Antibacterial skin-care polypropylene fiber master batch and fabric

A polypropylene fiber and polypropylene resin technology, applied in the field of functional fiber masterbatch and fabrics, can solve the problems of uneven distribution, difficult to play an effective role, low fiber strength, etc., to promote beneficial changes and reduce surface polarity. , the effect of reducing the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The antibacterial agent is Fe-doped zinc oxide nanosheets, and the Fe-doped zinc oxide nanosheets are prepared by the following steps:

[0041] S1. Weigh Zn(NO 3 ) 2 ·6H 2 O and Fe(NO) 3 9H2 O, stirred and dissolved in deionized water to obtain Zn 2+ and Fe 3+ The mixed solutions with ion concentrations of 0.3mol / L and 0.1mol / L were added to the mixed solution with a final concentration of 0.7mol / L, and after stirring and dissolving, they were transferred to a reaction kettle with a polytetrafluoroethylene liner and sealed. , reacted at a constant temperature at 120-130°C for 24 hours under autogenous pressure, cooled naturally to room temperature after the reaction was completed, separated the precipitate and washed it with deionized water, dried and ground to obtain powder A;

[0042] S2. Add polyethylene glycol dropwise in deionized water to obtain a mixed solution A, ultrasonically disperse the powder A obtained by grinding in the mixed solution A, transfer it ...

Embodiment 1

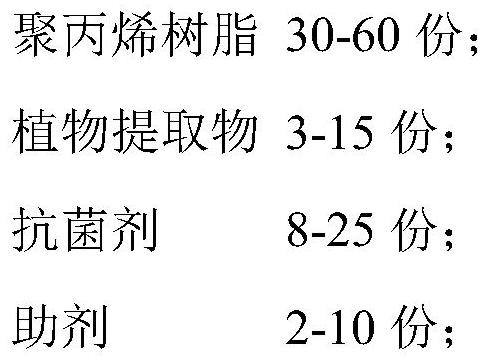

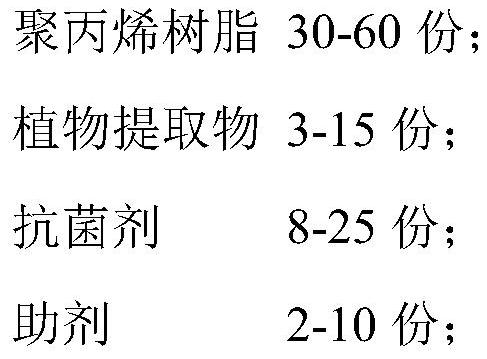

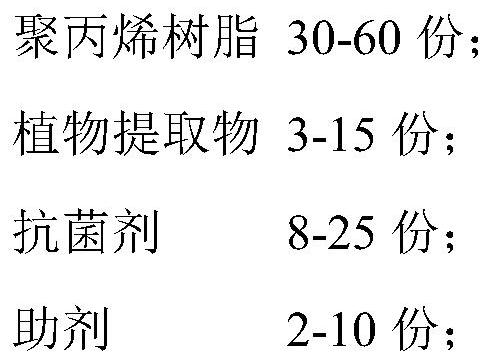

[0065] An antibacterial skin care polypropylene fiber masterbatch, by weight, has the following components:

[0066]

[0067] Wherein, the plant extract is centella asiatica extract and honeysuckle extract;

[0068] The preparation method of the centella asiatica extract is as follows: after the dried centella asiatica is crushed, it is extracted by adding ethanol with a volume fraction of 80-90%, the ratio of solid to liquid is 1:40-80, and the extraction is assisted by ultrasonic waves. centrifugation or suction filtration, and collect the filtrate; add activated carbon to the filtrate for decolorization, centrifuge, collect the decolorization filtrate, concentrate the decolorization filtrate, add macroporous adsorption resin for purification, elute with ethanol to obtain an eluent, and After the eluent is concentrated, desalted and dried, the Centella asiatica extract is obtained;

[0069] The preparation method of the honeysuckle extract is as follows: take dried honey...

Embodiment 2

[0079] On the basis of Example 1, the antibacterial skin care polypropylene fiber masterbatch also includes 3 parts of hydrophobically modified polysaccharide derivatives; the preparation method of the hydrophobically modified polysaccharide derivatives is:

[0080] Weigh 4-dimethylaminopyridine and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride respectively and dissolve them in dimethyl sulfoxide. After fully stirring and dissolving, add mass Polysaccharide-dimethyl sulfoxide solution with a fraction of 10%, and then one of the C18 fatty acids was added dropwise, stirred and reacted for 36 hours in a water bath at 36-40°C, and absolute ethanol was added after the reaction was completed, and the precipitate was precipitated after standing, filtered The precipitate was washed successively with absolute ethanol and ether, and vacuum-dried to obtain the hydrophobically modified polysaccharide derivative;

[0081] Wherein, the 4-dimethylaminopyridine and the 1-(3-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com