Sliding bearing bush material and preparation method thereof

A technology for sliding bearings and bushings, which is applied in the field of electric arc and semi-solid composite additive manufacturing processes, can solve problems such as black oxide inclusions and pores, tin-based alloys are prone to spatter, and weld quality is more limited, so as to reduce tooling Effect of cost and machining allowance, improvement of welding efficiency and arc density, improvement of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples, but the scope of the present invention will not be limited thereby.

[0025] Application: The bearing shell of the heavy-duty main shaft bearing for the rated power of 300MW hydroelectric generating set, the specification is φ1600mm×φ1400mm×1200mm.

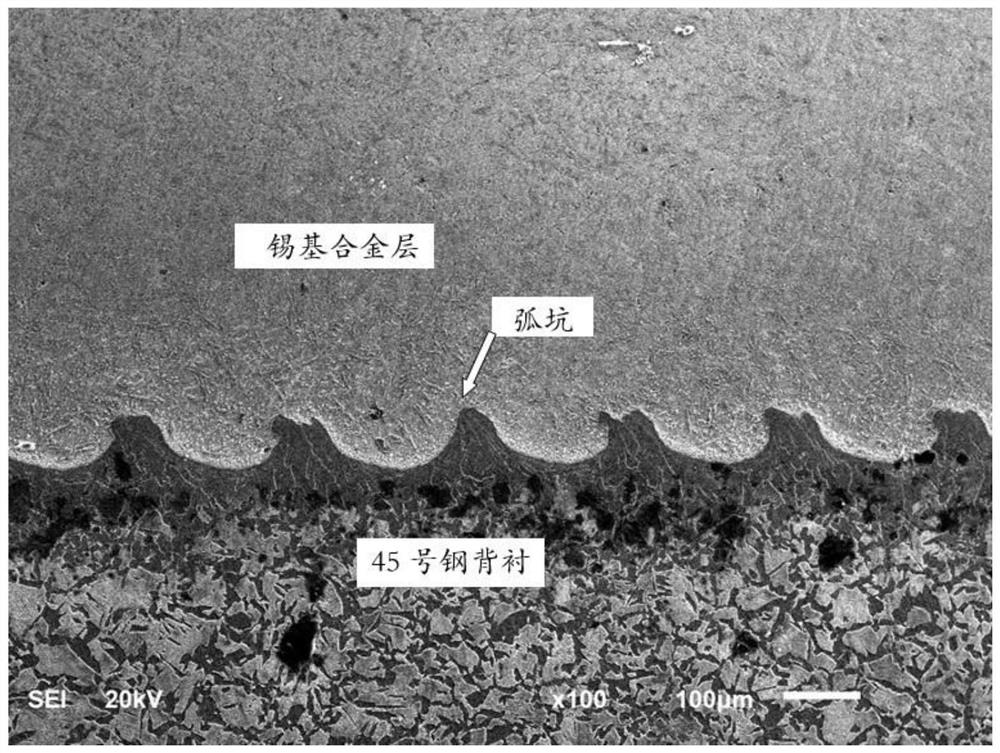

[0026] Technical requirements: The steel back is made of No. 45 steel, and the total thickness of the Babbitt bonding layer and the friction-reducing layer is 100mm.

[0027] Preparation:

[0028] (1) Clean the No. 45 steel backing, degrease, derust, and dry.

[0029] (2) bonding layer deposition

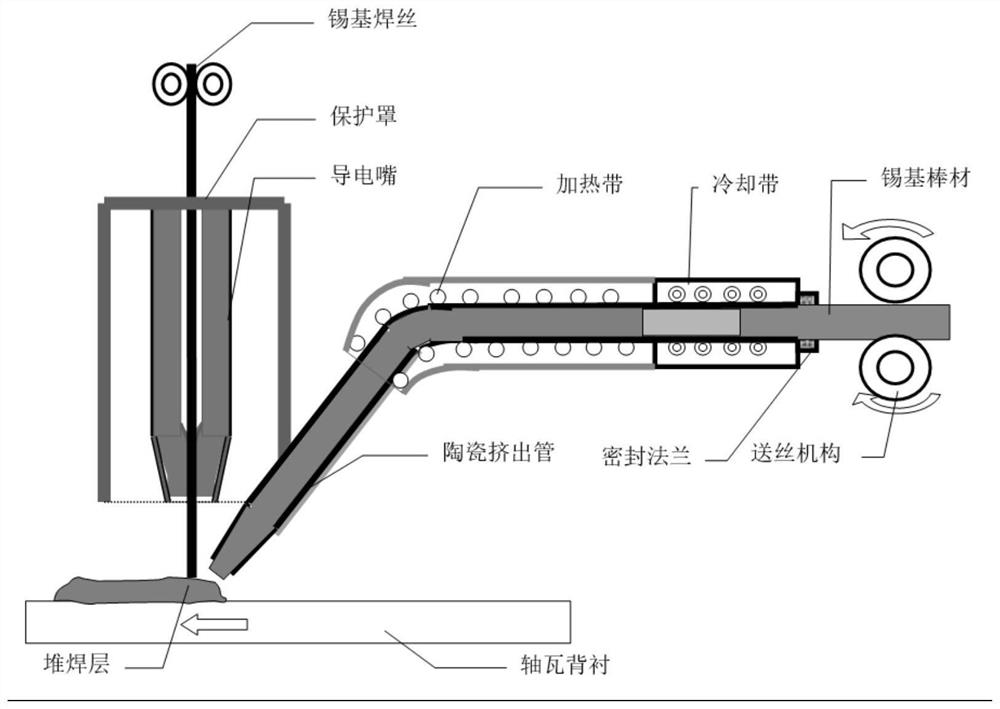

[0030] like figure 1 As shown, the angle between the welding torch of MIG welding and the extruded tube of semi-solid slurry ceramics is downward and the axis is 20-30° (that is, the angle between the extruded tube and the horizontal plane is 60-70°), and the current of the welding torch is set It is 200A, the voltage is 19V, the diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com