Method for preparing nano calcium hydroxide by adopting micro-channel reactor

A technology of microchannel reactor and calcium hydroxide, applied in calcium/strontium/barium oxide/hydroxide, nanotechnology, recycling technology, etc., can solve the problem of large particle size of nano calcium hydroxide particles and easy agglomeration question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

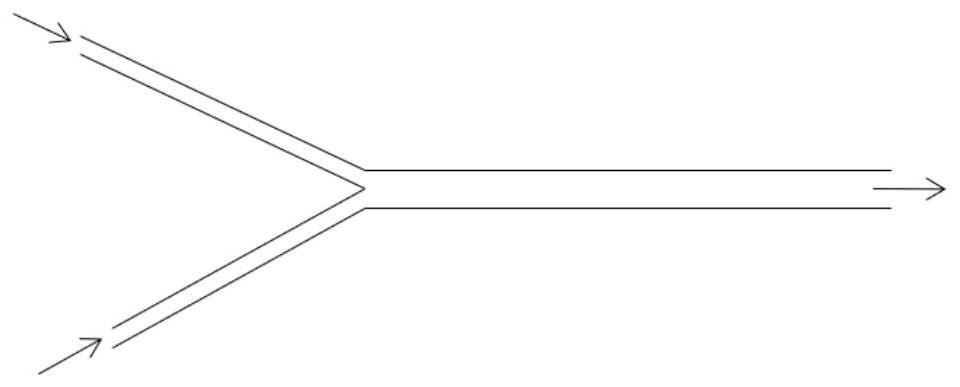

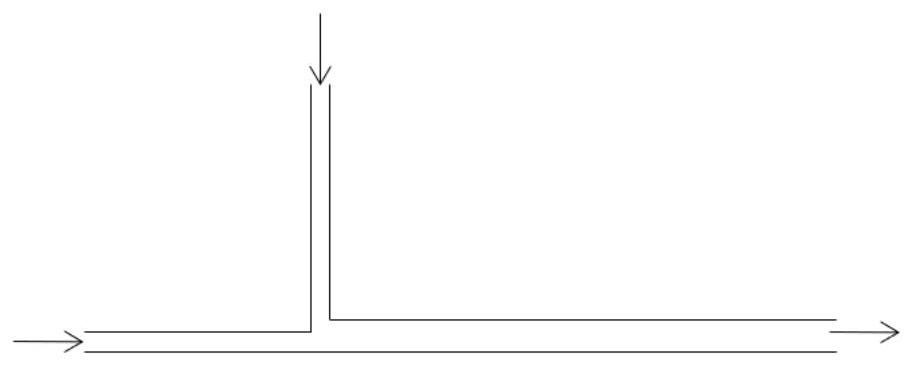

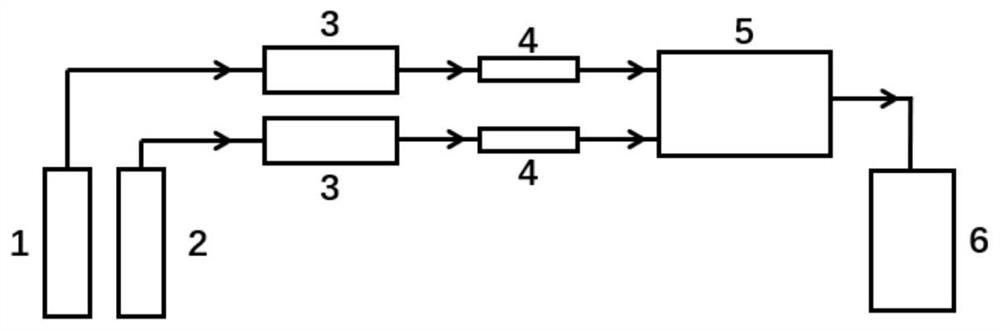

[0044] The mixed solution of calcium chloride and dispersant DT-1 at room temperature, with a calcium chloride concentration of 0.1mol / L dispersed agent concentration of 0.111g / L. The sodium hydroxide solution is tied at room temperature, and the concentration of sodium hydroxide is 0.1mol / L. Adjust the duplex flat pump flow to 5ml / min, and use the Y -type reactor to push the mixed solution and alkaline solution simultaneously. After entering the mixing kettle at high speed, it is quickly stirred at 1500rpm. After testing, the particle size is 75nm.

Embodiment 2

[0046] The mixed solution of calcium chloride and dispersant DT-1 at room temperature, calcium chloride concentration is 0.1mol / L, and the dispersant concentration is 0.111g / L. The sodium hydroxide solution is tied at room temperature, and the concentration of sodium hydroxide is 0.1mol / L. Adjust the duplex flat pump flow to 0.5ml / min, and use the Y -type reactor to enter the mixed solution and alkaline solution simultaneously. After entering 1500rpm at the high speed of the material, it is quickly stirred for 1 hour at a speed of 1500rpm to obtain a sample of nano hydrogen oxide. After testing, the particle size is 110nm.

Embodiment 3

[0048] The mixed solution of calcium chloride and dispersant DT-1 at room temperature, calcium chloride concentration is 0.1mol / L, and the dispersant concentration is 0.111g / L. The sodium hydroxide solution is tied at room temperature, and the concentration of sodium hydroxide is 0.2 mol / L. Adjust the duplex flat pump flow to 5ml / min, and use the Y -type reactor to push the mixed solution and alkaline solution simultaneously. After entering the mixing kettle at high speed, it is quickly stirred at 1500rpm. After testing, the particle size is 55nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com