hardness and the abrasion resistance), the water resistance, the aging resistance and the like of coatings; the nanometer materials are stable in performance and can be mixed with the strong-alkalinity inorganic coating without qualitative change; fillers are ground by nanometer sanders, the particle sizes of the fillers can be reduced and are smaller than or equal to 0.2 micrometer, accordingly, the method is favorable for preparing transparent inorganic coatings, the trend of agglomeration of the nanometer fillers can be weakened, and the toughening effects can be effectively realized by the nanometer fillers.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST

High-temperature-resistant and dampproof cable for industry

The invention belongs to the technical field of cables and discloses a high-temperature-resistant and dampproof cable for industry. The cable is formed by wrapping a wire in an insulating outer layer. The cable is characterized in that the insulating outer layer is prepared from graphite, silicon carbide, aluminum oxide, triphenyl phosphate, oleamide, zinc borate, glass fibers, sodium borate, palygorskite, stearic acid, aluminum nitride, egg shells, triallyl cyanurate, polypropylene resin, EPDM rubber, polyvinyl chloride and hydrogenated butadiene-acrylonitrile rubber. The cable has good high-temperature-resistant and dampproof performance and mechanical performance.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

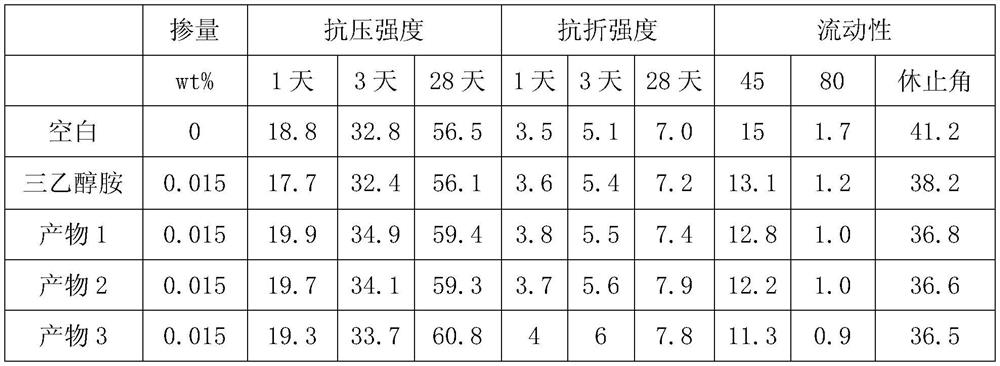

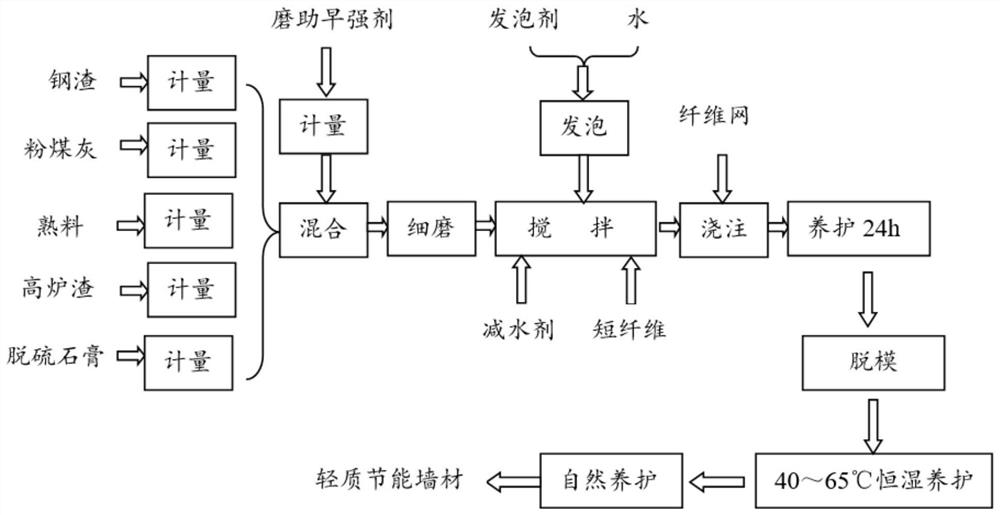

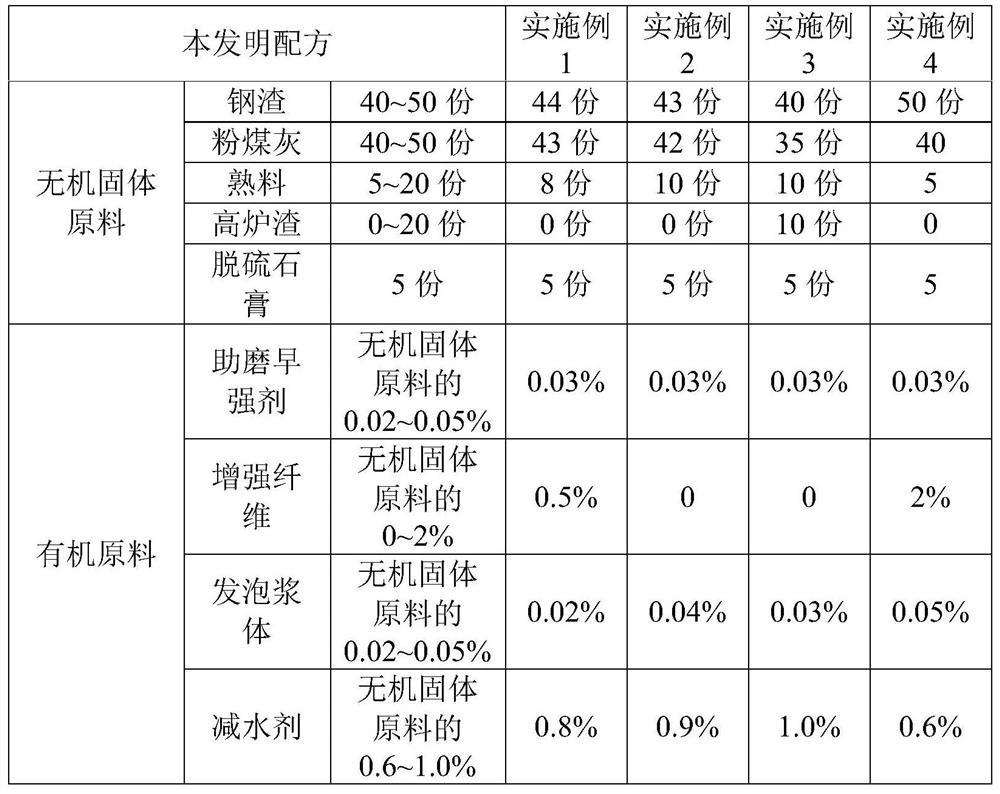

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

Insulating material for transmission line

InactiveCN105367858AReduce frictionReduce melt viscosityRubber insulatorsPlastic/resin/waxes insulatorsPalygorskiteAcrylonitrile

The invention belongs to the field of electric materials, and discloses an insulating material for a transmission line. The insulating material for the transmission line is prepared from, by weight, 1-2 parts of magnesium oxide, 1-2 parts of antimonous oxide, 1-2 parts of oleamide, 1-2 parts of borax, 2-3 parts of triphenyl phosphate, 2-3 parts of zinc borate, 2-3 parts of glass fiber, 3-4 parts of palygorskite, 4-6 parts of stearic acid, 5-7 parts of egg shells, 5-7 parts of kaolin, 8-10 parts of aluminum nitride, 8-10 parts of triallyl cyanurate, 12-15 parts of chlorinated polyethylene, 16-20 parts of ethylene propylene diene monomer and 16-20 parts of hydrogenated acrylonitrile butadiene rubber. The insulating material for the transmission line is good in insulating property and flame retardant property, excellent in mechanical property, good in corrosion resistance and suitable for various environments, the application range is greatly widened, and the service life is greatly prolonged.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Non-poisonous fireproof moistureproof insulating cable

InactiveCN105336390AReduce frictionHigh mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorAluminium hydroxide

The invention belongs to the field of cables, and discloses a non-poisonous fireproof moistureproof insulating cable. The cable is prepared in a manner that an insulating outer layer wraps a conductor, and the insulating outer layer is made of the following materials: aluminium hydroxide, graphite, silicon carbide, triphenyl phosphate, oleamide, magnesium hydroxide, glass fibers, borax, palygorskite, stearic acid, aluminium nitride, egg shells, triallyl cyanurate, polypropylene resin, EPDM, polyethylene, and hydrogenated butadiene-acrylonitrile rubber. The conductor is an aluminium alloy conductor or an aluminium copper alloy lead. The cable is better in fireproof, moistureproof and waterproof performances and mechanical performances.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Strong-strength corrosion-resistant water meter shell and preparation process for same

InactiveCN105131514ACompatibility is reasonableImprove mechanical propertiesPolymer sciencePolyvinyl chloride

The invention belongs to the field of flow measurement, and discloses a strong-strength corrosion-resistant water meter shell and a preparation process for the same. The water meter shell is prepared from the following raw materials: silica gel powder, talc powder, montmorillonite, boron nitride, silicon carbide, aluminum hydroxide, oleamide, borax, triphenyl phosphate, zinc borate, polyvinyl alcohol, egg shells, kaolin, aluminum nitride, triallyl cyanurate, polyvinyl chloride, hydrogenated butadiene-acrylonitrile rubber and phenolic resin. According to the water meter shell and the preparation process for the same, the raw material compatibility is reasonable, and the performance of a plastic shell is improved.

Owner:徐怀洪

Insulating material for power distribution system

InactiveCN105440378AReduce frictionReduce melt viscosityRubber insulatorsInsulated cablesInsulation layerAluminium hydroxide

The present invention belongs to the field of power materials, and discloses an insulating material for a power distribution system. The insulating material is prepared from the following raw materials: hydrogenated nitrile rubber, polyvinyl chloride, ethylene-propylene-diene rubber, polypropylene resin, triallyl cyanurate, aluminium nitride, egg shells, attapulgite, stearic acid, zinc borate, fiberglass, borax, triphenyl phosphate, oleamide, magnesium oxide, and aluminium hydroxide. The insulating material disclosed by the present invention is good in flame retardancy, excellent in mechanical properties and good in anti-corrosive property, and thus is suitable for making a cable insulation layer. In addition, the insulating material is used in a wide range, so that the service life of the cable is prolonged.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

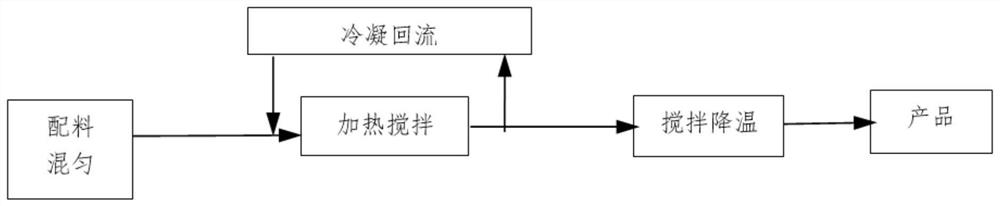

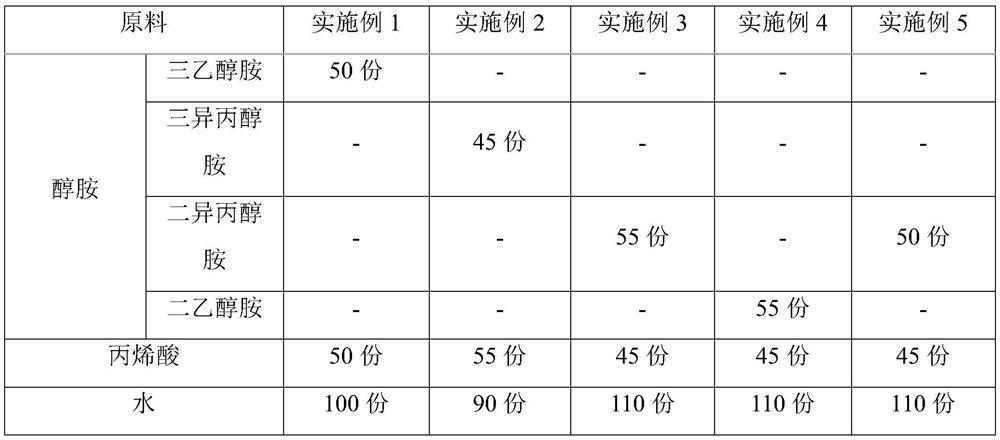

Modified grinding-aiding early strength agent for steel slag as well as preparation method and application method of modified grinding-aiding early strength agent

The invention discloses a modified grinding-aiding early strength agent for steel slag as well as a preparation method and an application method of the modified grinding-aiding early strength agent, and relates to the field of steel slag grinding aiding. The modified grinding-aid early strength agent comprises (a) 60%-75% of ester compounds based on the total weight of the modified grinding-aid early strength agent; (b) 5%-15% of polyacrylic acid based on the total weight of the modified grinding-aid early strength agent; (c) 10%-35% of alcohol amine and acrylic acid monomers based on the total weight of the modified grinding-aid early strength agent, the preparation method comprises the following steps: adding water into alcohol amine and acrylic acid, uniformly mixing, heating while stirring, reacting at 60-80 DEG C for 3-4 hours, and cooling the solution to room temperature to obtain the modified grinding-aiding early strength agent which is applied to grinding of a gel material with high doping amount of steel slag, so the problems of low grinding efficiency of an existing grinding aid, low activity of the steel slag in the early stage, complex synthesis process, high cost and the like are solved. The preparation process is simple, the raw material cost is low, the finished product quality and performance are stable, the use effect is good, and the 7d strength increase is greater than or equal to 30%.

Owner:安徽马钢嘉华新型建材有限公司 +1

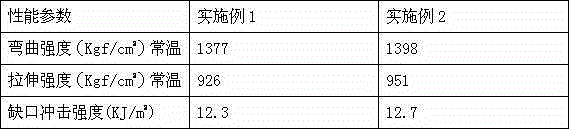

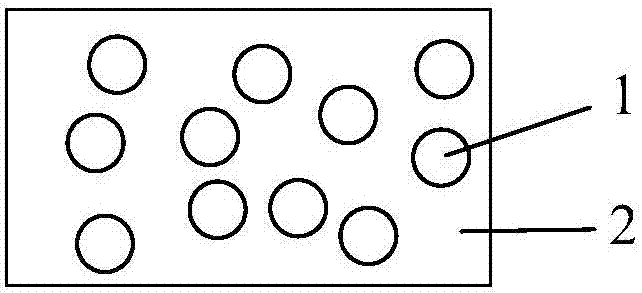

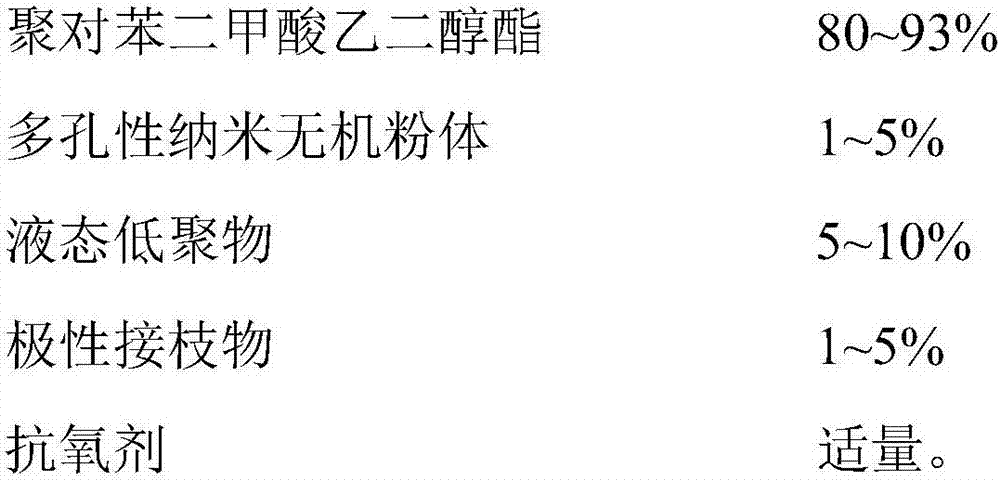

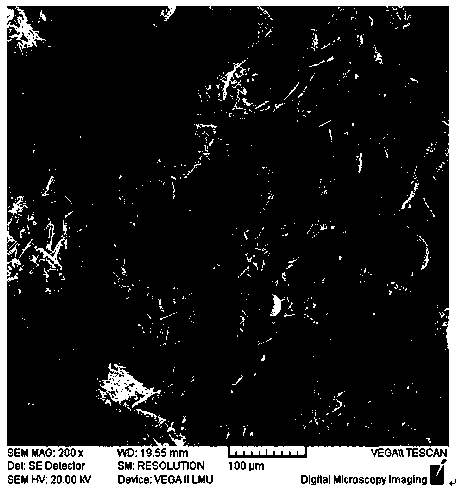

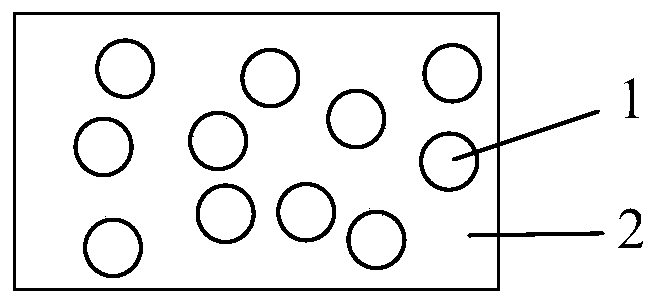

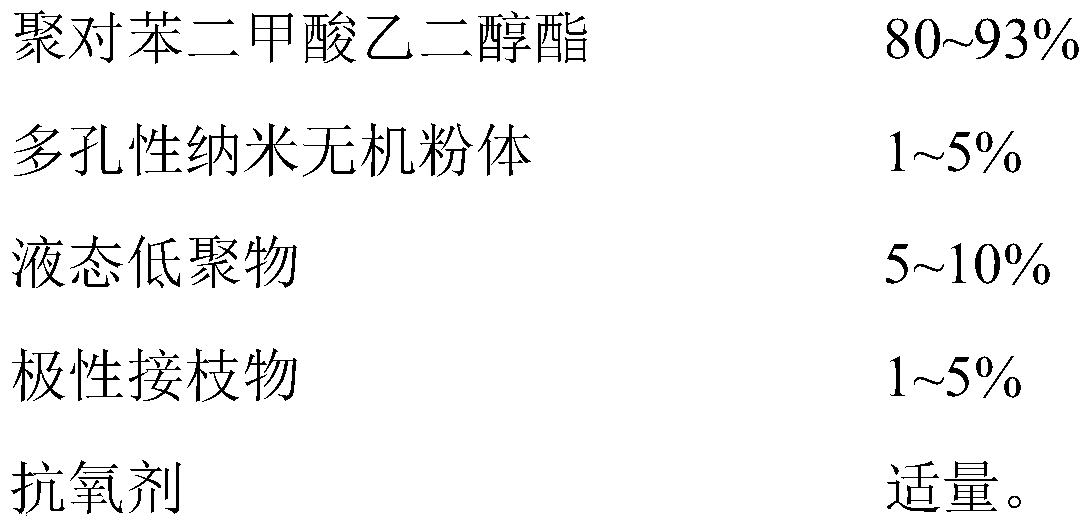

Soft nanometer micro area flexibility-enhanced PET composite material and preparation method thereof

ActiveCN107254149AImprove impact performanceGood optical performancePolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a soft nanometer micro area flexibility-enhanced PET composite material and a preparation method thereof. The flexibility-enhanced PET composite material comprises the following components in mass percent: 80 to 93 percent of polyethylene terephthalate, 1 to 5 percent of a porous nanometer inorganic powder, 5 to 10 percent of liquid low polymers, 1 to 5 percent of polar grafted polymers, and a proper amount of an antioxidant. The method comprises the steps of grinding PET into a powder after the PET is cooled, soaking the nanometer inorganic powder through the liquid low polymer, so as to ensure that the nanometer inorganic powder is sufficiently soaked and absorbed by the liquid low polymer and to form a soft and elastic spherical nanometer structure, and improving the wetting property of the surface of the nanometer inorganic powder through the polar grafted polymer, so as to ensure that the nanometer inorganic powder can be uniformly dispersed in a PET matrix and a soft nanometer micro area can achieve the effect of flexibility enhancement in the PET. A PET sheet produced by adding the flexibility-enhanced composite material has excellent impact property, and maintains good optical property.

Owner:中山京工高分子材料有限公司

Al18B4O33 whisker-reinforced silver-copper composite brazing filler metal and preparation method thereof

ActiveCN108115308AAvoid dependencyHigh average shear strengthWelding/cutting media/materialsSoldering mediaWhiskersFiller metal

The invention discloses an Al18B4O33 whisker-reinforced silver-copper composite brazing material and a preparation method thereof. The composite brazing filler metal is composed of, by mass, 60%-70% of Ag powder, 20%-30% of Cu powder and 5%-15% of Al18B4O33 whiskers. The preparation method comprises the following steps of 1, weighing 60%-70% of the Ag powder, 20% to 30% of the Cu powder and 5% 15%of the Al18B4O33 whiskers according to the mass percentage, and mixing to obtain original brazing filler metal powder; placing the original brazing filler metal powder and a grinding ball obtained inthe step 1 in a planetary ball mill tank, filling the ball mill tank with argon gas after vacuuming, and conducting ball-milling for 2-8 hours at a rotation speed of 100-150 r / min to obtain the Al18B4O33 whisker-reinforced silver-copper composite brazing filler metal. The method increases the strength of welding.

Owner:CHONGQING UNIV

Composite electric power cable having communication channel

InactiveCN105513683AReduce frictionReduce melt viscosityInsulated cablesPower cablesElectrical conductorCopper wire

The invention belongs to the field of cable technology, and discloses a composite electric power cable having a communication channel. The composite electric power cable is prepared by wrapping a communication conductor with a cable outer layer. The communication conductor is a wire core formed by twisting copper wires. The insulating outer layer of the cable is high in insulating performance, corrosion resistance, flame retardant property and mechanical property. The invention is simple in preparation process and suitable for industrial production on a large scale.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Preparation technology for electric-transmission-line insulation outer layer and application thereof

InactiveCN105504419AReduce frictionReduce melt viscosityRubber insulatorsPlastic/resin/waxes insulatorsElectric powerNanotechnology

The invention belongs to the field of manufacture of electric power materials, and discloses a preparation technology for an electric-transmission-line insulation outer layer. The preparation technology comprises the following steps: step 1) weighing raw materials; step 2) preparing a material 1; step 3), preparing a material 2; step 4) preparing a material 3; and step 5), preparing the insulation outer layer. The technology is simple and feasible, and the prepared insulation outer layer is relatively excellent in various performances.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Soft nanometer domain toughened pet composite material and preparation method thereof

ActiveCN107254149BReduced reunion tendencyGood dispersionPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a soft nanometer micro area flexibility-enhanced PET composite material and a preparation method thereof. The flexibility-enhanced PET composite material comprises the following components in mass percent: 80 to 93 percent of polyethylene terephthalate, 1 to 5 percent of a porous nanometer inorganic powder, 5 to 10 percent of liquid low polymers, 1 to 5 percent of polar grafted polymers, and a proper amount of an antioxidant. The method comprises the steps of grinding PET into a powder after the PET is cooled, soaking the nanometer inorganic powder through the liquid low polymer, so as to ensure that the nanometer inorganic powder is sufficiently soaked and absorbed by the liquid low polymer and to form a soft and elastic spherical nanometer structure, and improving the wetting property of the surface of the nanometer inorganic powder through the polar grafted polymer, so as to ensure that the nanometer inorganic powder can be uniformly dispersed in a PET matrix and a soft nanometer micro area can achieve the effect of flexibility enhancement in the PET. A PET sheet produced by adding the flexibility-enhanced composite material has excellent impact property, and maintains good optical property.

Owner:中山京工高分子材料有限公司

A preparation method of flame-retardant expandable polystyrene pellets containing exfoliated graphite

The invention discloses a method for preparing flame-retardant expandable polystyrene spheres containing delamination graphite, relates to a method for preparing flame-retardant expandable polystyrene spheres, and aims at solving the technical problems that the expandable polystyrene containing delamination graphite containing graphite granules prepared by the existing method is polymerized and easily aggregated in a suspension manner, the graphite granules are uneven to disperse in polystyrene, and poor in flame-retardant insulation performance of the expandable polystyrene. The preparation method disclosed by the invention comprises the following steps: 1, weighing raw materials according to parts by weight; 2, preparing a first mixture; 3, preparing a second mixture; 4, adding the second mixture to the first mixture under agitation, adding an emulsifier after reaction, continuing to react, and then adding pentane, charging nitrogen into a reaction kettle, heating up and reacting, naturally cooling after reaction is ended, slowly releasing a gas and discharging until the pressure is zero; washing and drying, so as to obtain the flame-retardant expandable polystyrene spheres containing delamination graphite. The method is applied to the field of preparation of the flame-retardant expandable polystyrene spheres.

Owner:HARBIN INST OF TECH

A method to improve the breakdown strength and energy storage density of polymers

ActiveCN107903441BEasy to operateLow equipment requirementsHeat-exchange elementsBreakdown strengthPolymer science

The invention relates to the technical field of energy storage materials, in particular to a method for improving the breakdown strength and energy storage density of polymers. The invention provides a method for improving the breakdown strength and energy storage density of a polymer. The method is: adding hydroxylated hexagonal boron nitride to the polymer, wherein the mass ratio of the polymer to the hydroxylated hexagonal boron nitride is : 100 parts by weight of polymer, 2 to 14 parts by weight of hydroxylated hexagonal boron nitride. The BNNSs modified product provided by the invention has a better dispersion effect in polymers, greatly reduces the tendency of BNNSs to agglomerate in polymers, and is very beneficial to the improvement of the breakdown strength and energy storage density of composite capacitors.

Owner:SICHUAN UNIV

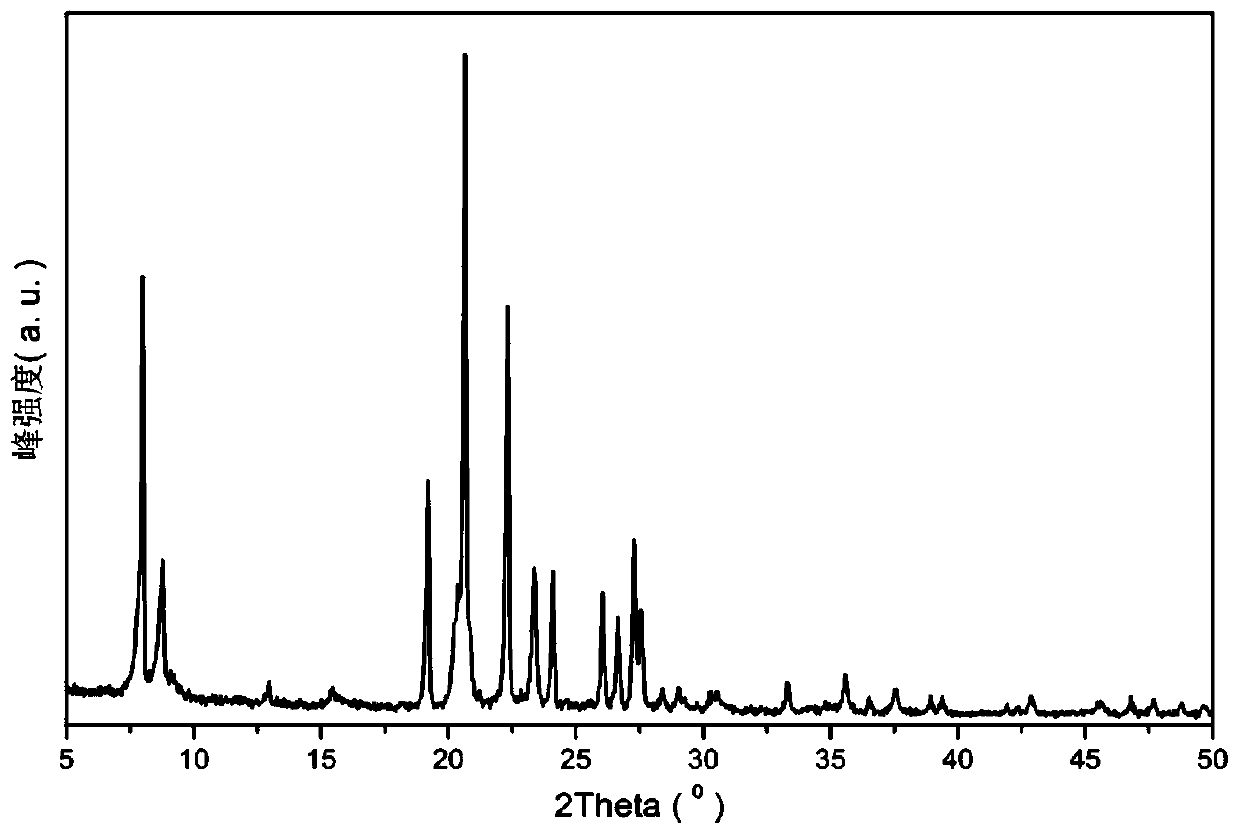

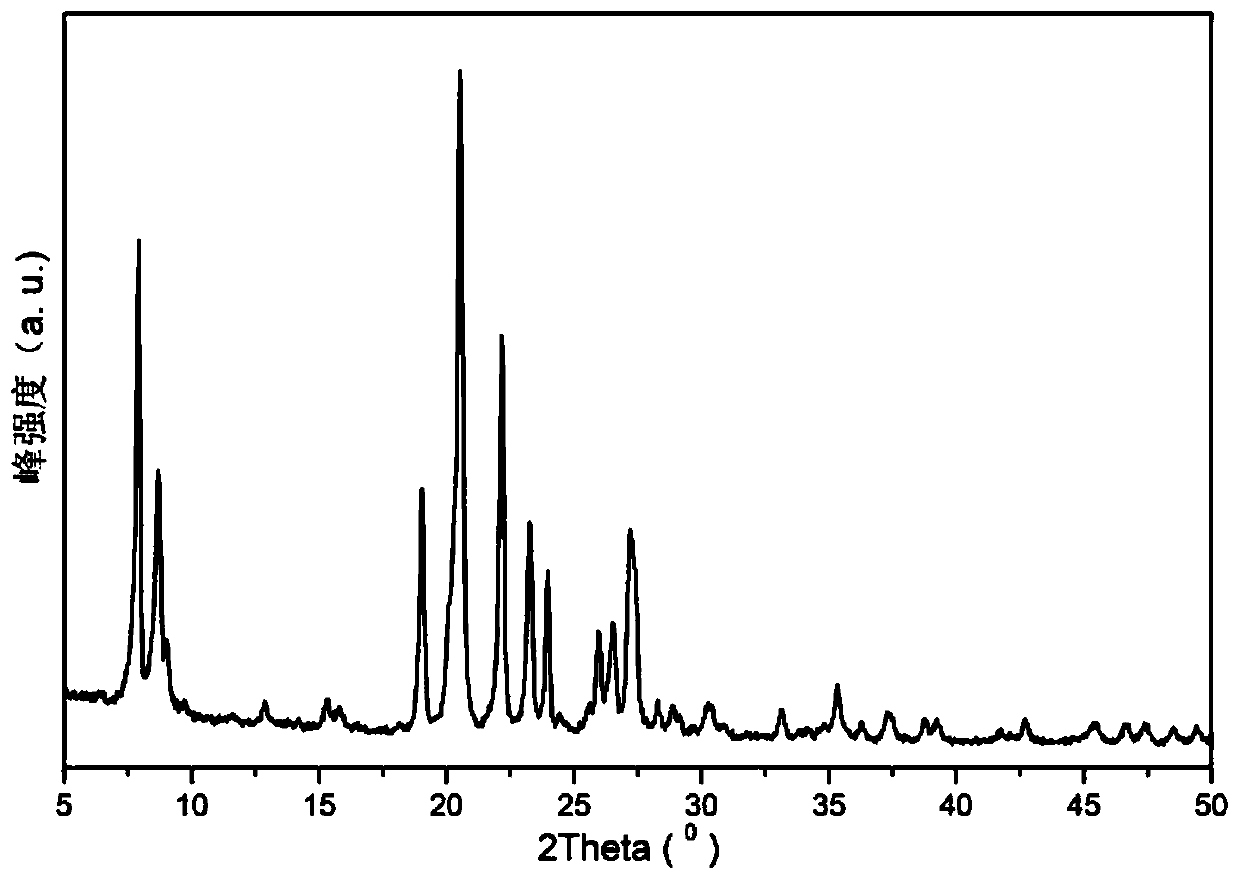

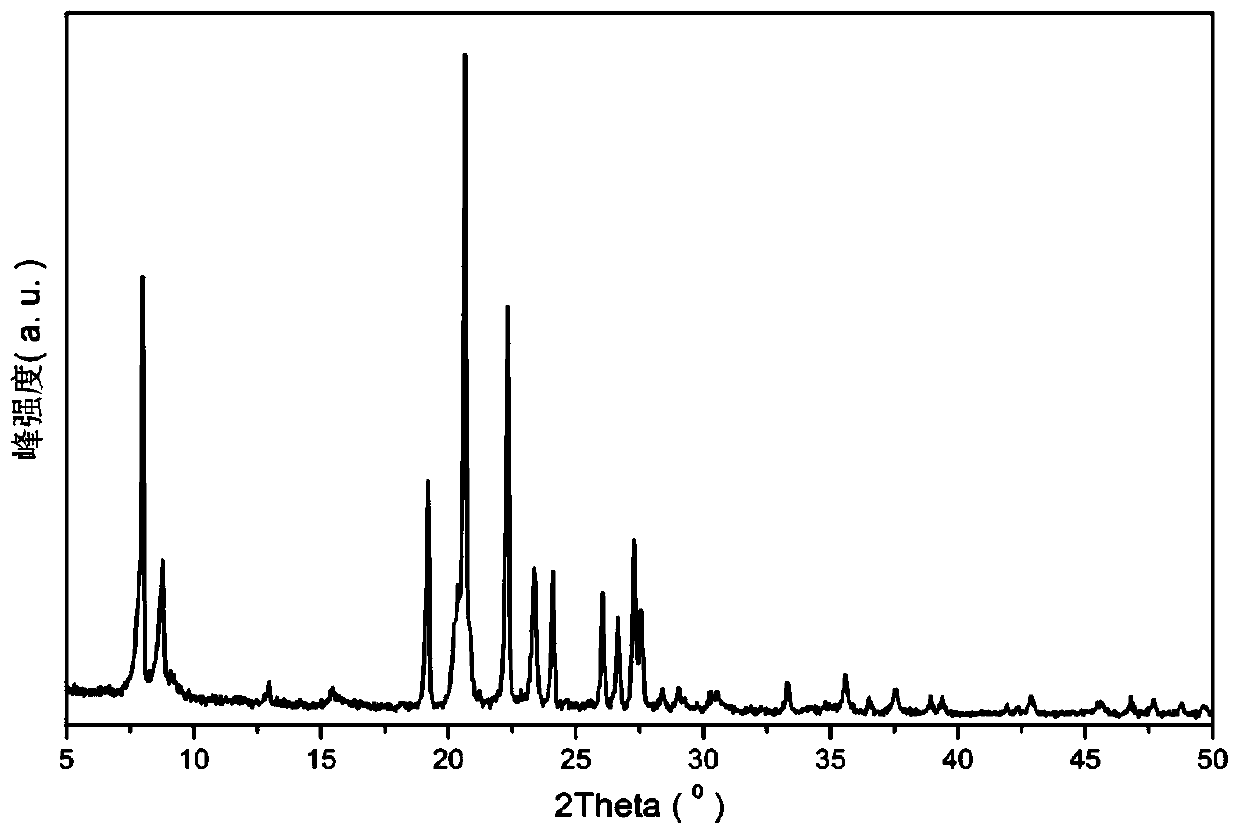

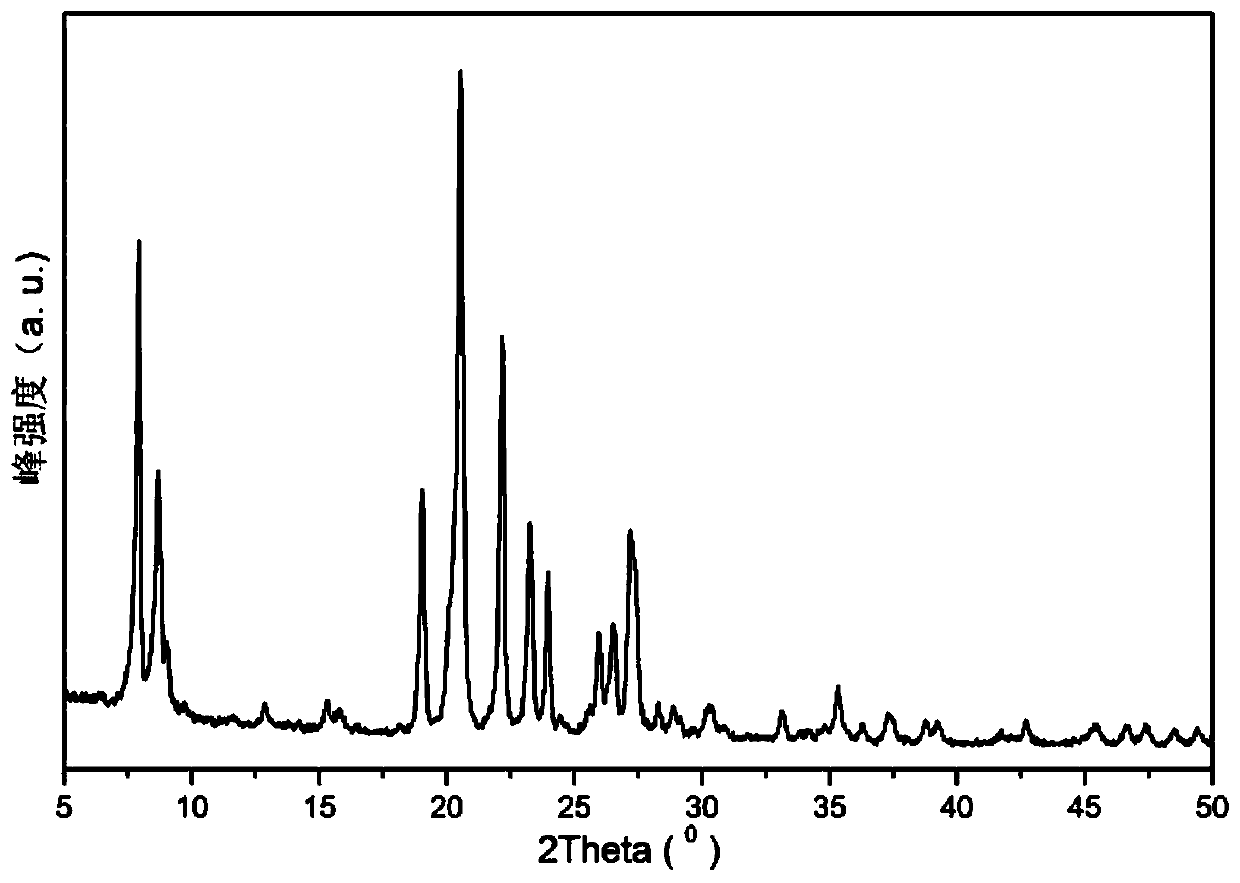

A kind of molecular sieve with multi-level pores and wide silicon-aluminum ratio euo structure and its synthesis method

ActiveCN108862314BSmall grain sizeImprove diffusion abilityMolecular-sieve and base-exchange compoundsXylyleneAlkane

Owner:CHINA CATALYST HLDG CO LTD

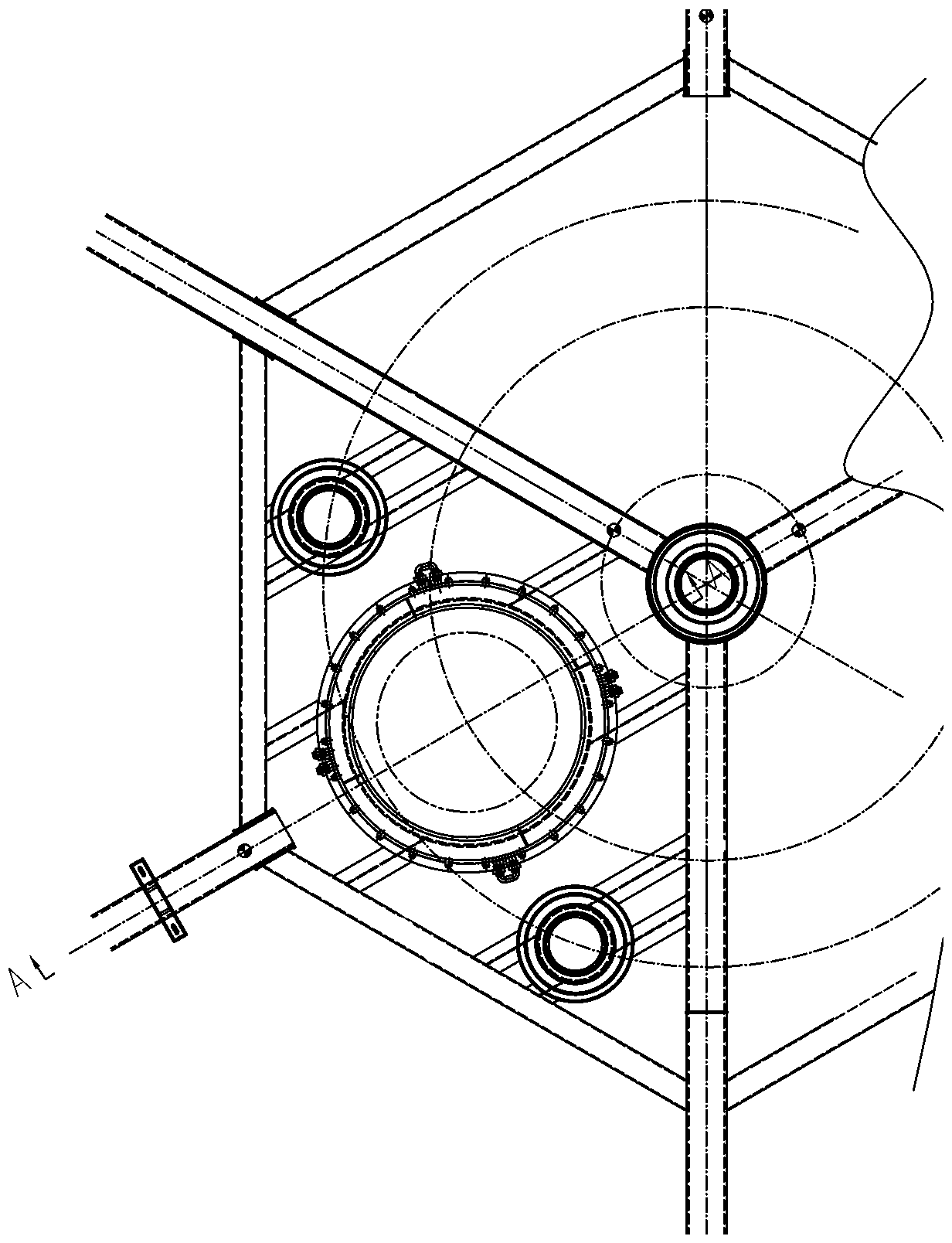

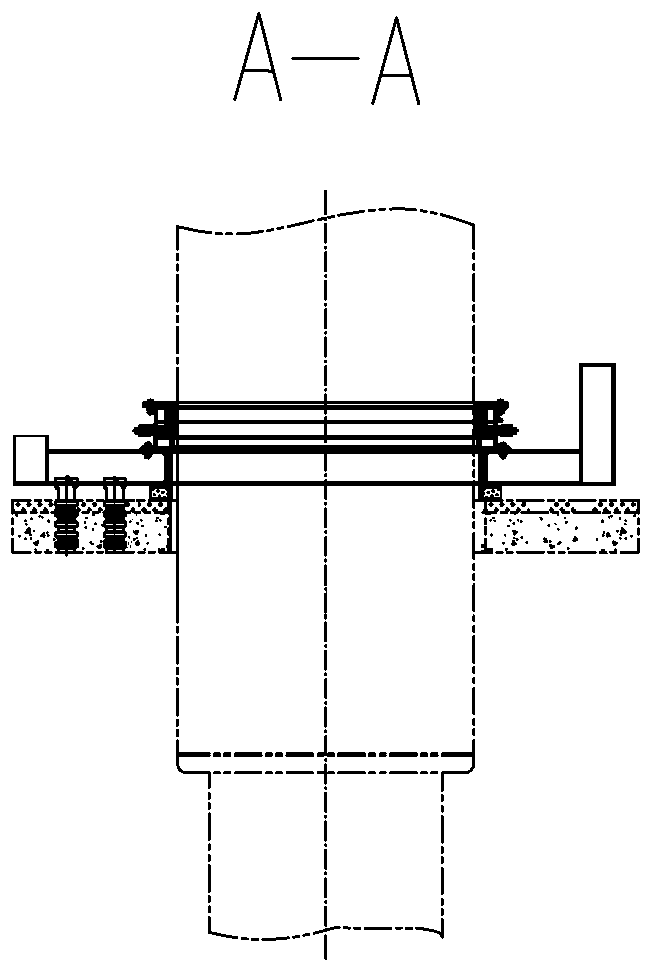

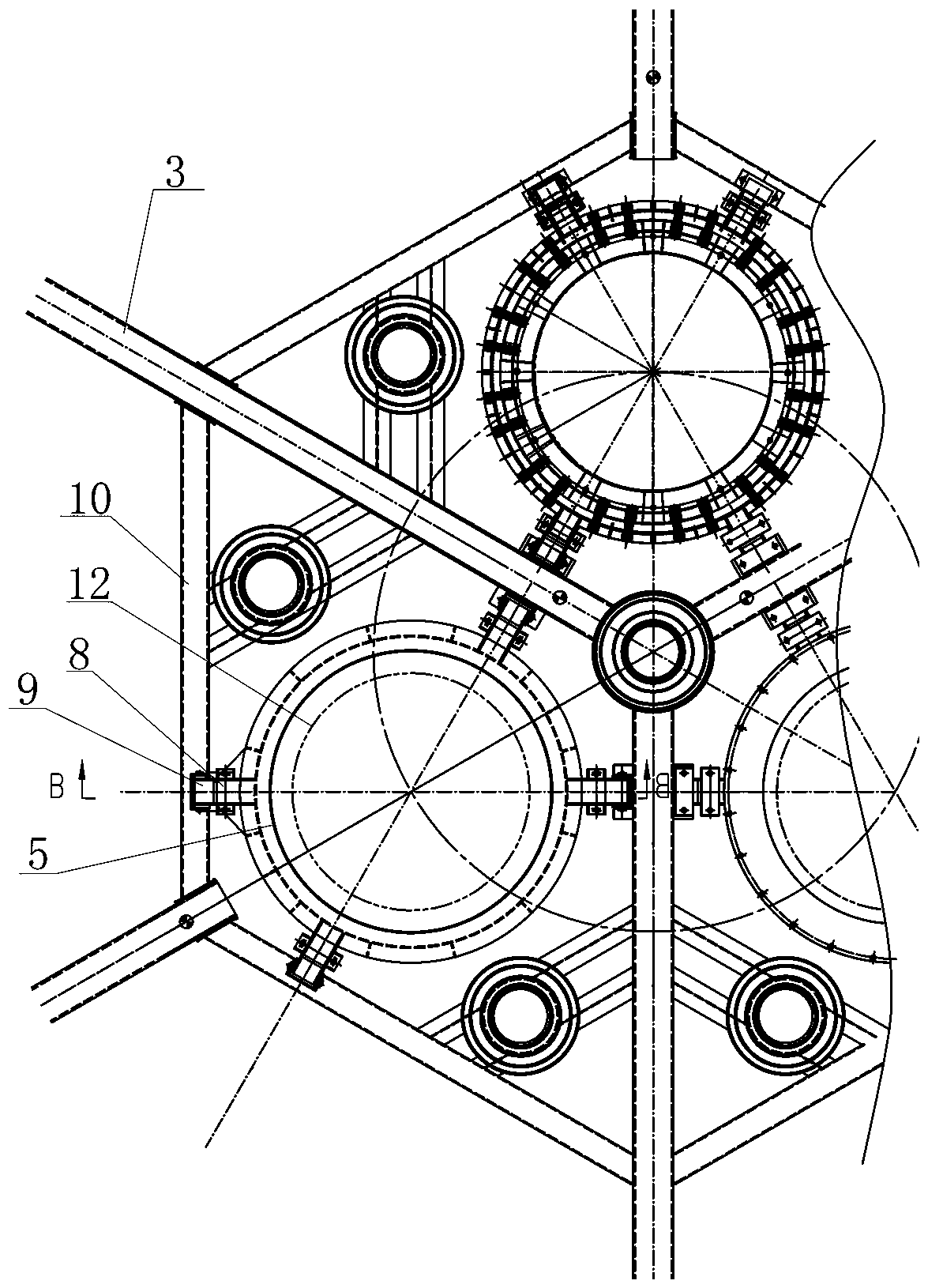

Novel insulating base for ore-smelting electric furnace

PendingCN110057188AChemically stableExtended service lifeLighting and heating apparatusInsulating bodiesBrickEngineering

The invention discloses a novel insulating base for an ore-smelting electric furnace. The novel insulating base comprises a furnace cover. The furnace cover and an electrode protective screen are connected in an inserting mode. A sealing ring pedestal is arranged at the top end of the furnace cover, and a supporting frame is arranged at the external diameter position of the sealing ring pedestal.A sealing ring II is arranged at the top end of the supporting frame, and the external diameter of the sealing ring II is fixedly connected with the supporting frame. A sealing brick ring is arrangedat the top end of the sealing ring II. An insulating box II is arranged at the external parameter position of the sealing brick ring, and the external diameter of the sealing brick ring is elasticallyconnected with the insulating box II. The insulating box II is fixedly connected with the supporting frame. A sealing ring I is arranged at the top end of the sealing brick ring, and the external diameter of the sealing ring I is fixedly connected with the insulating box II. An insulating box I which is fixedly connected with the insulating box II is arranged on the outer side of the insulating box II. The insulating box I is fixedly connected with a primary beam and a secondary beam. By adoption of the sealing brick ring, the electrode protective screen can effectively achieve insulated connection, and a good insulation effect is achieved. The sealing effect can be improved through the sealing rings, and the protective fixation function is also achieved. The primary beam and the secondary beam are connected with the insulating boxes, and the insulating effect is good.

Owner:临沂鑫海新型材料有限公司

Antibacterial skin-care polypropylene fiber master batch and fabric

ActiveCN112831125AImprove antibacterial propertiesSoft touchMonocomponent polyolefin artificial filamentArtifical filament manufactureHydrotalciteAnti bacterial

The invention provides an antibacterial skin-care polypropylene fiber master batch, which belongs to the field of functional fiber master batches and fabrics. The master batch comprises the following components by weight: 30-60 parts of polypropylene resin, 3-15 parts of a plant extract, 8-25 parts of an antibacterial agent, and 2-10 parts of an auxiliary agent. The plant extract is a plant extract with a skin care effect. The antibacterial agent is Fe-doped zinc oxide nanosheets, the Fe-doped zinc oxide nanosheets are prepared by preparing Zn-Fe hydroxides with hydrotalcite-like layered structures through a secondary hydrothermal method and then roasting in high-purity nitrogen to obtain a zinc oxide nanosheet having an oxygen defect, the surface polarity of zinc oxide is reduced, the agglomeration trend is reduced, and the compatibility with polypropylene melt is improved.

Owner:宁波共振运动科技有限公司

A kind of molecular sieve with hierarchical hole euo structure and its synthetic method

ActiveCN108946756BSmall grain sizeImprove diffusion abilityCrystalline aluminosilicate zeolitesXylyleneAlkane

Owner:CHINA CATALYST HLDG CO LTD

Preparation method of nano toughened inorganic transparent protective coating

ActiveCN109135367BImprove mechanical propertiesGood toughening effectAlkali metal silicate coatingsPhosphateActive agent

The invention relates to the field of inorganic coating, and aims to provide a method for preparing nanometer toughened inorganic transparent protective coating. The method includes weighing various raw components according to set weight percentages; adding methyl silicate, phosphate, nanometer fillers, dispersing agents, surfactants and deionized water into ingredient barrels, and stirring the methyl silicate, the phosphate, the nanometer fillers, the dispersing agents, the surfactants and the deionized water to form mixed slurry; injecting the mixed slurry into nanometer ball mills and grinding the mixed slurry; adding water glass and defoaming agents into dispersion machines, stirring the water glass and the defoaming agents and then adding the ground mixed slurry into the dispersion machines; continuing to stir the water glass, the defoaming agents and the ground mixed slurry to obtain the nanometer toughened inorganic transparent protective coating. The method has the advantages that inorganic coating is toughened by nanometer materials, and accordingly good toughening effects can be realized without deterioration of the mechanical properties (such as the hardness and the abrasion resistance), the water resistance, the aging resistance and the like of coatings; the nanometer materials are stable in performance and can be mixed with the strong-alkalinity inorganic coating without qualitative change; fillers are ground by nanometer sanders, the particle sizes of the fillers can be reduced and are smaller than or equal to 0.2 micrometer, accordingly, the method is favorable for preparing transparent inorganic coatings, the trend of agglomeration of the nanometer fillers can be weakened, and the toughening effects can be effectively realized by the nanometer fillers.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST

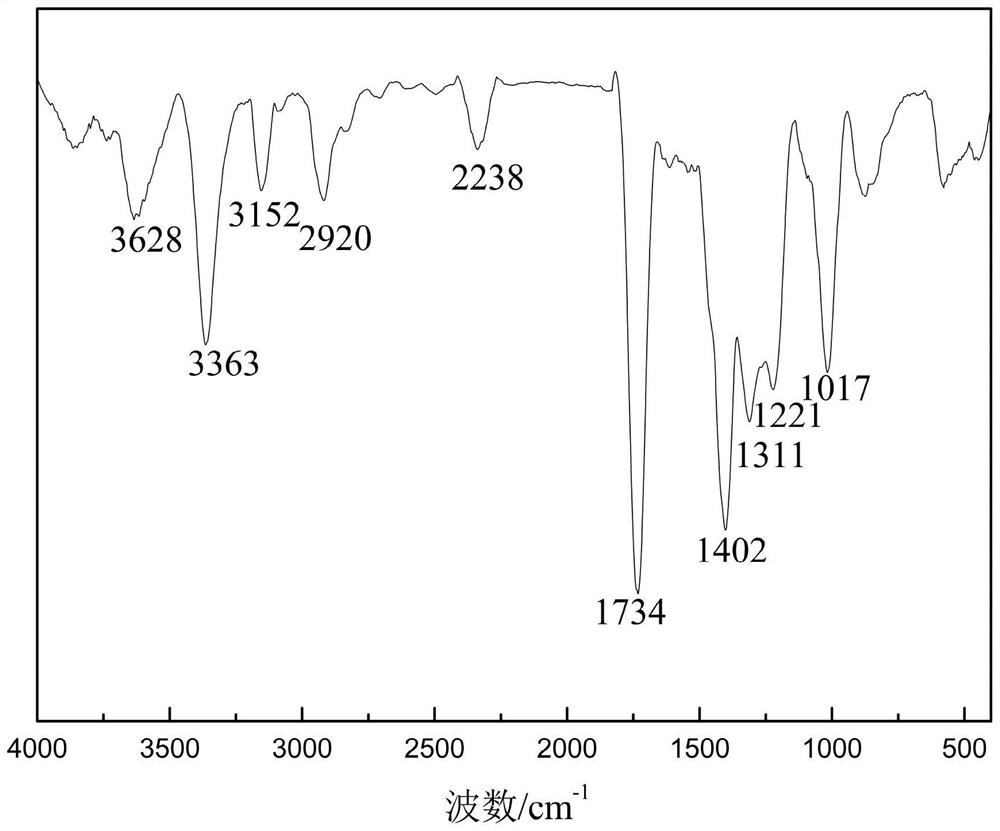

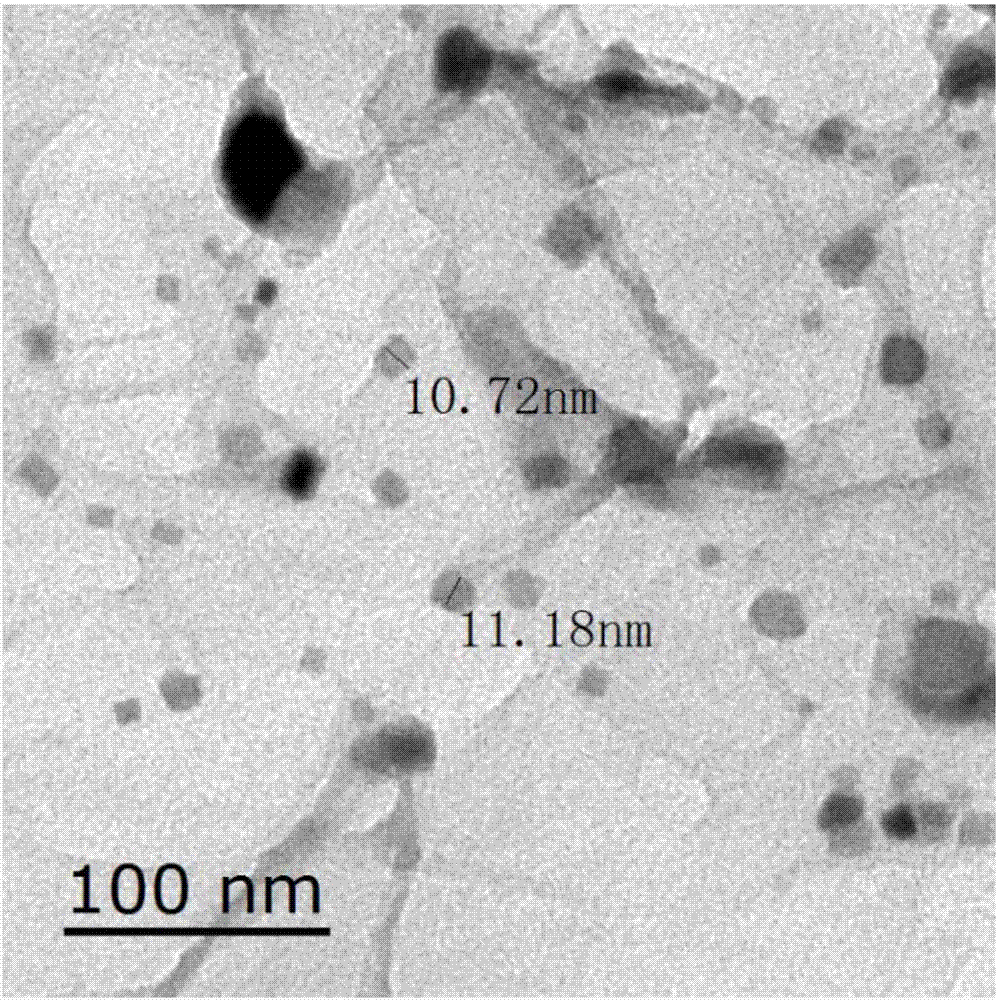

A kind of lead selenide quantum dot-graphene composite material and preparation method thereof

ActiveCN105836716BRestricted sizeReduced reunion tendencyGrapheneMetal selenides/telluridesLead saltCarboxylic acid

The invention provides a lead selenide quantum dot / graphene composite material and a preparation method thereof. The composite material is prepared with graphene oxide sheets as a hard template through an ionic complexing method. Firstly, through the complexing and electrostatic effects between carboxylic groups in the graphene oxide and soluble lead salt, lead ions are immobilized on the surface of the graphene oxide, and then a less amount of an alkaline solution is dropwisely added slowly, wherein a certain interval is maintained between graphene oxide sheets through electrostatic repulsion between hydroxide ions and carboxylate ions. A selenium precursor solution is prepared under protective of nitrogen and then is added to the graphene oxide / lead ion complex to to be in a reflux reaction. A reduction agent is then added to reduce the graphene oxide sheets to prepare the lead selenide quantum dot / graphene composite material. The method is simple in operation, is convenient to operate and is repeatable. The composite material has high electron transportation performance of graphene, is high in Seebeck coefficient, and has excellent application prospect in the field of thermoelectricity.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

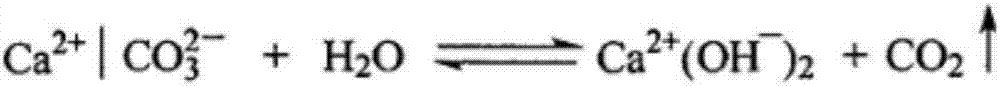

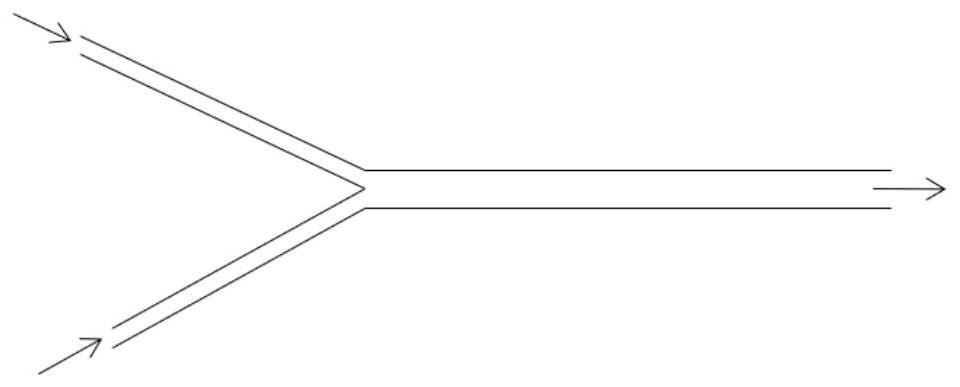

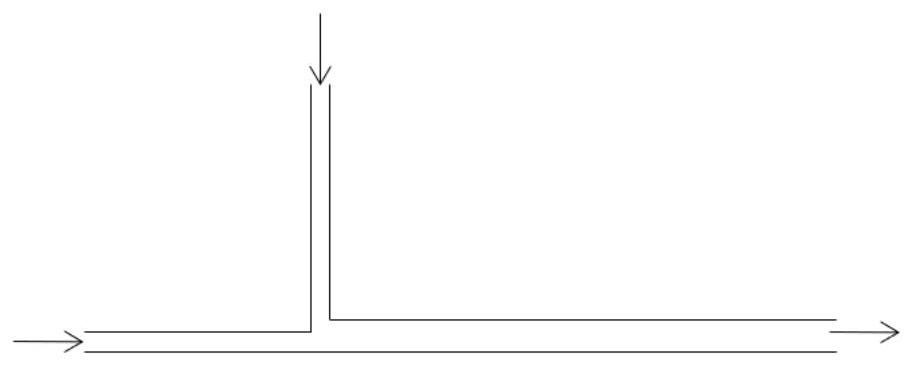

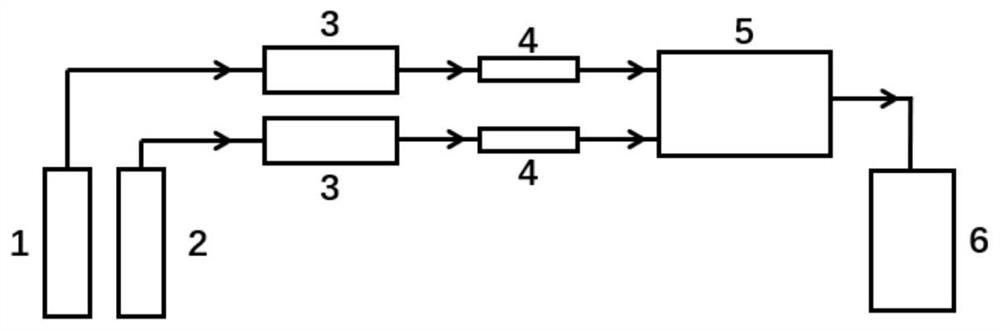

Method for preparing nano calcium hydroxide by adopting micro-channel reactor

PendingCN114853046AImprove mixing efficiencySmall particle sizePlastic recyclingNanotechnologyCalcium hydroxideSalt solution

The invention provides a method for preparing nano calcium hydroxide by adopting a micro-channel reactor, which comprises the following steps: preparing a mixed solution of calcium salt and a dispersing agent and an alkali solution, then simultaneously injecting the two solutions into the micro-channel reactor at a certain speed to react, and quickly stirring the flowing reaction solution to obtain a nano calcium hydroxide suspension. The mixing efficiency of the calcium salt solution and the alkali solution can be greatly improved by adopting a forced micro-mixing feeding mode of the micro-channel reactor, the particle size of the calcium hydroxide particles can be reduced, the particle size of the obtained calcium hydroxide particles is 50-200 nanometers, and the advantages are remarkable.

Owner:镇江华茂新材料科技有限公司

A kind of antibacterial skin care polypropylene fiber masterbatch and fabric

ActiveCN112831125BImprove antibacterial propertiesSoft touchMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceHydrotalcite

The invention provides an antibacterial skin care polypropylene fiber masterbatch, which belongs to the field of functional fiber masterbatch and fabrics. The masterbatch has the following components in parts by weight: 30-60 parts of polypropylene resin; plant extract 3-15 parts; 8-25 parts of antibacterial agent; 2-10 parts of auxiliary agent; wherein, the plant extract is a plant extract with skin care effect; the antibacterial agent is Fe-doped zinc oxide nanosheets, so The Fe-doped zinc oxide nanosheets are firstly prepared by a secondary hydrothermal method with Zn-Fe hydroxide with a hydrotalcite-like layered structure, and then roasted in high-purity nitrogen to prepare a zinc oxide with oxygen defects. Nano-sheets, reduce the surface polarity of zinc oxide, reduce the tendency of agglomeration, and improve the compatibility with polypropylene melt.

Owner:宁波共振运动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com