Evaporating crystallizer

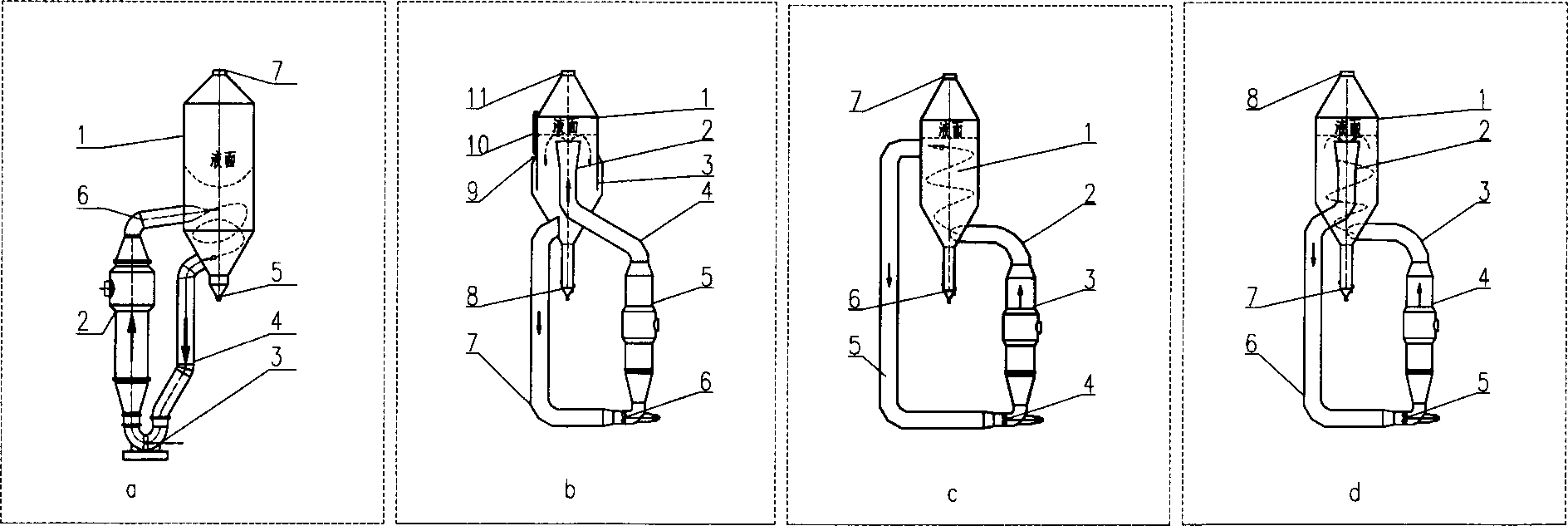

The technology of evaporative crystallizer and evaporation chamber is applied in the field of evaporative crystallizer tank for the middle inlet and outlet of salt production, which can solve the problems of poor clear liquid drainage, waste of supersaturation, etc., so as to prolong the normal production cycle and prolong the operation. Routes, Effects of Extended Stays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

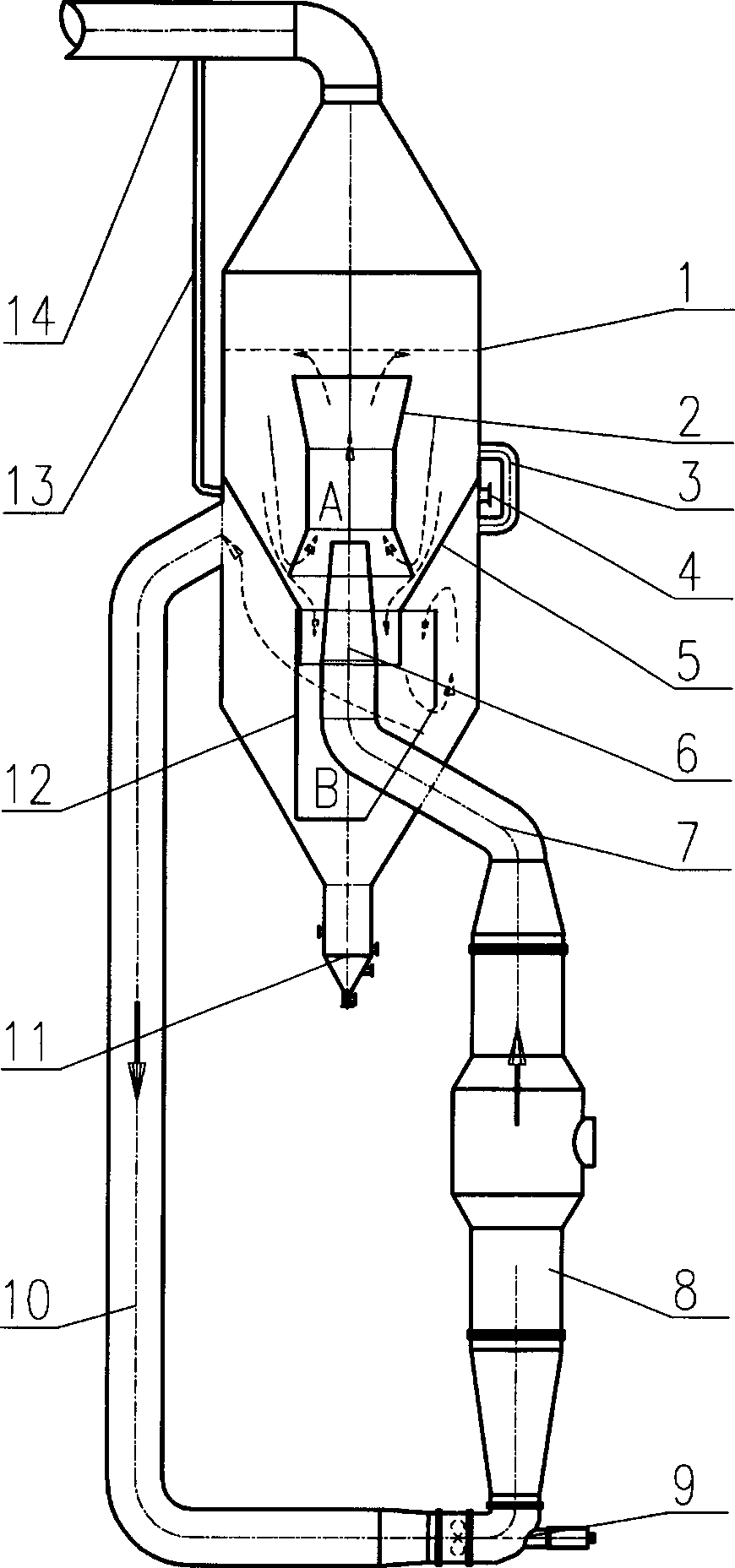

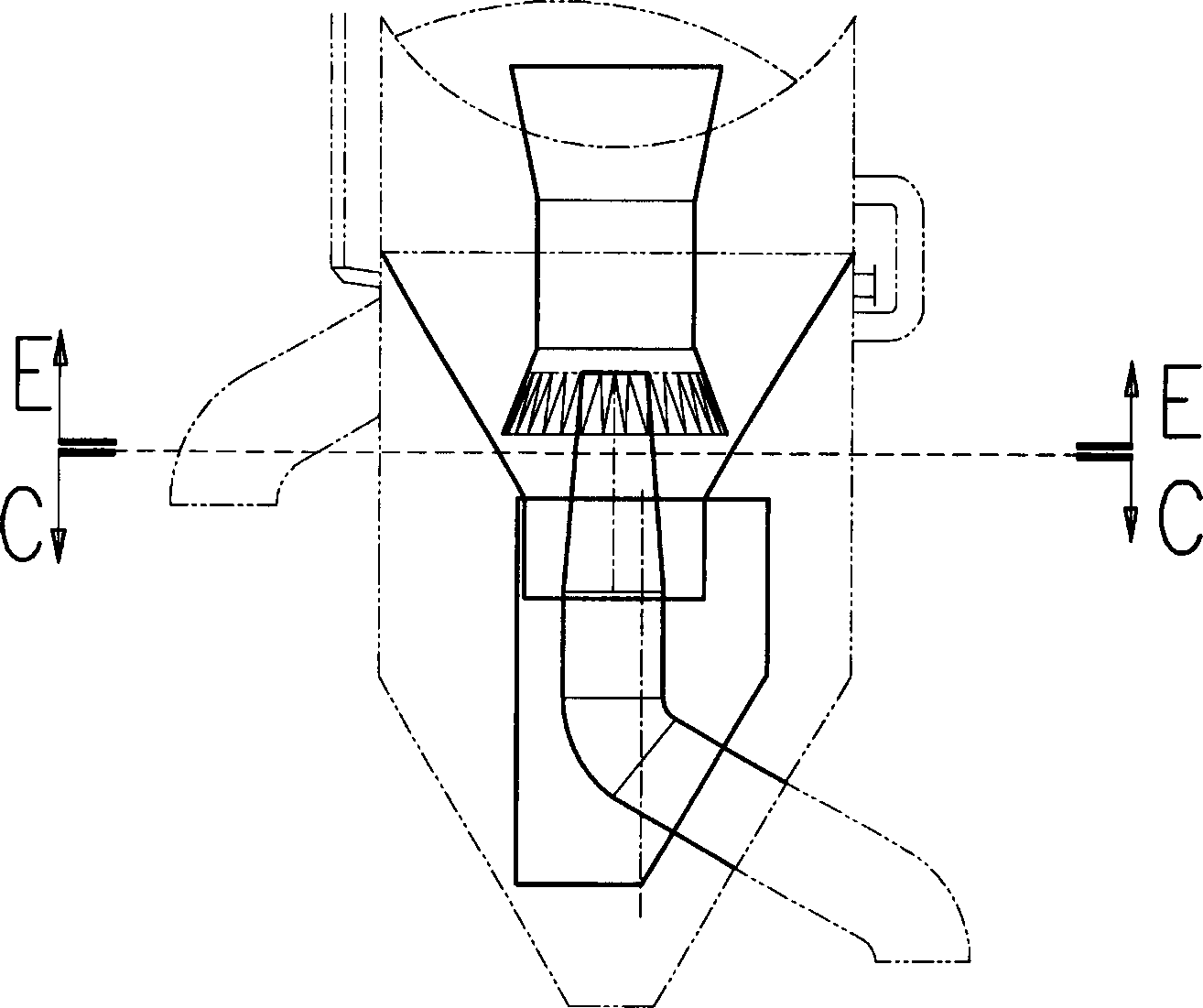

[0080] In the first effect of the 4-effect vacuum salt production evaporation, the internal and external circulation evaporation crystallization tank with the material in and out of the middle part is used. The tank consists of an evaporation chamber 1, a central drainage tube 2, a balance pipe 3, a clear liquid transfer pipe 4, a cone in the evaporation chamber 5, an outer circulation feeding nozzle 6, an upper circulation pipe 7, a heating chamber 8, a forced circulation pump 9, a lower It is composed of circulation pipe 10, salt foot 11, baffle tube 12 of crystal growth settling chamber, exhaust pipe 13, secondary steam pipe 14 and other conventional accessories.

[0081] The height of the cylinder of the evaporation chamber is 11 meters, and the inner diameter is 7 meters. An inner cone (cone angle 60°) is installed at a distance of 5.3 meters from the upper opening of the cylinder; the outlet pipe of the inner cone has a diameter of 2.5 meters and a height of 1.3 meters; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com