Disc piece solid laser

A solid-state laser and laser technology, applied in the field of lasers, can solve the problems of complex mechanical structure and high difficulty in optical adjustment, and achieve the effect of simple mechanical structure and adjustment, small drift of spot position, and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

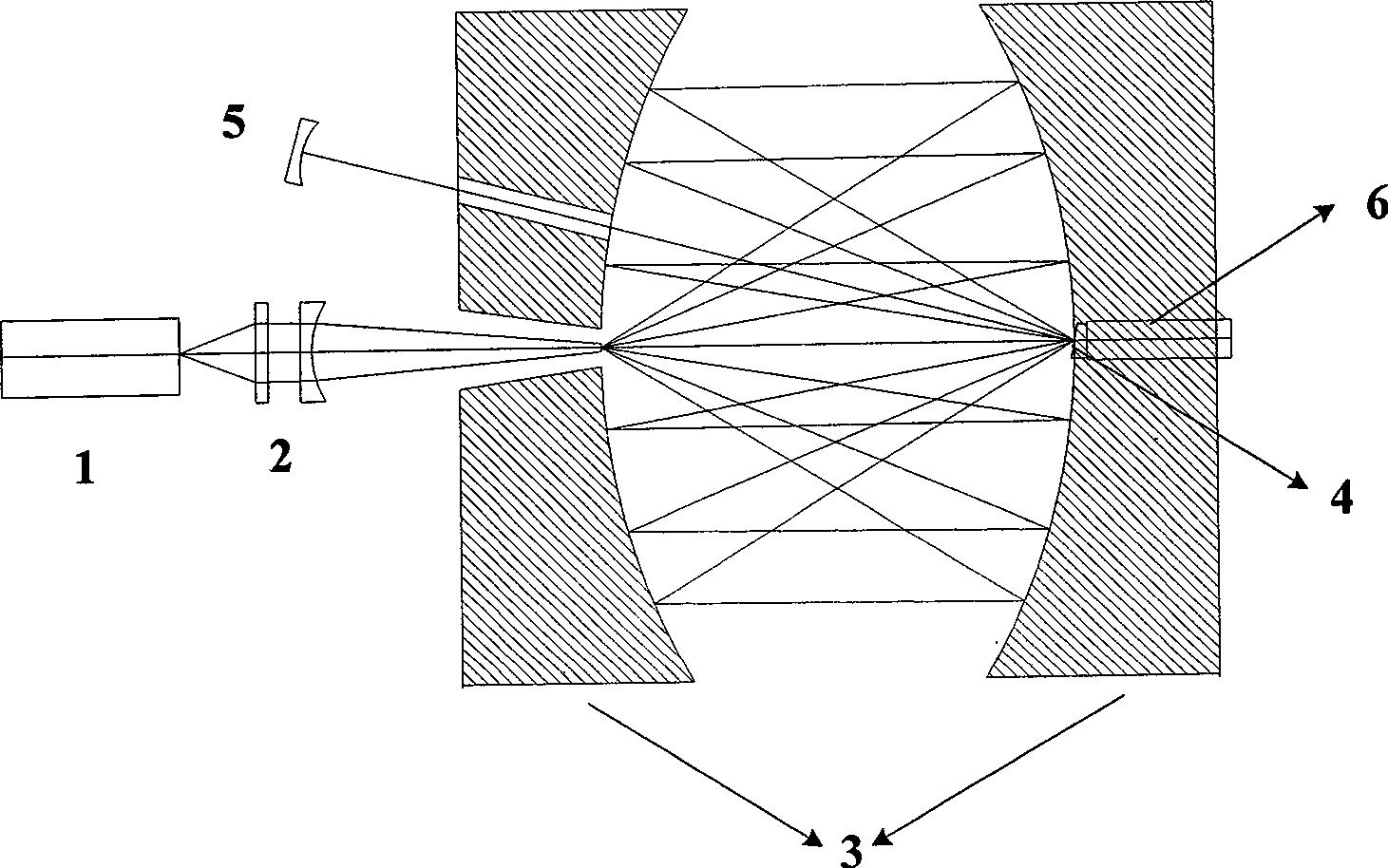

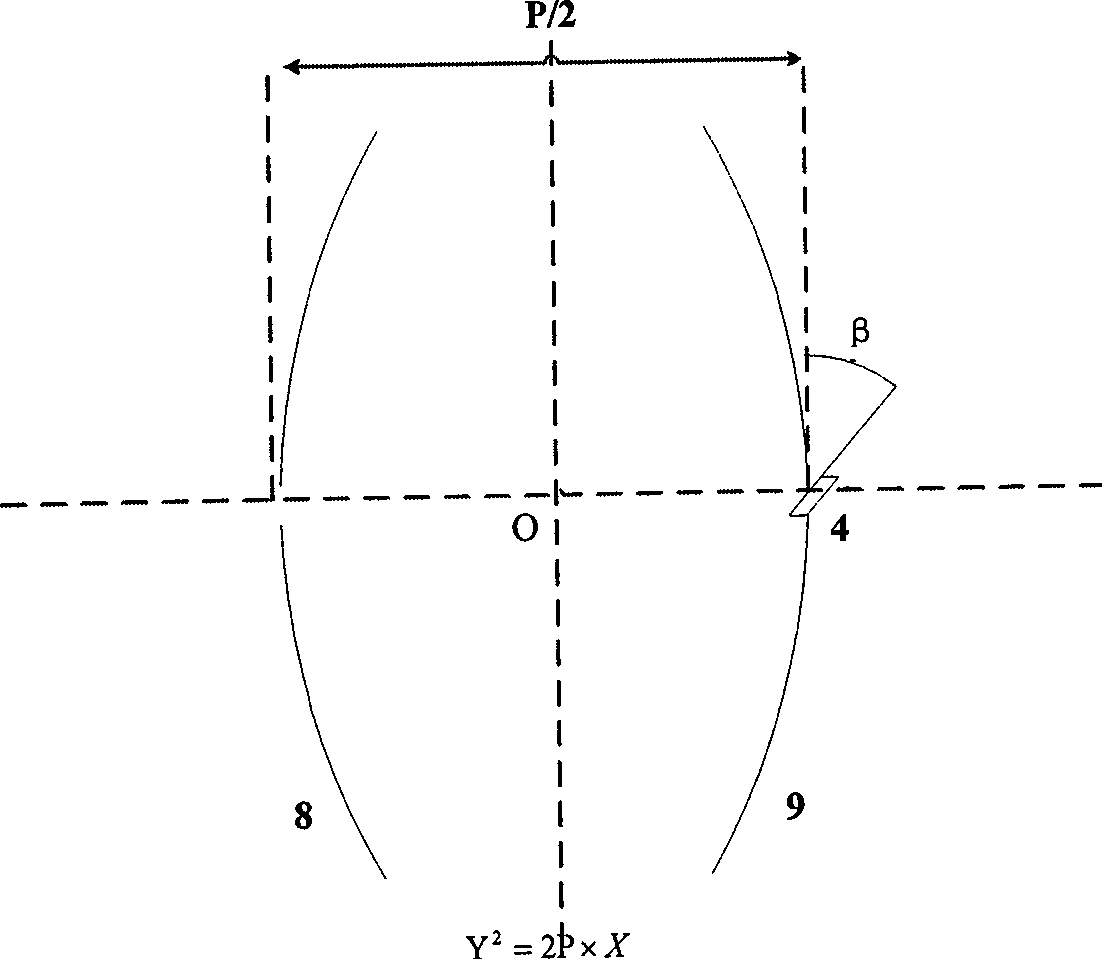

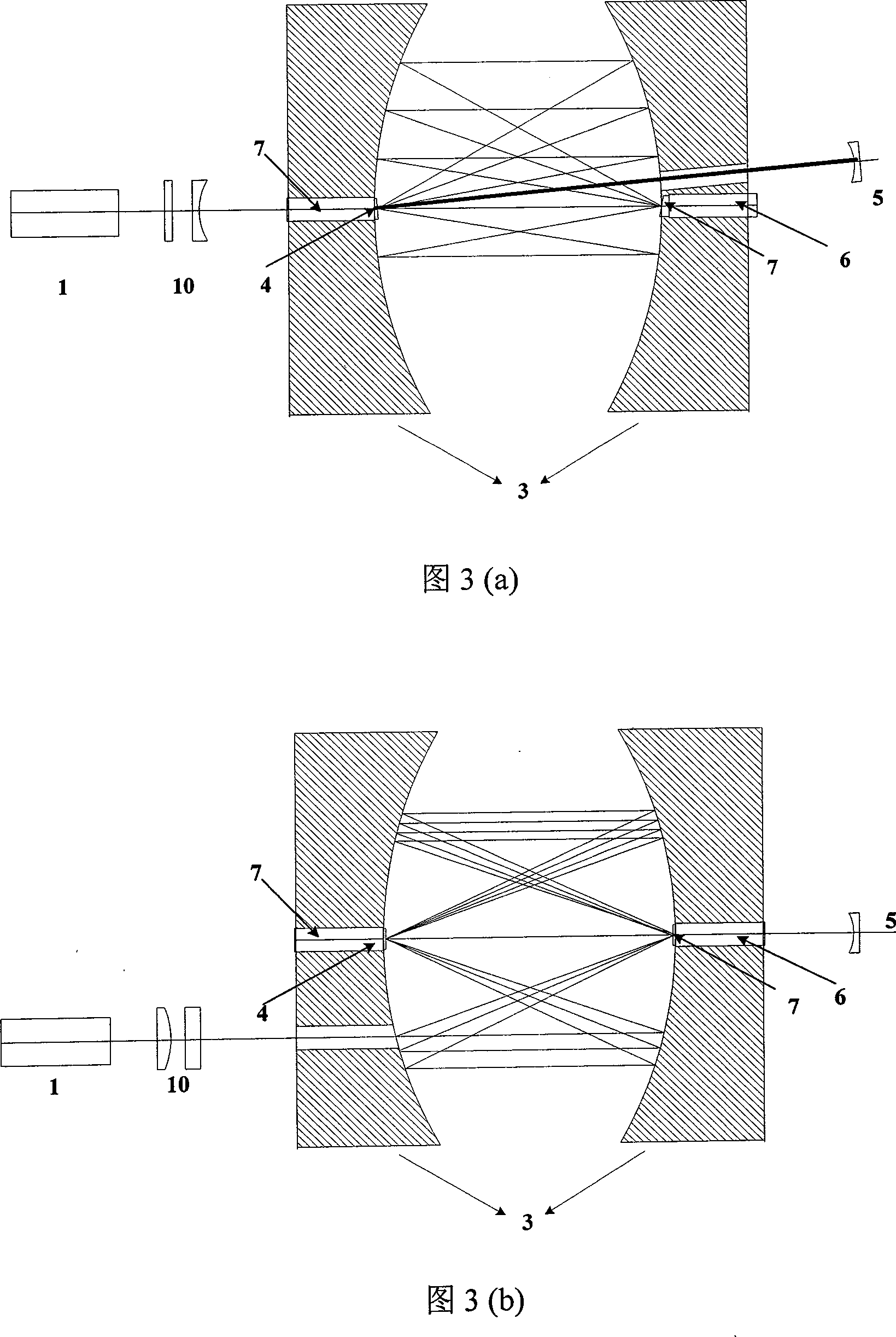

[0015] The invention adopts semiconductor laser array stack as pumping source, double parabolic mirrors placed in conjugates as light collecting cavity, utilizes the imaging characteristics of double parabolic mirrors placed in conjugates to realize high-efficiency pumping of light spots. In Scheme 1, the pump spot is imaged on the focal point of one paraboloid in the conjugated double parabolic mirror through the collimation imaging system, and a disc-shaped laser crystal is placed on the focal point of the other parabolic mirror. Dual parabolic mirrors image and confine the light for efficient pumping. The invention improves the performance index of the solid-state laser. In Scheme 2, the deflection compensation mirror and the inclined disc crystal are used to realize the translation and adjustment of the spatial position of the pump beam entering the conjugated double-parabolic reflective concentrator cavity after alignment, and the addition of discs The pumping times of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com