High-efficiency impact sand making machine

A kind of technology of counterattack and sand making machine, which is applied in the direction of grain processing, etc., which can solve the problems of small feed particle size, inconvenient maintenance, high production cost, etc., and achieve the effect of prolonging the use time, strong processing capacity and large feed particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

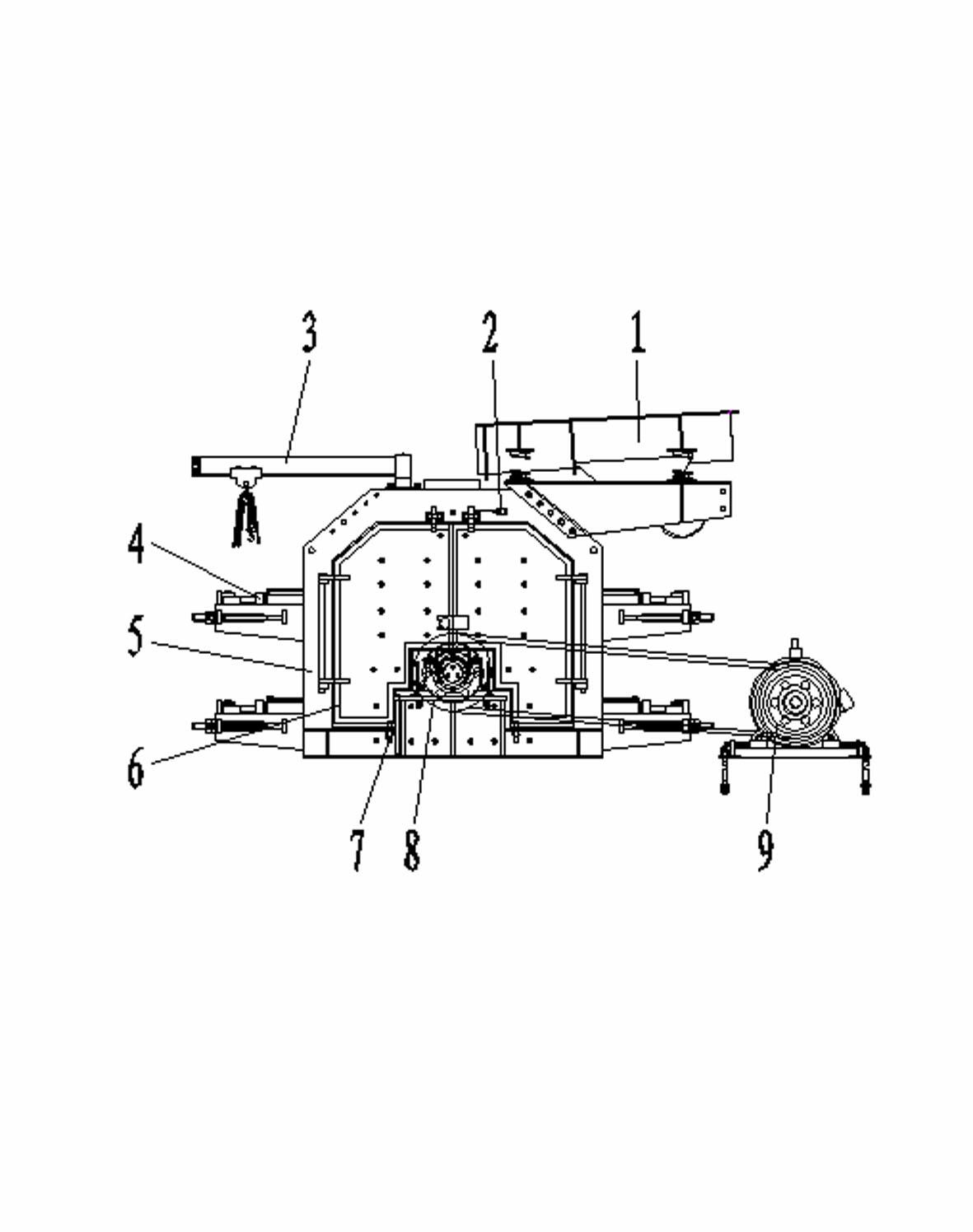

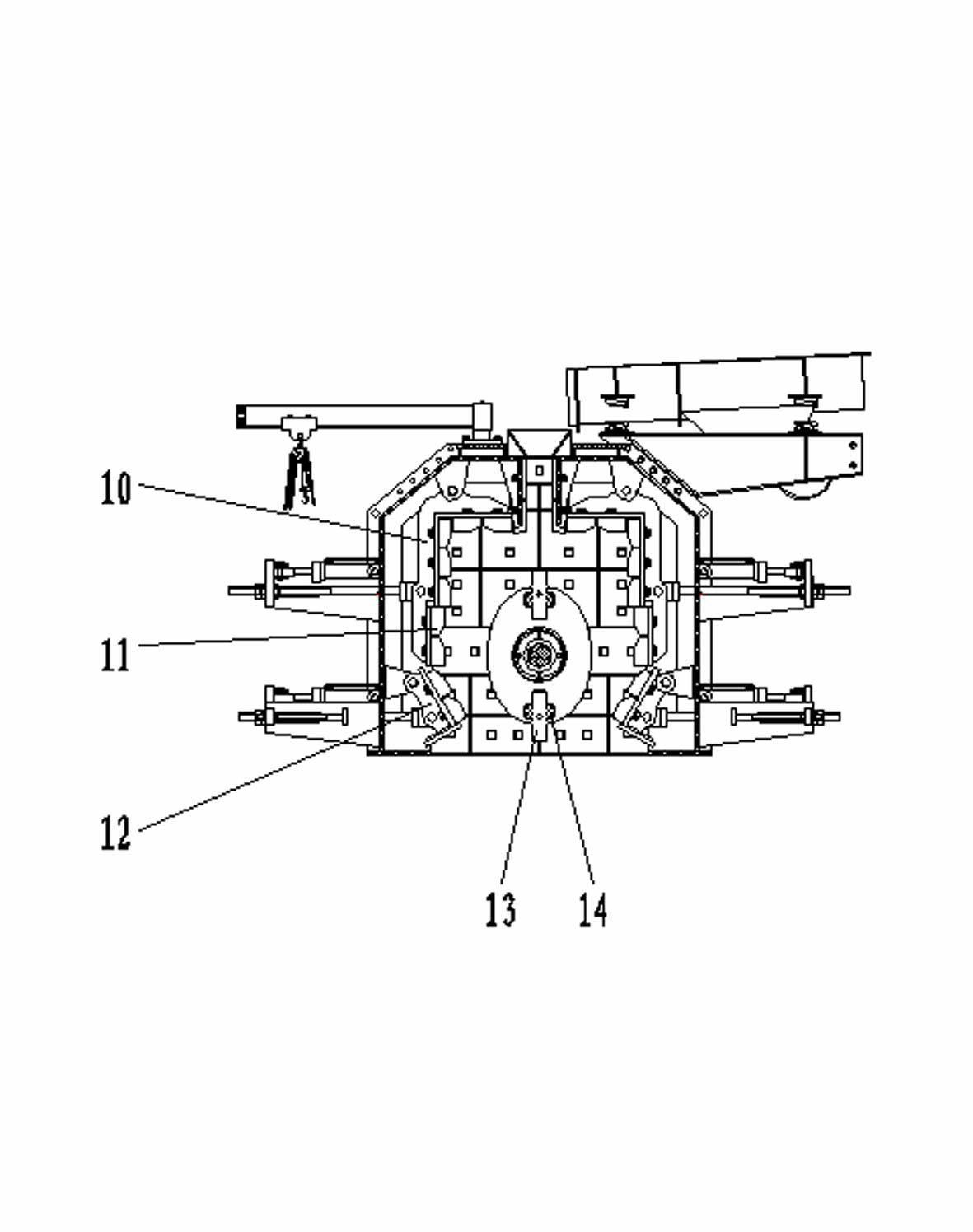

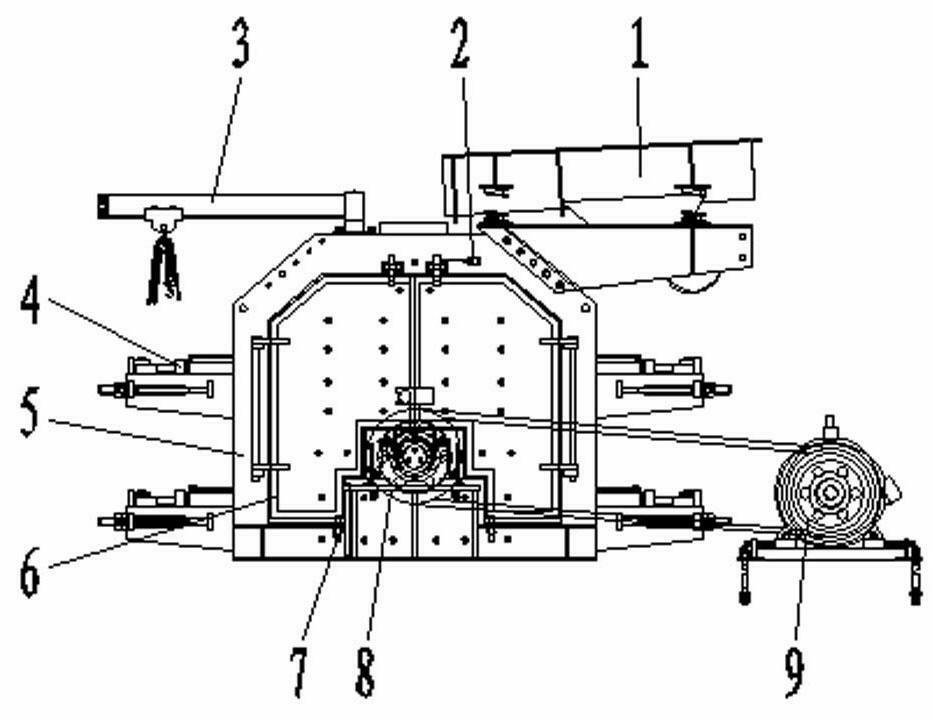

[0019] see figure 1 and figure 2 , a high-efficiency impact sand making machine, including a box body 5, a rotor part 8, an impact frame, a maintenance hanger 3 and a vibrating feed hopper 1, the box body 5 is a welded box body, and the two sides of the box body 5 are double doors structure, the doors 6 on both sides are connected to each other, and maintenance is extremely convenient; the side door 6 is equipped with wedge iron 7 around the door to lock the door, and the upper side of the side door 6 is equipped with a travel switch 2 on one side of the wedge iron 7, and the travel switch 2 and the motor implement chain control. When 6 is not closed properly, the motor cannot start. When the equipment is running, if the side door 6 is loose or suddenly opened, the motor will automatically cut off the power and stop running. The rotor is an elliptical double blow bar structure. The blow bar 13 is made of special alloy materials The fixing method adopts the plug-in type, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com