532nm parallel connection beam combination laser

A technology of lasers and beam combiners, which is applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems of low yield rate, difficult adjustment, and low beam quality of processed parts, so as to facilitate the arrangement of optical paths and improve cutting efficiency. The effect of precision, high beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

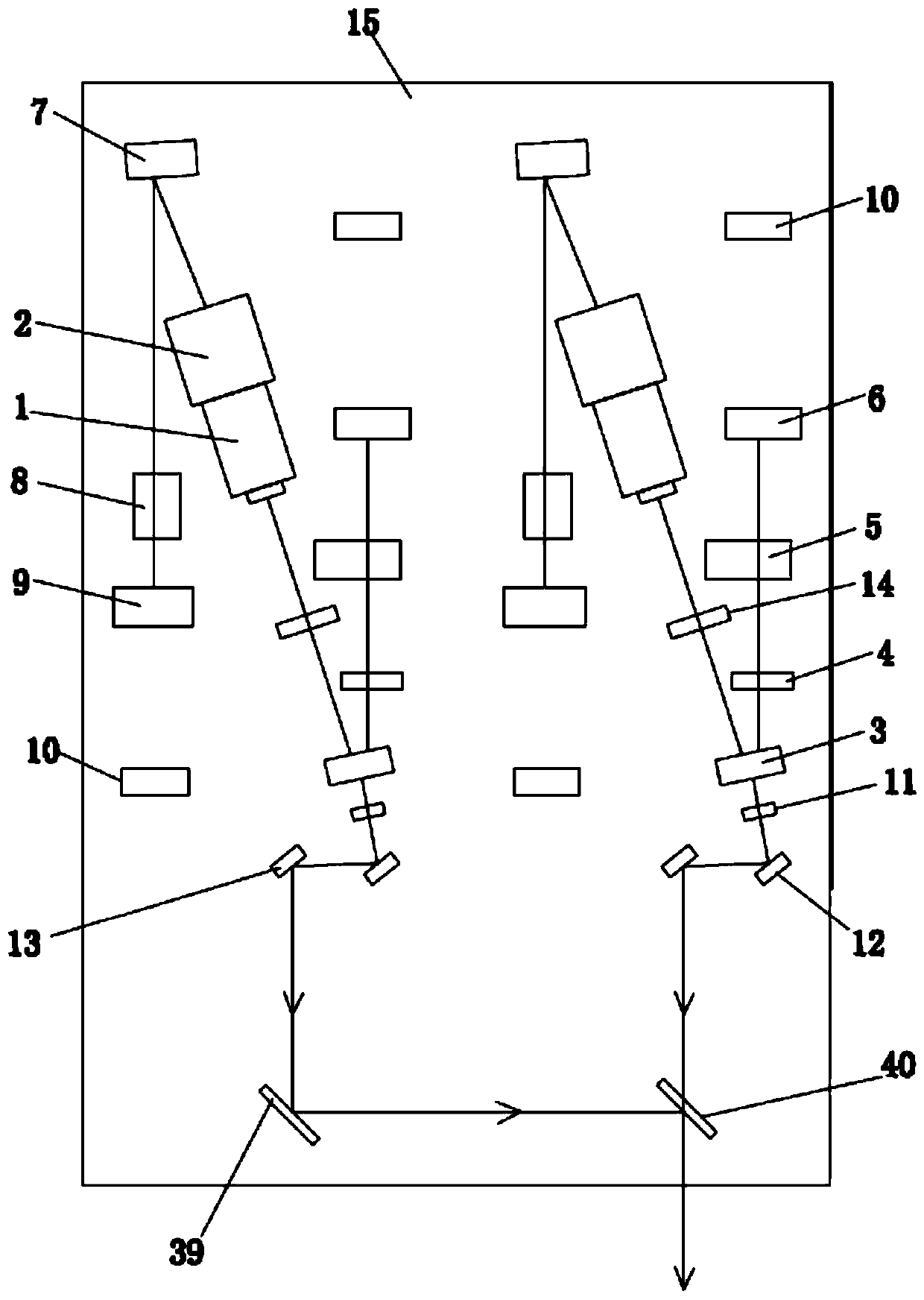

[0025] The specific embodiment of the present invention is as figure 1 As shown, a 532nm parallel combined beam laser includes a housing 15, and the housing 15 is provided with two Z-shaped resonators arranged side by side, and the Z-shaped resonator includes adjacently arranged acousto-optic Q switches 2 and 1064nm laser modules 1 and a resonant lens group for converting 1064nm light into 532nm light, and a wave plate 11 is provided at the output end of the Z-shaped resonant cavity. A laser beam combiner mirror group is provided on the output side of the two Z-shaped resonant cavities, and the combined laser beam is emitted from the light outlet of the casing 15 . The acousto-optic Q switch 2 is used to convert the continuous laser power output into laser pulse output with high peak power.

[0026] In this embodiment, the two Z-shaped resonant cavities are arranged left and right, and can also be arranged up and down. The output ends of the two Z-shaped resonators face the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com