Iron phosphate cement

A technology of phosphate cement and acid phosphate, which is applied in the field of building materials, can solve the problems of unfavorable high temperature and large-area construction, the difficulty of effectively controlling the setting time, and restrictions on the popularization and application of cementitious materials, etc. Strong construction and good strength and stability in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

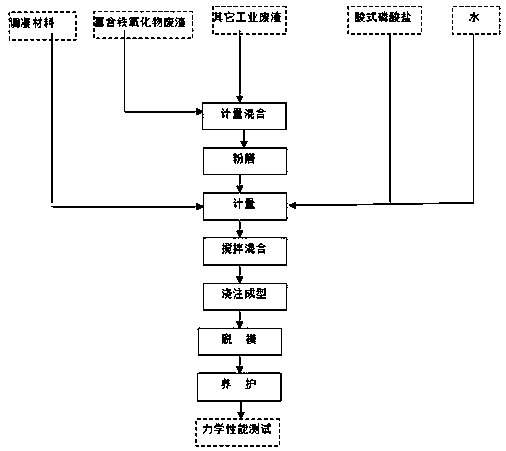

Method used

Image

Examples

Embodiment 1

[0023] The iron-based phosphate cement in this embodiment is made by uniformly mixing the following raw materials with a particle size of 1-100 μm. Each raw material and its content are: 100 parts by weight of acid phosphate and 400 parts by weight of iron-rich waste residue. 3 parts by weight of the setting material, 30 parts by weight of other industrial waste residues, and 15 parts by weight of water.

[0024] The acid phosphate described in this example is disodium hydrogen phosphate, the setting material is borax, and other industrial waste residues are fly ash (the content of the main component is SiO 2 48.96%, Al 2 O 3 30.13%, CaO4.81%), copper slag rich in iron oxide (the main component content is SiO 2 32.36%, Al 2 O 3 3.13%, FeO35.68%, CaO6.8%).

[0025] The preparation process of the iron-based phosphate cement described in this embodiment: pulverize the waste copper slag to a 180-mesh sieve of no more than 10%, weigh the disodium hydrogen phosphate and the waste copp...

Embodiment 2

[0028] The iron-based phosphate cement in this embodiment is made by uniformly mixing the following raw materials with a particle size of 1-100 μm. Each raw material and its content are: 100 parts by weight of acid phosphate and 500 parts by weight of iron-rich waste residue. The setting material is 4 parts by weight, other industrial wastes are 20 parts by weight, and the water is 40 parts by weight.

[0029] The acid phosphate described in this embodiment is a mixture of sodium dihydrogen phosphate, diammonium hydrogen phosphate, and dipotassium hydrogen phosphate in a ratio of 1:1:1. The setting material is borax, and other industrial waste residues are phosphorus slag ( The main component is SiO 2 41.08%, CaO47.60%, Al 2 O 3 4.13%), copper slag rich in iron oxide (the main component content is SiO 2 32.36%, Al 2 O 3 3.13%, FeO35.68%, CaO6.8%).

[0030] The preparation process of the iron-based phosphate cement described in this embodiment: pulverize the waste copper slag to...

Embodiment 3

[0033] The iron-based phosphate cement in this embodiment is made by uniformly mixing the following raw materials with a particle size of 1-100 μm. Each raw material and its content are: 100 parts by weight of acid phosphate and 600 parts by weight of iron-rich waste residue. The setting material is 4.5 parts by weight, other industrial waste is 20 parts by weight, and water is 60 parts by weight.

[0034] The acid phosphate in this embodiment is potassium dihydrogen phosphate; the setting material is boric acid; other industrial waste slag is steel slag (the content of the main component is SiO 2 15.34%, Al 2 O 3 5.16%, CaO43.22%); waste slag rich in iron oxide copper slag (the main component content is SiO 2 32.36%, Al 2 O 3 3.13%, FeO35.68%, CaO6.8%).

[0035] The preparation process of the iron-based phosphate cement described in this embodiment: Grind the waste copper slag to a 180-mesh sieve of no more than 10%, weigh the potassium dihydrogen phosphate and the waste copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com