Power transmission line unmanned aerial vehicle autonomous inspection system and working method thereof

A technology of transmission lines and inspection systems, which is applied in closed-circuit television systems, control/regulation systems, electrical components, etc., and can solve problems such as difficulty in ensuring the operational accuracy of inspection personnel, differences in operating experience and proficiency, and poor consistency of collected data , to achieve the effect of improving consistency and stability, solving technology dependence, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

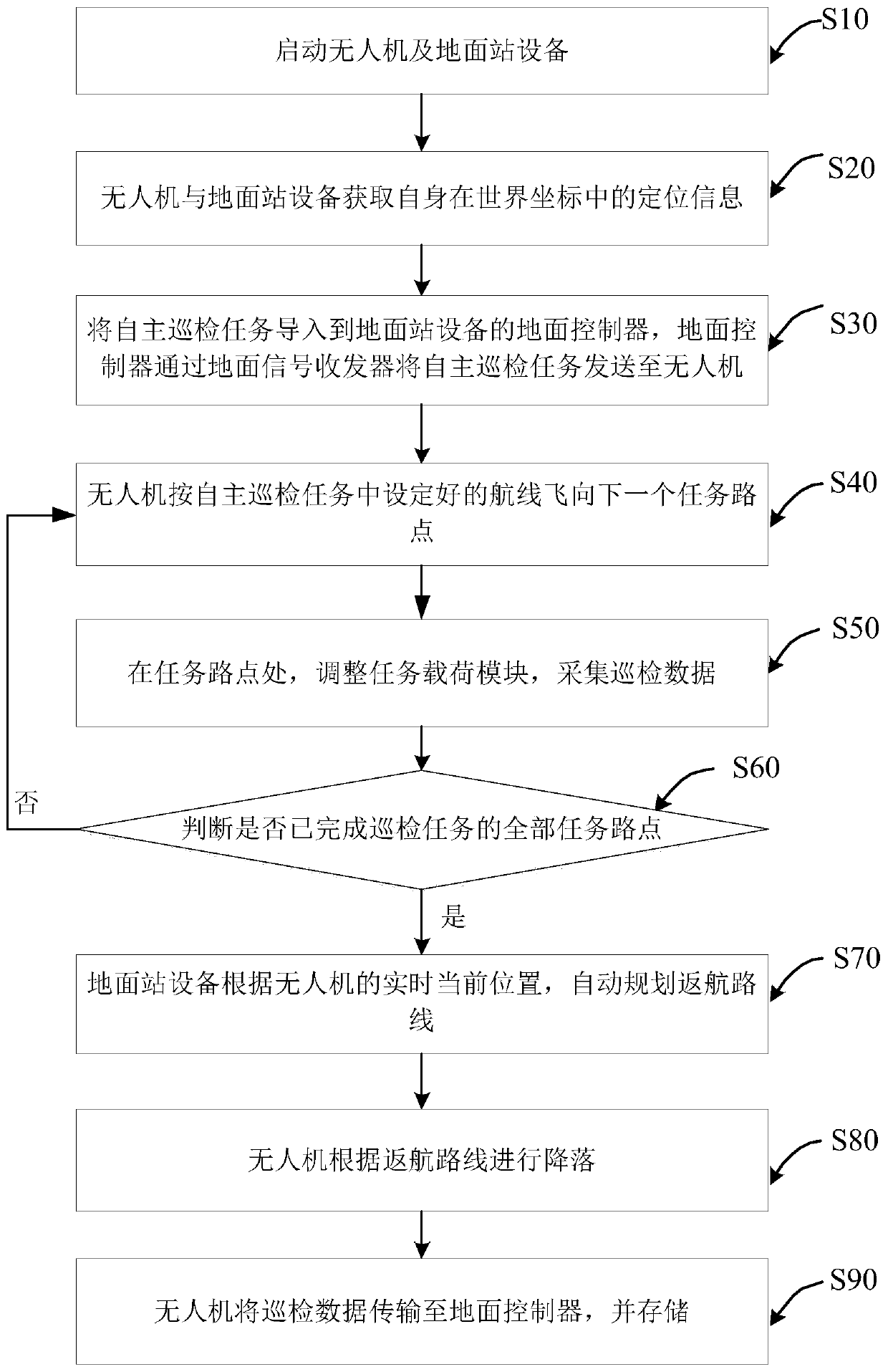

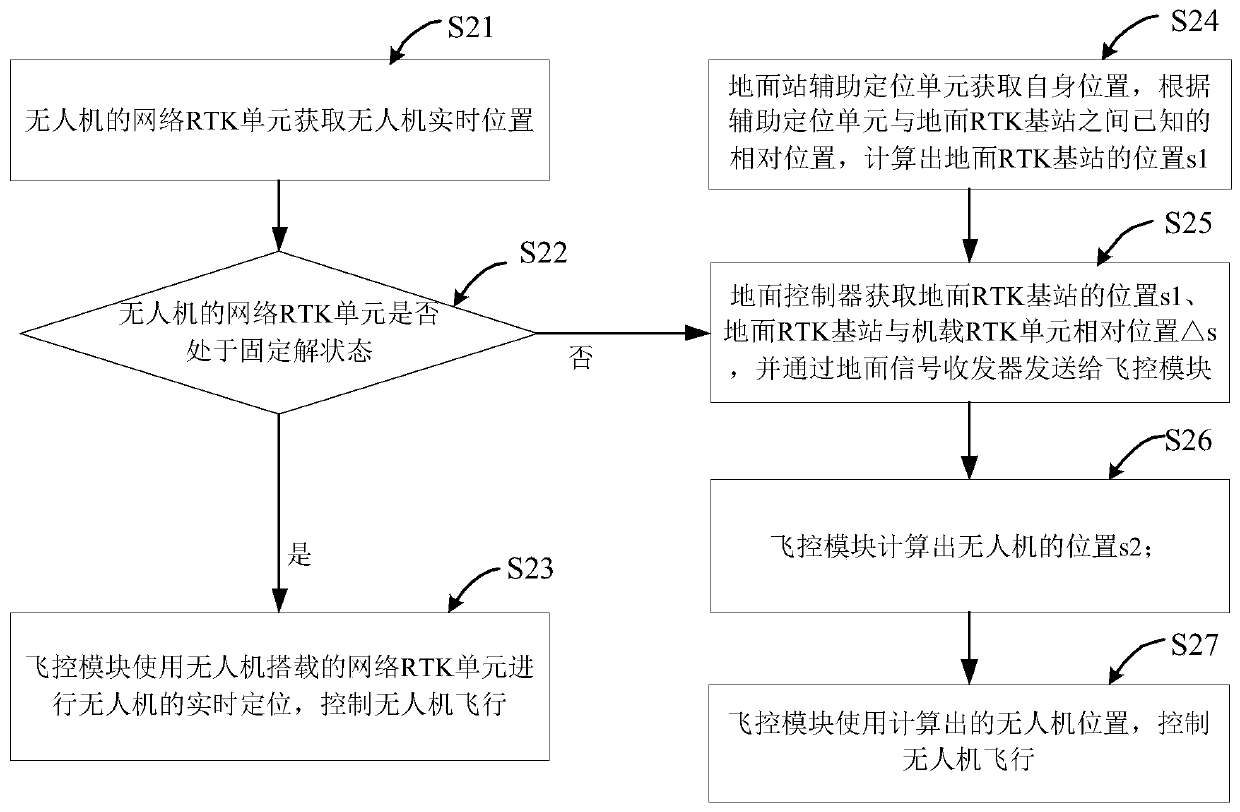

[0046] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

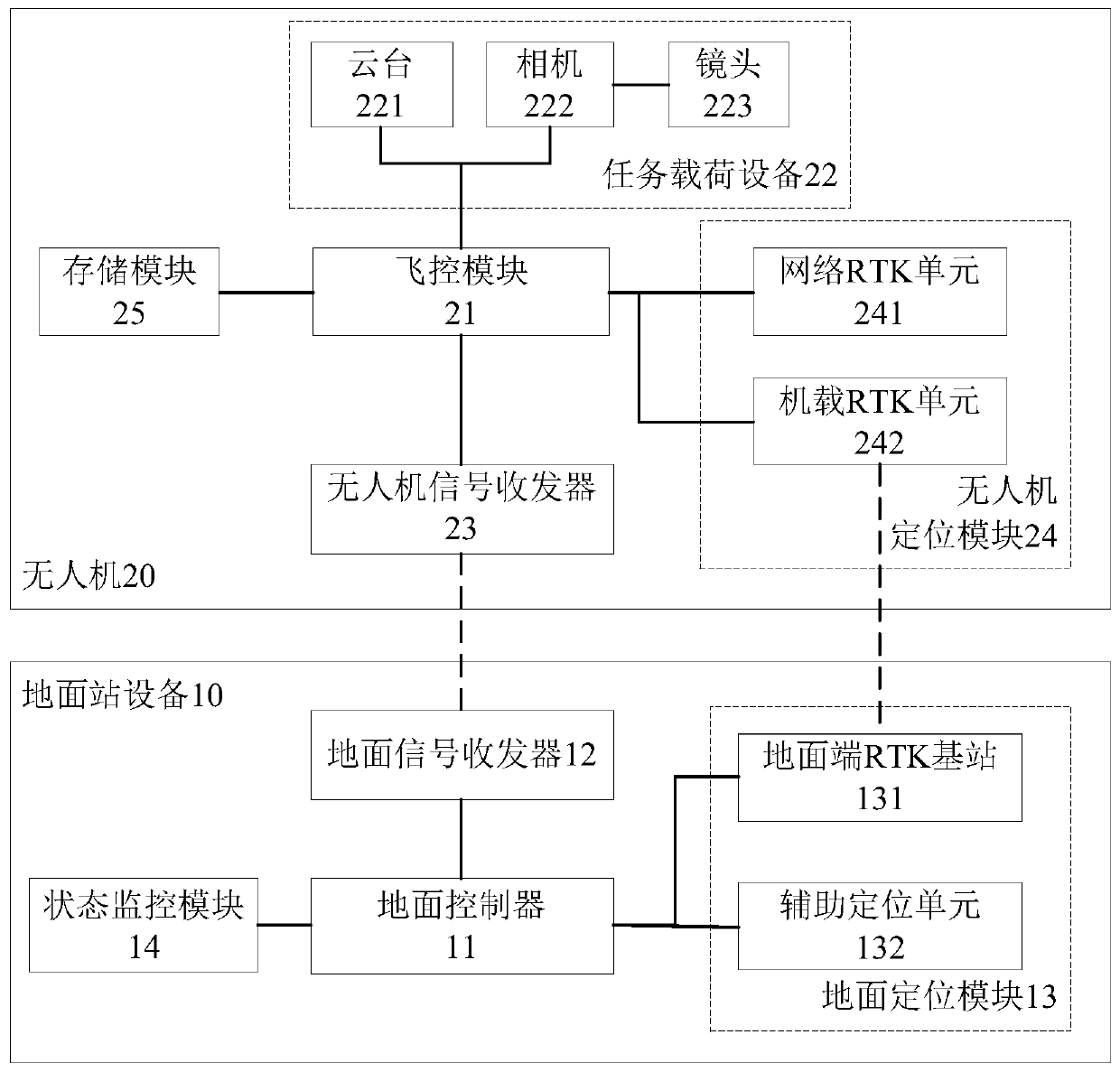

[0047] combine figure 1 , the present invention proposes an autonomous inspection system of a transmission line UAV 20 , the system includes a ground station device 10 , a UAV 20 , and a UAV positioning module 24 .

[0048] The UAV 20 includes a UAV body, a flight control module 21 , a mission load device 22 , and a UAV signal transceiver 23 mounted on the UAV body.

[0049] The flight control module 21 is respectively connected with the mission load device 22 , the UAV signal transceiver 23 , the first UAV positioning module 24 , and the second UAV positioning module 24 .

[0050] The ground station equipment 10 includes a ground controller 11 and a ground signal transceiver 12 connected to each other.

[0051] The ground signal transceiver 12 is connected to the UAV signal transceiver 23, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com