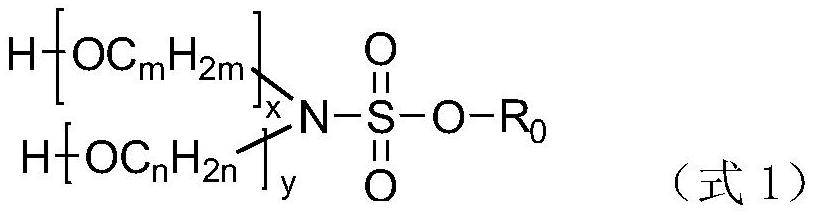

Preparation method and application of N, N-disubstituted sulfamic acid compound

A technology of dihydroxyalkylaminosulfonic acid and dimerized alkoxyaminosulfonic acid, which is applied in the field of chemical industry and can solve problems such as loss of predetermined functions and inability to achieve predetermined functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

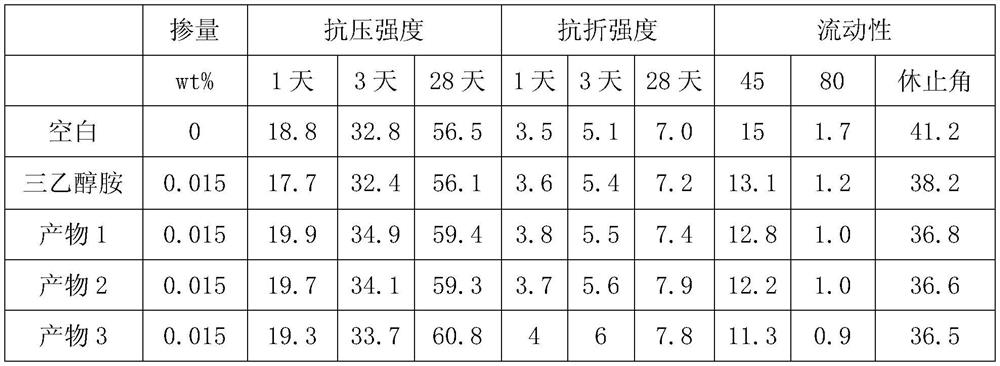

Examples

Embodiment 1

[0054] In this embodiment, sodium sulfamate is used as a substrate to react with ethylene oxide to make sodium dihydroxyethylsulfamate.

[0055] Concrete preparation process is as follows:

[0056] 200 grams, configured as a 55% aqueous solution with deionized water, was put into the reactor; vacuumized to -0.01Mpa, replaced with nitrogen to normal pressure, heated to 40°C, and then 74 grams of ethylene oxide was introduced step by step, React while stirring, and control the temperature in the kettle. As the reaction progresses, the pressure in the reactor first increases and then decreases until the pressure in the reactor is reduced to 0.01Mpa; While reacting, the temperature in the kettle is controlled at 80°C. During the reaction, the pressure in the reactor first increases and then decreases. After the pressure in the kettle drops to 0.01Mpa, keep it warm for 2 hours, vacuumize, discharge, and dry at 110°C , to obtain the product sodium dihydroxyethylsulfamate as a pale ...

Embodiment 2

[0059] In this embodiment, sodium sulfamate is used as a substrate to react with propylene oxide to prepare sodium dihydroxypropylsulfamate.

[0060] Concrete preparation process is as follows:

[0061] Put 200 grams of sodium sulfamate into a 55% aqueous solution with deionized water, and put it into the reactor; vacuumize to -0.01Mpa, replace it with nitrogen to normal pressure, raise the temperature to 50°C, and then introduce propylene oxide step by step 97.6 grams, react while stirring, control the temperature in the still, along with the carrying out of reaction, the pressure in the reaction still first increases and then decreases, until the pressure in the still is reduced to 0.01Mpa; then pass into 102.4 grams of propylene oxide step by step, React while stirring. The temperature in the kettle is controlled at 85°C. During the reaction, the pressure in the reactor first increases and then decreases. After the pressure in the kettle drops to 0.01Mpa, keep it warm for 2...

Embodiment 3

[0064] In this example, sodium sulfamate is used as a substrate, which is reacted with propylene oxide and ethylene oxide in sequence to prepare sodium N,N-hydroxyethyl hydroxypropyl sulfamate.

[0065] Concrete preparation process is as follows:

[0066] Put 200 grams of sodium sulfamate into a 55% aqueous solution with deionized water, and put it into the reactor; vacuumize to -0.01Mpa, replace it with nitrogen to normal pressure, raise the temperature to 50°C, and then introduce propylene oxide step by step 97.6 grams, react while stirring, control the temperature in the kettle, as the reaction proceeds, the pressure in the reactor first increases and then decreases, until the pressure in the kettle is reduced to 0.01Mpa; then feed 77.7 grams of ethylene oxide step by step , react while stirring, the temperature in the kettle is controlled at 75°C, during the reaction process, the pressure in the reactor first increases and then decreases, until the pressure in the kettle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com