Al18B4O33 whisker-reinforced silver-copper composite brazing filler metal and preparation method thereof

A composite solder and whisker technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effects of overcoming dependence, expanding the scope of application, and fully absorbing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment weighs 65% of Ag powder, 25% of Cu powder and 10% of Al by mass percentage. 18 B 4 o 33 Whiskers, mixed to obtain raw solder powder;

[0024] Place the above-mentioned original solder powder and balls in a planetary ball mill jar, fill the ball mill jar with argon gas after vacuuming, and ball mill for 4 hours at a speed of 120r / min to obtain Al 18 B 4 o 33 Whisker-reinforced silver-copper composite solder; the ball-to-material ratio is 9:1, and the filler ratio is 45%.

[0025] The ball-to-material ratio refers to the ratio of the mass of ceramic balls used in ball milling to the mass of the brazing filler metal; the filler ratio refers to the ratio of the total volume of balls + brazing filler metal powder to the volume of the ball milling tank.

[0026] Test 1:

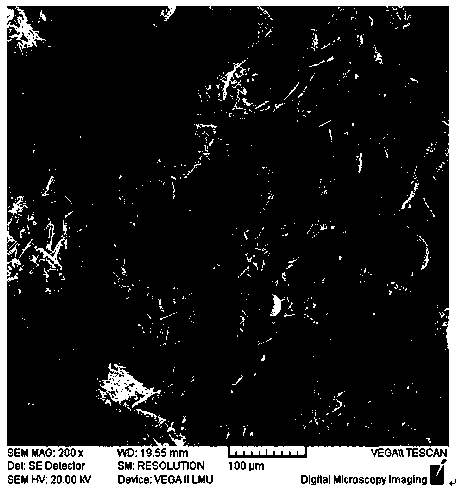

[0027] For the Al prepared above 18 B 4 o 33 The microscopic morphology of whisker-reinforced silver-copper composite solder was observed by scanning electron microscope, from figur...

Embodiment 2

[0038] The present embodiment weighs 60% Ag powder, 30% Cu powder and 10% Al by mass percentage. 18 B 4 o 33 Whiskers, mixed to obtain raw solder powder;

[0039] Place the above-mentioned original solder powder and balls in a planetary ball milling jar, fill the ball milling jar with argon gas after vacuuming, and ball mill for 2 hours at a speed of 100r / min to obtain Al 18 B 4 o 33 Whisker-reinforced silver-copper composite solder; the ball-to-material ratio is 6:1, and the filler ratio is 40%.

[0040] Test by the test 3 of embodiment 1, the Al of the present embodiment 18 B 4 o 33 Whisker-reinforced silver-copper composite solder for air brazing of Al 2 o 3 The average shear strength of ceramic brazed joints is 45 MPa.

Embodiment 3

[0042] The present embodiment weighs 70% Ag powder, 20% Cu powder and 10% Al by mass percentage. 18 B 4 o 33 Whiskers, mixed to obtain raw solder powder;

[0043] Place the above-mentioned original solder powder and balls in a planetary ball mill jar, fill the ball mill jar with argon gas after vacuuming, and ball mill for 8 hours at a speed of 150r / min to obtain Al 18 B 4 o 33 Whisker-reinforced silver-copper composite solder; the ball-to-material ratio is 12:1, and the filler ratio is 50%.

[0044] Test by the test 3 of embodiment 1, the Al of the present embodiment 18 B 4 o 33 Whisker-reinforced silver-copper composite solder for air brazing of Al 2 o 3 The average shear strength of ceramic brazed joints is 58 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com