Clamp for reshaping car lamp liner frame

A technology of lamps and fixtures, which is applied in the field of inspection tools, can solve the problems of waste products, lamps that cannot be inspected, and the influence and limitations of lamp design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

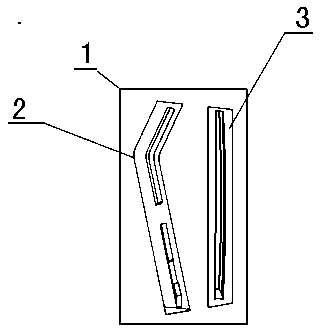

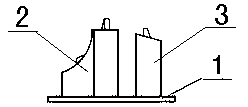

[0008] Depend on figure 1 , figure 2 Known, a fixture for the shaping of the lining frame of the car lamp is characterized in that it is composed of an aluminum plate base 1, a support limit block I2 and a support limit block II3, and the support limit block I2 and the support limit block II3 are fixed on On the aluminum plate base 1, the relative position between the support limit block I2 and the support limit block II3 is set according to the shape of the car lamp lining frame.

[0009] During production and processing, the product removed from the mechanical arm of the injection molding machine is placed directly on the two support limit blocks until the product is completely cooled and shaped before being removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com