Bragg refractive waveguide edge transmitting semiconductor laser with low horizontal divergence angle

A technology of Bragg reflection and divergence angle, which is applied to the structure of optical waveguide semiconductors, etc., can solve the problems of complex far-field patterns, epitaxial growth, preparation process, demanding working current and temperature, narrow lateral far-field divergence angle, etc., to achieve Improve the effect of catastrophic damage on the end face, stable single transverse mode operation, and large gain and loss difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

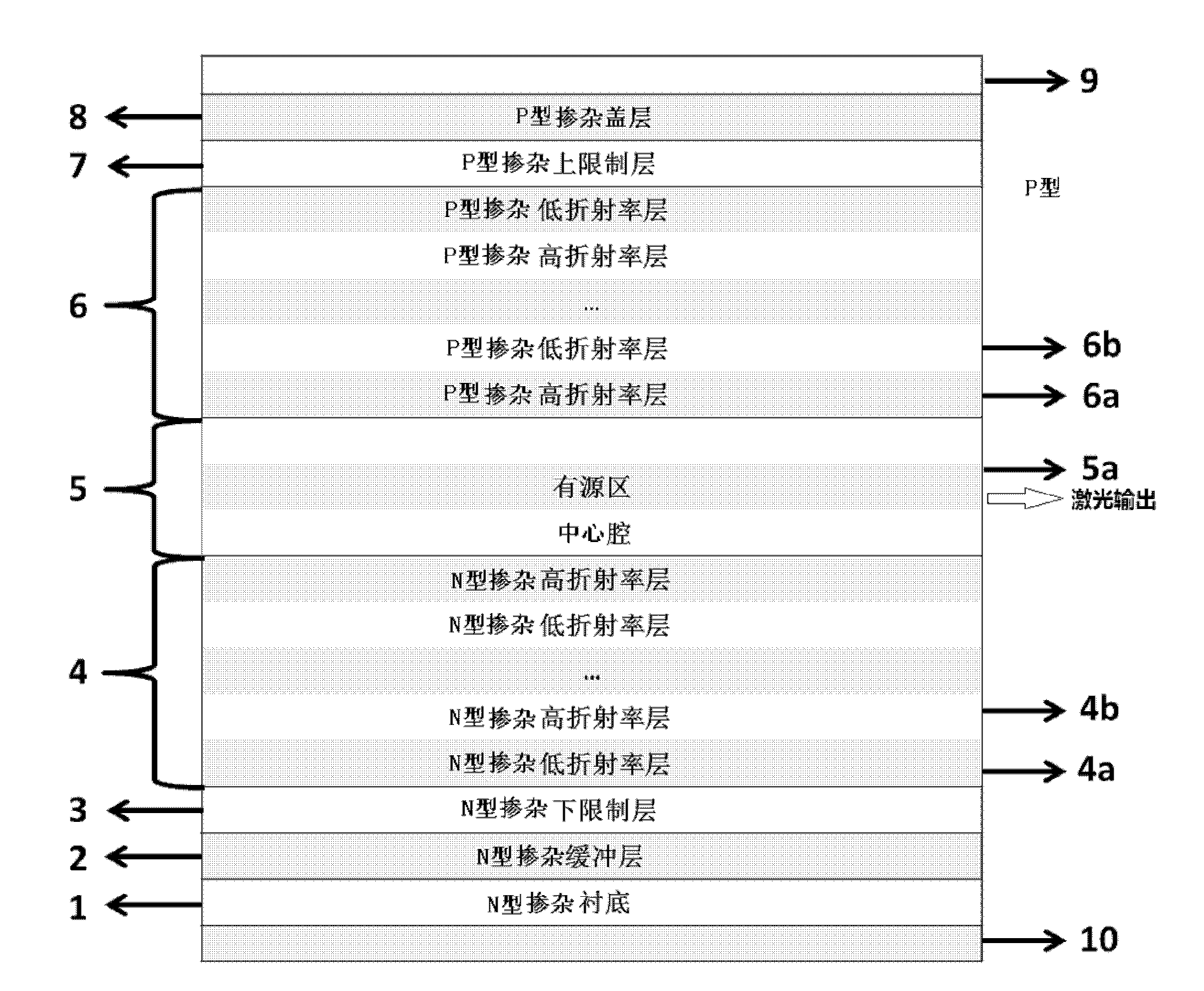

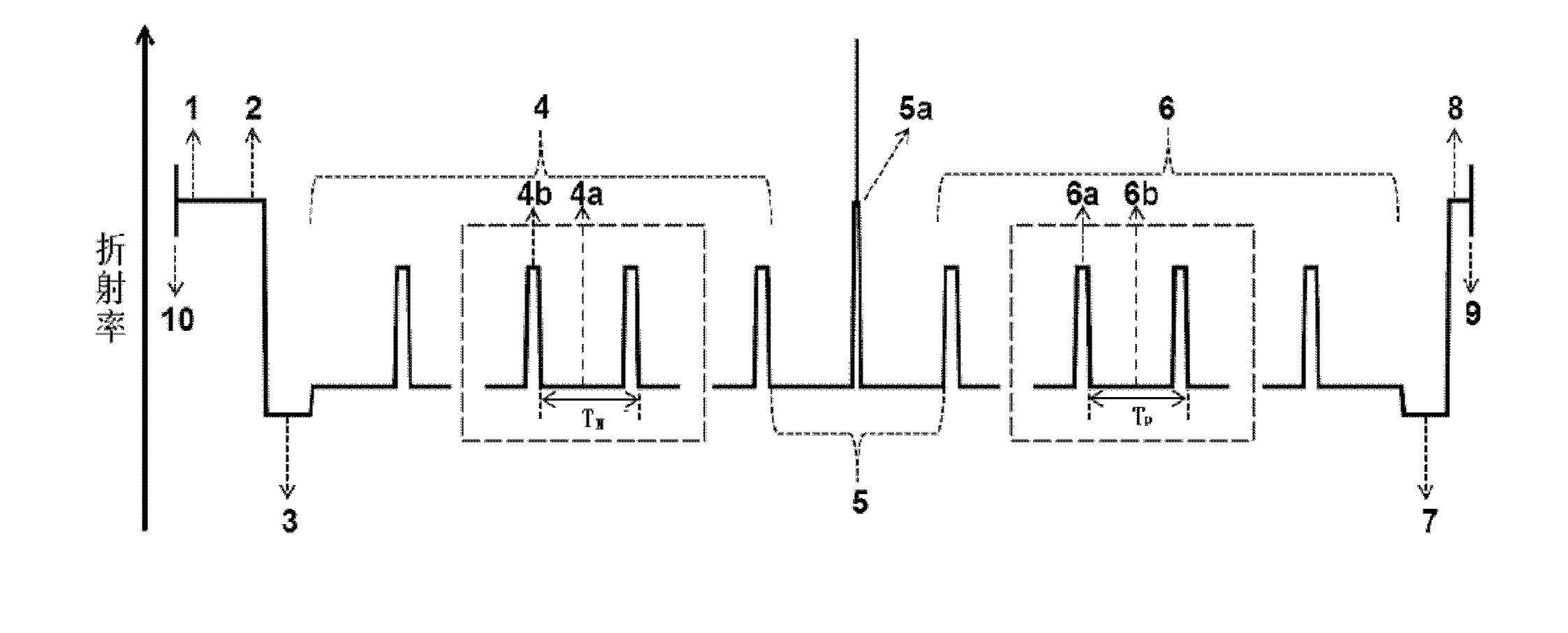

[0047] Such as Figure 3(a) , 3(b) , 3(c) is a schematic diagram of the refractive index distribution, fundamental transverse mode near-field and far-field distribution of a symmetrical low lateral divergence Bragg reflective waveguide edge-emitting semiconductor laser (wavelength 980nm). Its N-plane and P-plane waveguides both use 6 pairs of Al 0.1 Ga 0.9 As / Al 0.3 Ga 0.7 As periodic waveguide, the arrangement period T of the high and low refractive index layers of the lower waveguide layer 4 N The high and low refractive index layers of the upper waveguide layer 6 are arranged with a period T P Equal, the material and thickness of the high and low refractive index layers in each cycle of the upper waveguide layer 6 and the lower waveguide layer 4 are respectively the same. The active area is located in the center of the central cavity, using In 0.2 Ga 0.8 As / GaAs double quantum wells (QWs). As can be seen from the near-field distribution of the fundamental mode in F...

Embodiment 2

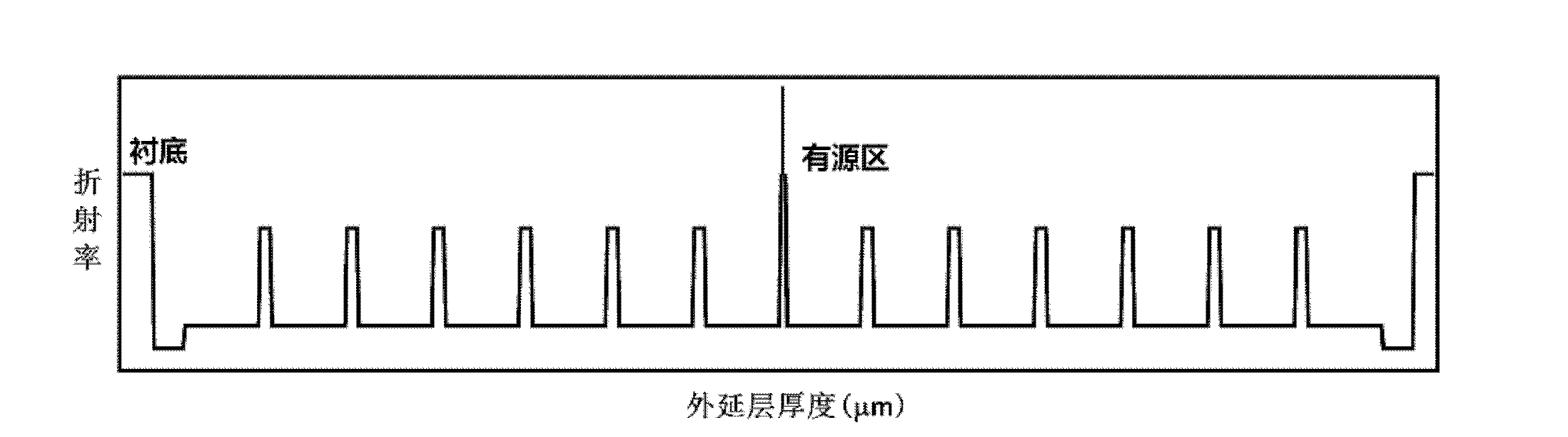

[0049] Such as Figure 4(a) , 4(b) , 4(c) is a schematic diagram of the refractive index distribution, the near-field and far-field distribution of the fundamental transverse mode of an asymmetric low lateral divergence Bragg reflective waveguide edge-emitting semiconductor laser (wavelength is 980nm), and its N surface and P-plane waveguides respectively use 8 pairs and 4 pairs of Al 0.1 Ga 0.9 As / Al 0.3 Ga 0.7 As periodic waveguide; the material and thickness of the high and low refractive index layers in each period of the lower waveguide layer 4 and the upper waveguide layer 6 are the same, but the period logarithm of the upper waveguide layer 6 is smaller than that of the lower waveguide layer 4 . The active area uses In 0.2 Ga 0.8 As / GaAs double quantum wells (QWs). In the figure, 4(a) is the refractive index distribution, 4(b) and 4(c) are the transverse near-field distribution and far-field distribution of the fundamental transverse mode, respectively. It can b...

Embodiment 3

[0051] Such as Figure 5 As shown, it is a schematic diagram of the refractive index distribution of an asymmetric low lateral divergence Bragg reflective waveguide edge-emitting semiconductor laser, the high refractive index layer 4b in its lower waveguide layer 4 and the high refractive index layer in the upper waveguide layer 6 6a. The material and thickness of the low refractive index layer 4a in the lower waveguide layer 4 and the low refractive index layer 6b in the upper waveguide layer 6 are not exactly the same, and the period logarithms in the two waveguide layers can be the same or different . The central cavity 5 is located between the lower waveguide layer 4 and the upper waveguide layer 6, and is a defect layer common to the two photonic crystals. Its refractive index and thickness are not exactly the same as those of any layer in the period of the lower waveguide 4 and the upper waveguide 6. The defect layer is designed so that the lateral transmission constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com