Metal shell forming process, integrated shell forming process, shell and electronic device

A molding process and shell molding technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., can solve problems such as poor precision and inability to obtain product shapes, and achieve The effect of short processing time, low cost and precise shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

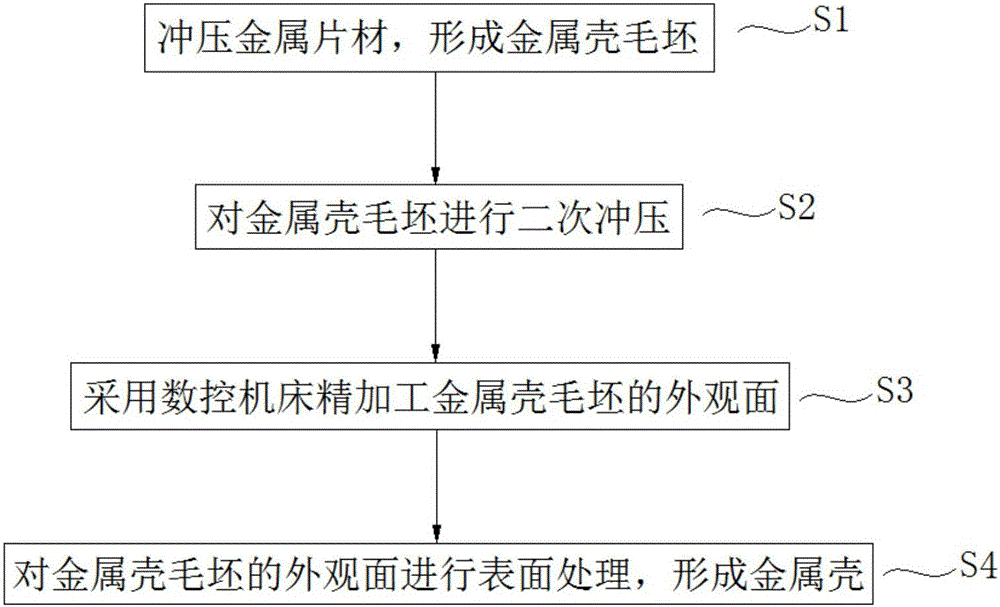

[0038] refer to Figure 1 to Figure 4 , in this embodiment, a metal shell molding process is provided. The metal shell molding process includes the following steps:

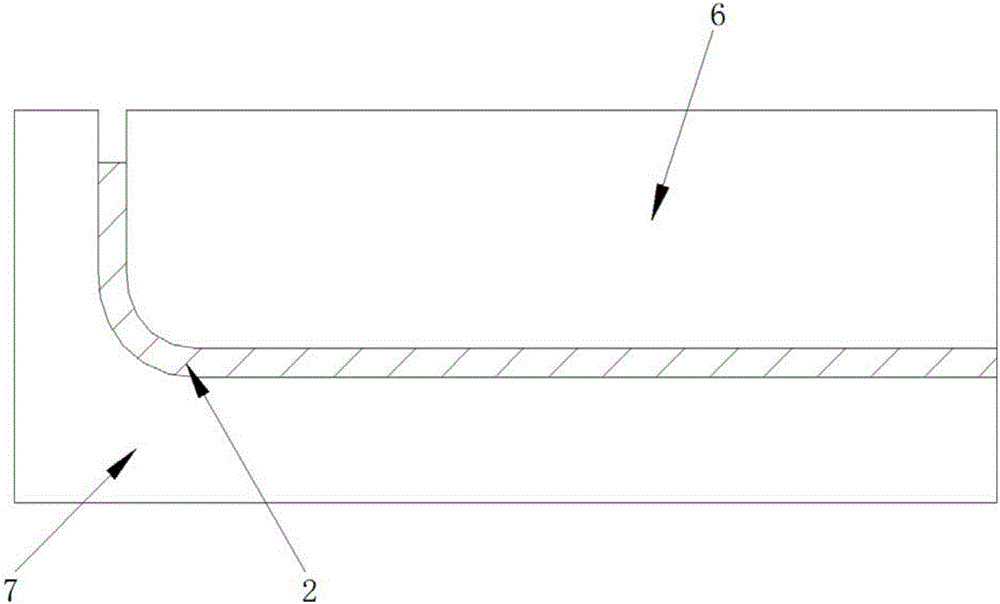

[0039] S1, punch metal sheet 1, form metal shell blank 2 (combine figure 2 and image 3 , image 3 Punch 6 and die 7 used for stamping sheet metal 1 are shown in );

[0040] S2, carrying out secondary stamping to metal shell blank 2, to carry out shaping to metal shell blank 2 (combining Figure 4 ,exist Figure 4 , the downward arrow indicates the direction of stamping);

[0041] S3. Finishing the appearance surface of the metal shell blank 2 with a numerical control machine tool;

[0042] S4. Surface treatment is performed on the appearance surface of the metal shell blank 2 to form a metal shell.

[0043] Thus, after the secondary stamping, the metal shell blank 2 can be shaped, and the springback of the metal shell blank 2 after the first stamping can be compensated, so that an accurate product shape...

Embodiment 2

[0048] refer to Figure 5 to Figure 11 , in this embodiment, an integrated shell molding process is provided, and the integrated shell molding process includes the following steps:

[0049] Step 1, stamping metal sheet 1, forms metal shell blank 2 (combining Image 6 and Figure 7 , Figure 7 Punch 6 and die 7 used for stamping sheet metal 1 are shown in );

[0050] Step 2, carrying out secondary punching to the metal shell blank 2, to shape the metal shell blank 2 (combining Figure 8 ,exist Figure 8 , the downward arrow indicates the direction of stamping);

[0051] Step 3, side punch forming side hole 3 on metal shell blank 2 (combined with Figure 9 );

[0052] Step 4. Mold the plastic part 4 on the metal shell blank 2 by in-mold injection molding to form an integrated shell, wherein the mold for in-mold injection molding is provided with bumps (such as lateral sliders), during the injection molding process , the bump is inserted into the side hole 3 and seals the...

Embodiment 3

[0065] This embodiment provides an integrated shell, which is made by the integral shell molding process described in Embodiment 2, and its partial structure can be referred to Figure 11 structure shown. The one-piece shell has precise shape, short processing time, and low cost of the one-piece shell. Preferably, the one-piece housing of this embodiment is one-piece battery cover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com