Method for the continuous production of a multiaxial contexture web

A fabric-web, multi-axial technology used in nonwovens, textiles and papermaking, layered products, etc., which can solve problems such as slowness and low manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

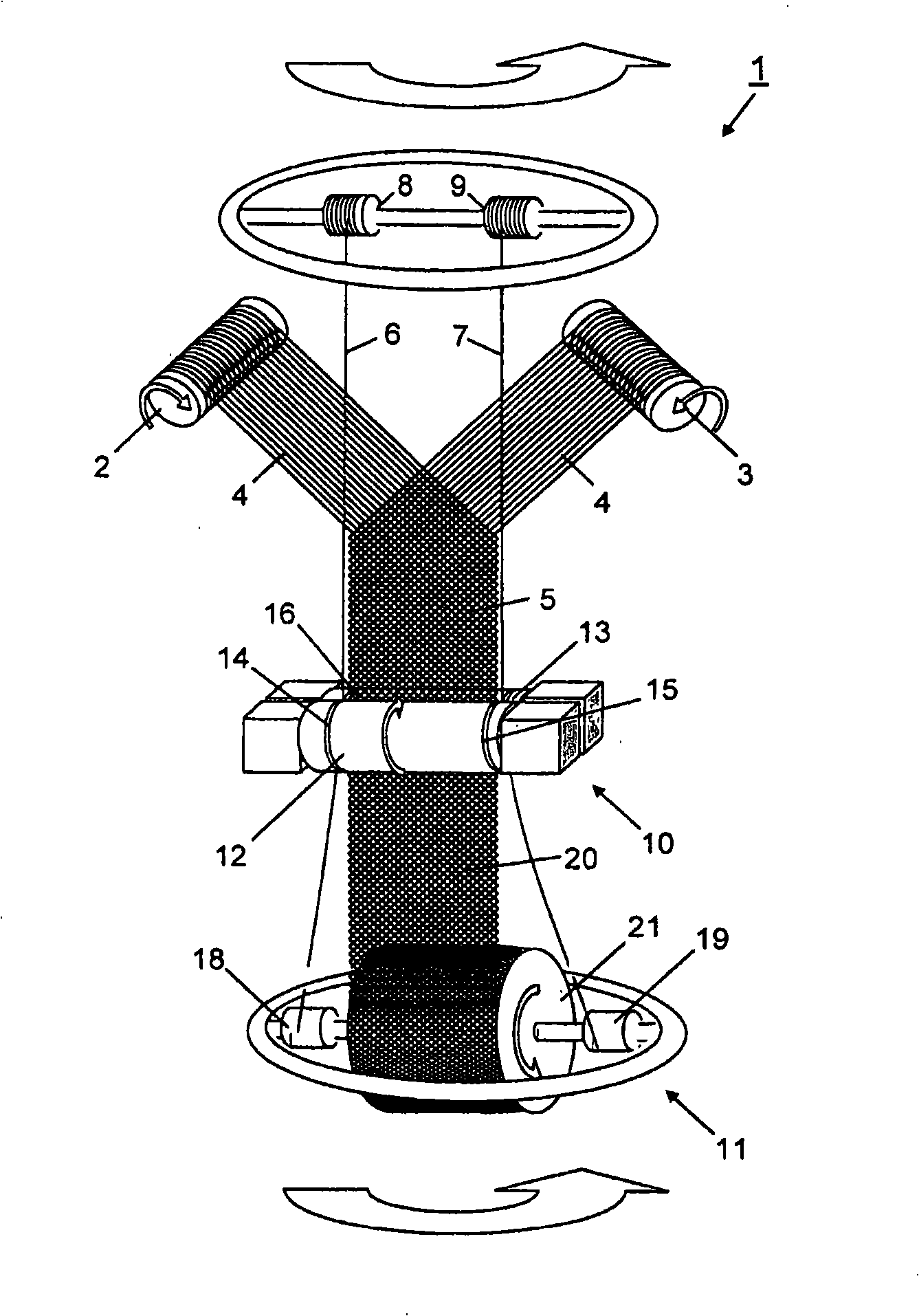

[0092] figure 1 A winding device 1 is depicted, which can be used in a method for continuously producing a multiaxial fabric web. In the winding device 1 there are two winding rollers 2 and 3 , from which the fiber material 4 is unwound and formed into a multiaxial fabric 5 . The winding rollers 2 and 3 are arranged stationary, which means that they do not move in space, but otherwise rotate about their own axis in order to be able to unwind the fiber material 4 . Parallel to the extension of the multiaxial fabric 5, two tensioning elements 6 and 7 are tensioned in the winding device 1, which are unwound from rollers 8 and 9 and serve as a boundary for a plane which passes through the two tensioning elements 6 and 7 form. The synchronously rotating tensioning elements 6 and 7 by means of rollers 8, 9, a calendering and separating device 10 and a winding device 11 rotate about an axis parallel to the two tensioning elements 6 and 7 and extending centrally.

[0093]In this fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com