Rubberizing device and rubberizing method thereof, cylindrical battery cell flaking winding machine

A glue sticking device and sticking technology, which is applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, circuit, etc., can solve the problem that the cell is easily compacted too tightly, which affects the overall time of sticking and affects the quality of the cell. and other problems, to achieve the effect of ensuring the quality of the glue, preventing the compaction from being too tight, and ensuring the quality of the winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

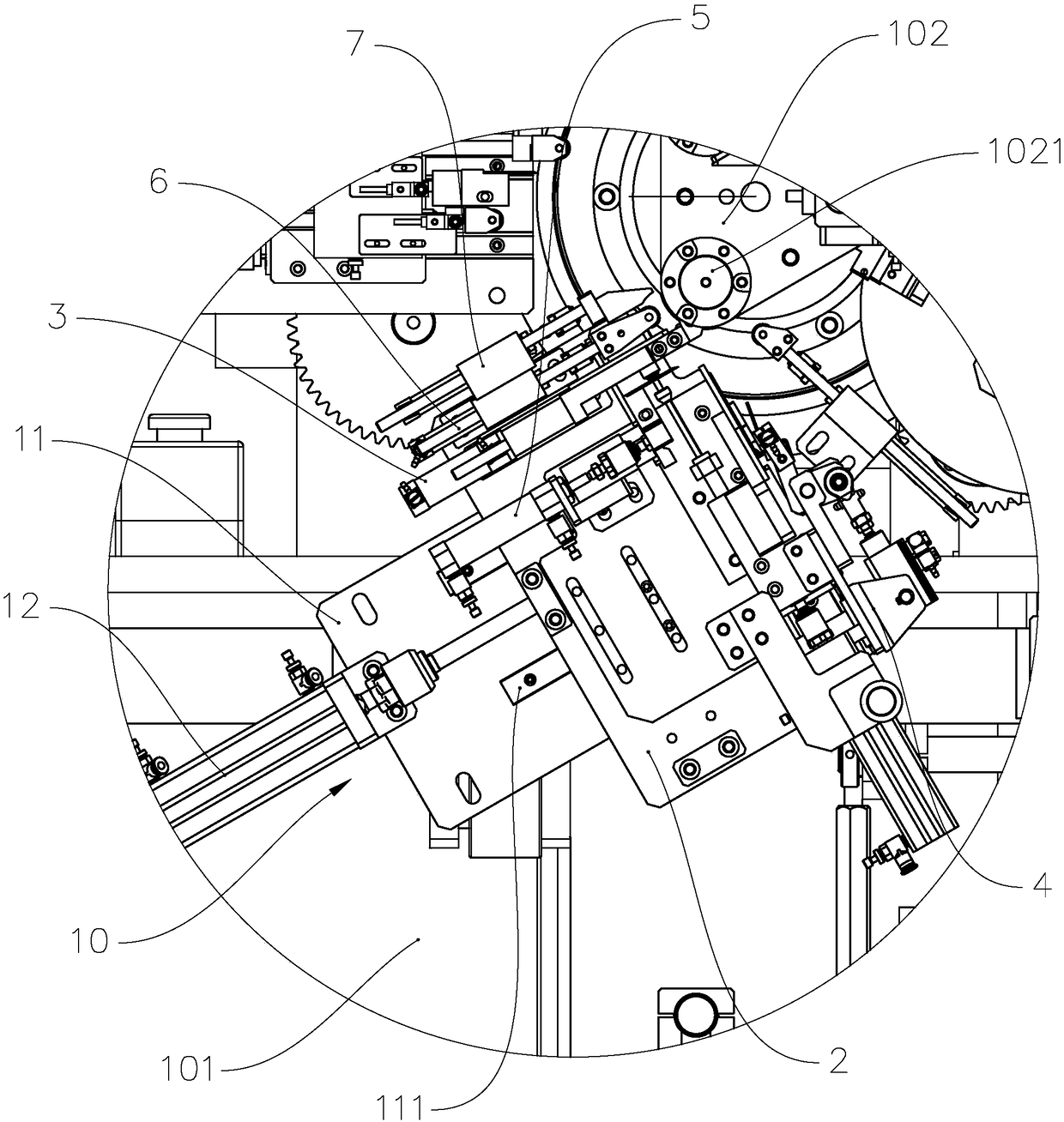

[0032] Cylindrical cell sheet winding machine embodiment:

[0033] refer to figure 1 , the cylindrical battery sheet winding machine includes a frame 101, a winding head 102 and a glue application device 103, wherein the winding head 102 is rotatably mounted on the frame 101 around its own axis, and the winding head 102 is used for After the positive pole piece, negative pole piece, separator, etc. are wound into batteries at the winding station, the rolled battery cores are moved to the gluing station for gluing the rolled battery cores. The gluing device 10 is installed on the frame 101, and the gluing device 10 is positioned at the gluing station of the winding head 102, and the gluing device 101 is used for winding the electric coils rolled by the winding head 102 at the winding station. The core is glued to prevent the rolled battery core from falling apart.

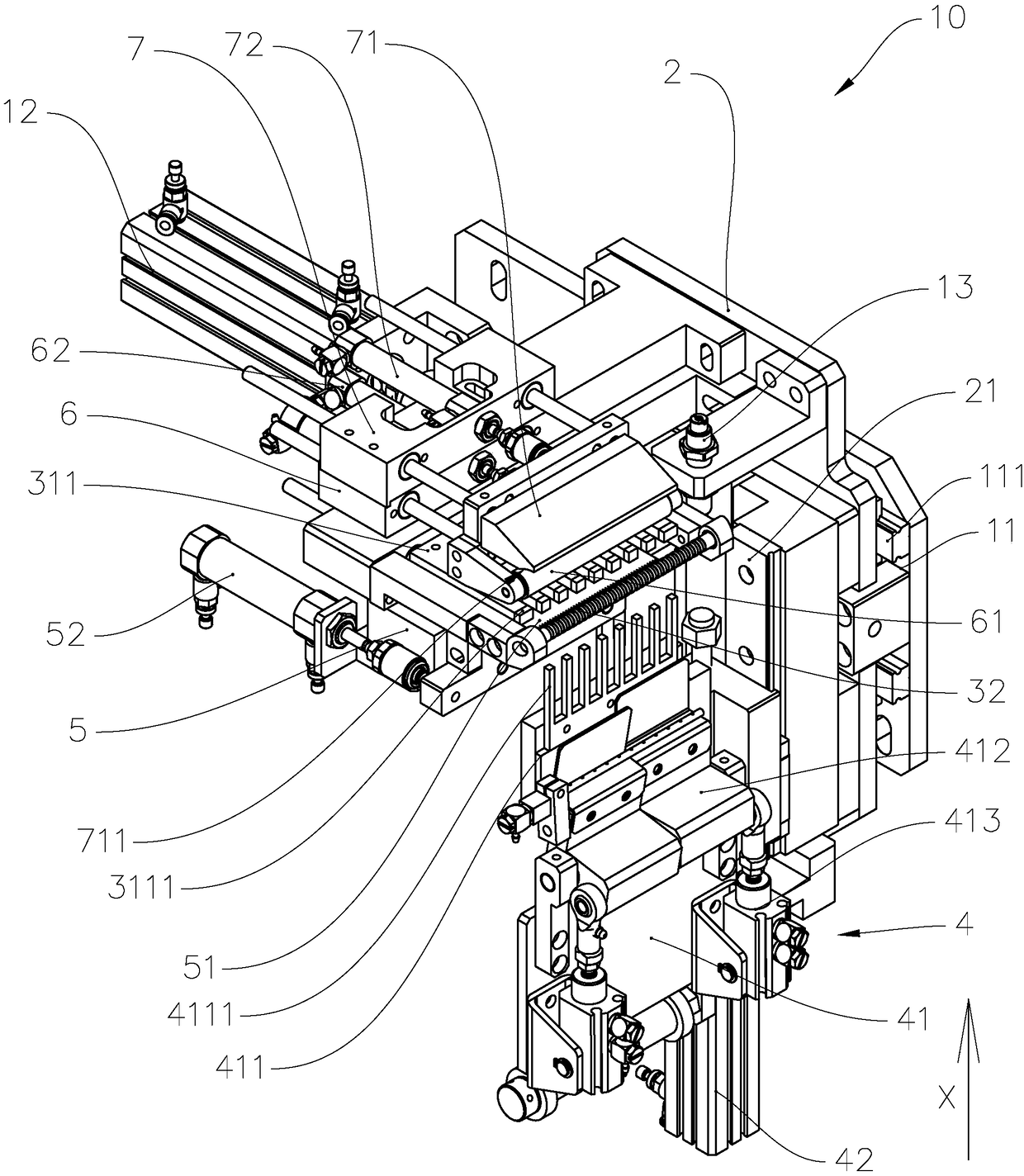

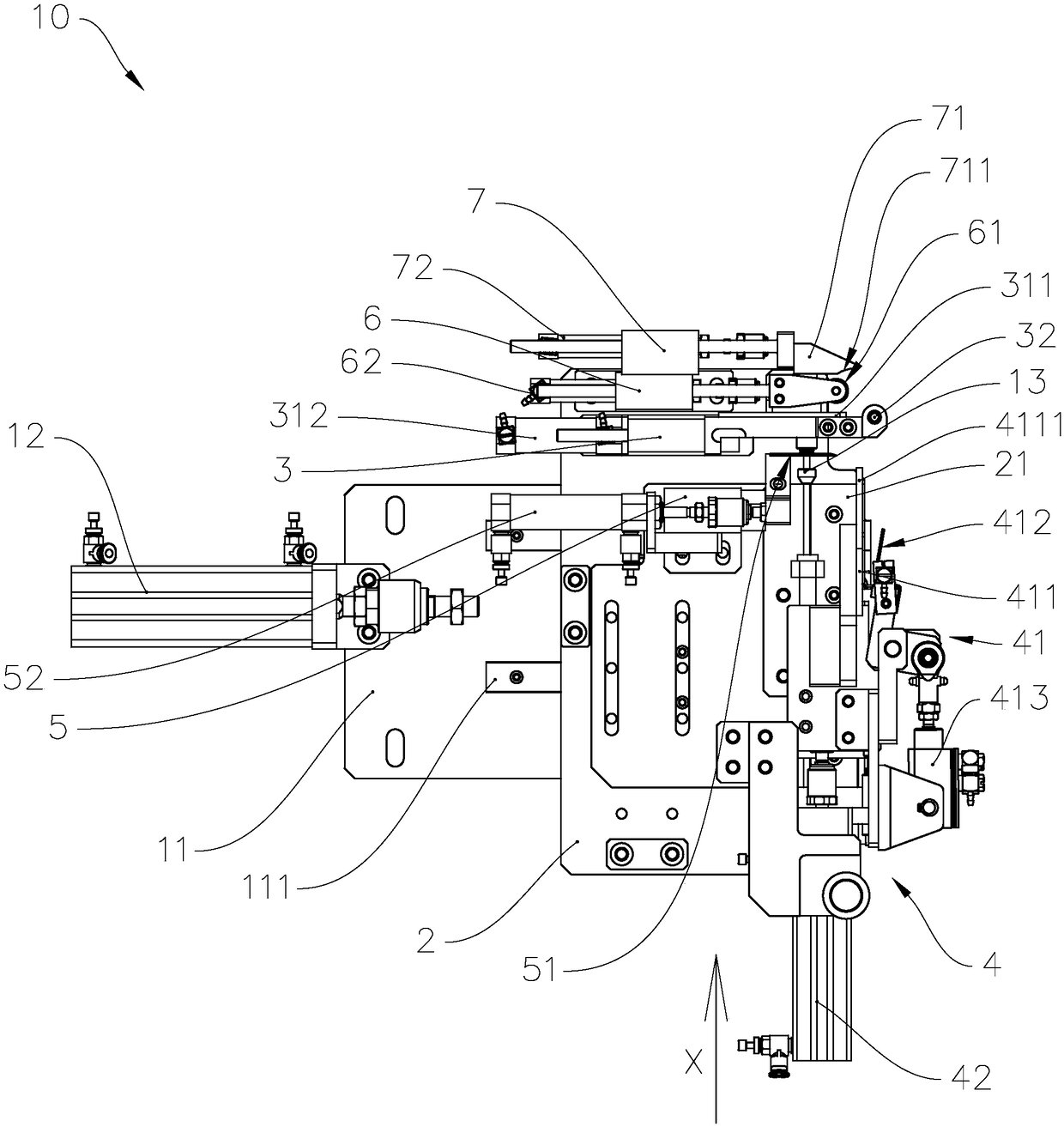

[0034] refer to figure 2 and image 3 , and combined with figure 1 The gluing device 10 includes a mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com