Patents

Literature

73results about How to "Wide feeding range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency flocculating agent

InactiveCN105540789AStable chemical propertiesReduce dosageWater/sewage treatment by flocculation/precipitationPulverized fuel ashTreated water

The invention discloses a high-efficiency flocculating agent. The high-efficiency flocculating agent is prepared from pulverized fuel ash, starch, ferrous sulfate, sodium oxide, zinc chloride, zinc chloride, aluminum sulfate, polyacrylamide, polyvinylpyrrolidone, polymeric phosphato-aluminum chloride, cellulose powder and diatomaceous earth. The high-efficiency flocculating agent has the advantages of stable chemical performance, small dosage, wide feeding range, high treatment efficiency, safety and no pollution, and basically does not influence the pH value of treated water.

Owner:FOSHAN MINGQIAN TECH

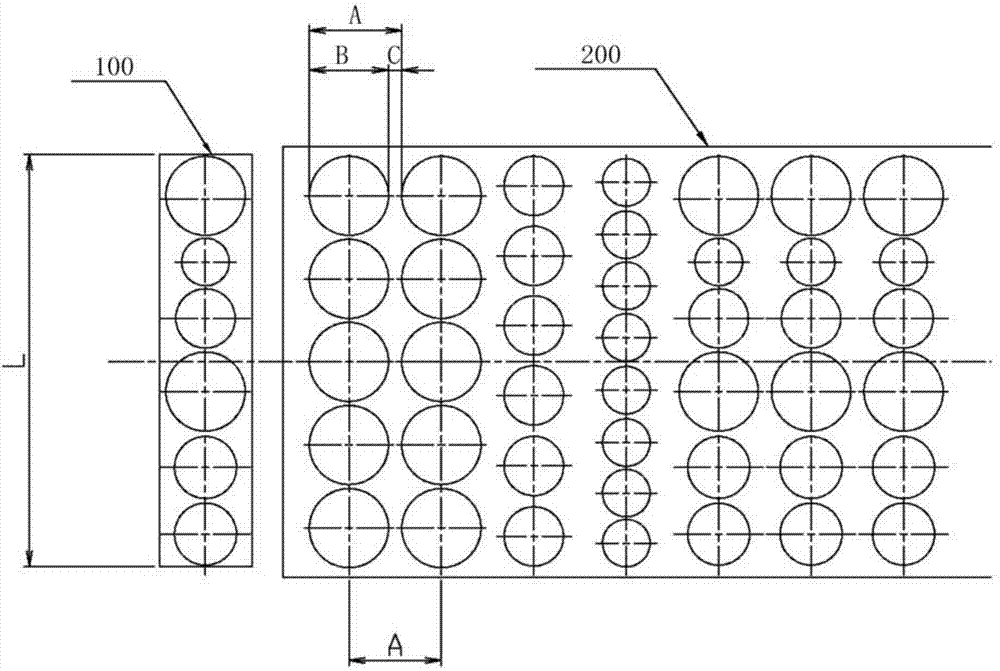

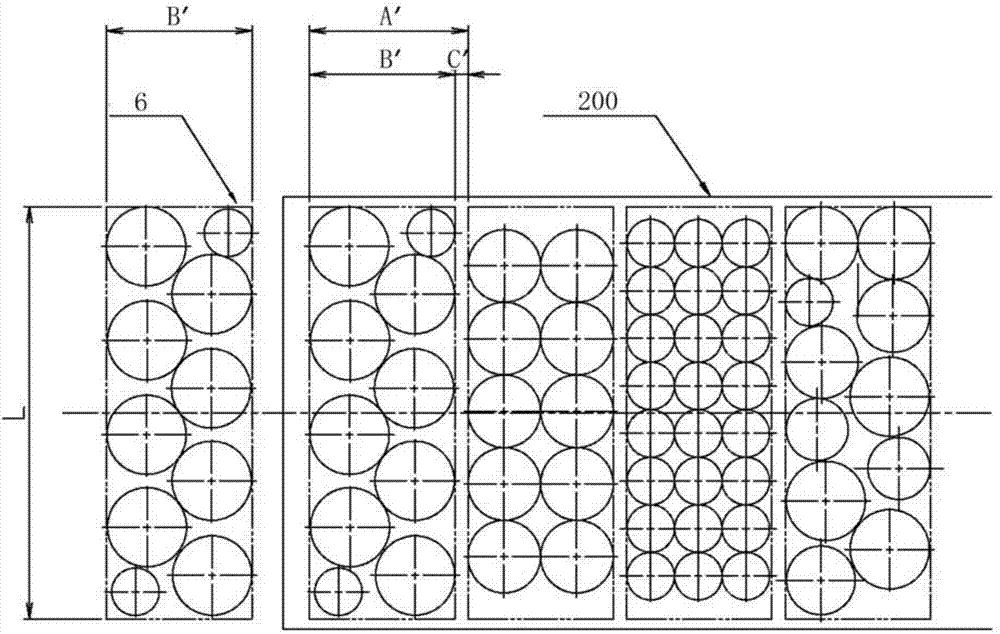

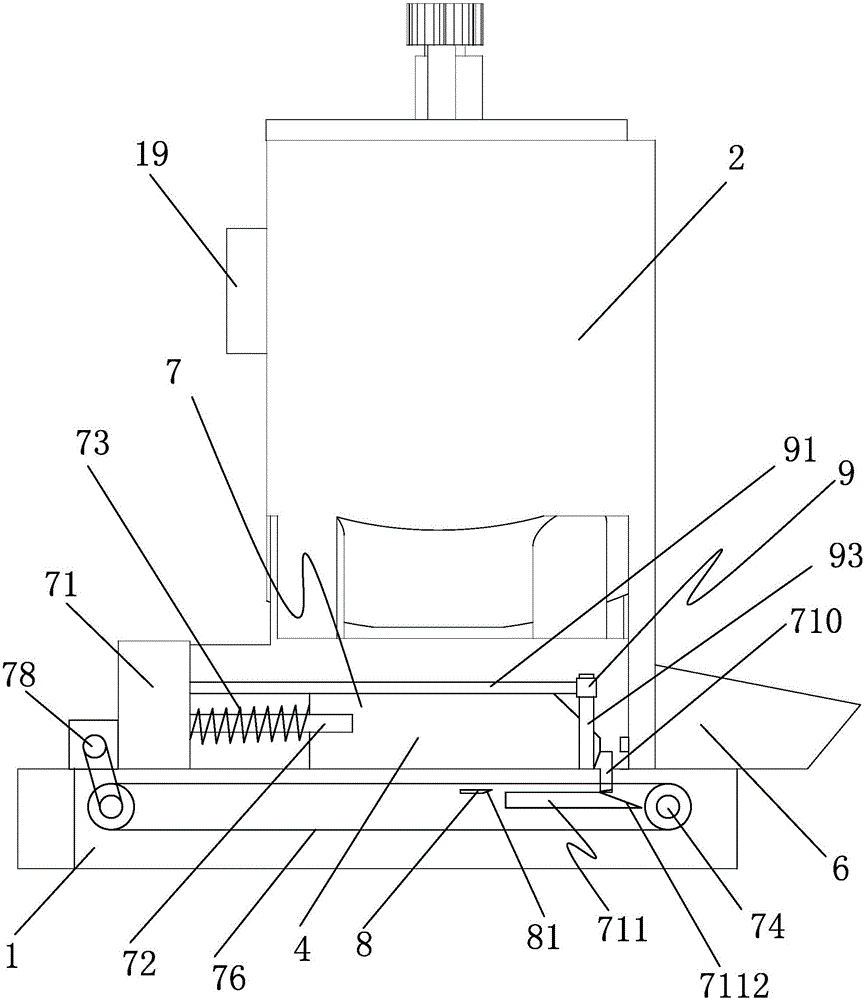

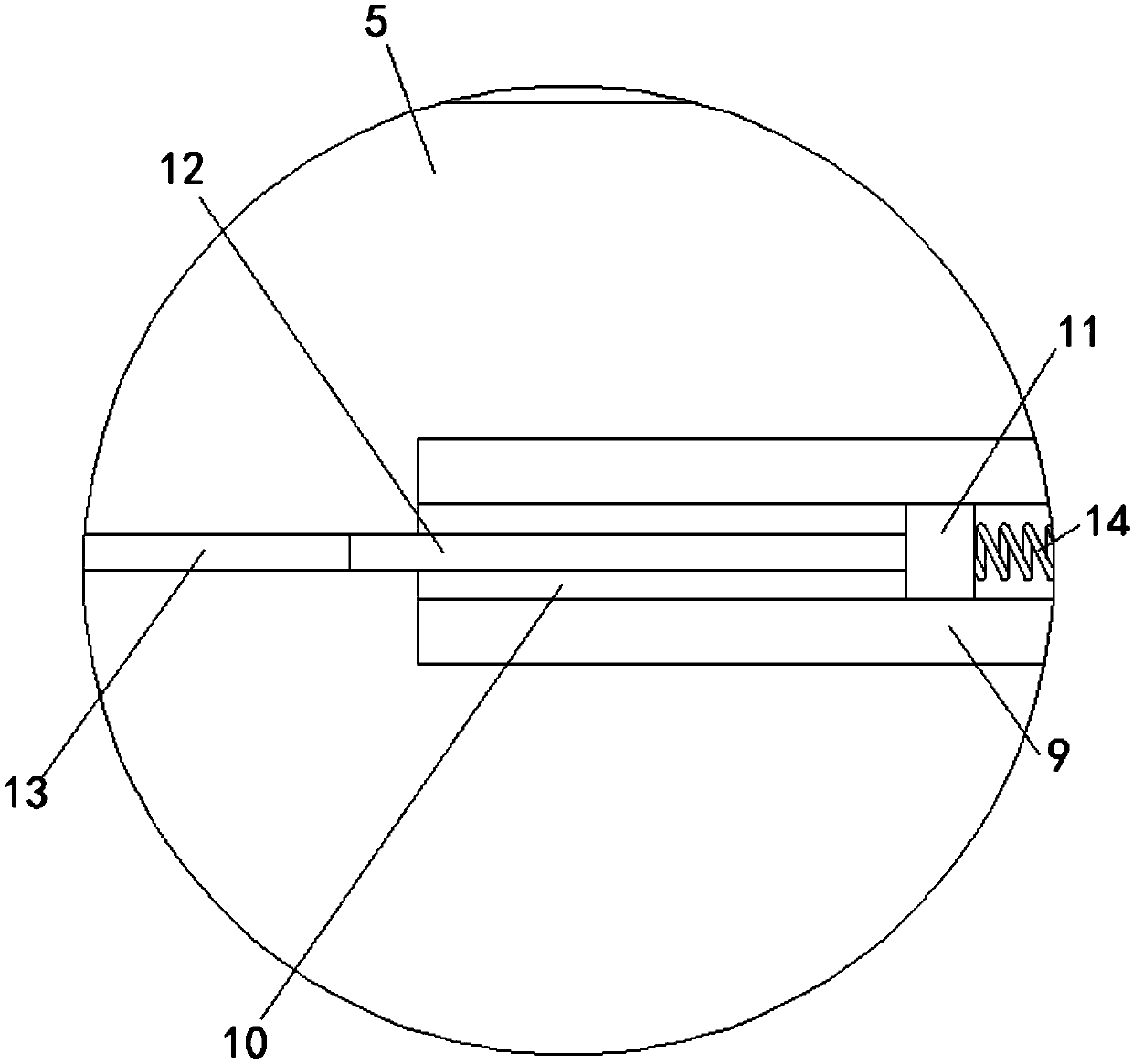

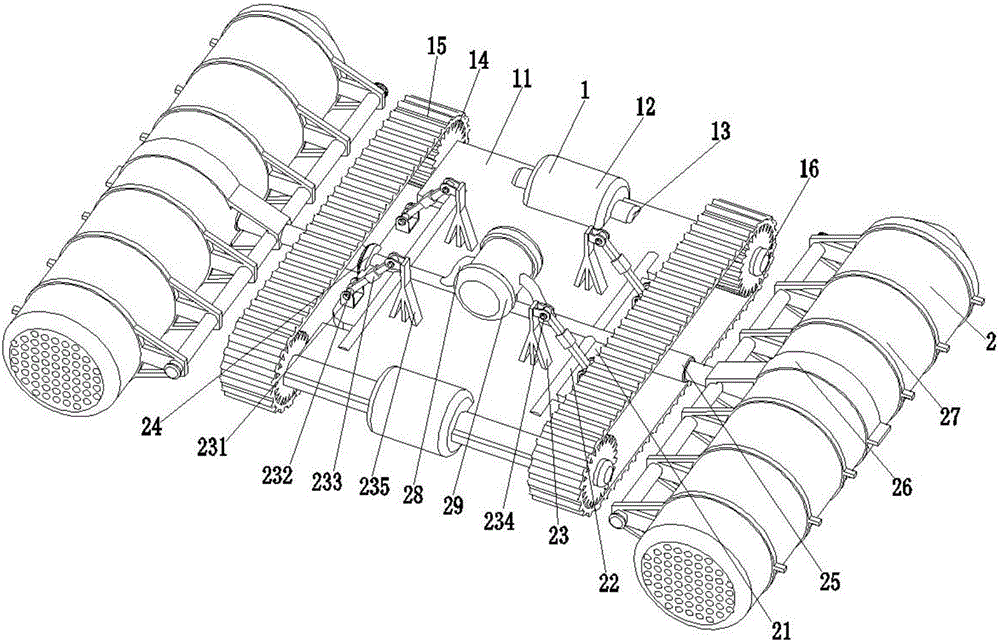

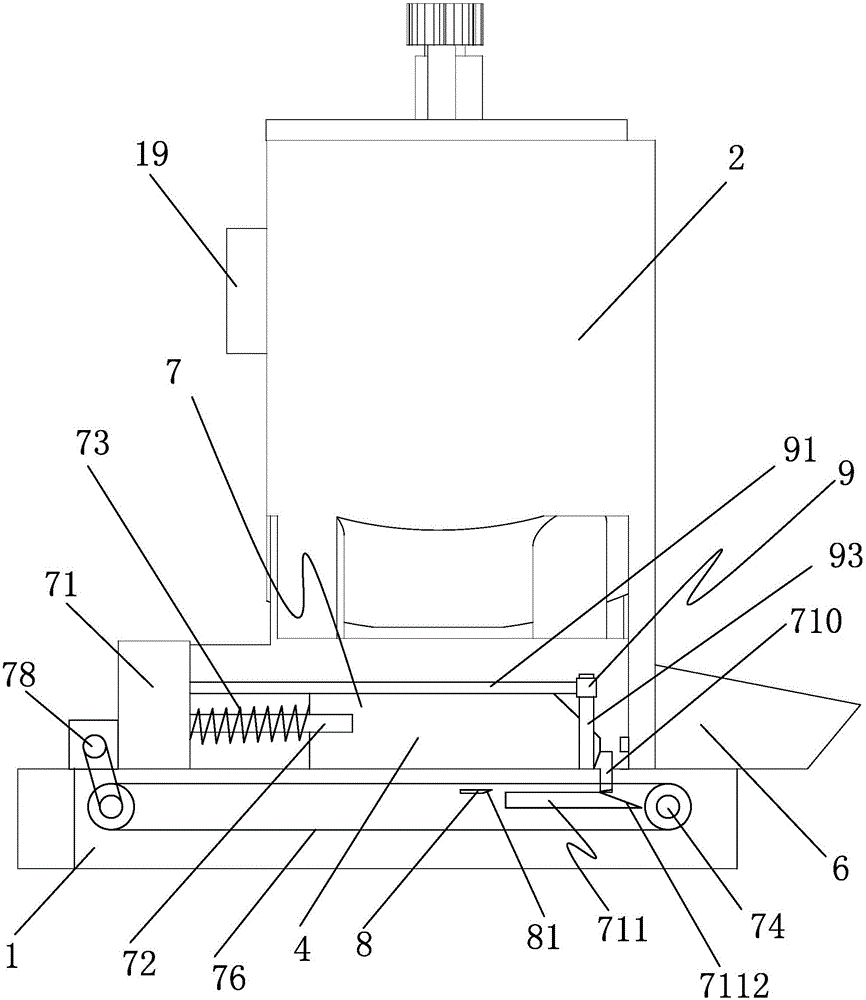

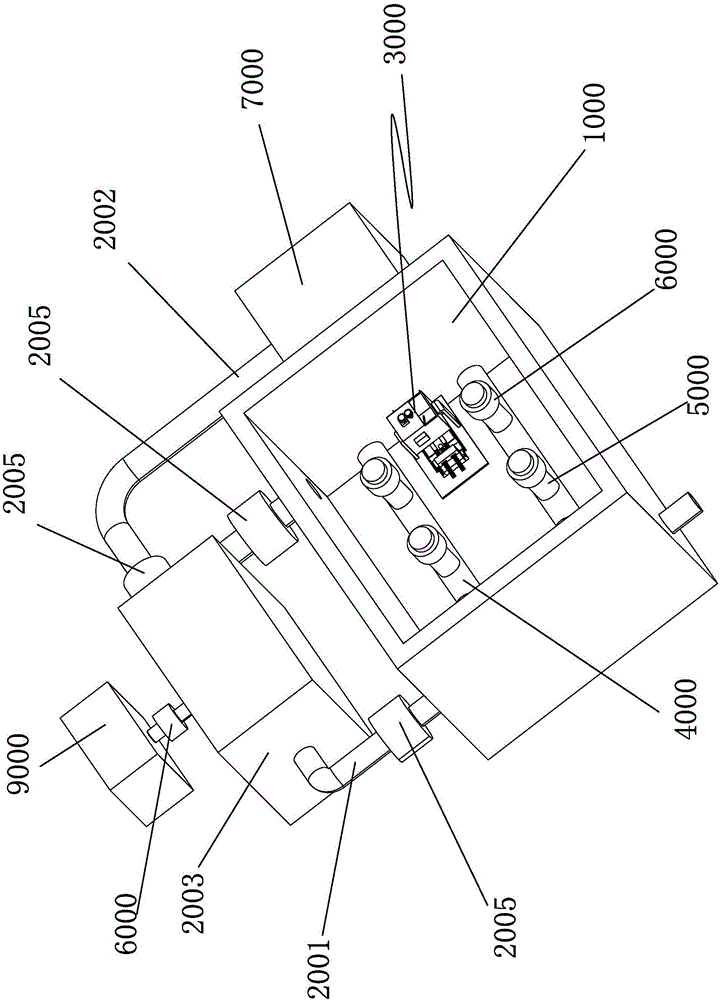

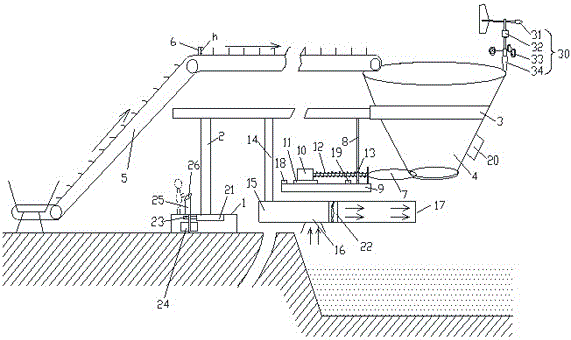

Power-and-free material-loading and transporting apparatus used for material-basket-free thermal-treatment furnace of aluminum alloy product

ActiveCN104328263ASpeed up the loading processIncrease delivery speedFurnace typesHeat treatment process controlUtilization rateHeat treating

A power-and-free material-loading and transporting apparatus used for a material-basket-free thermal-treatment furnace of an aluminum alloy product belongs to the technical filed of thermal treatment devices of the aluminum alloy product. By means of parts, including a transporting roller track, a pre-assembling roller track, a material pushing machine, a material-feeding detection photoelectric tube, a material-full detection photoelectric tube, a power-and-free roller track, a removing roller cylinder, a removing motor, a material-loading fork and the like, the power-and-free material-loading and transporting apparatus enables workpieces arranged in a material-loading zone on the power-and-free roller track to be changed from one row into two or more rows, wherein the workpieces are pre-arranged by a material baffle. Redundant workpieces are removed from the roller cylinder and from the material-loading zone. The pieces in the material-loading zone are sent to the thermal-treatment furnace by the material-loading fork in one step for thermal treatment. By means of the power-and-free material-loading and transporting apparatus, automatic level of the device is improved and time period during material loading is effectively prolonged. In addition, the power-and-free material-loading and transporting apparatus can increase effective space in the thermal-treatment furnace by 20%, can reduce a production cost and can increase energy resource utilization rate.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

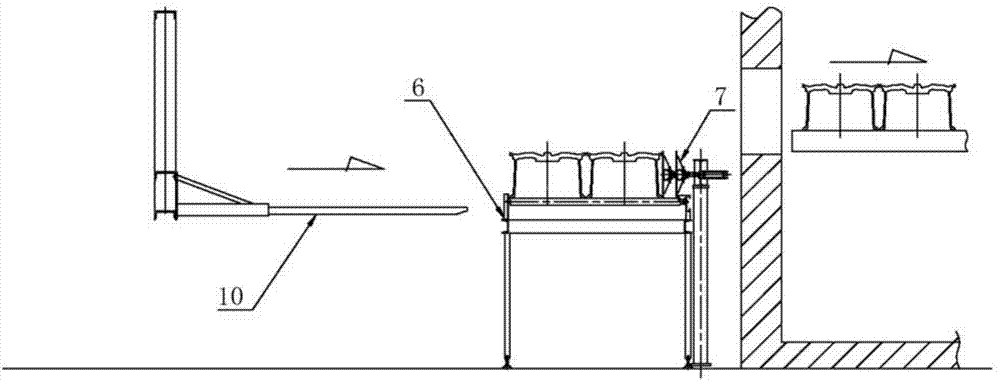

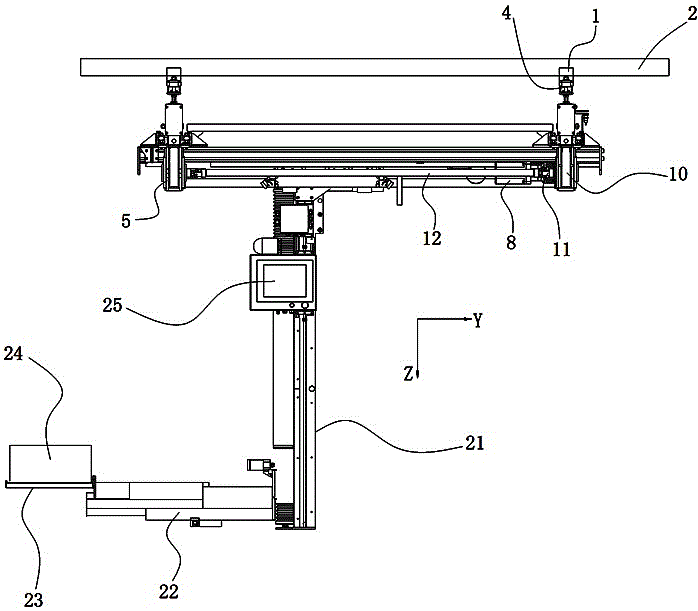

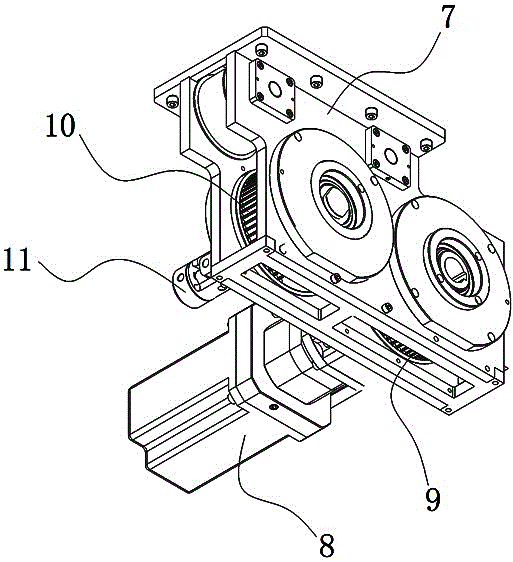

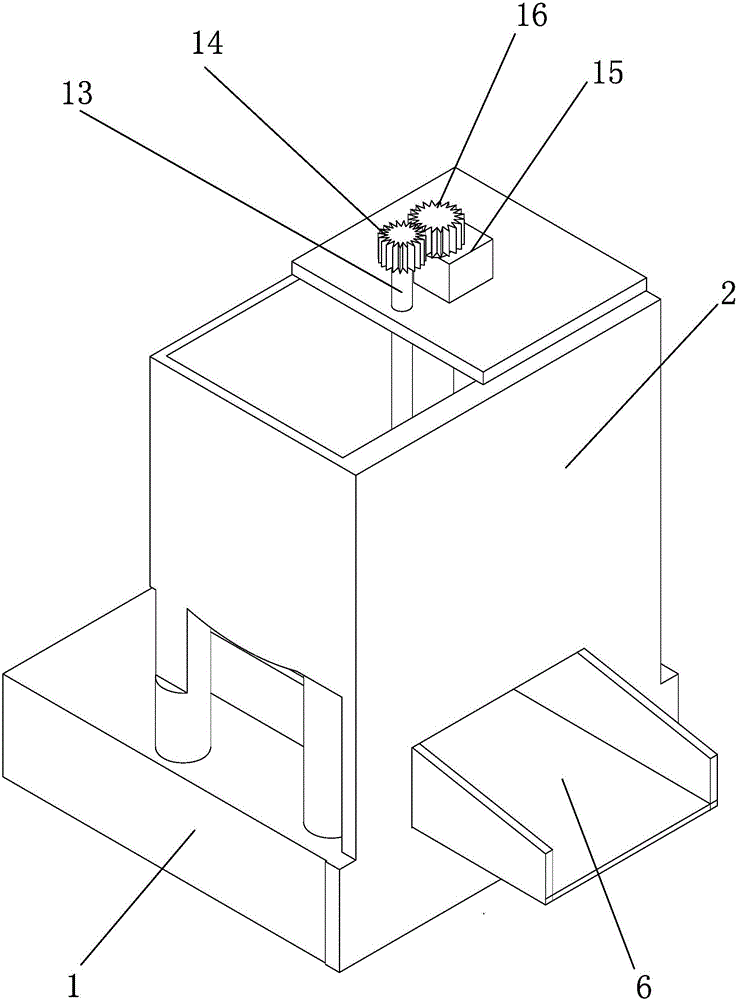

Automatic transfer equipment used for yarn roll

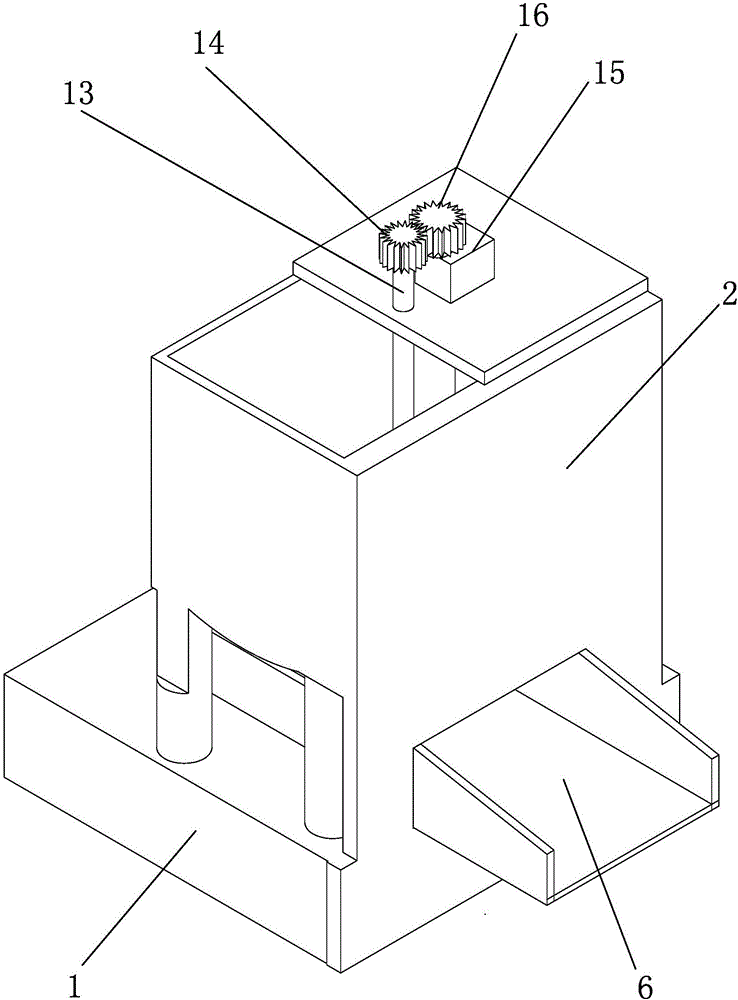

ActiveCN106064728APrecise control over movementSimple structureMechanical conveyorsForeign matterYarn

The invention relates to automatic transfer equipment used for a yarn roll. The equipment comprises an X-direction moving mechanism, a Y-direction moving mechanism, a rotating mechanism, a lifting mechanism, a telescopic mechanism and a yarn taking plate. The X-direction moving mechanism comprises an X-direction rail, joist steel, a tackle, an X-direction motor and a transmission rod; the Y-direction moving mechanism comprises a Y-direction rail, a Y-direction motion assembly, a Y-direction motor and a synchronous belt; the rotating mechanism comprises a mounting plate, a rotating motor, a rotating driving gear and a rotating driven gear; the upper end of the lifting mechanism is connected with the output end of the rotating driven gear, the telescopic mechanism is connected with the lower end of the lifting mechanism, the yarn taking plate is mounted at the output end of the telescopic mechanism, an industrial camera is arranged at the tail end of the yarn taking plate, infrared sensors used for detecting whether foreign matter exists or not are arranged on the four side walls of the lifting mechanism, and a control panel is arranged on one side of the lifting mechanism; and the automatic transfer equipment has the beneficial effects of being reasonable in structural arrangement, high in taking precision and small in occupied space.

Owner:JUSHI GROUP CHENGDU

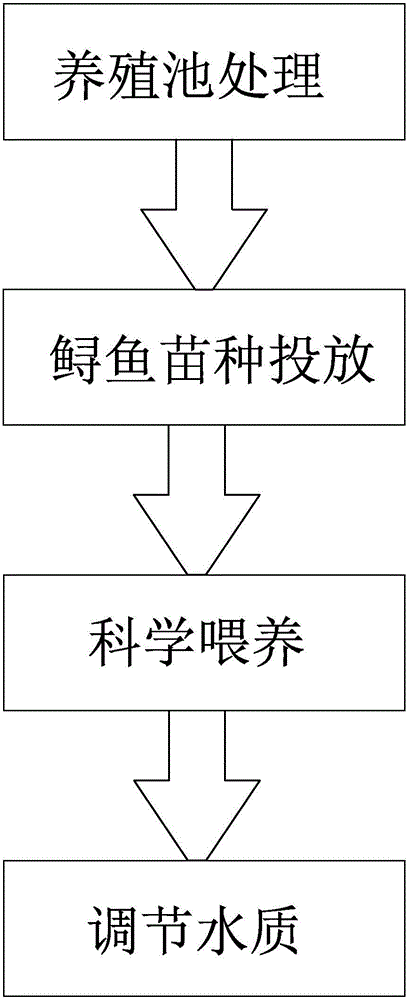

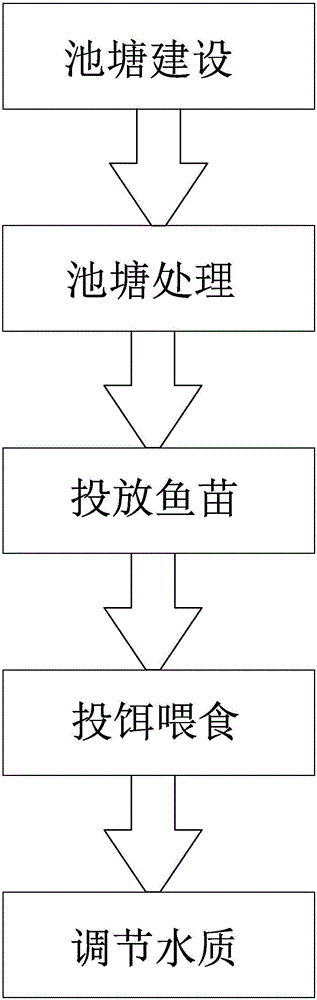

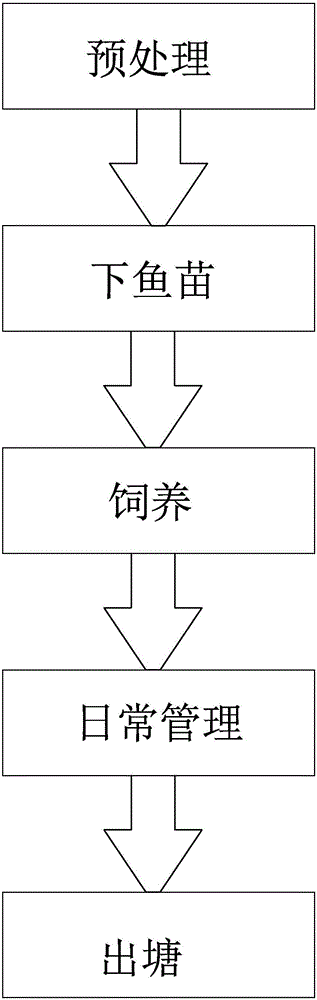

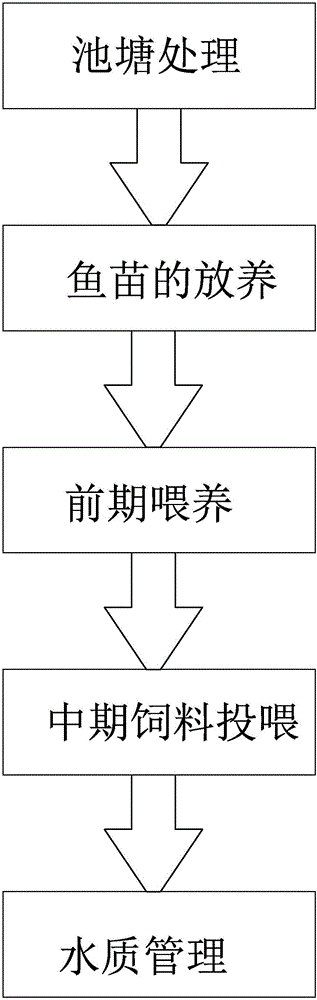

Sturgeon aquaculture method

InactiveCN105815253AReduce the cost of farmingBreeding method is simpleClimate change adaptationPisciculture and aquariaImproved survivalWater quality

The invention discloses a sturgeon breeding method, which is characterized in that it comprises the following steps: A, treating a breeding pond; B, feeding sturgeon seedlings; C, scientifically feeding; D, adjusting water quality. The purpose of the present invention is to overcome the deficiencies in the prior art, and provide a method for cultivating sturgeons that can improve the survival rate, reduce the cost of cultivating sturgeons, facilitate feeding, have good dispersion of bait, and facilitate the feeding of the sturgeons.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

High-efficiency impact sand making machine

The invention relates to a high-efficiency impact sand making machine, comprising a box body, a rotor part, an impact rack, a maintenance hanging bracket and a vibratory feeding hopper, wherein the rotor part is mounted on a lower base of the box body, the impact rack is hung on the top of two inner sides of the box body, the maintenance hanging bracket and the vibratory feeding hopper are mounted on the top of the box body respectively, and a crushing cavity is formed between the impact rack and the rotor. Materials can be subjected to multiple-likelihood continuous impact and crushing in the crushing cavity more than twice, and multiple impact and crushing can be realized between the materials; impact lining board and flat hammer are made of alloy material, thereby prolonging the service time of the high-efficiency impact sand making machine; the high-efficiency impact sand making machine has wide feeding scope, the feeding grain size can reach 80mm; the high-efficiency impact sand making machine has high rotating speed and the linear speed of the rotor can be as high as 80m / s, thus one-step formation rate of the materials is up to more than 60%, and the product can obtain excellent grade; the high-efficiency impact sand making machine has the advantages of being low in weight, large in feeding grain size, strong in processing capability, high in yield, low in energy consumption, simple in operation and convenient in maintenance.

Owner:韶瑞重工(广东)有限公司

Microbial organic nutritional element function enhancing feed and production process

ActiveCN104054904AFree lickReduce consumptionFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to microbial organic nutritional element function enhancing feed and a production process. The microbial organic nutritional element function enhancing feed is prepared from the following raw materials. The raw materials mainly comprise the following four matrix materials in percentage by weight: (1) 4.0% of an inorganic microelement matrix material; (2) 0.5% of a vitamin and amino acid matrix material; (3) 35.50% of a mineral matrix material; (4) 60% of a biological matrix material. The production process of the enhancing feed comprises the following steps: preparing the raw materials; uniformly stirring and fermenting; airing; examining. The feed provided by the invention is abundant in nutrition and is the microbial organic nutritional element function enhancing feed which facilitates growth of beasts and birds and improves the growing quality. The process provided by the invention is simple and easy to operate, and the feeding cost can be greatly saved.

Owner:新疆七彩珍珠农业科技发展有限责任公司

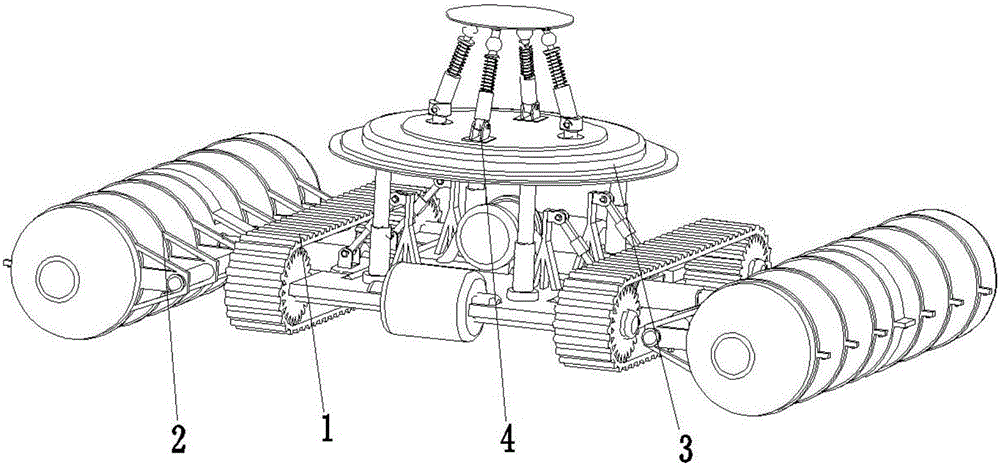

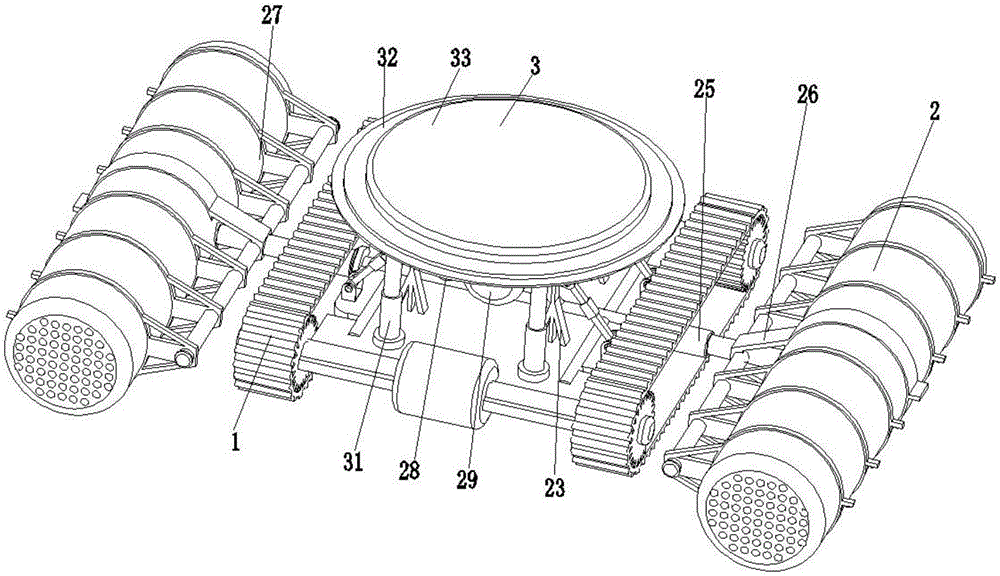

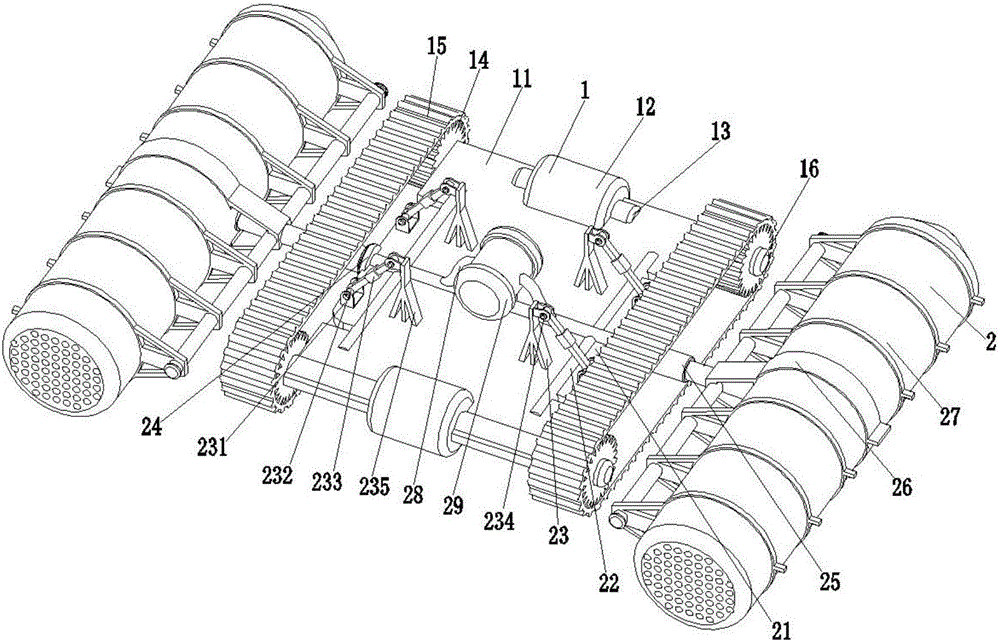

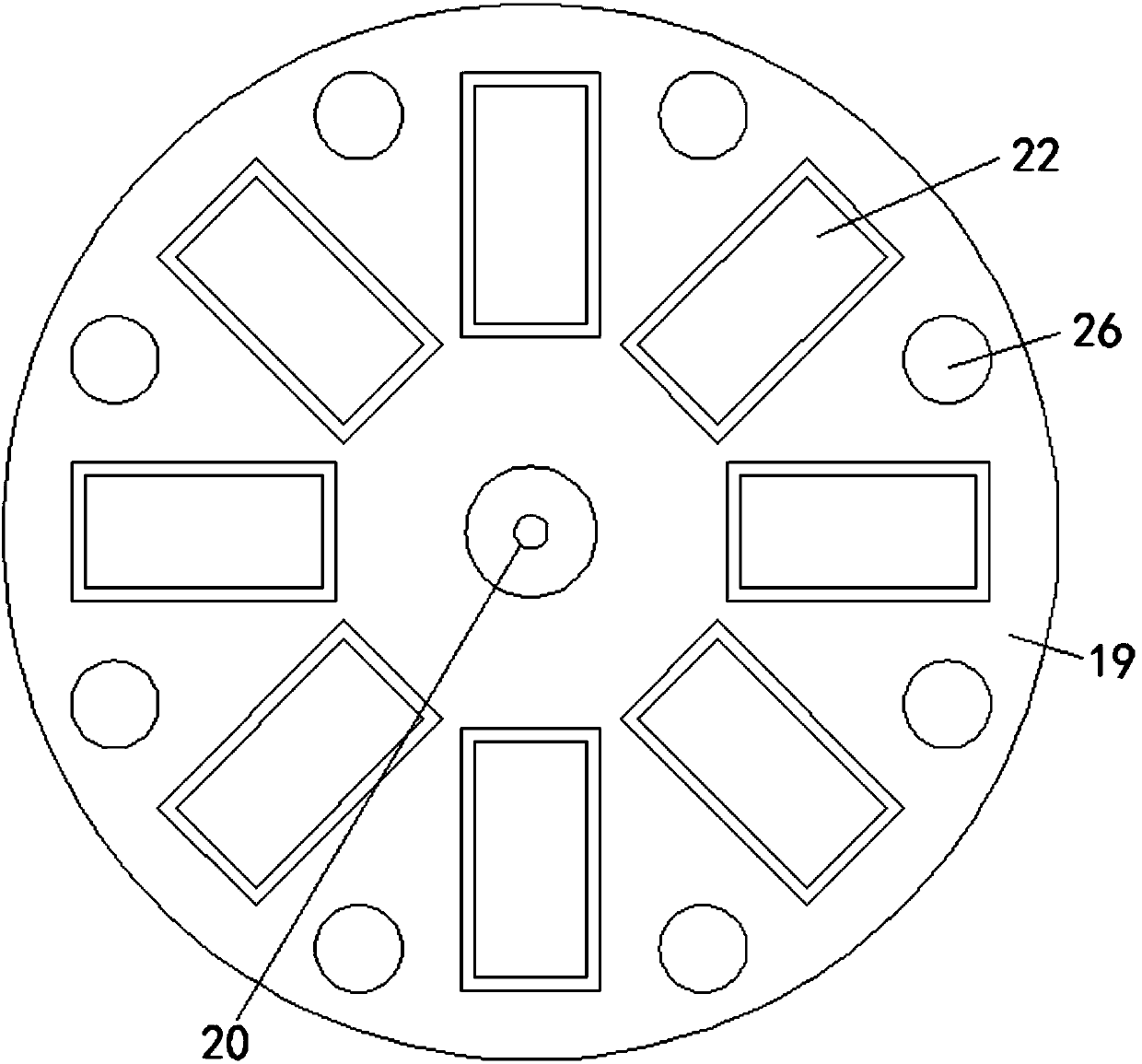

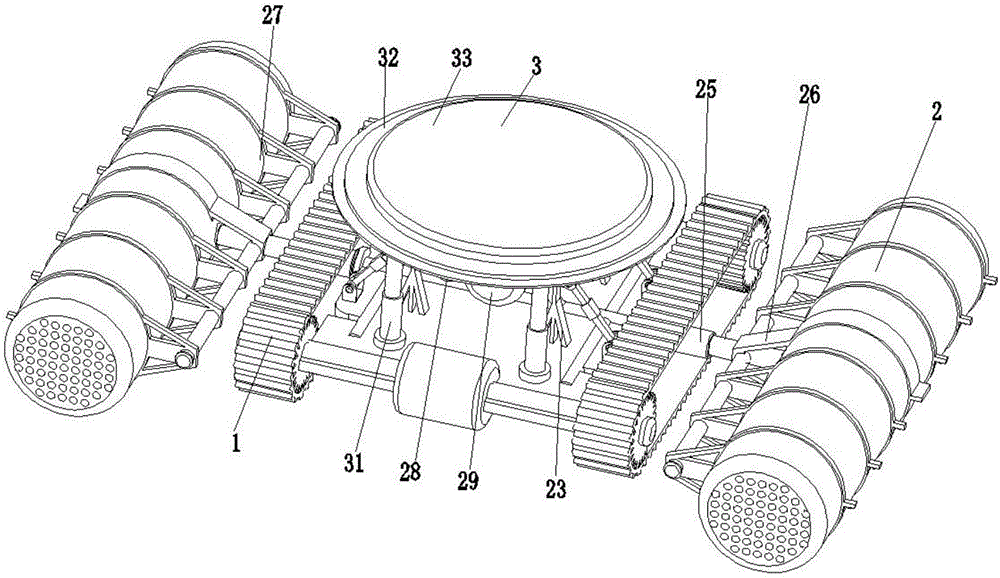

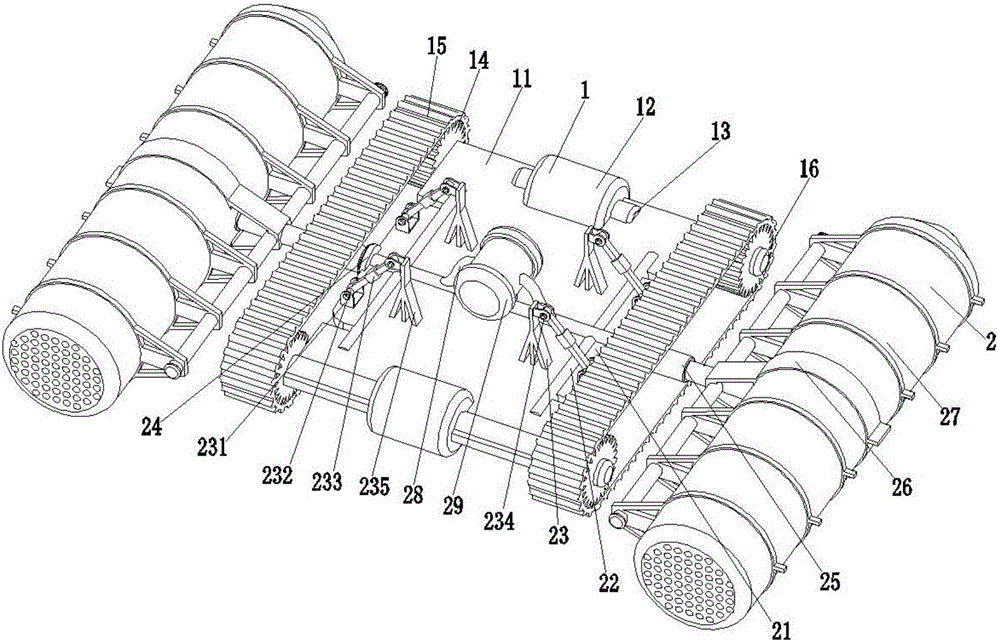

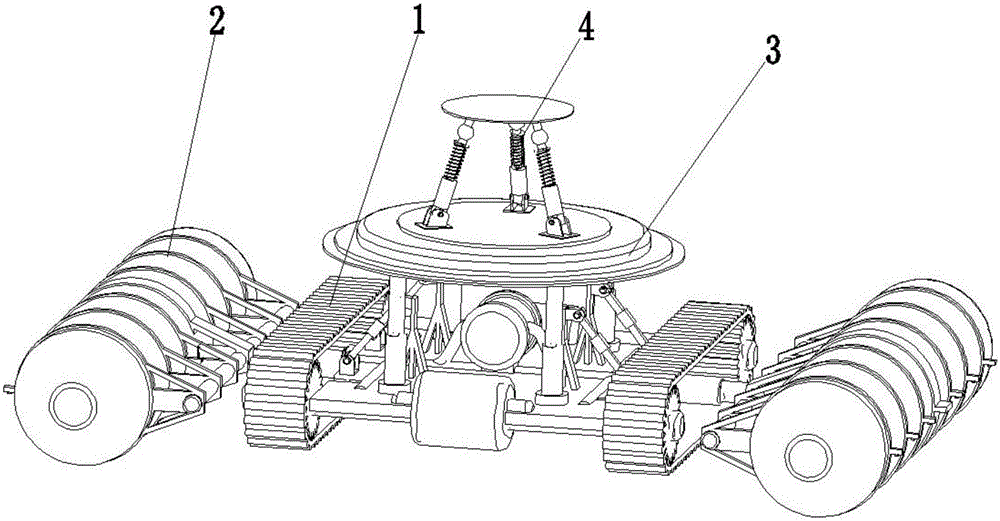

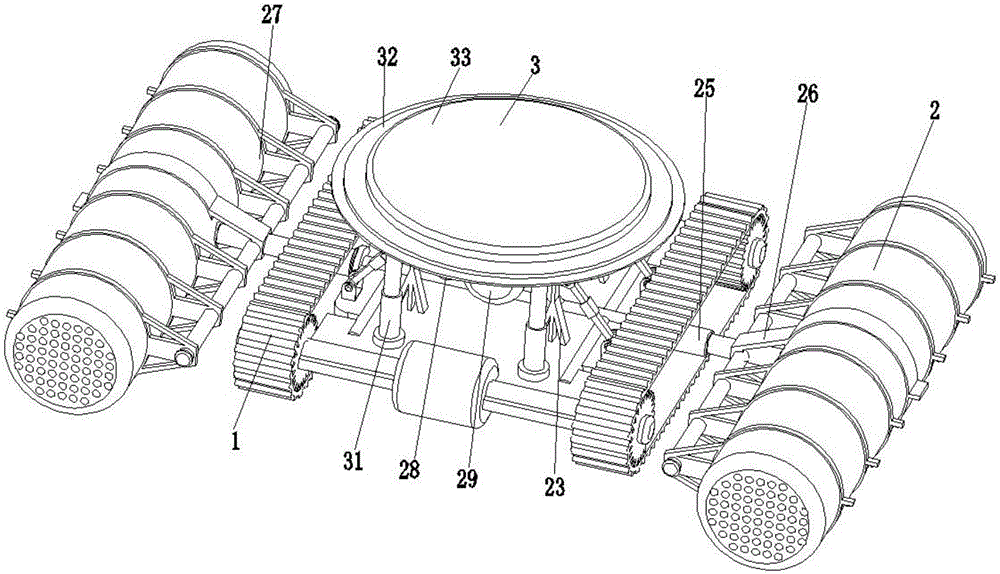

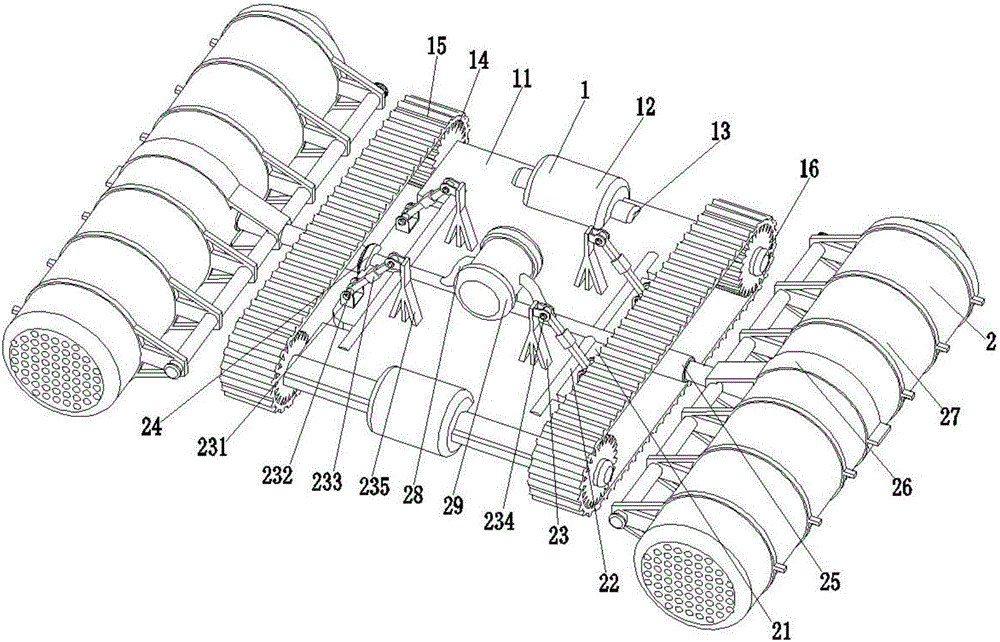

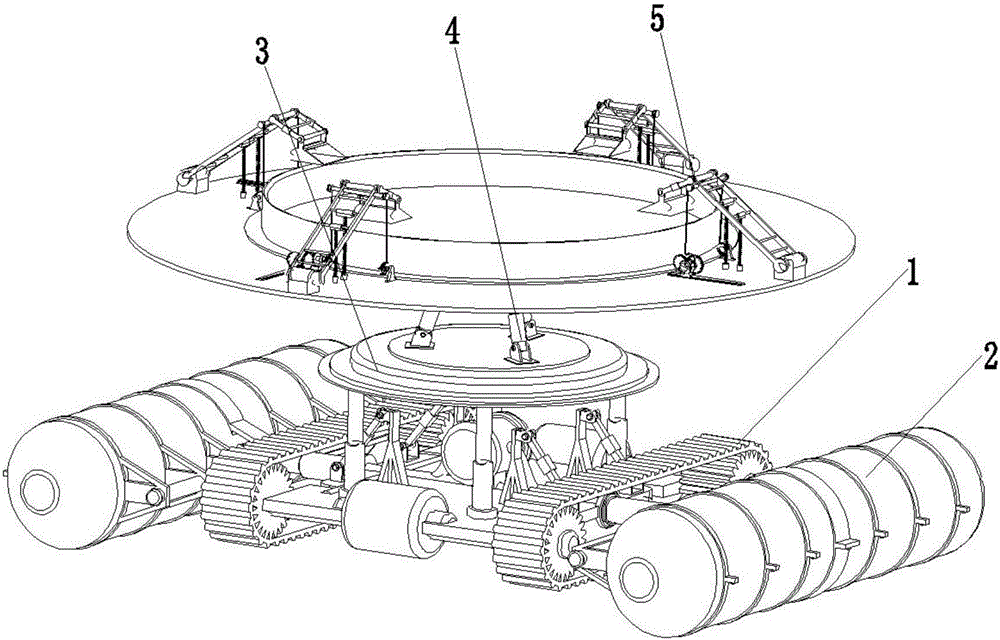

Four-freedom degree base of intelligent robot for feeding fishes and shrimps in reservoir

ActiveCN106114094AEasy to walkEasy to adjustAmphibious vehiclesClimate change adaptationPosition angleEngineering

Owner:王兴民

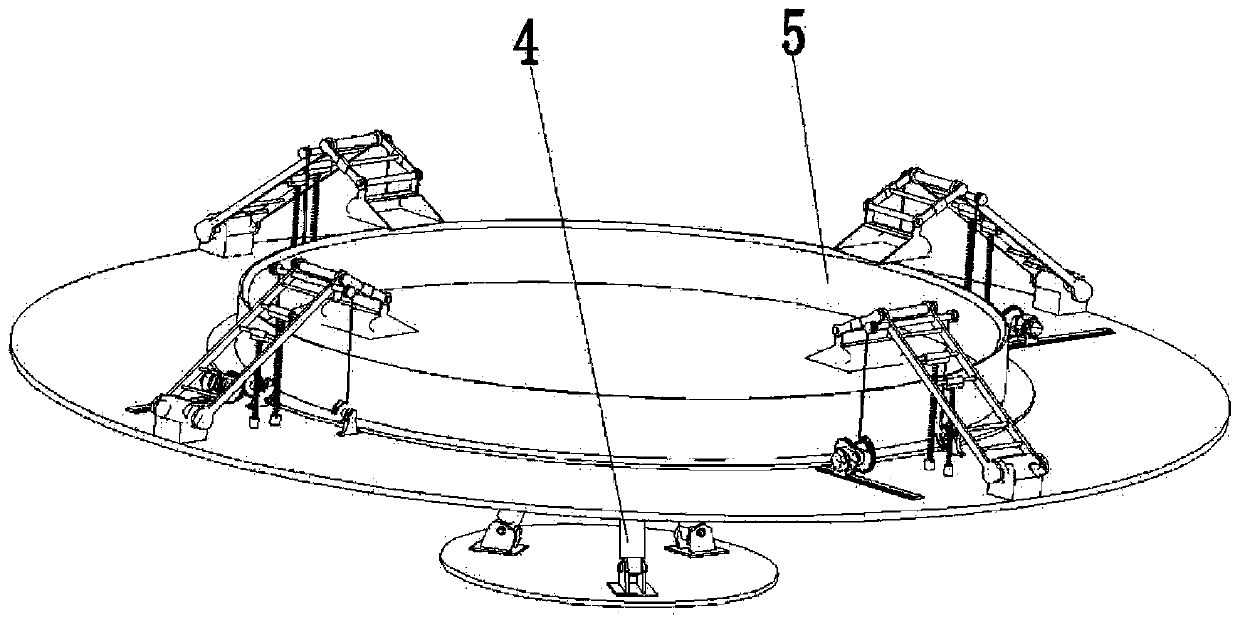

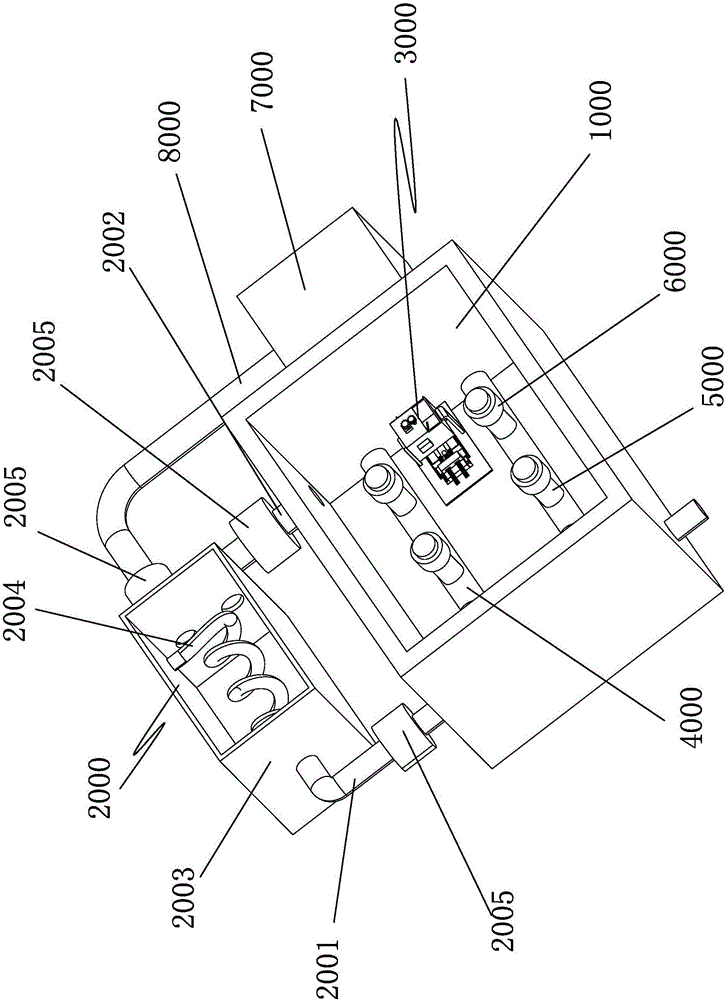

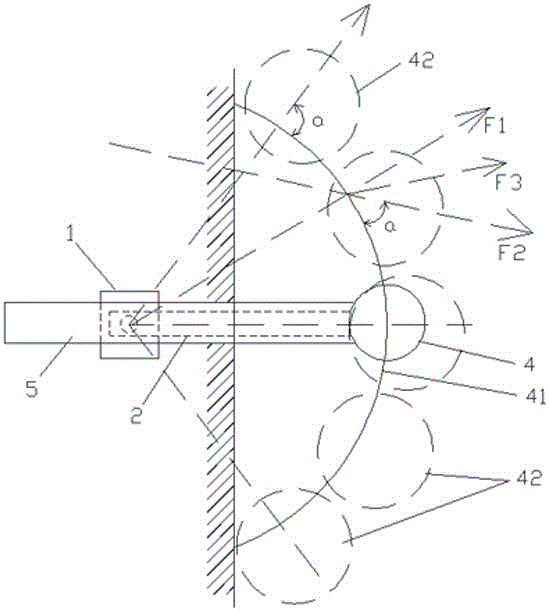

Full-intelligent executing manipulator for integrated fish pond feeding machine

ActiveCN109699554ARealize the function of automatic feedingHigh degree of intelligenceClimate change adaptationPisciculture and aquariaEngineeringWorkload

Owner:江苏苋活生鲜食品有限公司

Aquiculture method for giant salamanders

InactiveCN105941307ABreeding method is simpleEasy to operateFood processingClimate change adaptationWater qualityGiant salamander

The invention discloses an aquiculture method for giant salamanders which is characterized by comprising following steps: A pond construction; B. pond treatment; C. fingerling release; D. bait feeding; E. water quality adjusting. The invention is aimed at solving the deficiency of the prior art and to provide an aquiculture method for giant salamanders which has convenient operation, high survival rate, convenient feeding, good dispersibility of bait and is easy for giant salamander feeding.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

Cultivation method for weever

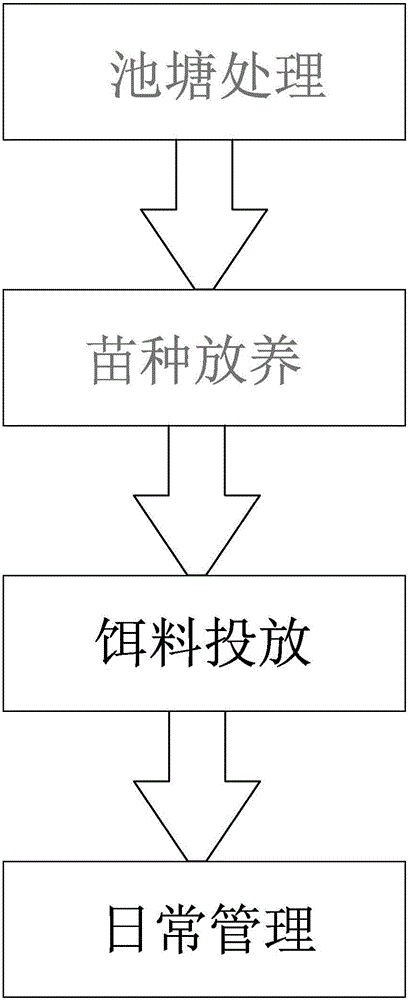

InactiveCN105875454AImprove survival rateIncrease productionFood processingClimate change adaptationAnimal scienceSebastes

The invention discloses a cultivation method for weever. The cultivation method is characterized by comprising the following steps: (A) treating a pool; (B) breeding larvae; (C) putting in baits; and (D) daily managing. The invention aims to overcome the defects of the prior art and provides the cultivation method for weever that has the advantages of convenience in cultivation, high survival rate of weever, high yield, good bait feeding dispersibility and convenience for eating of weever.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

Matrimony vine feeds and its processing method

InactiveCN1833528ARich in proteinHigh nutritional valueFood processingAnimal feeding stuffLycium chinenseVine

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

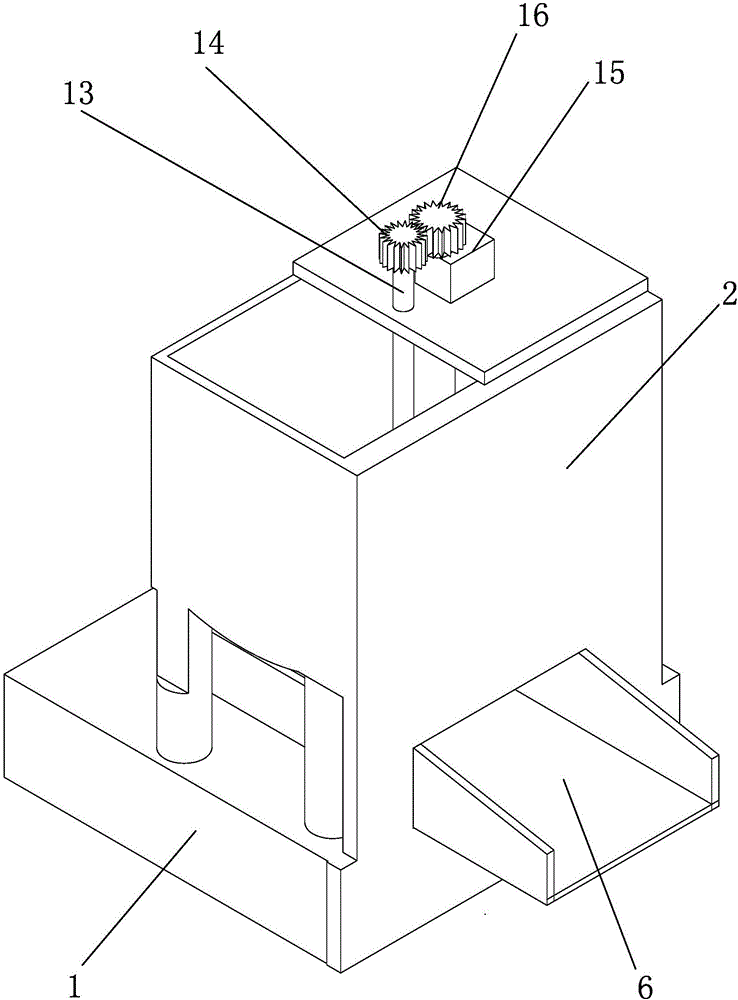

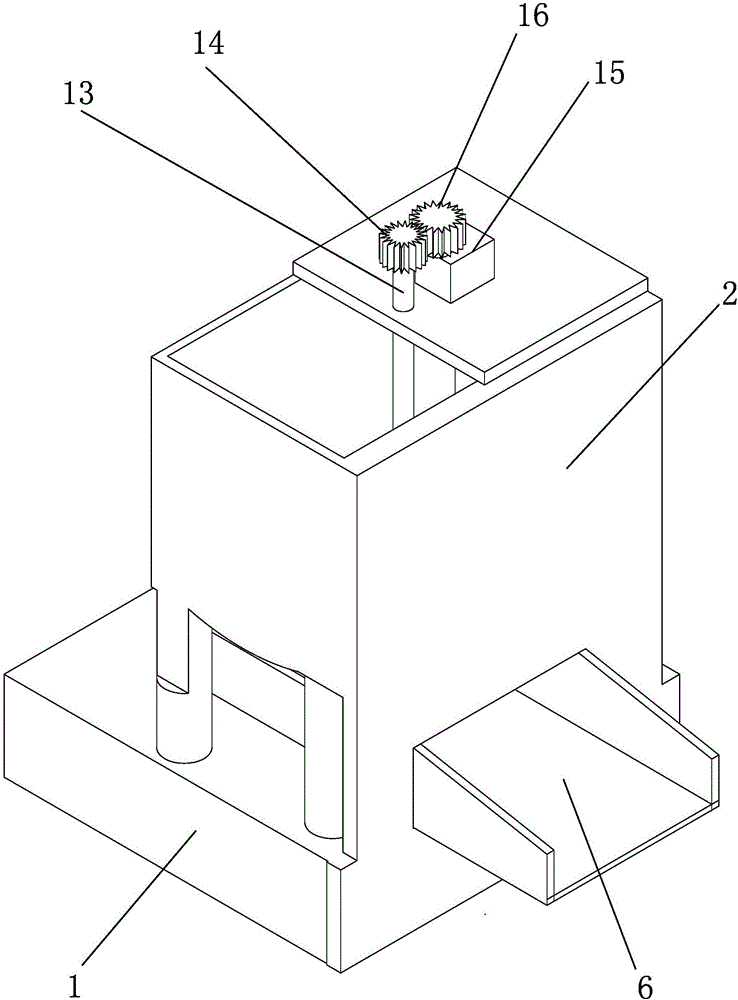

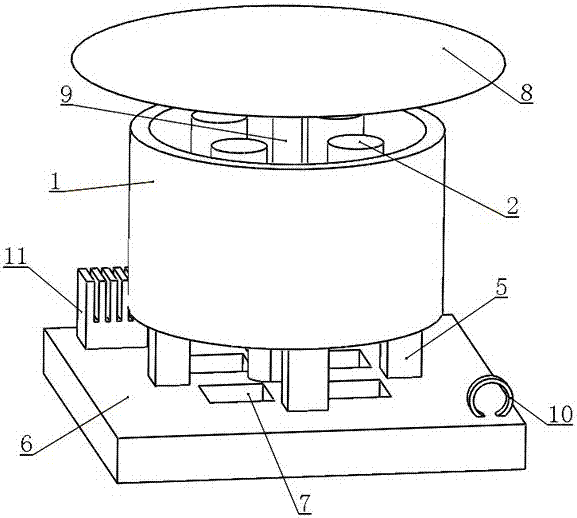

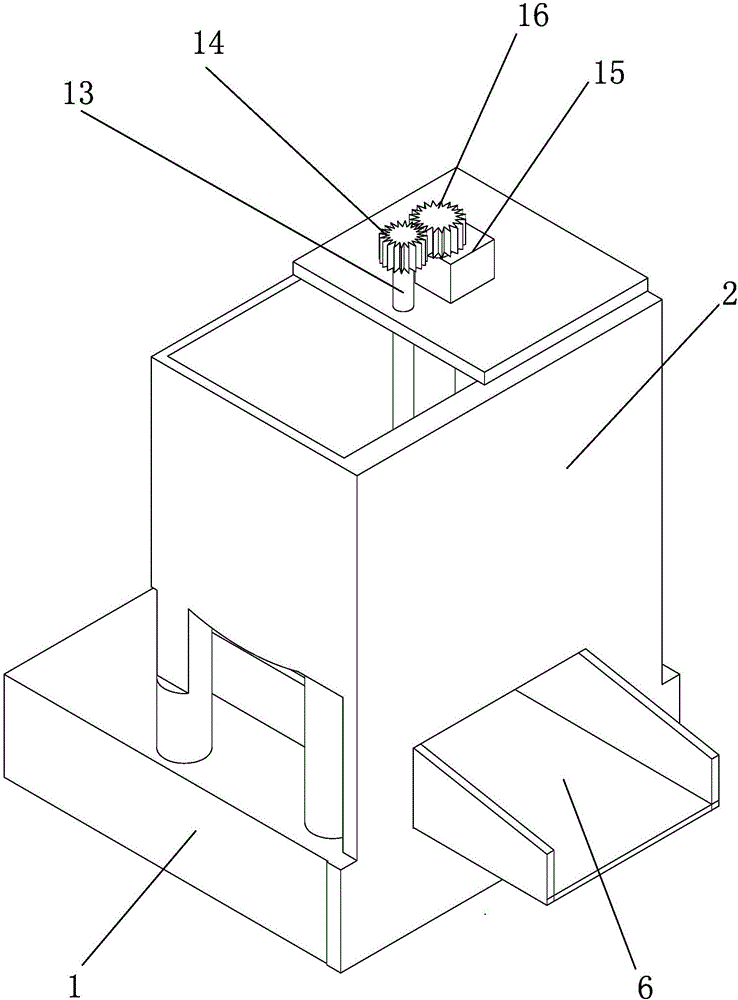

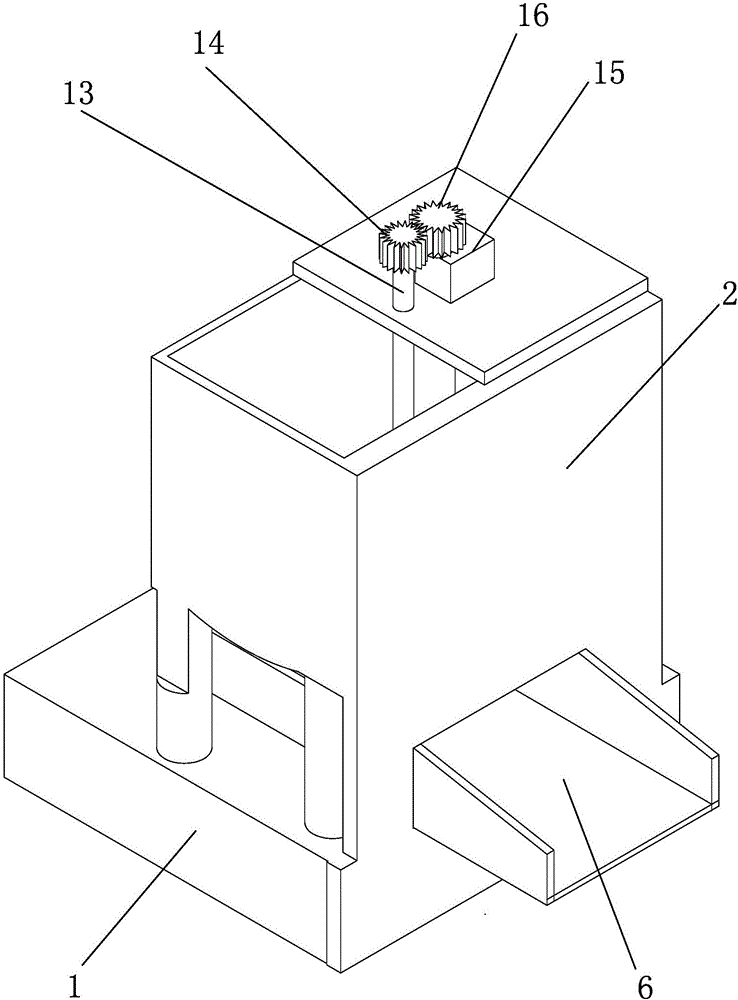

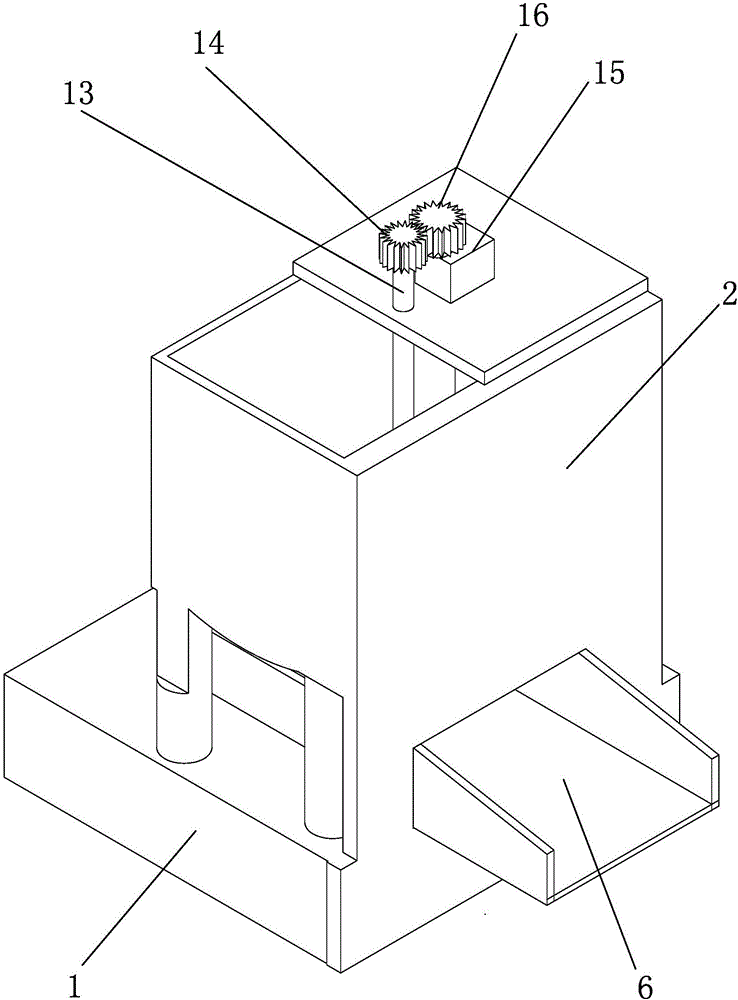

Feeding machine suitable for agaricus bisporus cultivating

InactiveCN108792607AWide feeding rangePrecise position controlConveyorsCultivating equipmentsEngineeringHydraulic pump

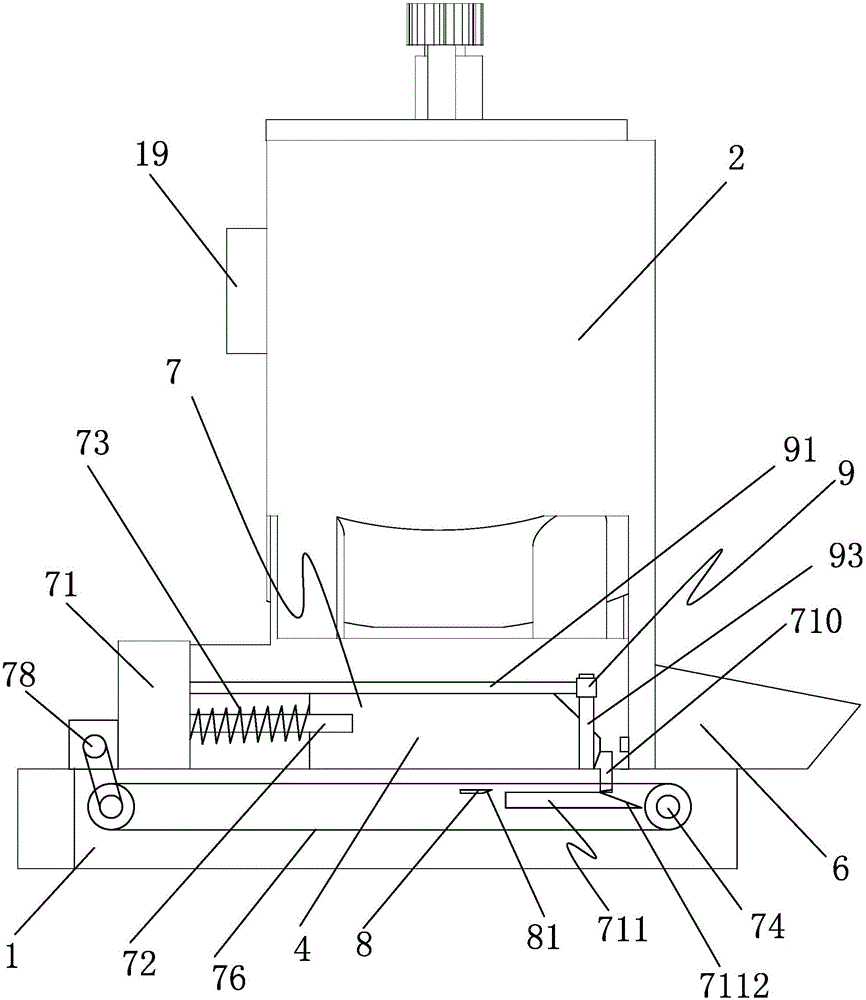

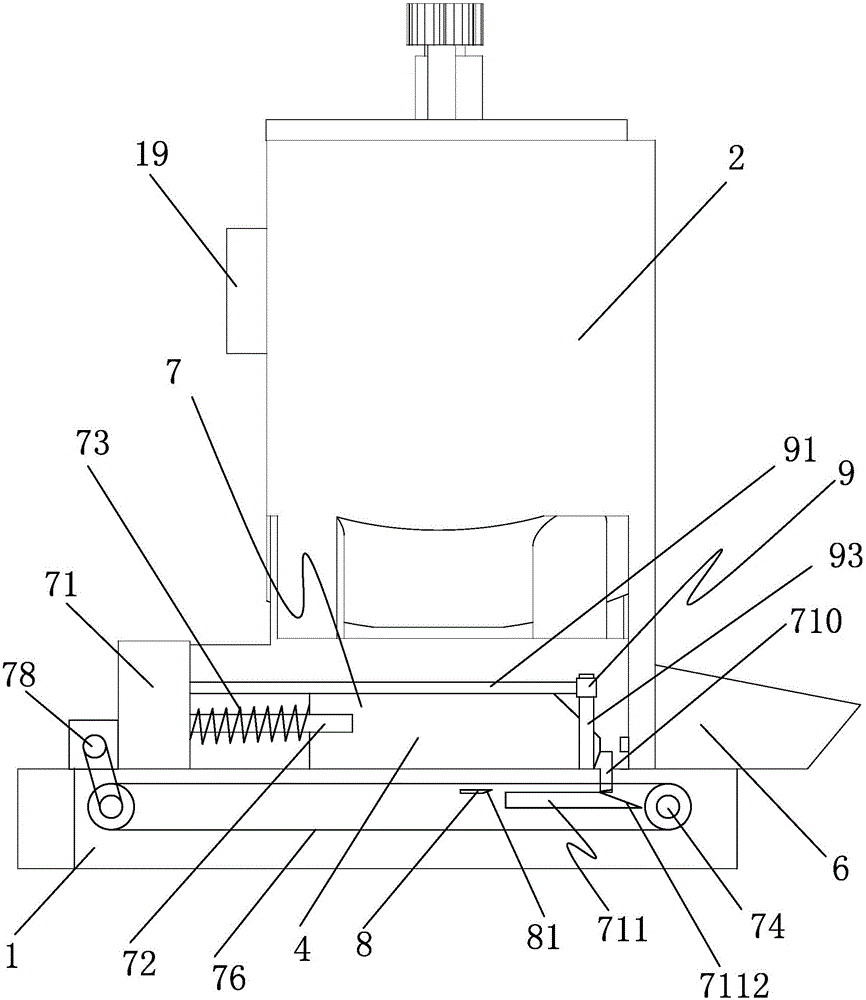

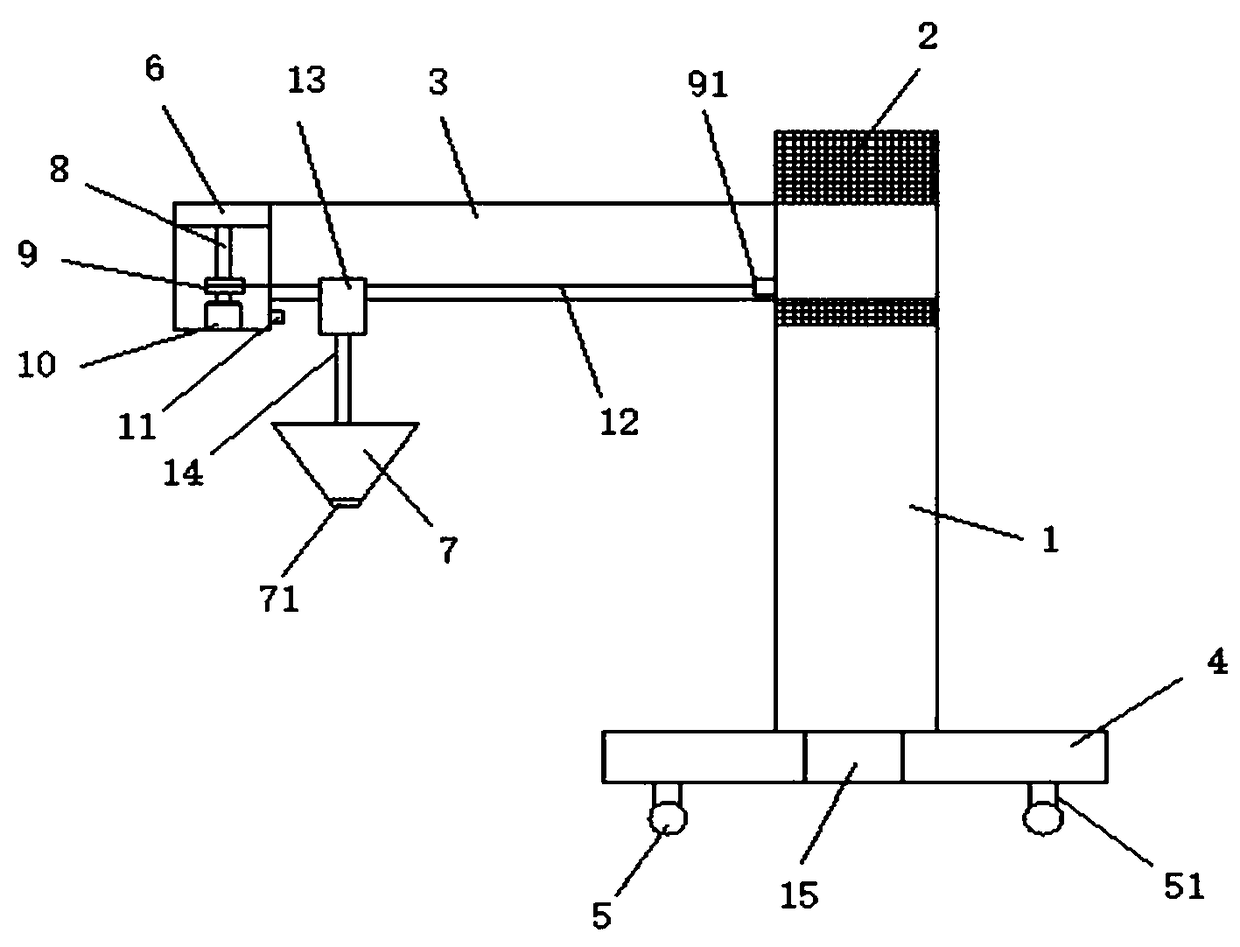

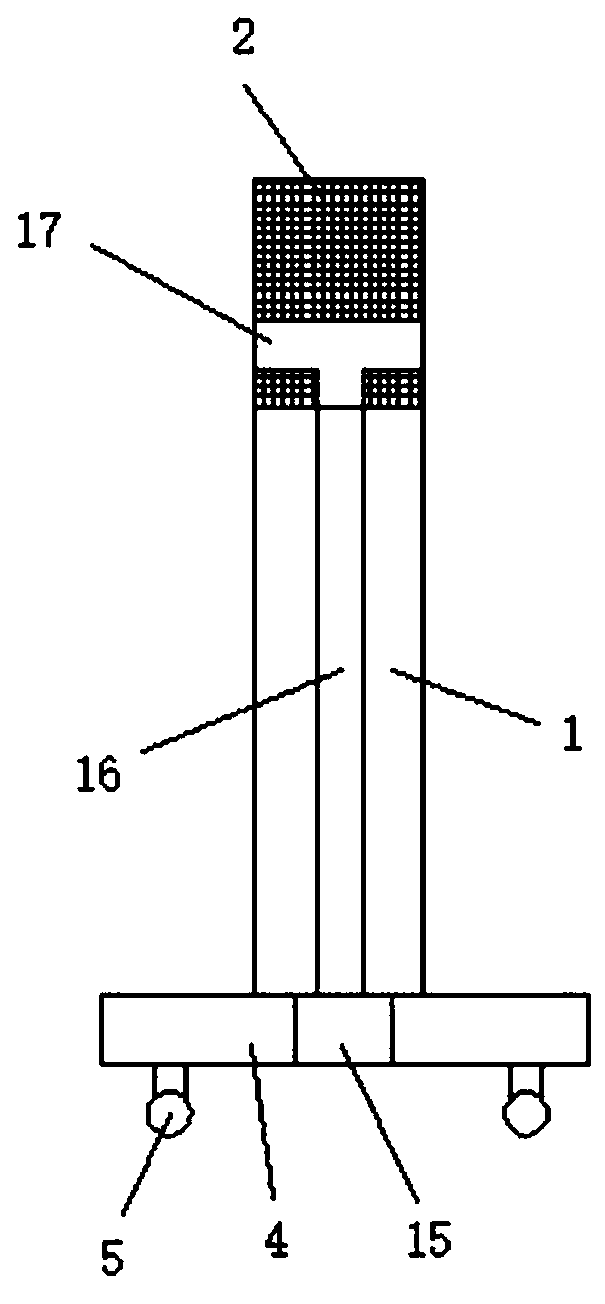

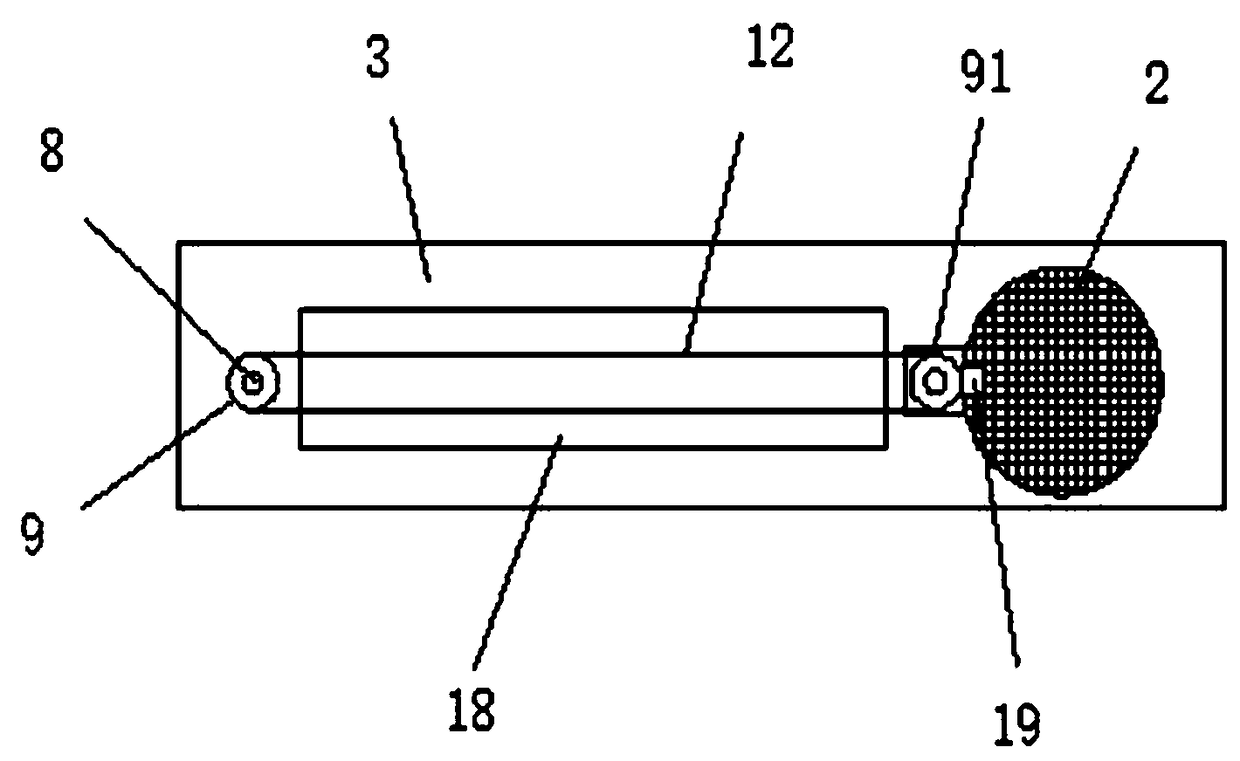

The invention discloses a feeding machine suitable for agaricus bisporus cultivating. The feeding machine suitable for agaricus bisporus cultivating structurally comprises a main machine frame, the top of the main machine frame is fixedly connected with a rotating base, an arm is connected to the main machine frame in a sliding mode, and a protruding block is fixedly connected to the side, away from the main machine frame, of the arm. The bottom of the main machine frame is fixedly connected with a pedestal, the bottom of the pedestal is fixedly connected with four connecting rods, the bottomsof the connecting rods are rotationally connected with universal wheels, the lower portion of the arm is in sliding connection with a hopper, a vertical sliding groove is formed in the surface of themain machine frame, and the upper portion of the vertical sliding groove is connected with a rotating sliding groove in a penetrating mode. A hydraulic pump is arranged to drive the arm to move up and down along the vertical sliding groove, the rotating base is arranged to drive the arm located on the rotating sliding groove to conduct left-right rotating movement, an infrared sensor can controlrotation of an engine according to the measured distance of a movable block, and thus the position of the hopper is controlled, and the non-uniform feeding situation of the feeding machine is avoided.

Owner:汤世军

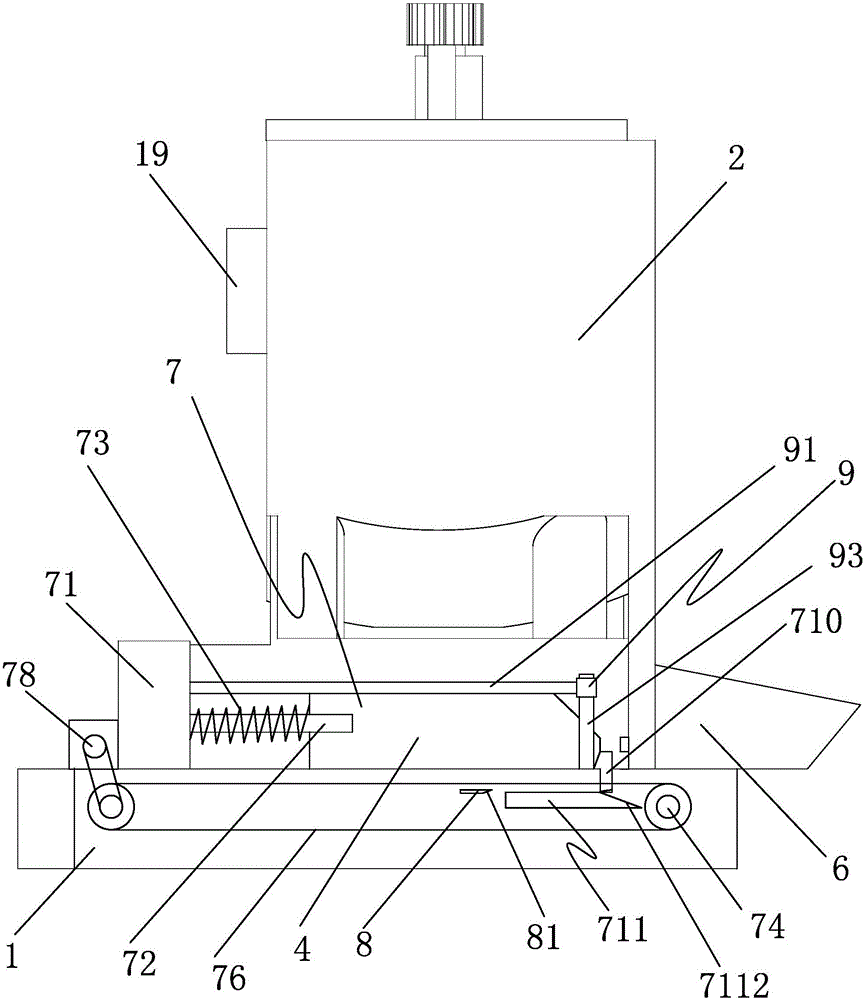

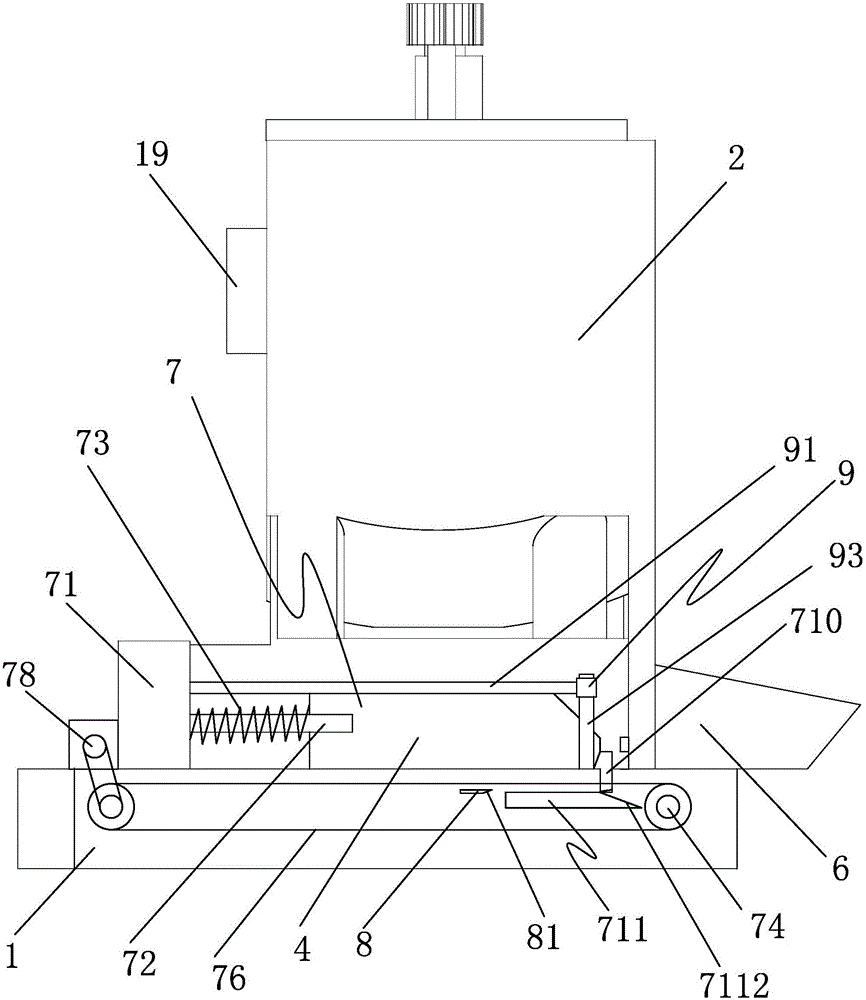

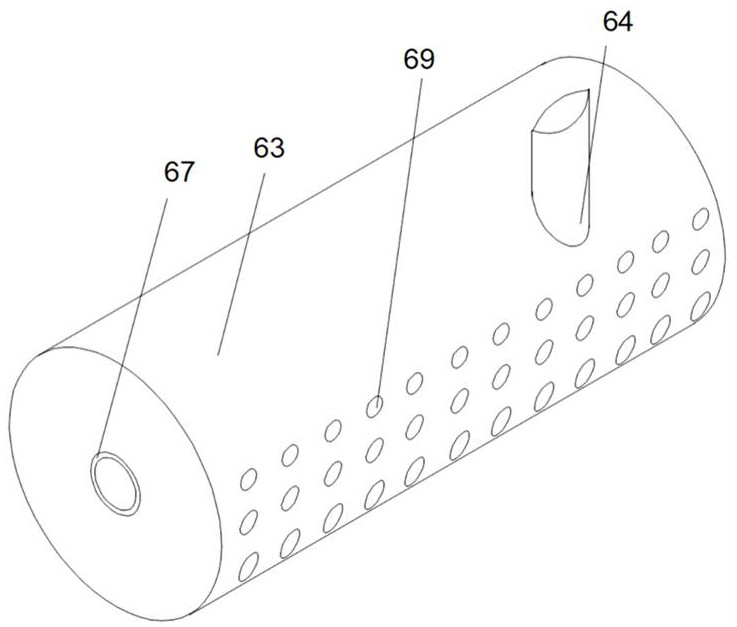

Feeding device wider in feeding range

InactiveCN107787896AWide feeding rangePrevent spoilageClimate change adaptationPisciculture and aquariaLivestock breedingEngineering

The invention relates to the technical field of livestock breeding, and discloses a feeding device wider in feeding range. The feeding device comprises a base mounted on the ground, the upper surfaceof the base is fixedly connected with a conveying belt, the right side face of the base is fixedly connected with a supporting plate, and the upper surface of the supporting plate is fixedly connectedwith an extending plate. According to the feeding device wider in feeding range, a first telescopic rod cooperates with a connecting plate, a storage groove, a first spring, a piston and a scraper, and therefore the inner wall of a storage bucket can be cleaned; a winding groove cooperates with a pop-up groove, a fixed rod, a fixed ring, a second spring, a first mounting disc, a first discharginghole, a second mounting disc, a second discharging hole, a powerful fan and a rope, the feeding range of feed can be wider, the feed can be put more evenly, and it is avoided that due to uneven distribution of the feed, the fish growth degree difference is large; the feed can be prevented from being accumulated in the storage bucket for a long time, fishes fall ill due to the feed going bad, andbenefits are guaranteed.

Owner:程建

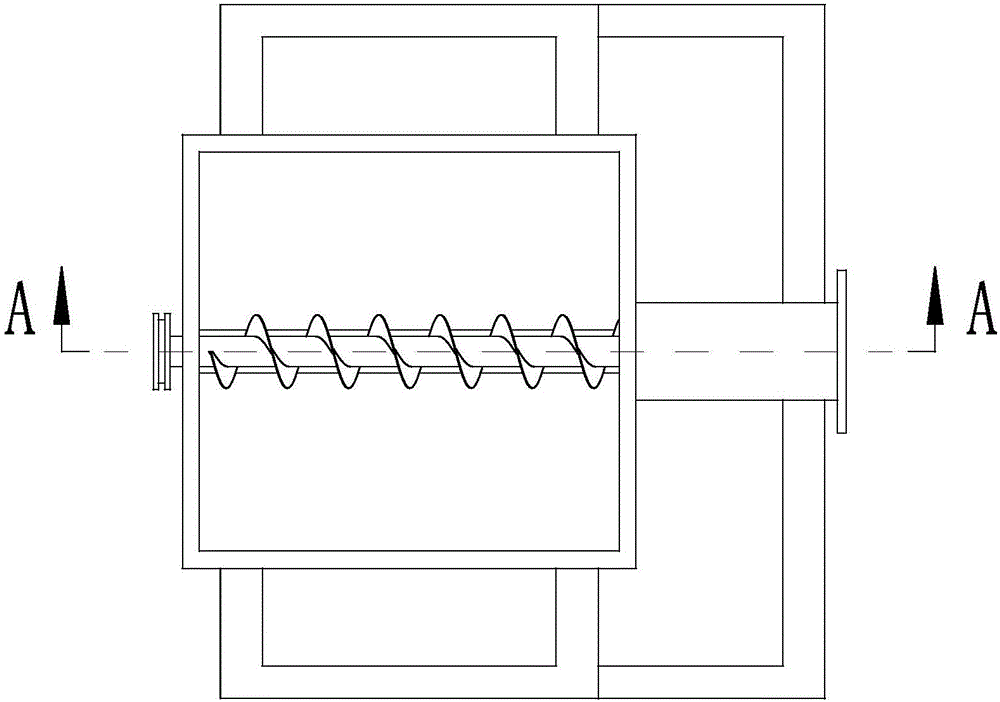

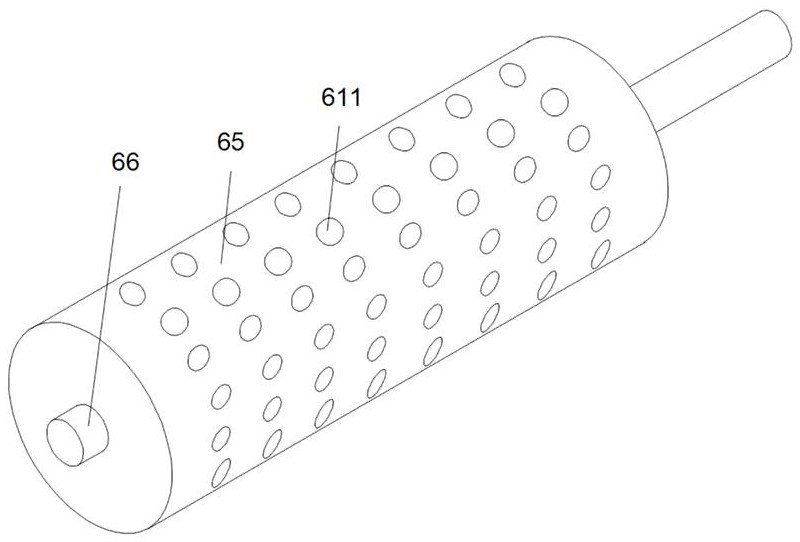

Automatic feeding robot for aquaculture

ActiveCN106614210AImprove mobilityAvoid harmClimate change adaptationPisciculture and aquariaFish stockingEngineering

The invention relates to the field of aquaculture, in particular to an automatic feeding robot for aquaculture. The automatic feeding robot for aquaculture comprises a feeding body and a dragging device. The feeding body is connected with the dragging device, and a floating device is installed on the feeding body. The feeding body comprises a storage bin, a conveying motor, a conveying column, a feeding pipe, a spiral auger and a tail conveying device. The dragging device comprises a dragging main frame, a second air bag, a pushing motor and a paddle. It is not needed to manually lay a conveying pipe in a fish pond or manually recycle the conveying pipe, high maneuverability is achieved, time and labor are saved, the feeding range is wide, and the situation that fish stocks gather together to fight for food, so that fishes are hurt is avoided.

Owner:安徽省振沱水产养殖有限责任公司

Novel feeder for breeding of hairy crabs

InactiveCN107114289ASmooth feedingSimple structureClimate change adaptationPisciculture and aquariaAgricultural scienceFodder

Owner:宣城市乐丰农业技术服务有限公司

Flocculating agent

InactiveCN105645535AStable chemical propertiesReduce dosageWater/sewage treatment by flocculation/precipitationRetention timeTreated water

The invention discloses a flocculating agent. The flocculating agent comprises the following components: coal ash, starch, ferrous sulphate, sodium oxide, zinc chloride, aluminum sulfate, polyacrylamide, polyvinylpyrrolidone, and polymeric phosphato-aluminum chloride. The flocculating agent has the advantages of stable chemical performance, low consumption amount, wide feeding range, short precipitation formation time, large form for facilitating precipitation, shortened retention time of water samples in a treatment system, and the like; the treatment capability of the system is improved, and pH value of treated water is not influenced.

Owner:FOSHAN MINGQIAN TECH

Carp aquiculture method

InactiveCN105941210ABreeding method is simpleImprove reliabilityFood processingClimate change adaptationState of artAnimal science

The invention discloses a carp aquiculture method which is characterized by comprising following steps: A pretreatment; B fingerling release; C aquiculture; D daily management; E out of pond. The aim of the invention is to overcome the deficiency of the prior art and to provide a carp cultivation method which is reliable and environmental, has high yield, good dispersivity of released bait, and easy feeding for carp.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

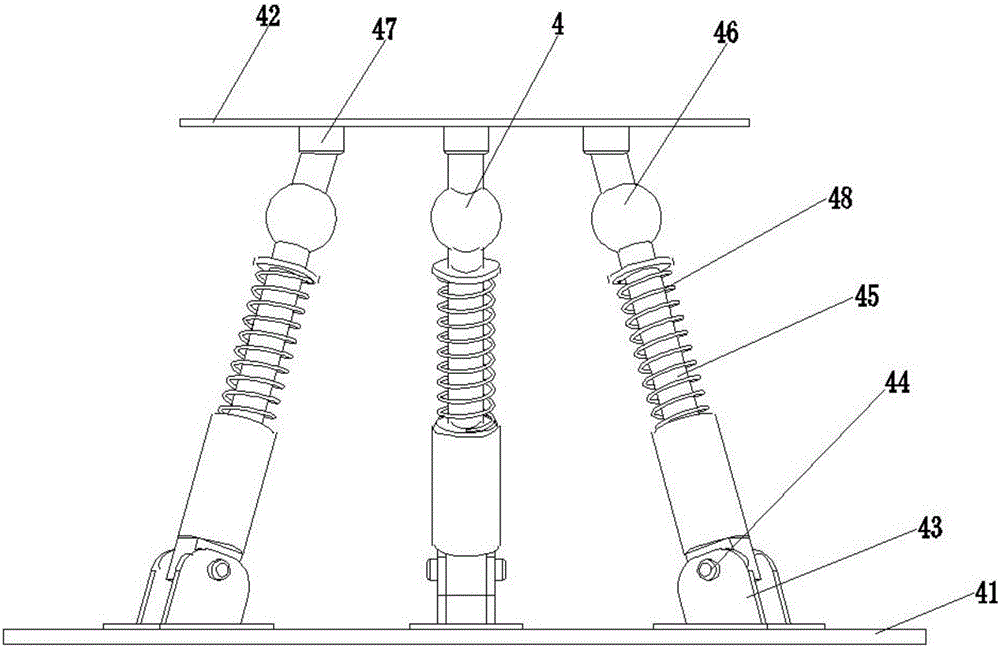

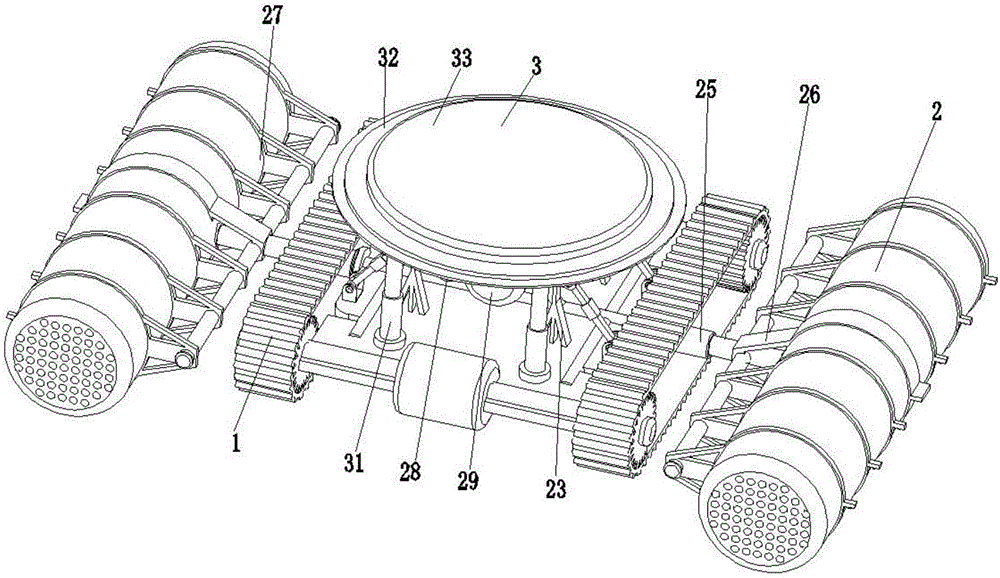

Special parallel-series base for intelligent robot for purification treatment of lake sewage

ActiveCN106006781AEasy to walkEasy to adjustWater/sewage treatment apparatusContaminated waterways/lakes/ponds/rivers treatmentSewageEngineering

The invention relates to a special parallel-series base for an intelligent robot for purification treatment of lake sewage. The special parallel-series base comprises a land walking device, water walking devices, a lifting device and a parallel-series mechanism, wherein the two water walking devices are arranged, located on the left side and the right side of the land walking device and connected with the land walking device, the lifting device is located over the land walking device, the lower end of the lifting device is connected with the upper end of the land walking device, the parallel-series mechanism is located over the lifting device, and the lower end of the parallel-series mechanism is connected with the lifting device. The special parallel-series base has the functions of land walking, water walking and orientation angle adjusting, the robot can rapidly and conveniently walk, the orientation angle is convenient and flexible to adjust, and the problems of poor movement flexibility, narrow application range and poor stability of bases of existing feeding robots for sewage purification are solved.

Owner:无锡开迪环保科技有限公司

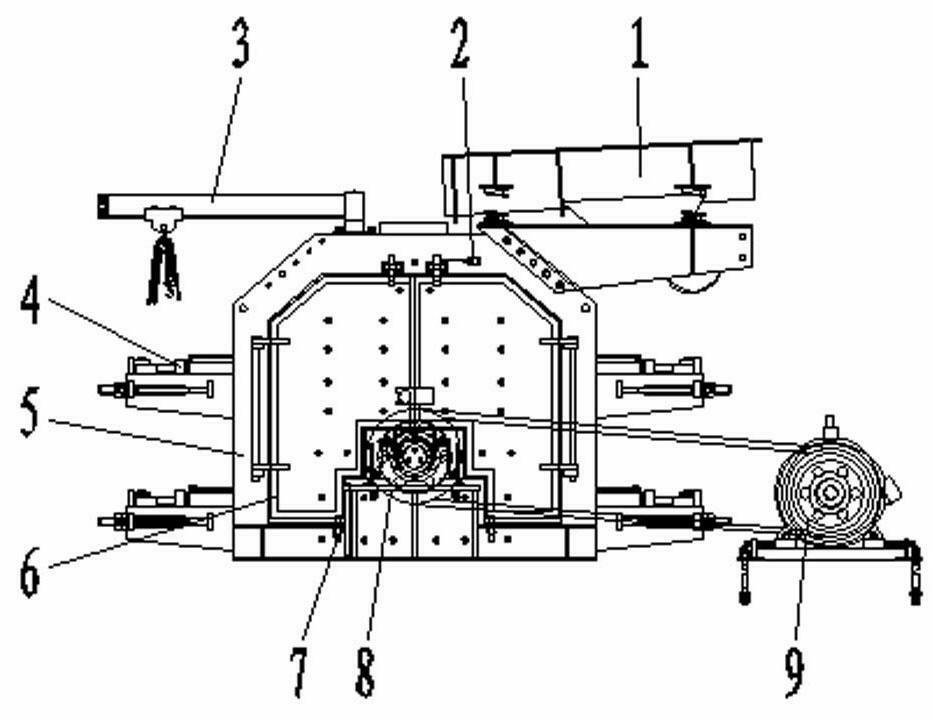

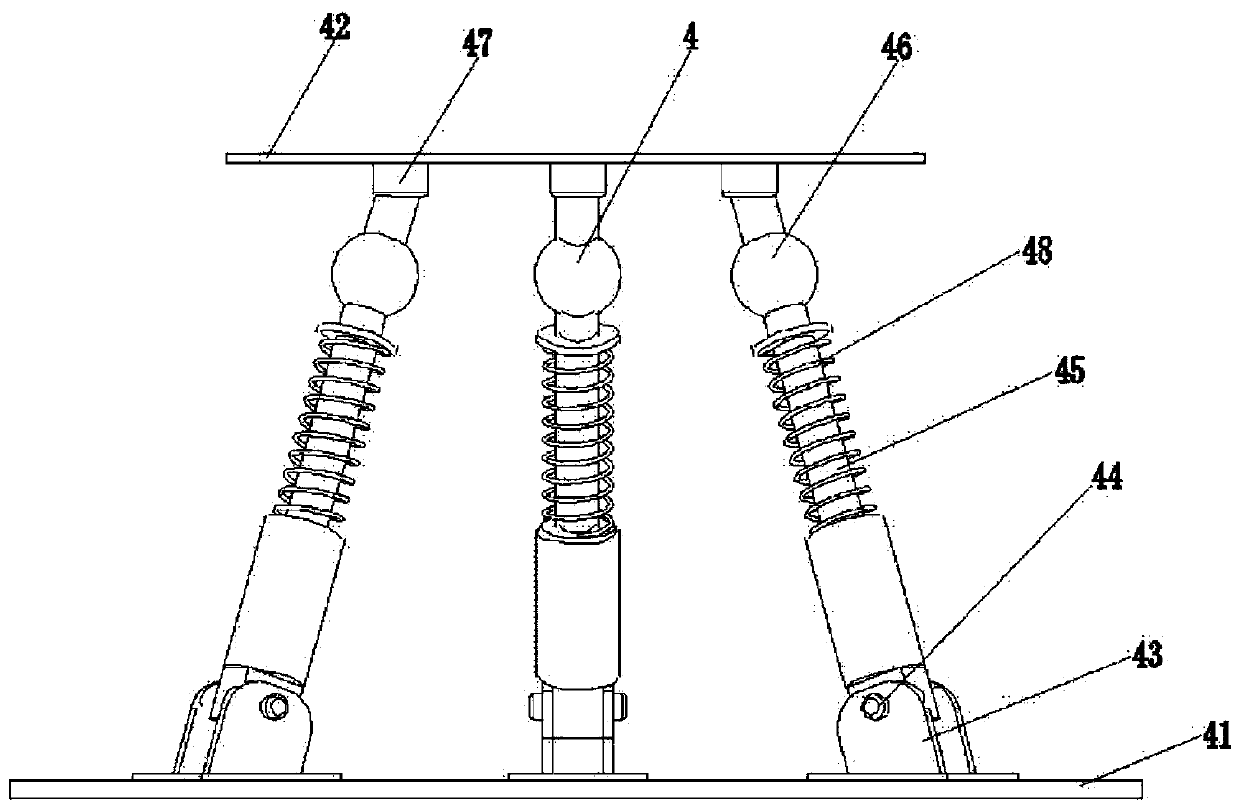

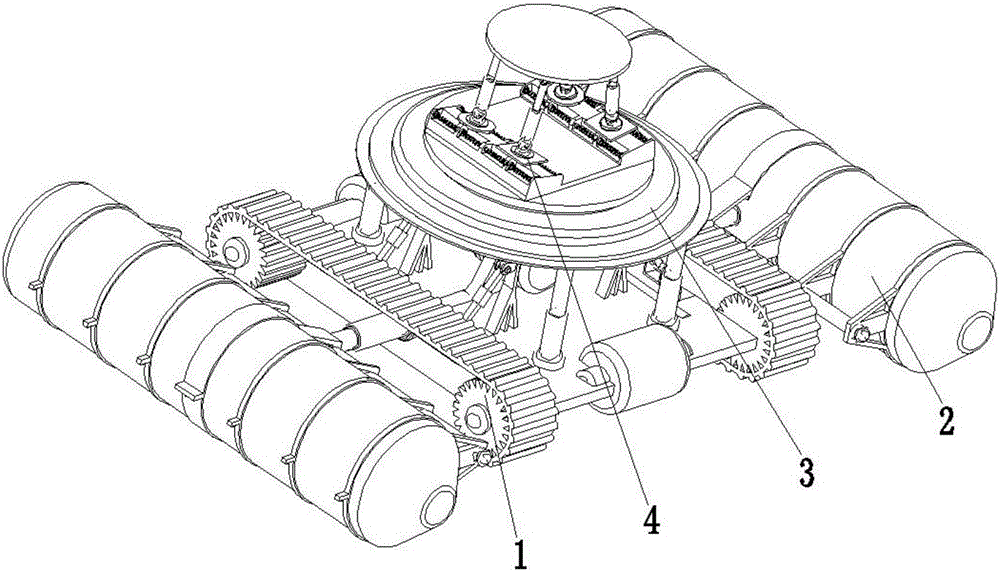

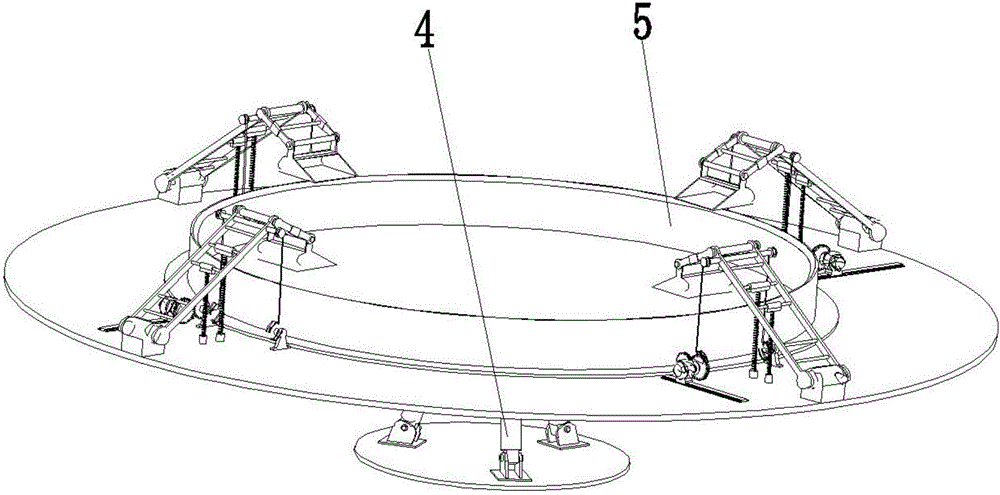

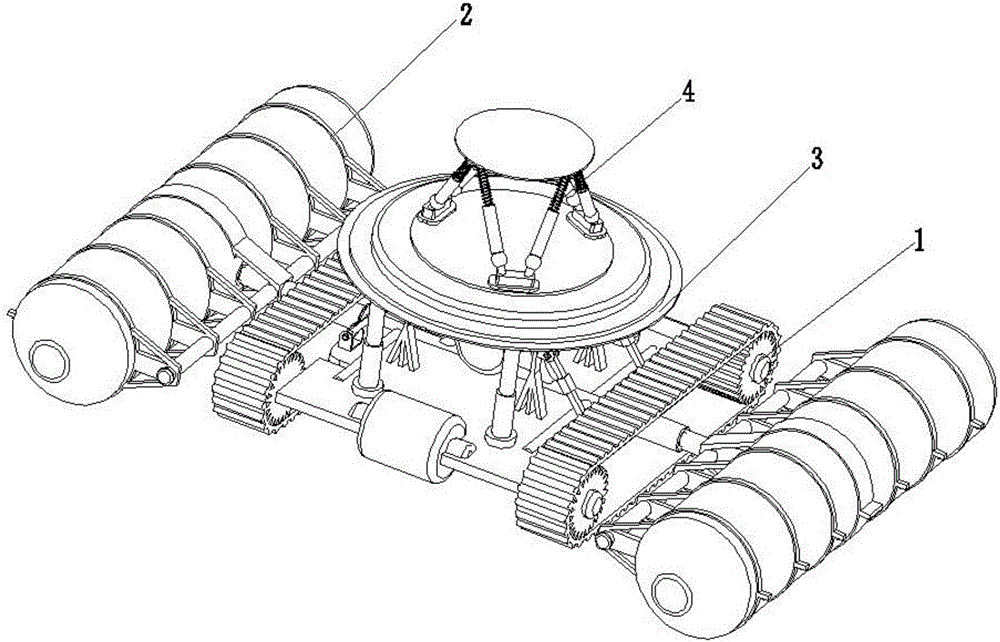

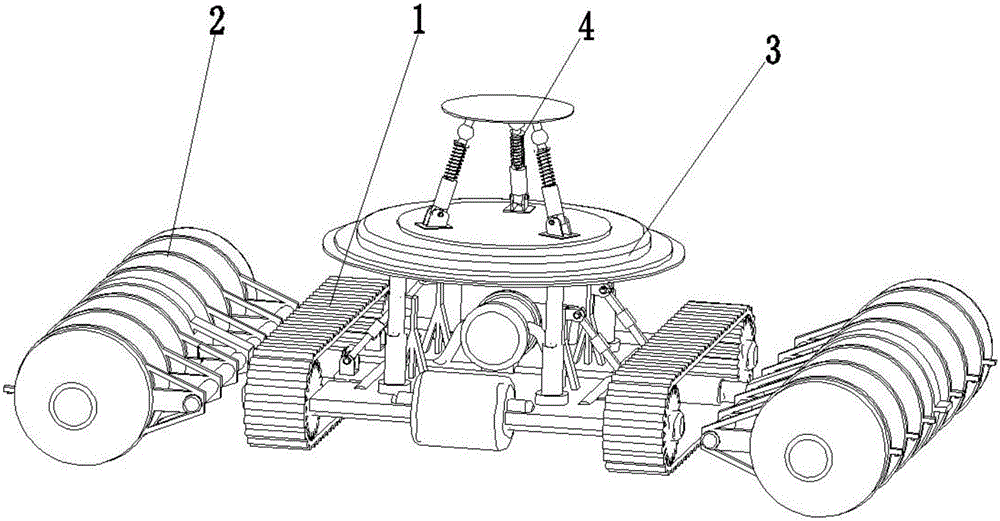

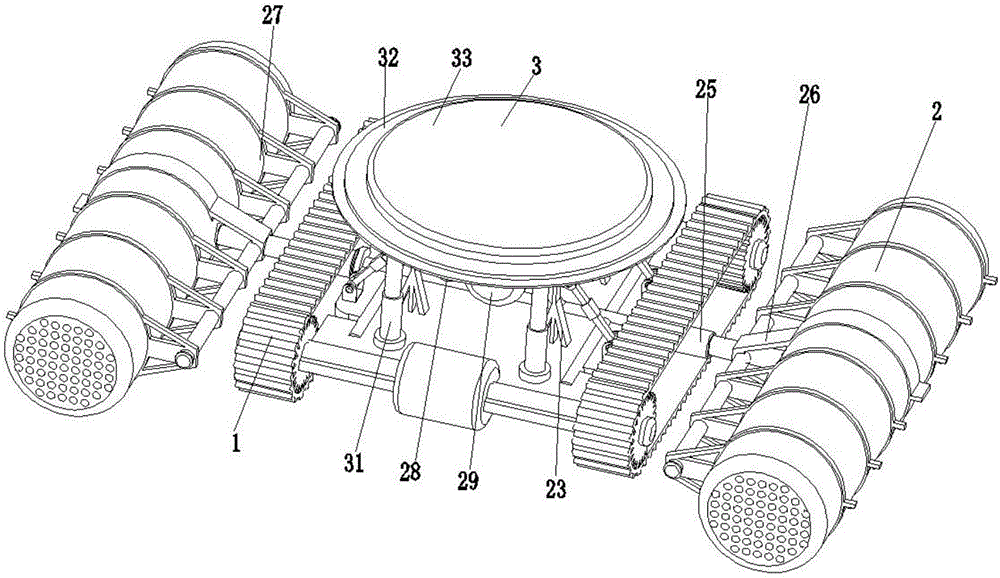

Base special for full-intelligent fishpond feed putting integrated machine

ActiveCN106069965AAddress flexibilitySolution rangeClimate change adaptationPisciculture and aquariaThree degrees of freedomEngineering

The invention relates to a base special for a full-intelligent fishpond feed putting integrated machine. The base comprises a land walking device, two water surface walking devices, a lifting device and a three-degree-of-freedom parallel mechanism. The two water surface walking devices are located on the left side and the right side of the land walking device respectively and are connected with the land walking device, the lifting device is located over the land walking device, the lower end of the lifting device is connected with the upper end of the land walking device, the three-degree-of-freedom parallel mechanism is located over the lifting device, and the lower end of the three-degree-of-freedom parallel mechanism is connected with the lifting device. The base special for the full-intelligent fishpond feed putting integrated machine has the land walking, water surface walking and orientation angle adjusting functions; besides, walking is fast and convenient, orientation angle adjustment is convenient and flexible, and the problems that an existing feed putting robot base is poor in movement flexibility, narrow in adaptation range and poor in stability are solved.

Owner:南陵县建设投资有限责任公司

Feeding machine for salangid culture

InactiveCN112544533AAchieve freedom of movementWide feeding rangeClimate change adaptationPisciculture and aquariaAnimal scienceElectric machinery

The invention provides a feeding machine for salangid culture, and relates to the technical field of fish culture. The feeding machine comprises a floating plate, a positioning ball, a micro motor, apropeller, feeding blades and a feed box. The positioning ball is mounted below the floating plate through a traction rope, the micro motor is mounted on the upper surface of the floating plate, the micro motor is connected with the propeller positioned below the floating plate through a transmission box, the feeding blades and the feed box are arranged above the micro motor, the feeding blades and the feed box are mounted on a same rotating shaft, and an electromagnetic feeding device is arranged at the top end of the rotating shaft. The feeding machine for salangid culture has the followingbeneficial effects that the position of the floating plate can be freely moved through the propeller, and a feeding point can be changed; and meanwhile, the falling of feed can be automatically controlled through the operation of the motor, and the rotation of the feeding blades can effectively increase the spreading range.

Owner:阜南县京淮特种水产有限公司

Tilapia culture method

InactiveCN105961234ABreeding method is simpleHigh population yieldClimate change adaptationPisciculture and aquariaIntermediate stageTotal quality management

The invention discloses a tilapia culture method, characterized by comprising the following steps: A, handling a pond; B, stocking fries; C, feeding in an early stage; D, feeding forage in an intermediate stage; E, performing water quality management. An objective of the invention is to overcome defects of the prior art, and to provide the tilapia culture method which is high in population yield, good in meat quality, good in bait putting dispersibility, and easy in feeding.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

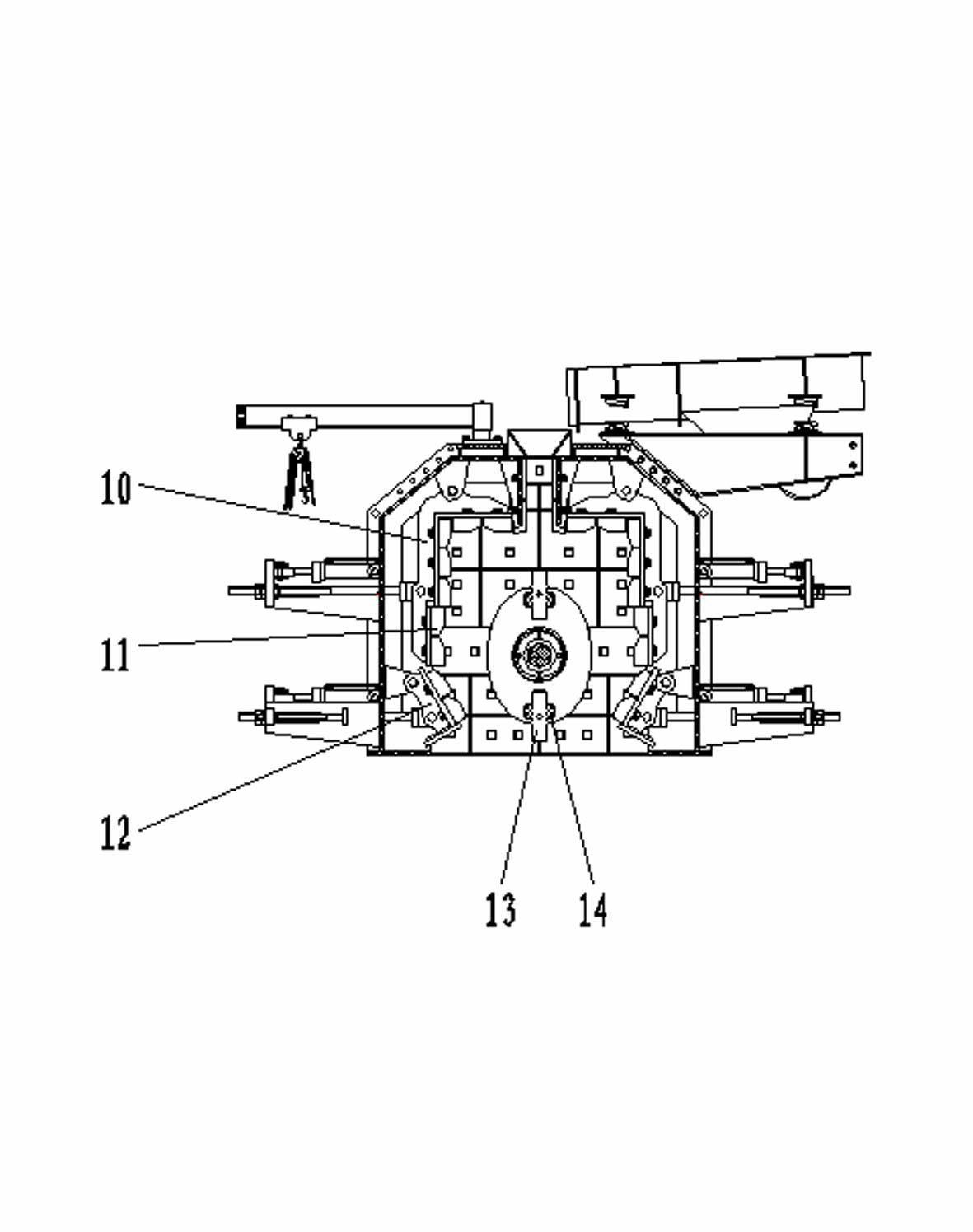

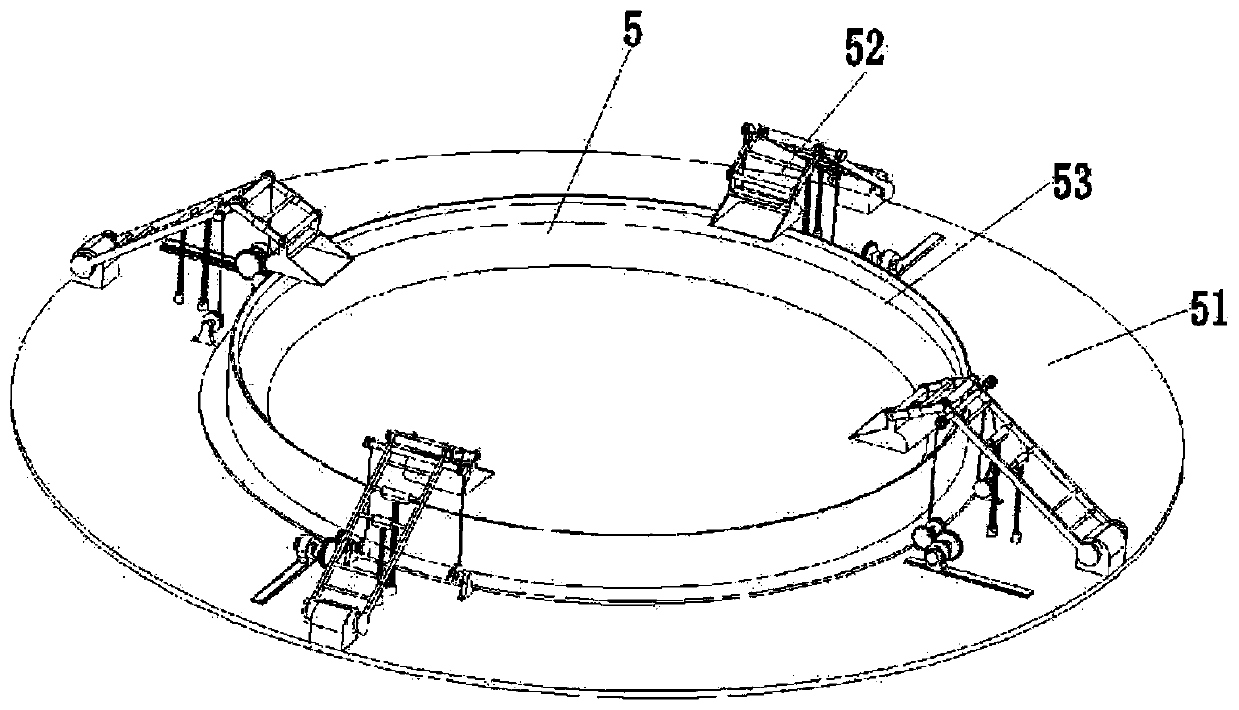

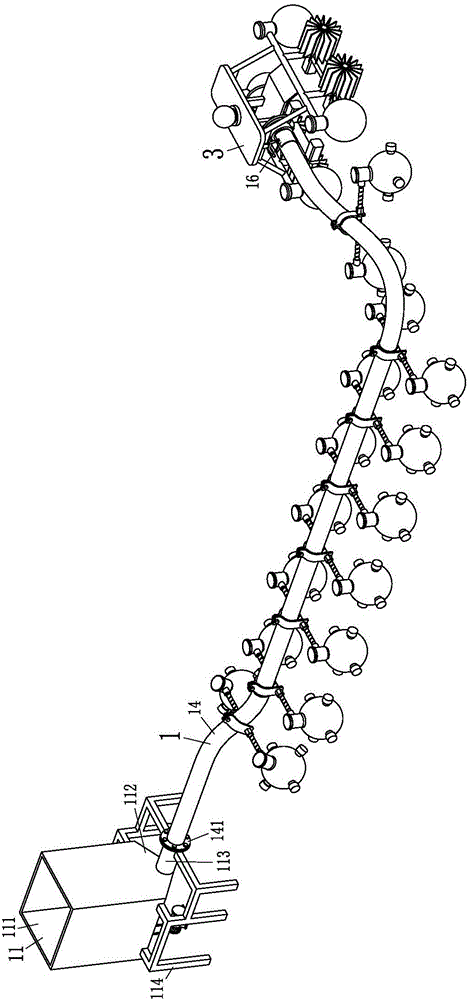

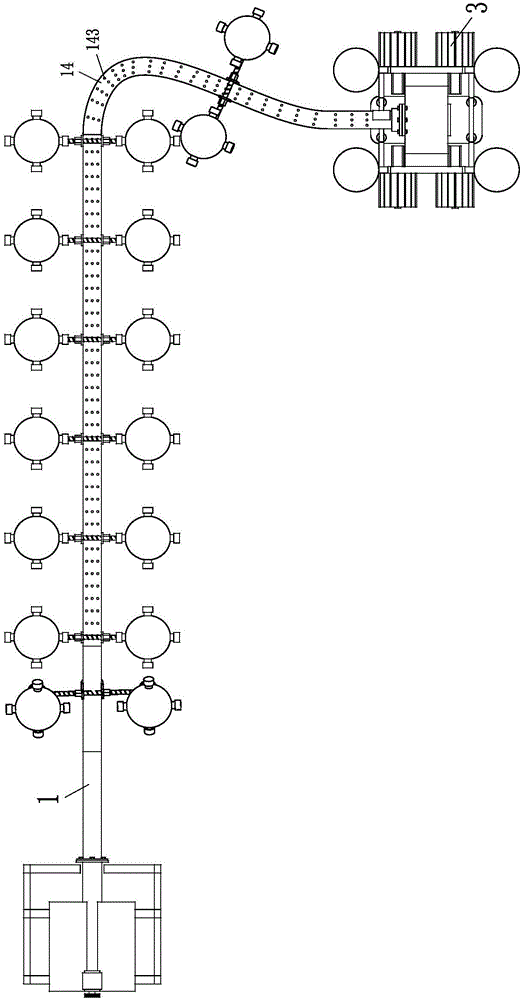

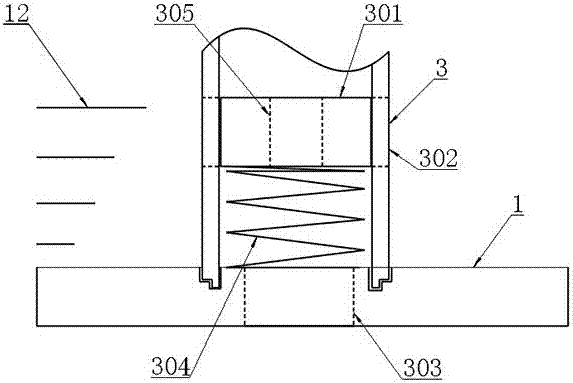

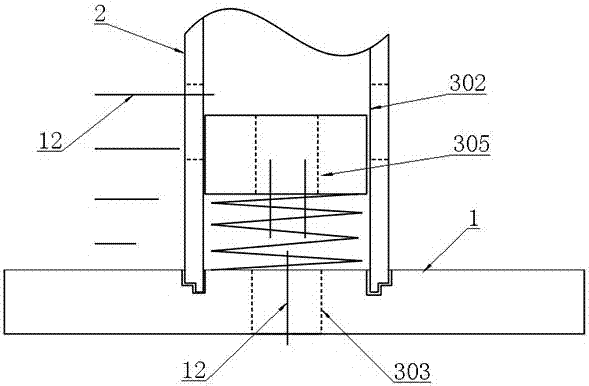

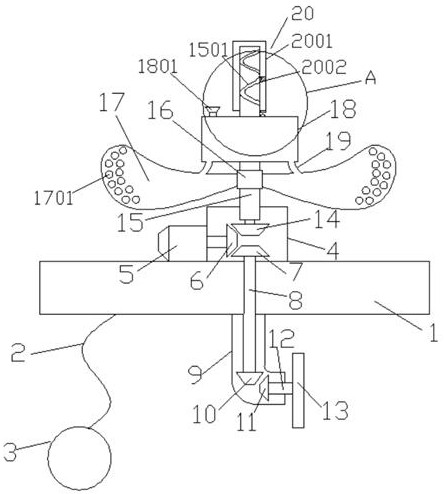

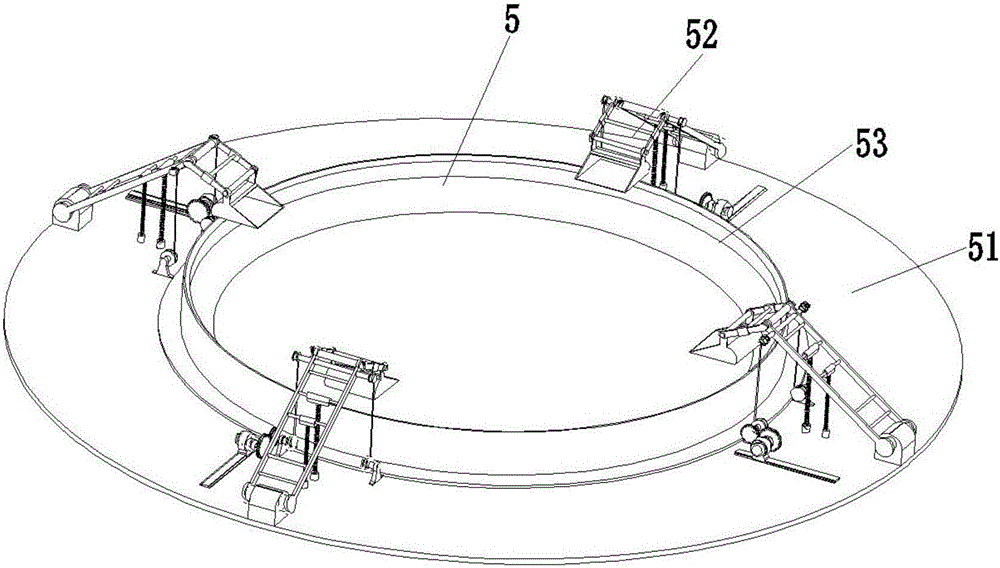

Executing mechanical arm used for complete intelligent fishpond feeding all-in-one machine

InactiveCN106035180ARealize the function of chargingTo achieve the effect of shrinking the wire ropeClimate change adaptationPisciculture and aquariaThree degrees of freedomEngineering

The invention relates to an executing mechanical arm used for a complete intelligent fishpond feeding all-in-one machine. The executing mechanical arm includes a three-degree-of-freedom parallel mechanism and a feeding device. The three-degree-of-freedom parallel mechanism is disposed exactly below the feeding device and the upper end of the three-degree-of-freedom parallel mechanism is connected with the feeding device. The executing mechanical arm has functions of direction and angle adjustment and feed loading and delivery, so that a function of automatic feeding in fishery breeding is realized. Besides, the executing mechanical arm is high in intelligent degree, flexible and convenient for direction and angle adjustment, high in feeding speed and long in feeding distance, and problems of large working load, large risks, low efficiency and the like of prior manual feeding realized by workers riding boats are solved.

Owner:东营尚牧农业科技有限公司

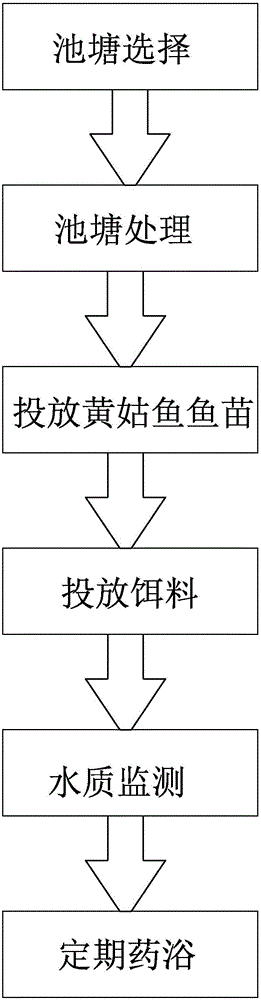

Nibea albiflora breeding method

InactiveCN105961233ABreeding method is simpleImprove survival rateFood processingClimate change adaptationWater qualityObserved Survival

The invention discloses a Nibea albiflora breeding method, characterized by comprising the following steps: A, selecting a pond; B, treating the pond; C, putting Nibea albiflora fries; D, putting bait; E, monitoring water quality; F, performing medicated bath at regular periods. An objective of the invention is to overcome defects in the prior art, and provide the Nibea albiflora breeding method. The Nibea albiflora can be cultured artificially, and survival rate is high, feeding is convenient, bait putting dispersibility is good, and the method provides convenience for Nibea albiflora to eat.

Owner:ZHONGSHAN ZHINING BIOTECH CO LTD

Six-degree-of-freedom fishery breeding automatic feeding robot base

ActiveCN105941244AAddress flexibilitySolution rangeClimate change adaptationPisciculture and aquariaLand TravelEngineering

The invention relates to a six-degree-of-freedom fishery breeding automatic feeding robot base which comprises a land traveling device, two water traveling devices, a lifting device and a Stewart parallel connection mechanism. The water traveling devices are positioned on the left side and the right side of the land traveling device respectively and connected with the land traveling device, the lifting device is positioned right above the land traveling device, the lower end of the lifting device is connected with the upper end of the land traveling device, the Stewart parallel connection mechanism is positioned right above the lifting device, and the lower end of the Stewart parallel connection mechanism is connected with the lifting device. The six-degree-of-freedom fishery breeding automatic feeding robot base has functions of land traveling, water traveling and direction and angle adjusting, and is quick and convenient in traveling and convenient and flexible in direction and angle adjusting, and the problem that existing feeding robot bases are low in moving flexibility, narrow in application range and low in stability.

Owner:威海雅乐生物科技有限公司 +1

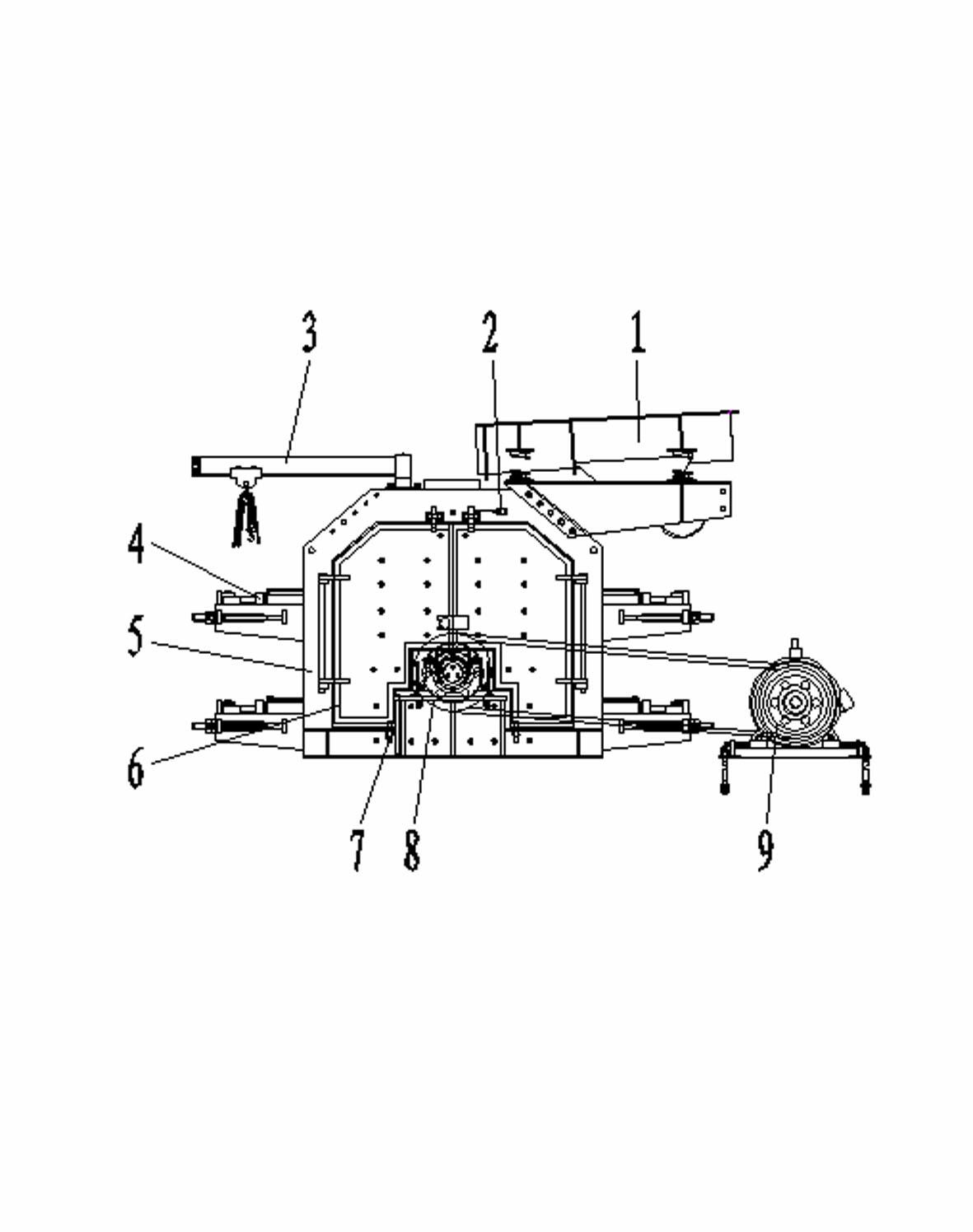

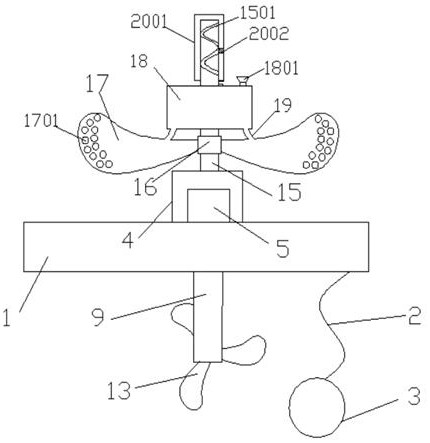

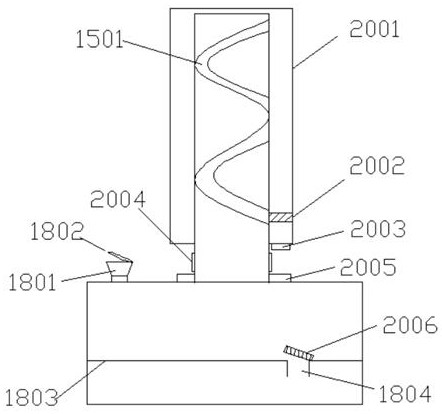

Full-intelligent fishpond feed putting integrated machine

ActiveCN106069964ARealize the function of chargingTo achieve the effect of shrinking the wire ropeClimate change adaptationPisciculture and aquariaThree degrees of freedomEngineering

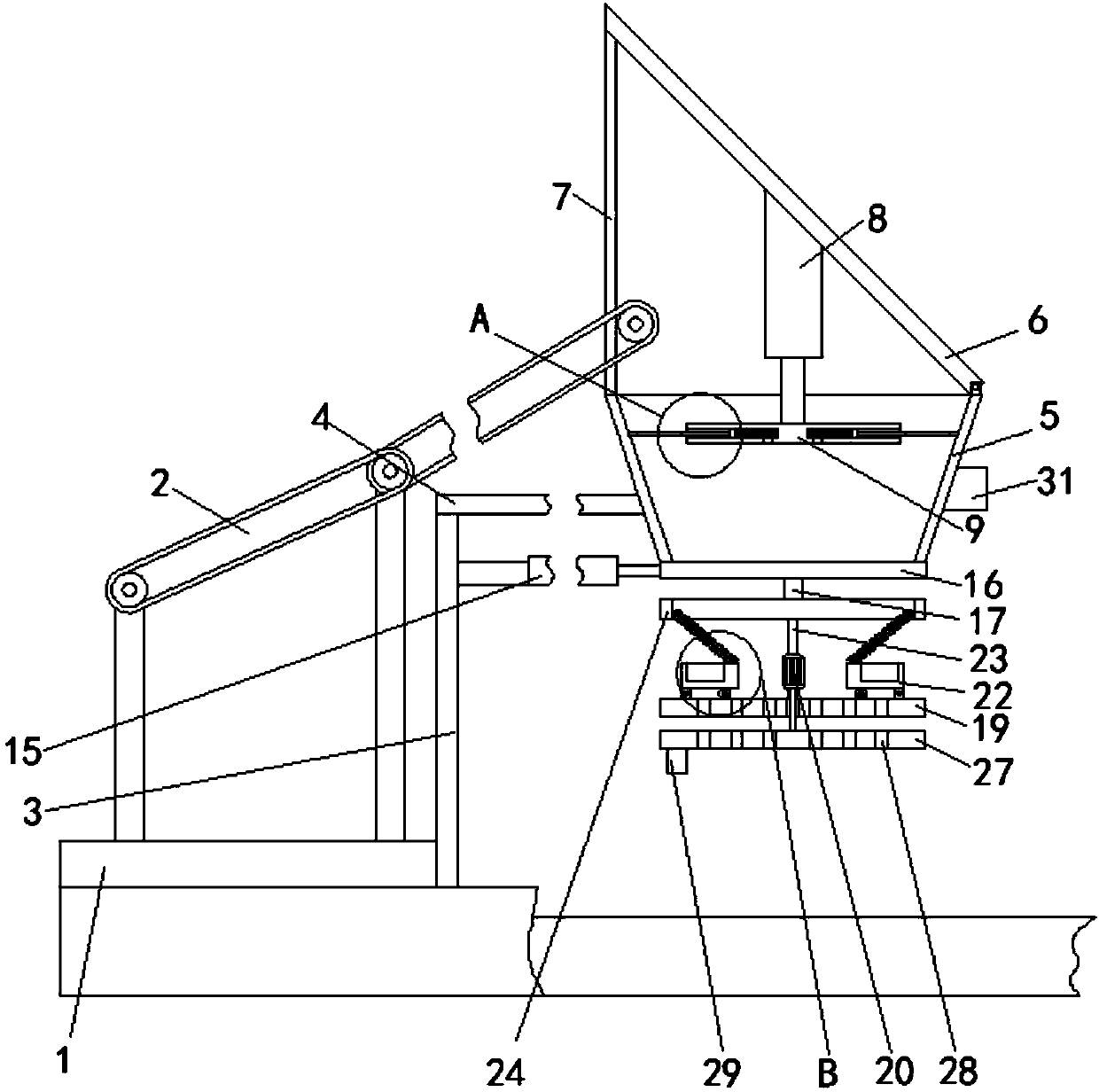

The invention relates to a full-intelligent fishpond feed putting integrated machine. The full-intelligent fishpond feed putting integrated machine comprises a land walking device, water surface walking devices, a lifting device, a three-degree-of-freedom parallel mechanism and a feed putting device. The water surface walking devices are located on the left side and the right side of the land walking device respectively and are connected with the land walking device, the lifting device is located over the land walking device, the lower end of the lifting device is connected with the upper end of the land walking device, the three-degree-of-freedom parallel mechanism is located between the lifting device and the feed putting device, the lower end of the three-degree-of-freedom parallel mechanism is connected with the lifting device, and the upper end of the three-degree-of-freedom parallel mechanism is connected with the feed putting device. The full-intelligent fishpond feed putting integrated machine has the land walking, water surface walking, orientation angle adjusting and feed charging and putting functions, and the automatic feed putting function of fishery breeding can be achieved; besides, the full-intelligent fishpond feed putting integrated machine is high in intelligence degree, orientation angle adjustment is convenient and flexible, the feed putting speed is high, the feed putting distance is large, and the problems that the workload of existing manual feed putting by a boat is large, high dangerousness exists, and efficiency is low are solved.

Owner:ANHUI YUNFENG AGRI DEVS CO LTD

Cultivation system with adjustable water temperature

InactiveCN105961232ASimple structureEffective temperature regulationClimate change adaptationPisciculture and aquariaAquatic productEngineering

The invention discloses a cultivation system with adjustable water temperature. The system comprises a pond. The outer side of the pond is provided with a pond water heat exchanging system. The water inlet pipe of the pond water heat exchanging system is arranged in one end of the pond, the water outlet pipe of the pond water heat exchanging system is arranged in the other end of the pond, and the pond is internally provided with a feeding device. The feeding device comprises a floating platform. The floating platform is provided with a storage vat. A discharging port is arranged on the lower part of the storage vat. The floating platform under the discharging port is provided with a feeding plate. The front end of the feeding plate is provided with a feeding port. The floating platform is provided with a discharging base. The feeding port is arranged on the same side of the discharging base. The floating platform is provided with an ejection device which can eject materials in a feeding plate out of the discharging base. An objective of the invention is to provide the cultivation system with adjustable water temperature, and the system can adjust water temperature of pond water, makes aquatic products safely overwinter, and the system is good in cultivation effect, good in bait dispersibility in feeding, and wide in feeding range.

Owner:ZHONGSHAN NUODUN SCI RES TECH SERVICE CO LTD

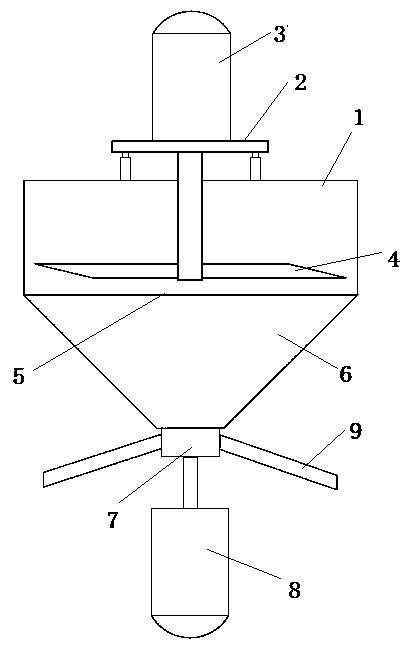

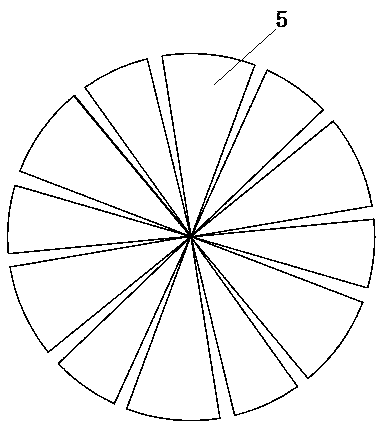

Crushed material feeder for fishpond

InactiveCN110140684AEasy to eatAvoid gatheringClimate change adaptationPisciculture and aquariaDrive shaftEngineering

The invention provides a crushed material feeder for a fishpond. The crushed material feeder comprises a feeding unit and a storage unit at the upper end of a feeding mechanism. The storage unit comprises a cylindrical storage bin and a crushing mechanism at the upper end of the storage bin. The crushing mechanism comprises an electric lifting table at the top of the storage bin, a crushing motormounted on the electric lifting table and a plurality of horizontal blades mounted on a driving shaft of the crushing motor, and the driving shaft of the crushing motor vertically and downwardly extends into the storage bin. The bottom of the storage bin is provided with an electric valve, the feeding unit comprises a sending pipe connected to the lower portion of the storage bin and a rotary feeding mechanism arranged below the sending pipe, the rotary feeding mechanism comprises a horizontal rotating bin and a feeding motor which drives the horizontal rotating bin to rotate, and a pluralityof feeding pipes are radially distributed on the horizontal rotating bin. By the crushing mechanism, the size of feed particles is changed; by means of radial feeding, a feeding range is wide, and fish gathering can be prevented.

Owner:YANCHENG INST OF IND TECH

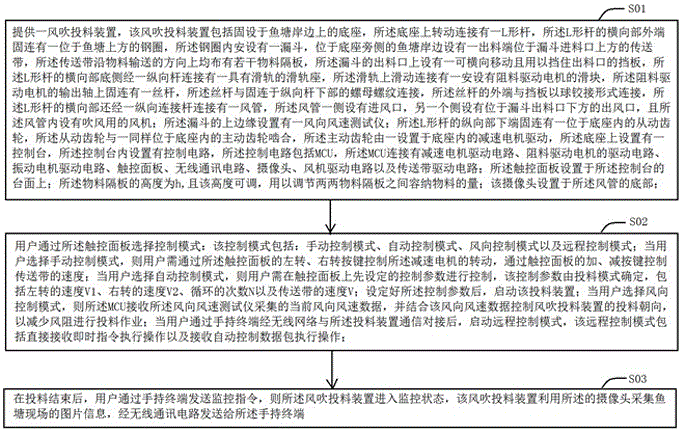

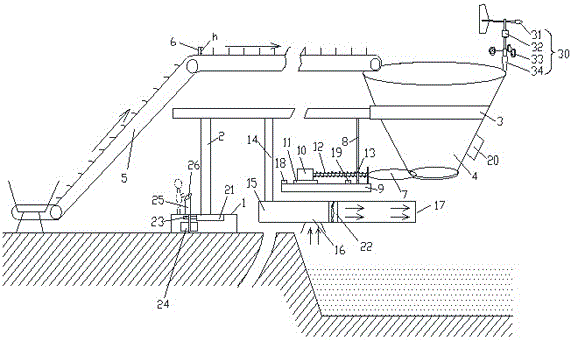

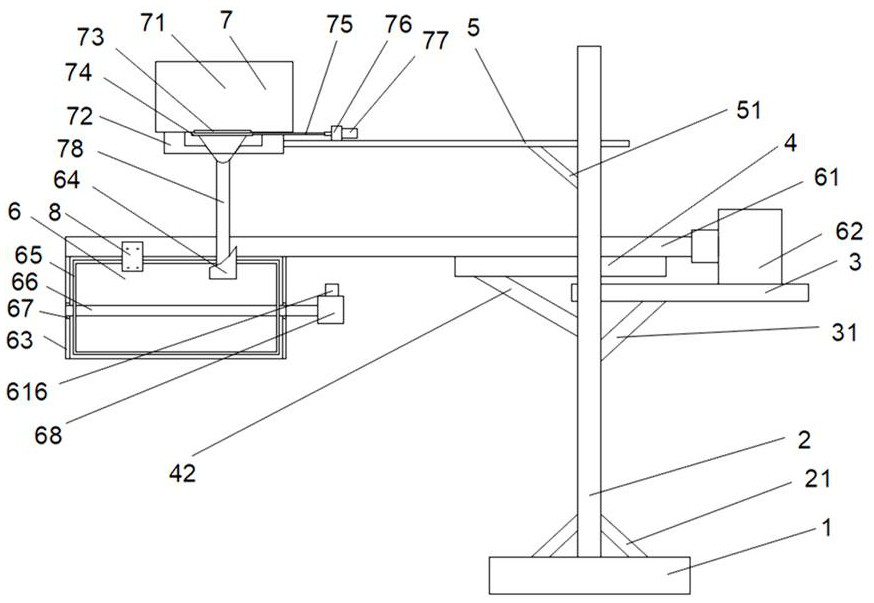

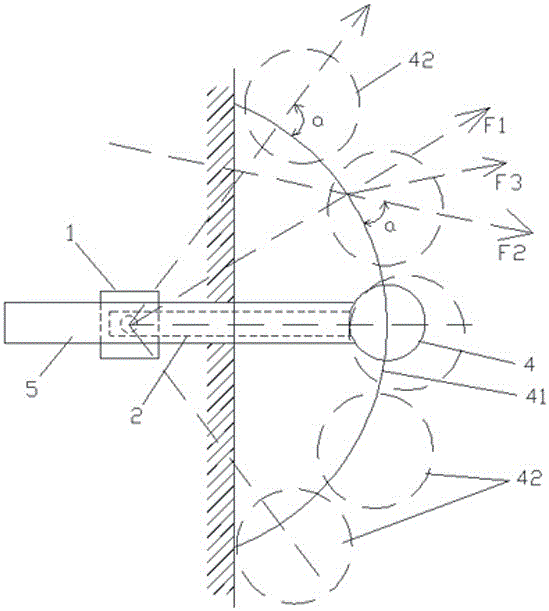

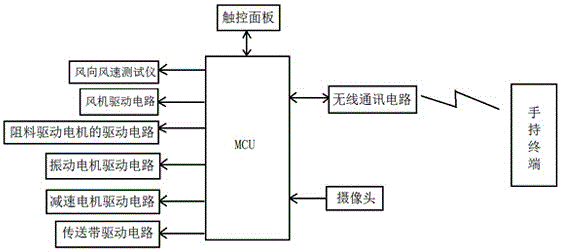

A method for realizing fishpond feeding by wind blowing

InactiveCN104839078BMeet feeding needsSimple methodClimate change adaptationPisciculture and aquariaAutomatic controlRemote control

The invention relates to an implementation method of air-blowing feeding for a fishpond, which comprises the steps that S01, an air-blowing feeding device is provided, wherein the air-blowing feeding device comprises a base fixedly arranged on a bank side of the fishpond, the base is rotatably connected to an L-shaped rod, the outer end of a transverse portion of the L-shaped rod is fixedly connected to a steel ring located above the fishpond, and a funnel is installed in the steel ring; S02, a user selects control modes through a touch panel, wherein the control modes comprise a manual control mode, an automatic control mode, an air direction control mode and a remote control mode; and S03, the user sends a monitoring instruction through a handheld terminal after feeding is finished, so that the air-blowing feeding device gets into a monitoring state, the air-blowing feeding device acquires on-site picture information of the fishpond by using a camera and sends the picture information to the handheld terminal through a wireless communication circuit. The method provided by the invention is simple and convenient to operate, and realizes feeding in a mode of blowing fish feed through a fan, thereby being wide in feeding range and good in effect.

Owner:钦州市钦南区园牧种养专业合作社

An energy-saving and environment-friendly aquaculture fish, shrimp and crab multifunctional feed feeder

ActiveCN110074034BTiming outputAvoid situations that cause differences in the amount of feedClimate change adaptationPisciculture and aquariaAnimal scienceZoology

Owner:湛江市润晖水产有限公司

A wind blowing feeding system for fish ponds

ActiveCN104839077BMeet feeding needsSimple structureClimate change adaptationPisciculture and aquariaEngineeringDrive motor

The invention relates to an air-blowing feeding system for a fishpond, which comprises a base and is characterized in that the base is rotatably connected to an L-shaped rod, the outer end of a transverse portion of the L-shaped rod is fixedly connected to a funnel, the fishpond band side located by the side of the base is provided with a conveyor belt located above a charging opening of the funnel, a discharging opening of the funnel is provided a blocking plate which can transversely move and is used for blocking the discharging opening, the bottom side of the transverse portion of the L-shaped rod is connected to a sliding rail base with a sliding rail through a longitudinal rod, the sliding rail is slidably connected to a sliding block provided with a material blocking driving motor, an output shaft of the material blocking driving motor is fixedly connected to a lead screw, the lead screw is in threaded connection with a nut which is fixedly connected to the lower part of the longitudinal rod, the transverse portion of the L-shaped rod is further connected to an air pipe through a longitudinal connecting rod, and an air outlet of the air pipe is located under the discharging opening. The air-blowing feeding system provided by the invention is simple in structure and convenient to operate, and realizes feeding in a mode of blowing fish feed through a fan, thereby being wide in feeding range and good in effect.

Owner:SUSONG FUMIN AQUATIC PROD CULTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com