Method for acoustic-electric coupling isolation among multiple surface acoustic wave filters integrated on single substrate

A surface acoustic wave, monolithic integration technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of channel signal crosstalk, surface acoustic wave device consistency, compliance and reliability adverse effects, and achieve multi-filter channel count , easy to achieve synchronously, high isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

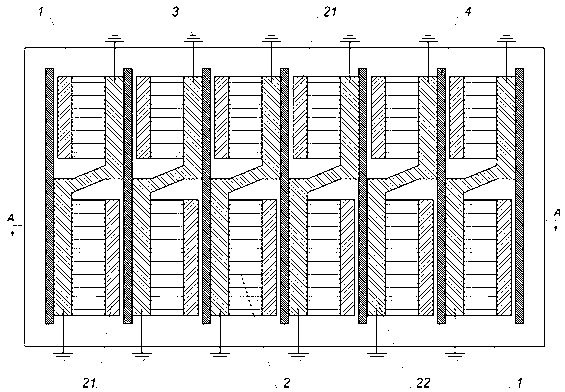

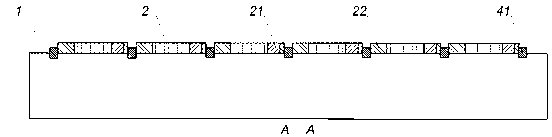

[0022] The longitudinal groove 41 covering the metal film is used to isolate the acoustic-electric coupling between the channels of the monolithic integrated surface acoustic wave filter bank.

[0023] Such as figure 2 As shown, a longitudinal groove 41 covered with a metal film is formed between each surface acoustic wave filter 2 as an acoustic and electrical isolation structure, and is connected to the ground electrode 22 of the surface acoustic wave filter.

[0024] The process implementation steps of the present embodiment are:

[0025] (1) Make longitudinal grooves at designated positions on the surface of the substrate by physical etching;

[0026] (2) Fabricate an aluminum-copper alloy film on the surface of the substrate by magnetron sputtering;

[0027] (3) Fabricate the graphic structure of the surface acoustic wave filter and the graphic structure of the metal film covering the groove by photolithography and etching technology.

[0028] In this embodiment, the ...

Embodiment 2

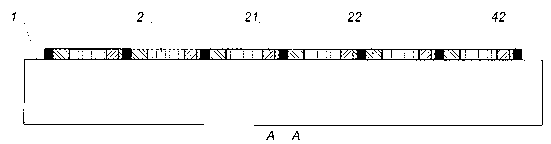

[0031] The metal film electrode 42 having a higher density than the graphic structure of the surface acoustic wave filter and being heterogeneous with the graphic structure of the surface acoustic wave filter is used to isolate the acoustic-electric coupling between the channels of the monolithic integrated surface acoustic wave filter bank.

[0032] Such as image 3 As shown, a high-density metal film electrode 42 which is heterogeneous to the graphic structure of the surface acoustic wave filter is arranged between each surface acoustic wave filter 2 as an acoustic and electrical isolation structure, and is connected to the ground electrode 22 of the surface acoustic wave filter.

[0033] The process implementation steps of the present embodiment are:

[0034] (1) Fabricate an aluminum-copper alloy film with a high copper doping ratio on the surface of the substrate by magnetron sputtering;

[0035] (2) Metal film isolation electrodes are fabricated by photolithography and ...

Embodiment 3

[0041] The metal film electrode 43 which is thicker than the graphic structure of the surface acoustic wave filter and homogeneous with the graphic structure of the surface acoustic wave filter is used to isolate the acoustic-electric coupling between the channels of the monolithic integrated surface acoustic wave filter group.

[0042] Such as Figure 4 As shown, a thickened metal film electrode 43 that is homogeneous to the graphic structure of the surface acoustic wave filter is arranged between each surface acoustic wave filter 2 as an acoustic and electrical isolation structure, and is connected to the ground electrode 22 of the surface acoustic wave filter.

[0043] (1) Fabricate a thickened aluminum-copper alloy film with a conventional copper doping ratio on the surface of the substrate by magnetron sputtering;

[0044] (2) Metal film isolation electrodes are fabricated by photolithography and etching processes;

[0045] (3) Fabricate an aluminum-copper alloy film wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com