Soft nanometer domain toughened pet composite material and preparation method thereof

A composite material and soft technology, which is applied in the field of soft nano-micro-region toughened PET composite materials and its preparation, can solve the problem of system rigidity, strength, heat resistance decline, and does not consider the influence of the transparency of composite toughened products, etc. problem, to achieve the effect of good optical performance and excellent impact performance

Active Publication Date: 2019-10-01

中山京工高分子材料有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Add the above ingredients into the twin-screw extruder at a processing temperature of 250-300°C. While shearing and mixing, the crosslinking agent will undergo a ring-opening reaction with the epoxy group, so that the epoxy group Elastomer cross-linking, cross-linked elastomer dispersed in the PET continuous phase, can improve the impact resistance of PET, but at the same time it also caused a serious decline in the rigidity, strength, heat resistance, etc. of the system

[0005] In summary, no matter whether it is the method of toughening with elastomer or using inorganic nanomaterials to synergistically toughen with elastomer, while improving the toughening effect, it does not consider the impact of composite toughening on the transparency of the product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038]

Embodiment 2

[0040]

Embodiment 3

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

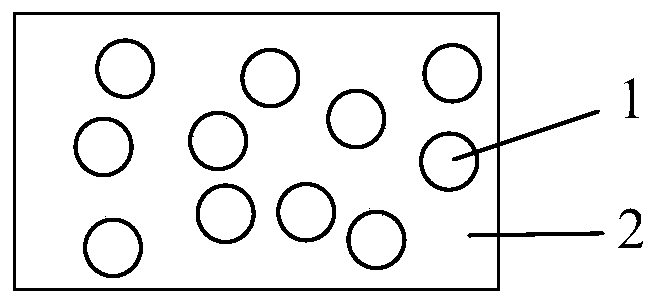

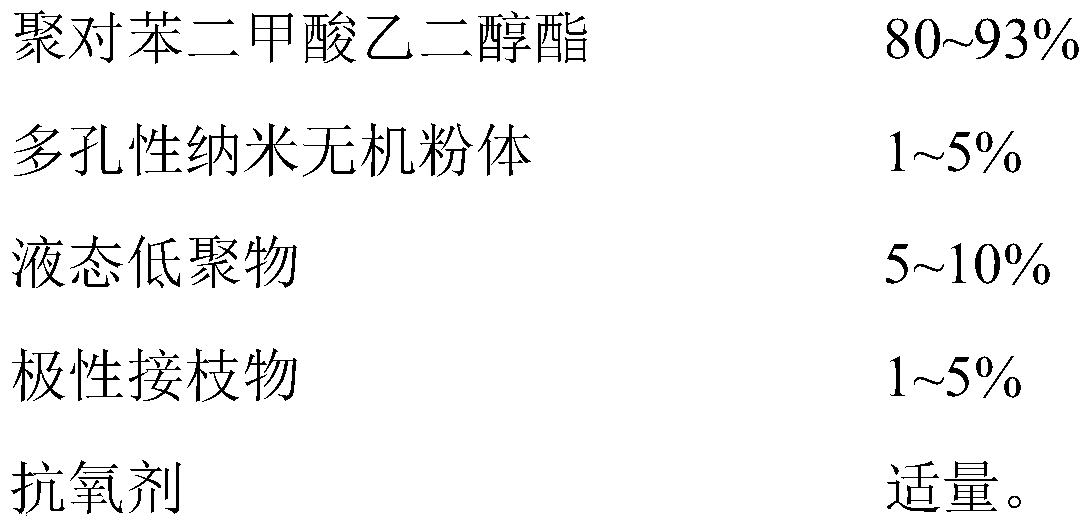

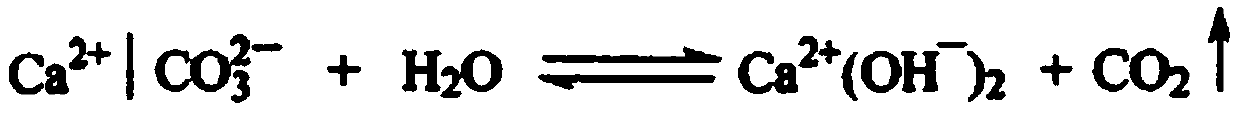

The invention discloses a soft nanometer micro area flexibility-enhanced PET composite material and a preparation method thereof. The flexibility-enhanced PET composite material comprises the following components in mass percent: 80 to 93 percent of polyethylene terephthalate, 1 to 5 percent of a porous nanometer inorganic powder, 5 to 10 percent of liquid low polymers, 1 to 5 percent of polar grafted polymers, and a proper amount of an antioxidant. The method comprises the steps of grinding PET into a powder after the PET is cooled, soaking the nanometer inorganic powder through the liquid low polymer, so as to ensure that the nanometer inorganic powder is sufficiently soaked and absorbed by the liquid low polymer and to form a soft and elastic spherical nanometer structure, and improving the wetting property of the surface of the nanometer inorganic powder through the polar grafted polymer, so as to ensure that the nanometer inorganic powder can be uniformly dispersed in a PET matrix and a soft nanometer micro area can achieve the effect of flexibility enhancement in the PET. A PET sheet produced by adding the flexibility-enhanced composite material has excellent impact property, and maintains good optical property.

Description

【Technical field】 [0001] The invention relates to a soft nano-micro-region toughened PET composite material and a preparation method thereof, belonging to the technical field of PET modified materials. 【Background technique】 [0002] Polyethylene terephthalate (English abbreviation: PET) has excellent properties such as electrical insulation, heat resistance and chemical resistance, and has been widely used in the production fields of fibers, films and sheets. PET materials are low in price, excellent in comprehensive performance, easy to recycle, and have stronger market competitiveness than non-environmentally friendly polyvinyl chloride (PVC). Therefore, PET materials in the market have a tendency to gradually replace PVC. However, due to the disadvantages of high brittleness and poor impact performance of PET, its application in packaging, electronics, electrical appliances, automobiles, machinery and other fields is limited. [0003] Chinese patent ZL200810198221.9 tou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L67/02C08L51/06C08K9/10C08K7/24C08K7/26

Inventor 涂志刚郑惠君钟永强陈梓銮

Owner 中山京工高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com