Novel insulating base for ore-smelting electric furnace

A submerged heat electric furnace and insulating seat technology, which is applied in the direction of insulators, lighting and heating equipment, etc., can solve problems such as poor insulation effect, and achieve the effects of long service life, enhanced compatibility, and weakened agglomeration tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

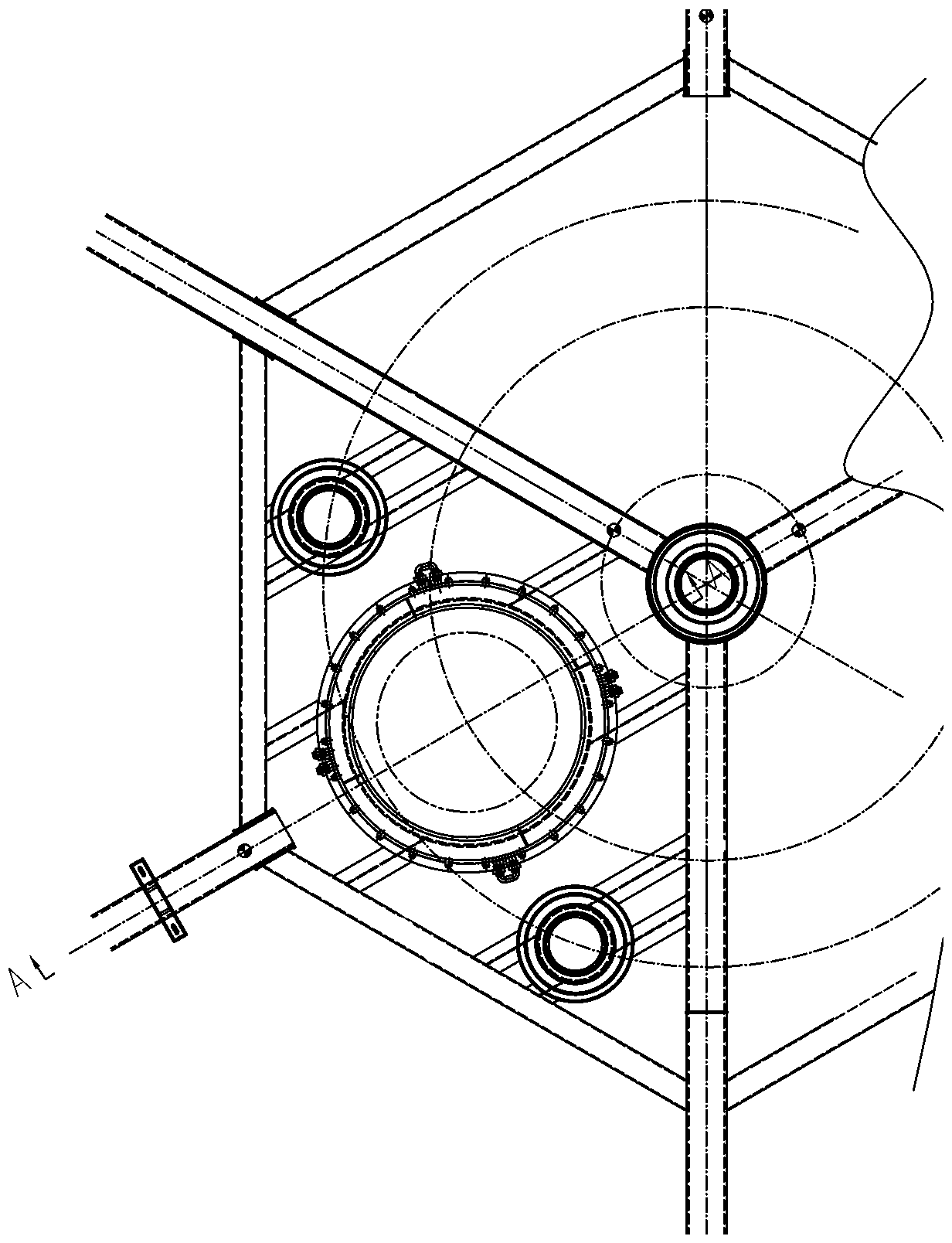

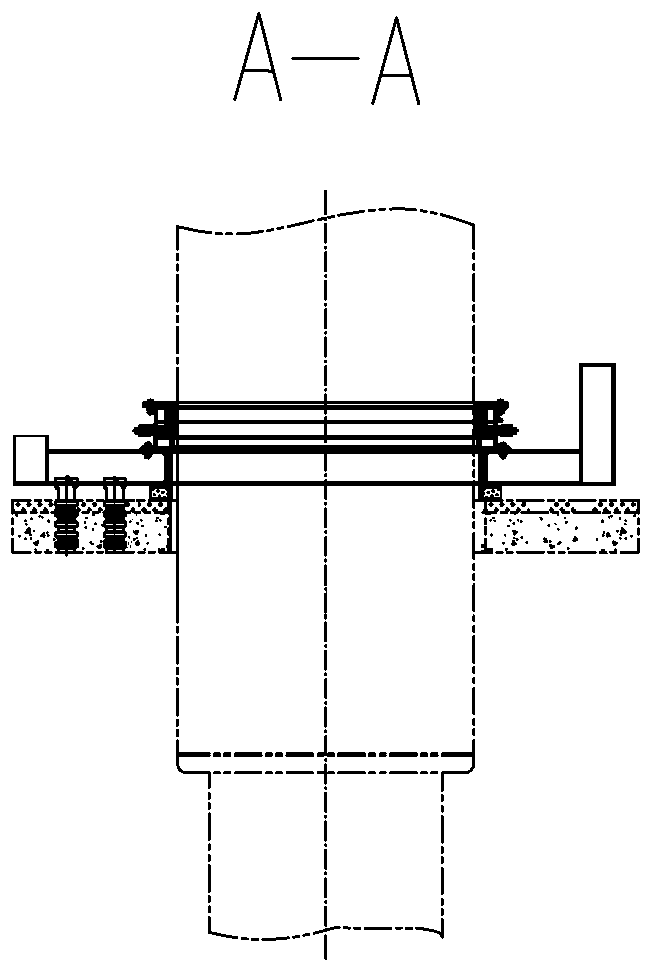

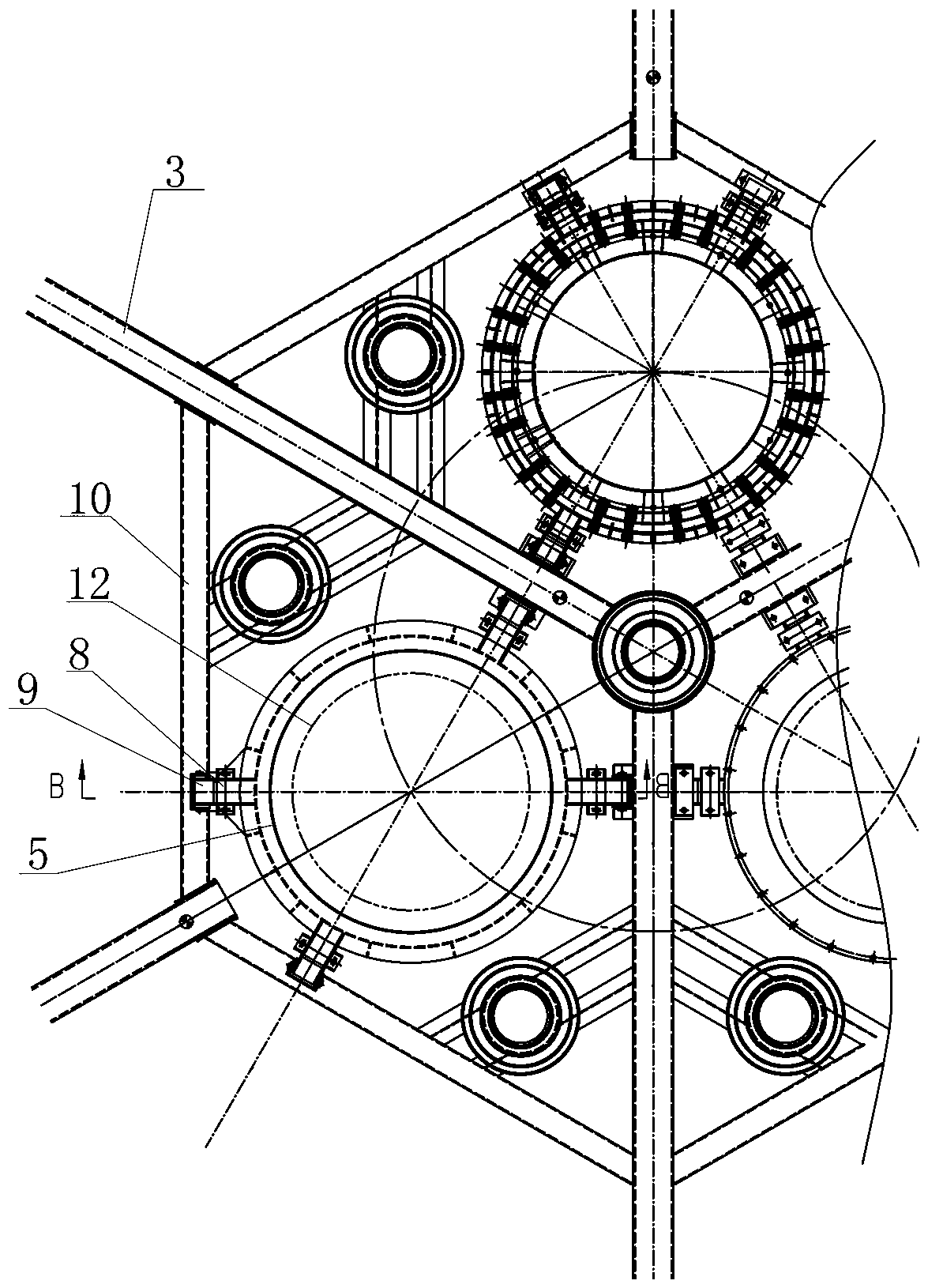

[0028] refer to Figure 1 to Figure 4 , the present invention includes a furnace cover 12; the furnace cover 12 is plugged with the electrode shield 11 through the jack 13 at its top; the main points are:

[0029] The top of the furnace cover 12 is provided with a sealing ring base 1 corresponding to the aperture of the jack 13, and the outer diameter of the sealing ring base 1 is provided with a support frame 2; The screen 11 corresponds to the sealing ring II6 that fits and plugs in, and the outer diameter of the sealing ring II6 is fixedly connected to the support frame 2; the top of the sealing ring II6 is provided with a sealing brick ring that fits and plugs in correspondingly to the electrode shield 11 4;

[0030] The outer diameter of the sealing brick ring 4 is provided with an insulating box II8, and the outer diameter of the sealing brick ring 4 is elastically connected to the insulating box II8 through a pre-tension spring 7; the insulating box II8 and the support...

Embodiment 2

[0037] A sealing brick ring material, which is prepared according to the following process:

[0038]Add nano-diatomaceous earth, nano-zeolite powder and dibutyl maleate into the stirring tank in turn, and stir while heating. When the temperature reaches 80°C, add tetrabutyl titanate, and continue stirring for 30 minutes under the condition of heat preservation, and then Cool down to 60°C, add polyolefin elastomer, and continue to stir for 60 minutes to obtain modified polyolefin elastomer; wherein, the nano diatomaceous earth, nano zeolite powder, dibutyl maleate, tetrabutyl titanate and poly The mass ratio of olefin elastomer is 10:7:2:3:78;

[0039] Add talcum powder, sodium tripolyphosphate, sodium dodecylsulfonate, phthalate, polyvinyl alcohol and modified polyolefin elastomer in a mass ratio of 1:2:2:5:10:70 Put it into the mixing tank, raise the temperature to 75°C, and stir at 200rpm for 30 minutes; then raise the temperature to 90°C, continue to stir at 200rpm for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com