Isolated type fireproof cable

A fireproof cable and isolation technology, applied in the field of wire and cable, can solve the problems of failing to achieve cooling and extinguishing the flame, insufficient flexibility of the stainless steel sleeve, and reduced explosion-proof performance of the cable, achieving good waterproof and explosion-proof effect, good waterproof and explosion-proof effect , The effect of preventing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

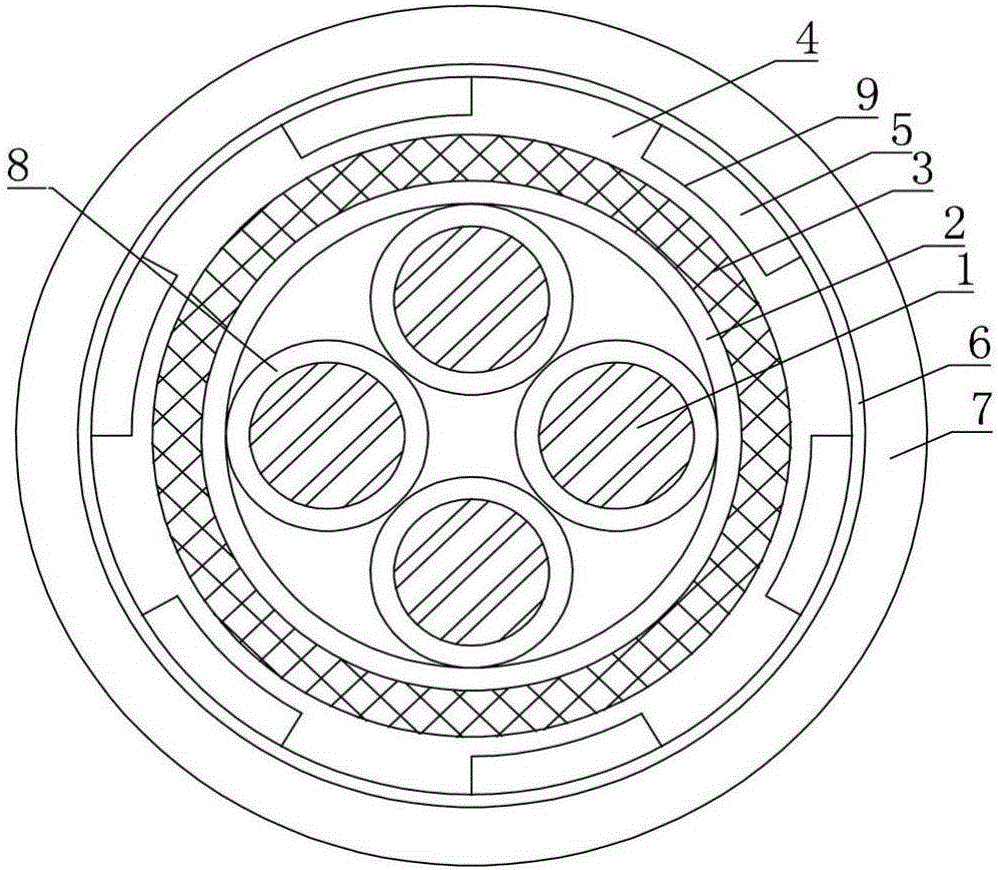

[0038] Such as figure 1 As shown, an isolated fireproof cable includes a conductor 1, an outer insulating layer 2 located outside the conductor 1, an insulating sleeve 3 located outside the outer insulating layer 2, a toothed sleeve 4 located outside the insulating sleeve 3, and a toothed sleeve 4 located outside the outer insulating layer 2. The fireproof layer 5 on the outer side of the shape sleeve 4, the halogen-free flame-retardant tape 6 outside the fireproof layer 5, the low-smoke halogen-free sheath 7 outside the halogen-free flame-retardant tape 6;

[0039] The conductor 1 is formed by twisting wires, and each wire is provided with an inner insulating layer 8, and the inner insulating layer 8 is composed of a mineral compound;

[0040] The outer insulating layer 2 consists of a mineral compound;

[0041] The isolation sleeve 3 is a metal sleeve;

[0042] The toothed sleeve 4 is a cross-linked polyethylene toothed sleeve, and accommodating grooves 9 are formed betwee...

Embodiment 2

[0048] Such as figure 1 As shown, an isolated fireproof cable includes a conductor 1, an outer insulating layer 2 located outside the conductor 1, an insulating sleeve 3 located outside the outer insulating layer 2, a toothed sleeve 4 located outside the insulating sleeve 3, and a toothed sleeve 4 located outside the outer insulating layer 2. The fireproof layer 5 on the outer side of the shape sleeve 4, the halogen-free flame-retardant tape 6 outside the fireproof layer 5, the low-smoke halogen-free sheath 7 outside the halogen-free flame-retardant tape 6;

[0049] The conductor 1 is formed by twisting wires, and each wire is provided with an inner insulating layer 8, and the inner insulating layer 8 is composed of a mineral compound;

[0050] The outer insulating layer 2 consists of a mineral compound;

[0051] The isolation sleeve 3 is a metal sleeve;

[0052] The toothed sleeve 4 is a cross-linked polyethylene toothed sleeve, and accommodating grooves 9 are formed betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com