Alpha-Fe2O3 multilayer hollow nanometer spherical structure, preparation method and application

A nanostructure, spherical structure technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of restricting and destroying the structure of active materials, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

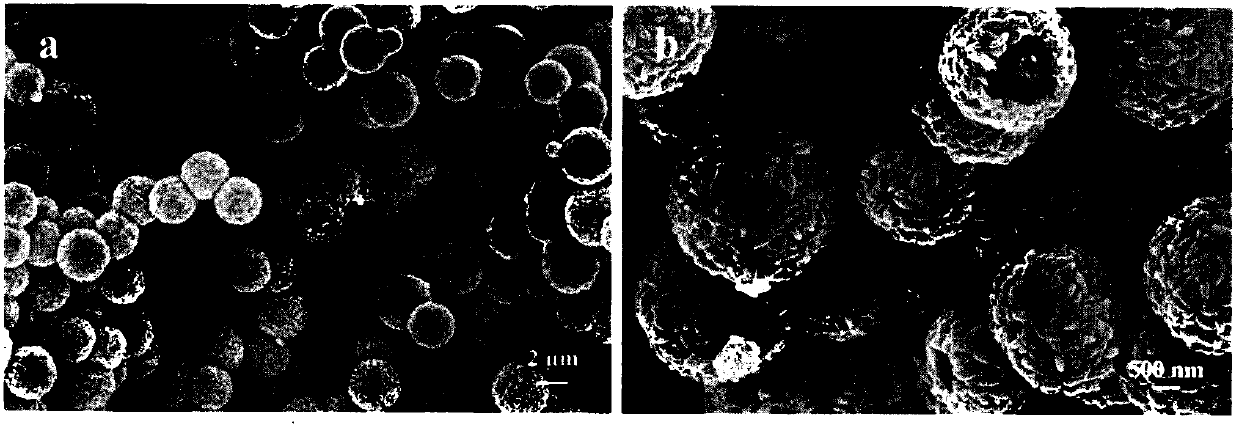

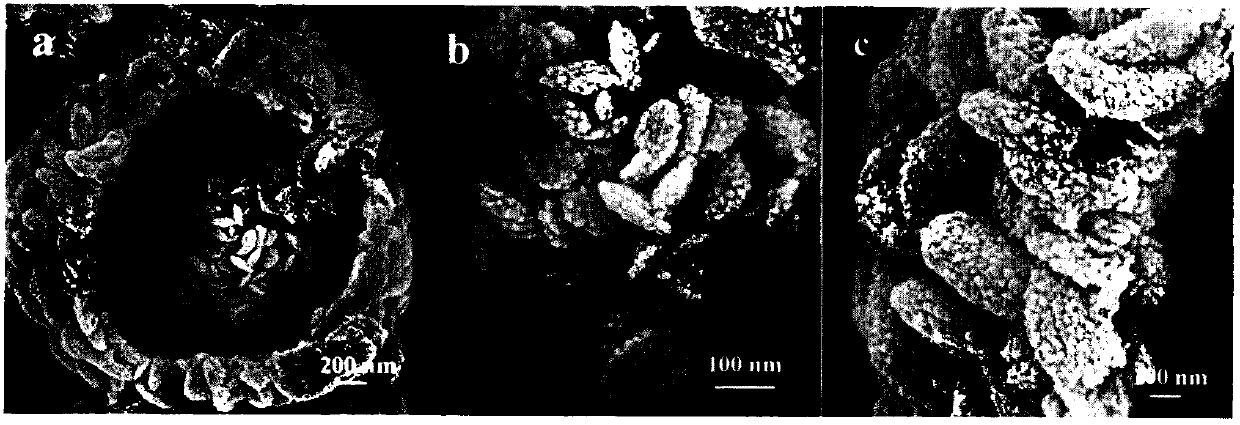

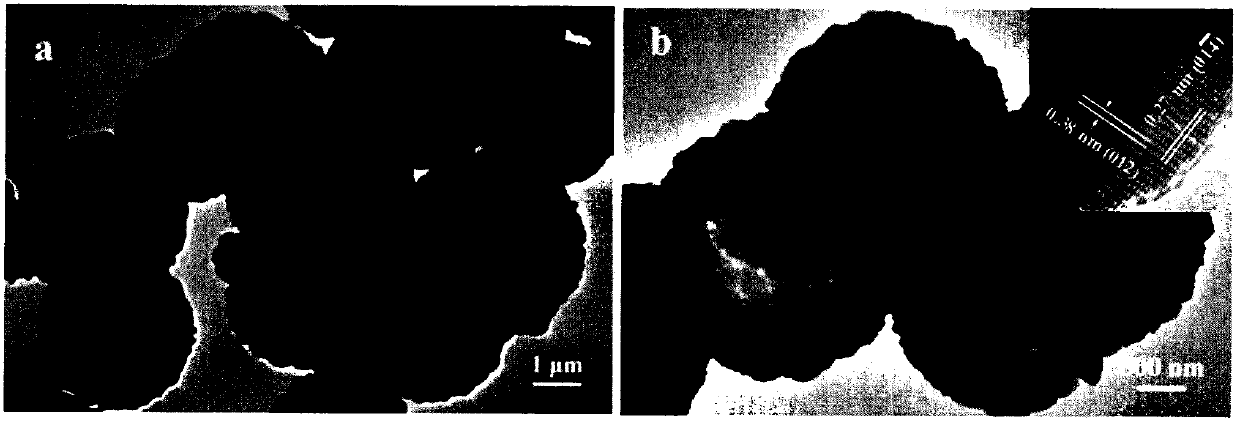

[0022] 0.16gFeCl 3 ·6H 2 O was dissolved in a mixed solution of 2 mL of water and 18 mL of ethanol, 0.1 g of glycine was added, and then the above mixture was transferred to a hydrothermal kettle and heated at 160 °C for 12 h. After naturally cooling to room temperature, the red powder collected by centrifugation is the product, and the obtained product is multilayer α-Fe 2 o 3 Hollow nanostructures.

Embodiment 2

[0024] 0.16gFe(NO 3 ) 3 ·6H 2 O was dissolved in a mixed solution of 2 mL of water and 18 mL of ethanol, 0.1 g of glycine was added, and then the above mixture was transferred to a hydrothermal kettle and heated at 160 °C for 12 h. After naturally cooling to room temperature, the red powder collected by centrifugation is the product, and the obtained product is multilayer α-Fe 2 o 3 Hollow nanostructures.

Embodiment 3

[0026] 0.16gFeCl 3 ·6H 2 O was dissolved in a mixed solution of 10 mL of water and 10 mL of ethanol, 0.1 g of glycine was added, and then the above mixture was transferred to a hydrothermal kettle and heated at 160 °C for 12 h. After naturally cooling to room temperature, the red powder collected by centrifugation is the product, and the obtained product is multilayer α-Fe 2 o 3 Hollow nanostructures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com