Crushed material feeder for fishpond

The technology of a feeding machine and a feeding mechanism is applied in the field of fish pond aquaculture, which can solve the problems of death of fish, hypoxia of fish, increase of excrement, etc., and achieve the effect of wide feeding range and preventing aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

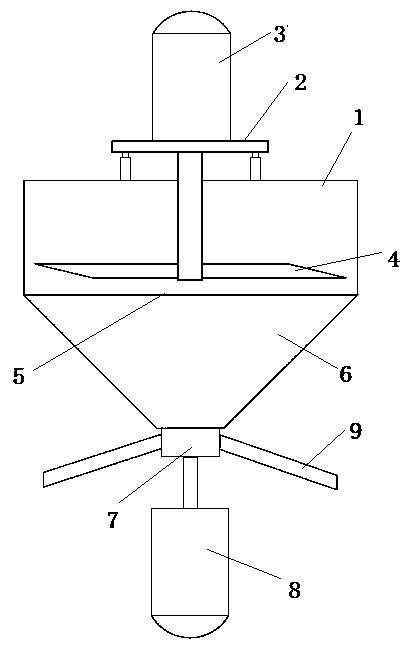

[0013] The invention proposes a feeder for broken materials in fish ponds, which includes a feeding unit and a storage unit located at the upper end of the feeding mechanism.

[0014] The material storage unit includes a cylindrical storage bin 1 and a crushing mechanism located at the upper end of the storage bin 1; Broken material motor 3 and some fan horizontal blades 4 installed on the crushed material motor 3 drive shafts, said crushed material motor 3 drive shafts vertically extend downwards in the storage bin 1.

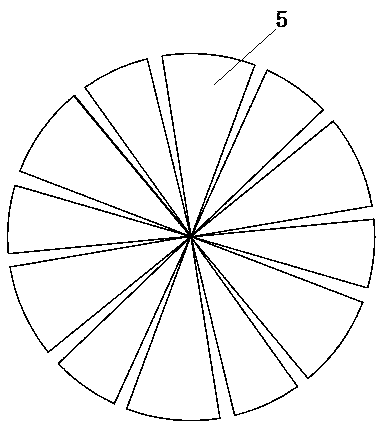

[0015] The bottom of the storage bin 1 is provided with an electric valve 5 . The electric valve 5 is a guide vane valve with the same diameter as the bottom of the storage bin 1, including a plurality of fan-shaped blades symmetrically arranged in the center, and the fan-shaped blades can be electrically driven to rotate by 90°. The structure of this guide vane valve adopts the IGV, which is commonly used in centrifuges and other units to adjust the inlet ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com