Cultivation system with adjustable water temperature

A water temperature adjustment and water temperature technology, applied in the field of aquaculture systems, can solve the problems of poor bait dispersion, unsatisfactory effect, low survival rate, etc., and achieve the effects of avoiding waste, simple structure and wide feeding range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

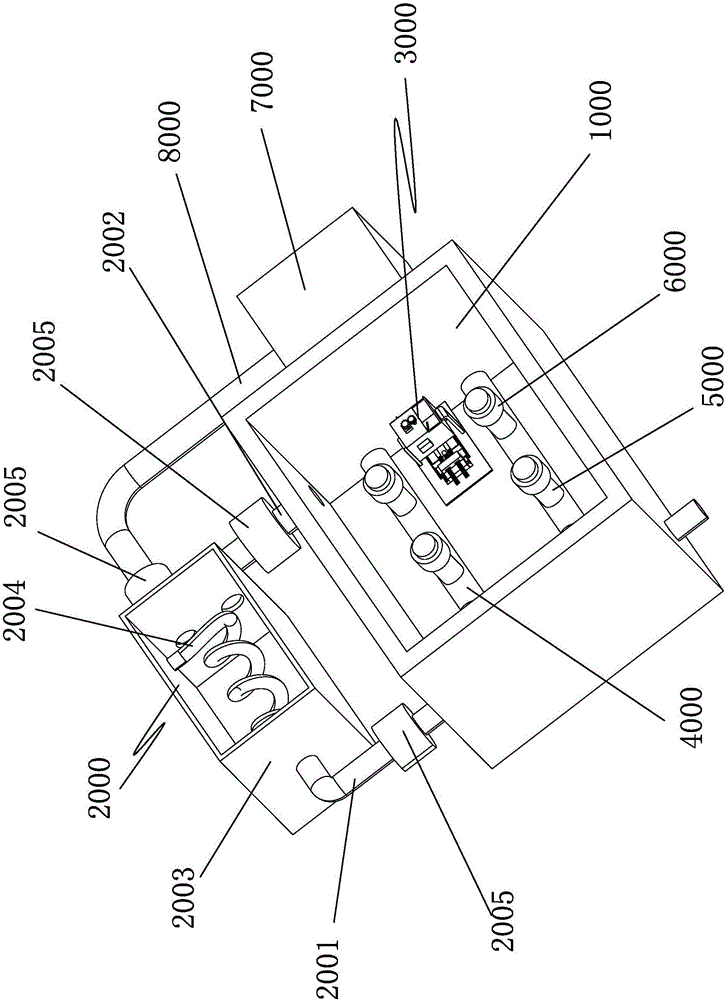

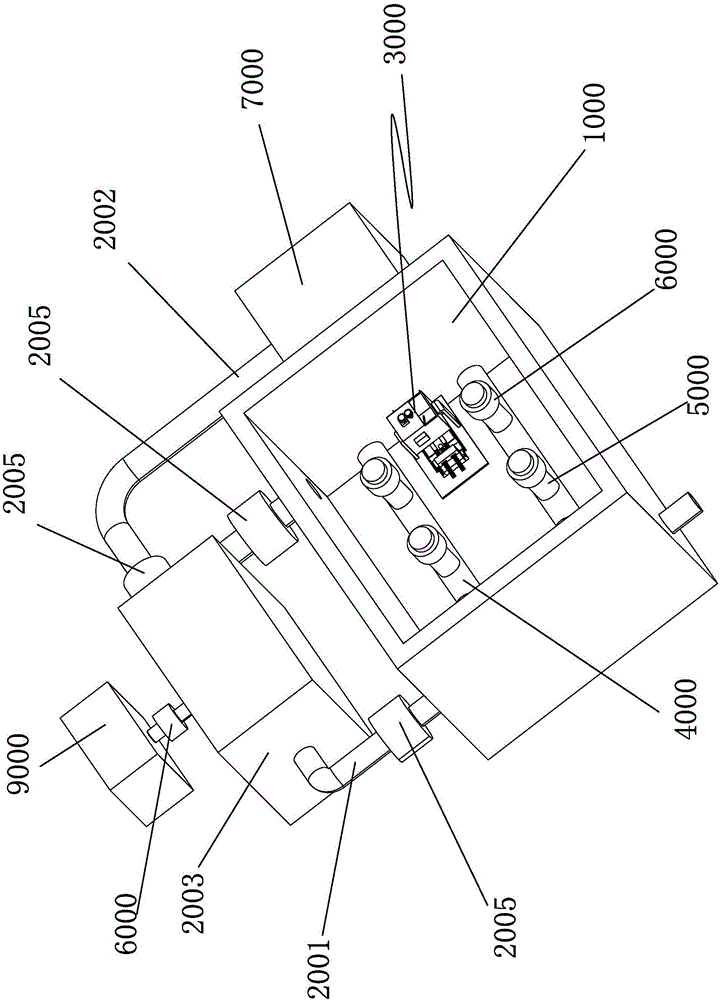

[0048] In an embodiment of the present invention, the heat exchange pool 2003 is a sealed pressure vessel, the water inlet pipe 2001 and the water outlet pipe 2002 are respectively provided with control valves 6000, and the outside of the pond 1000 is provided with a pressurizing device 9000, The pressurizing device 9000 is connected with the heat exchange pool 2003 through a pressurizing pipe 9001, and a control valve 6000 is provided on the pressurizing pipe 9001.

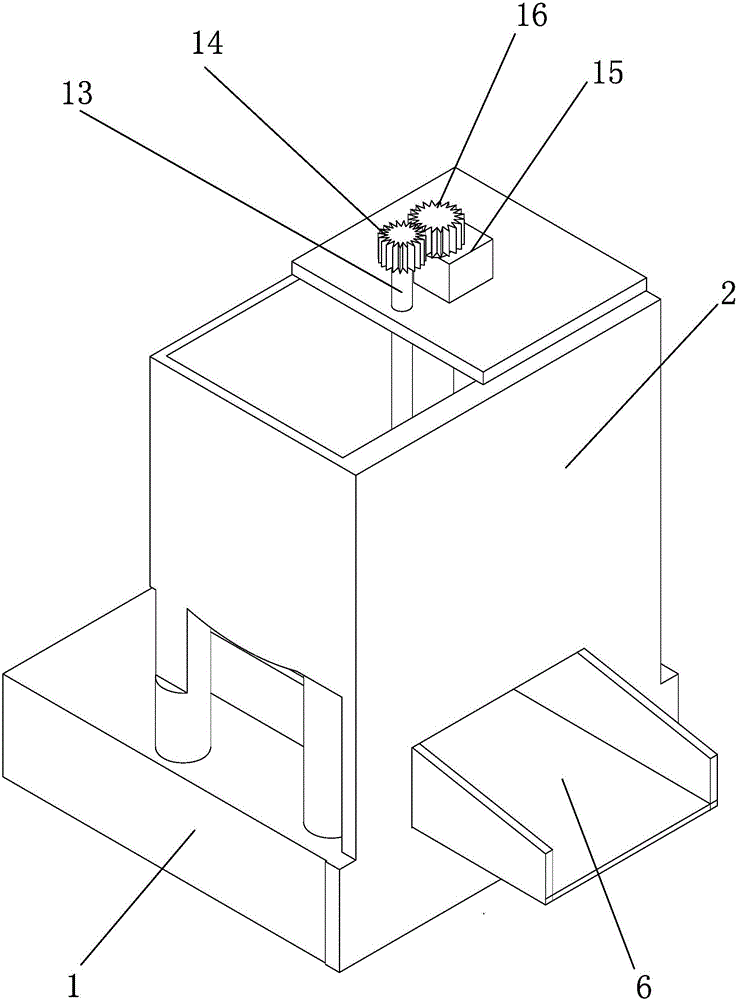

[0049] In the present invention, the ejection device 7 includes a fixed seat 71 that is fixedly connected to the floating platform 1 , a guide rod 72 is provided on the fixed seat 71 , and a connection hole is provided on the rear end of the feeding tray 4 , so The guide rod 72 is arranged in the connecting hole, a spring 73 is sleeved on the guide rod 72 between the rear end of the feeding tray 4 and the fixed seat 71, a mounting groove is provided in the floating platform 1, A front sprocket axle 74 and a rear ...

Embodiment 1

[0063] Example 1 - Anti-rust coating

[0064] The anti-rust coating of the present invention comprises the following components by weight percentage:

[0065]

[0066]

[0067] Preparation method: Mix graphene, strontium chromate, lead tetroxide, ammonium metaborate and titanium dioxide evenly, grind to a fineness of <60μm in a conical grinder, then add silicone modified acrylate emulsion, adjacent Dibutyl phthalate, propylene glycol methyl ether and other components are uniformly dispersed.

Embodiment 2

[0068] Example 2 - Anti-rust coating

[0069] The anti-rust coating of the present invention comprises the following components by weight percentage:

[0070]

[0071] Preparation method: Mix graphene, strontium chromate, lead tetroxide, ammonium metaborate and titanium dioxide evenly, grind to a fineness of <60μm in a conical grinder, then add silicone modified acrylate emulsion, adjacent Dibutyl phthalate, propylene glycol methyl ether and other components are uniformly dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com