A kind of molecular sieve with hierarchical hole euo structure and its synthetic method

A synthesis method and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of limited catalytic life of molecular sieves, easy occurrence of miscellaneous crystals, and product yield to be improved, and achieve industrial implementation, small grain size, The effect of a wide feeding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

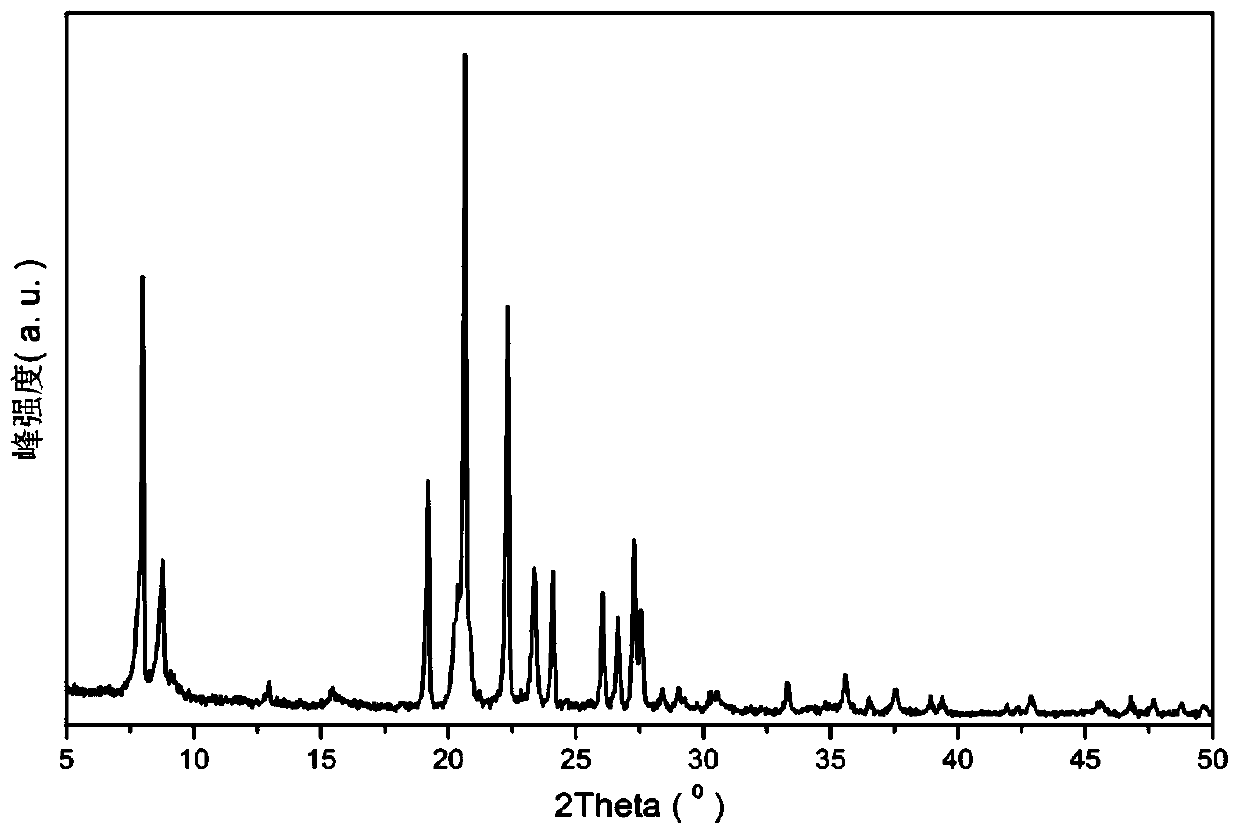

[0052] A method for synthesizing molecular sieves with hierarchical pores EUO structure, comprising the following steps:

[0053] (1) Preparation of mixed sol: take quantitative cetyltrimethoxysilane and dissolve it in methanol to form a solution and stir to disperse to form a solution of cetyltrimethoxysilane; Add quantitative NaOH, water glass, 1,6-bis(N-methylpiperidinium)hexane and deionized water H to the silane solution 2 O, to obtain a silicon source mixed solution; under the condition of 60° C., add quantitative pseudo-boehmite to the silicon source mixed solution, stir vigorously for 90 minutes, and leave to stand at room temperature for 12 hours to obtain a mixed sol; the mixed sol was used as Crystallization precursor mixture, which consists of:

[0054] Na 2 O:SiO 2 :Al 2 o 3 :LCS:OSDA:H 2 O=0.12:1:0.0211:0.0042:0.08:15.

[0055] (2) Crystallization: Place the mixed sol obtained in step (1) in a crystallization kettle, and crystallize at 170°C, wherein the t...

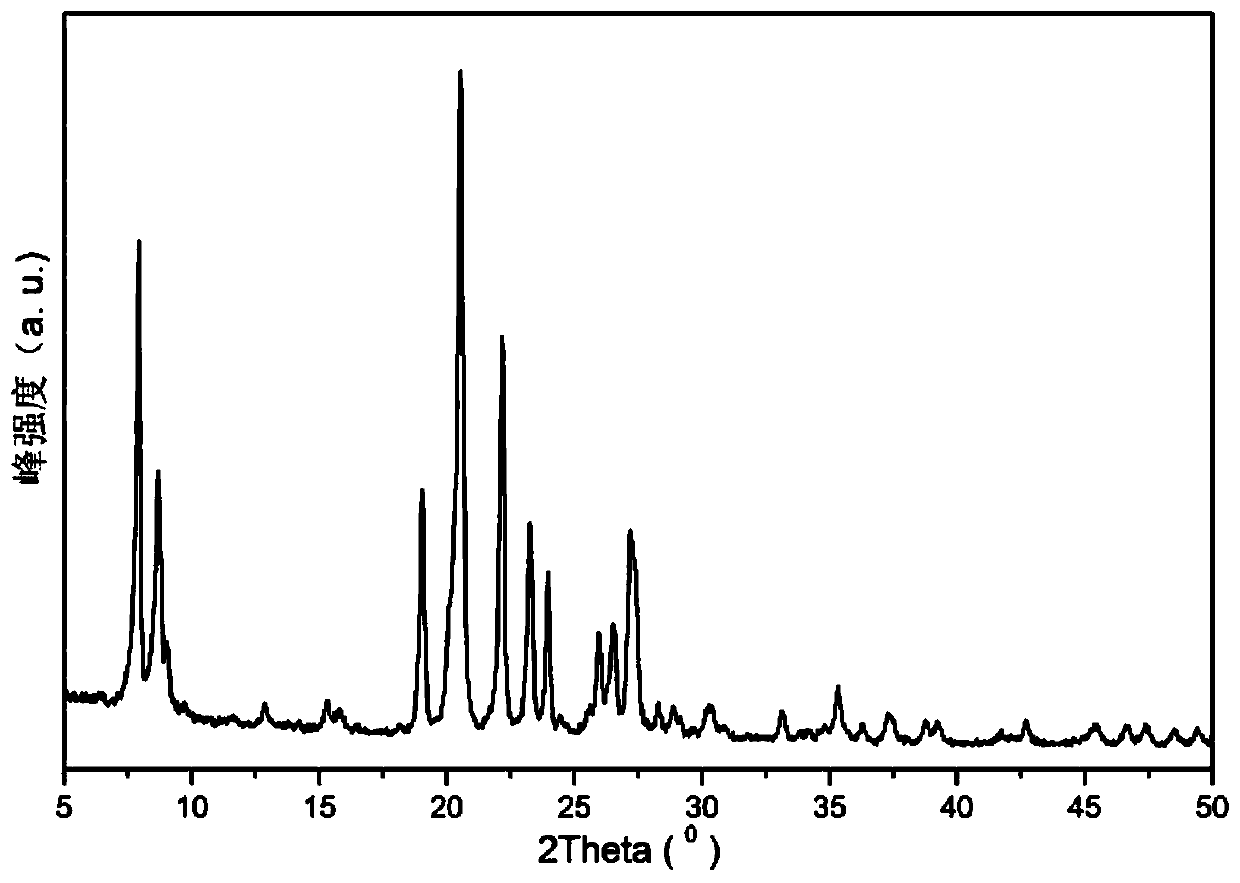

Embodiment 2-8

[0065] Synthesize using the same synthesis method as in Example 1, the selected silicon source, aluminum source, long-chain organosilane, biquaternary ammonium salt template type and feeding ratio, heating rate, crystallization temperature, crystallization time and other parameters Selection, referring to Table 2; The physicochemical properties of the product EUO-2-EUO-8 prepared by embodiment 2-8 are as shown in Table 3:

[0066] Table 2: Selection of parameters in the EU-1 molecular sieve synthesis method in the examples

[0067]

[0068]

[0069] Table 3: Physical and chemical properties of EU-1 molecular sieve products synthesized in Examples and Comparative Examples

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com