Soup dumplings

A technology for dumplings and soup filling, which is applied to machinery or equipment for baking, dough forming, dough processing, etc. Stuffing mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

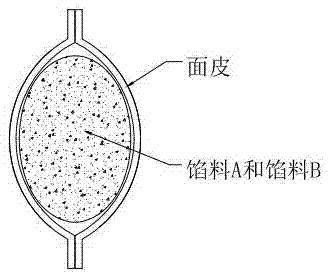

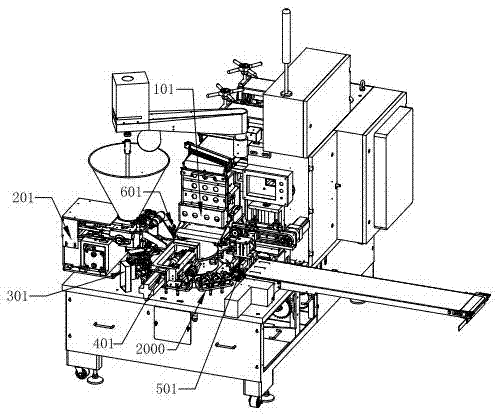

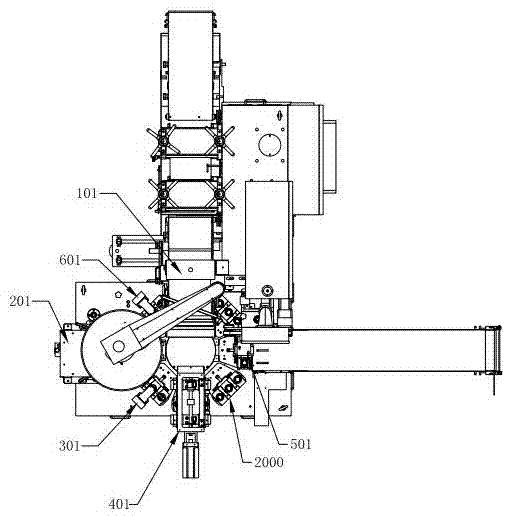

[0119] A dumpling filled with soup includes a dough skin, the two sides of the left end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000, and the two sides of the right end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000. The dough is wrapped with the solid filling material injected from the first filling device 201 and the liquid filling material injected from the second filling device 301, the top part of the dough skin is pressed and connected by the molding device 401, and the dough skin is in a sealed state as a whole .

[0120] The soup-filled dumplings of the present application can realize that the dumplings are wrapped with solid fillings and liquid fillings in the dough after automatic production, avoiding that in the prior art, all the liquid fillings in the soup-filled dumplings are frozen into solid Defects that are then wrapped in dough. The existing tech...

Embodiment 2

[0122] A dumpling filled with soup includes a dough skin, the two sides of the left end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000, and the two sides of the right end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000. The dough is wrapped with the solid filling material injected from the first filling device 201 and the liquid filling material injected from the second filling device 301, the top part of the dough skin is pressed and connected by the molding device 401, and the dough skin is in a sealed state as a whole .

[0123] The dough is round or rectangular. The shape of the specific dough can be adjusted at any time according to actual production needs.

[0124] The liquid and solid fillings inside the dough are mixed with each other. That is, the mixing of the fillings occurs after filling, not before filling.

[0125] The liquid filling is formed by mixi...

Embodiment 3

[0132] A dumpling filled with soup includes a dough skin, the two sides of the left end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000, and the two sides of the right end of the dough are connected by pressing and connecting with multiple filling primary forming molds 2000. The dough is wrapped with the solid filling material injected from the first filling device 201 and the liquid filling material injected from the second filling device 301, the top part of the dough skin is pressed and connected by the molding device 401, and the dough skin is in a sealed state as a whole .

[0133] The dough is round or rectangular. The shape of the specific dough can be adjusted at any time according to actual production needs.

[0134] The liquid and solid fillings inside the dough are mixed with each other. That is, the mixing of the fillings occurs after filling, not before filling.

[0135] The liquid filling is formed by mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com