Preparation method of teflon composite material

A technology of polytetrafluoroethylene and composite materials, applied in the field of preparing PTFE composite materials, can solve the problems of difficult to mix evenly with fillers, loss of filler particles, restricting the performance of PTFE composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

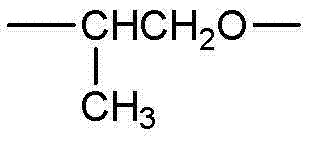

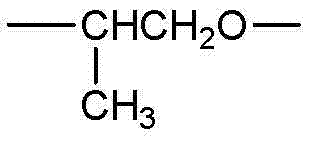

Image

Examples

Embodiment 1

[0040] Embodiment 1, a kind of method for preparing polytetrafluoroethylene composite material, carry out following steps successively:

[0041] 1) Add 1KG deionized water and 2 grams of sodium lauryl sulfate to a 2L glass beaker at room temperature (about 15~25°C), stir (speed 800 rpm) for 5 minutes, then add 495 grams of PTFE (particle size 50 μm), continue to stir for 10 minutes, add 5 grams of nano-Al modified by silane coupling agent KH560 2 o 3 (particle size of 50 nm), stop stirring after 15 minutes.

[0042] The above-mentioned nano-Al modified by silane coupling agent KH560 2 o 3 The preparation method is as follows:

[0043] Add 50 ml of absolute ethanol, 10 g of nano-alumina (particle size: 50 nm), and 0.4 g of silane coupling agent KH560 to a 200 ml single-necked bottle, and stir at 25°C for 1 hour, then centrifuge to remove absolute ethanol and solid Wash with deionized water three times, each time with 50 ml of deionized water, and then dry at 120 °C for 6 h...

Embodiment 2

[0050] Embodiment 2, a kind of method for preparing polytetrafluoroethylene composite material, carry out following steps successively:

[0051] 1) Add 1KG deionized water and 200mg ammonium perfluorooctanoate to a 2L glass beaker at room temperature (about 15~25°C), stir for 5 minutes, add 495g PTFE (particle size: 50 μm), and continue stirring for 10 minutes. Add 5 grams of nano-Al modified by silane coupling agent KH560 2 o 3 (50 nm), stirring was stopped after 15 minutes.

[0052] The above-mentioned nano-Al modified by silane coupling agent KH560 2 o 3 The preparation method is with embodiment 1.

[0053] 2), with embodiment 1.

[0054] The tensile properties and friction and wear properties of the composite material are tested according to the national standard HGT 2902-1997 and GB-T3960-1983 respectively, in which:

[0055] Tensile strength: 30.48 MPa,

[0056] Elongation at break: 428%,

[0057] Consumption: 50.7 mg,

[0058] Friction coefficient: 0.18.

Embodiment 3

[0059] Embodiment 3, a kind of method for preparing polytetrafluoroethylene composite material, carry out following steps successively:

[0060] 1) Add 1KG deionized water and 2 grams of non-ionic surfactant L44 (a copolymer of ethylene glycol and propylene glycol, with an average molecular weight of 2200, purchased from Nantong) into a 2L glass beaker at room temperature Xinbaoyuan Chemical Co., Ltd.), after stirring for 5 minutes, add 495 grams of PTFE (particle size is 50 μm), continue stirring for 10 minutes, add 5 grams of nano-Al modified by silane coupling agent KH560 2 o 3 (50 nm) and stop stirring after 15 min.

[0061] The above-mentioned nano-Al modified by silane coupling agent KH560 2 o 3 The preparation method is with embodiment 1.

[0062] 2), with embodiment 1.

[0063] The tensile properties and friction and wear properties of the composite material are tested according to the national standard HGT 2902-1997 and GB-T3960-1983 respectively, in which:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com