Forming device for sand casting cavity

A molding device and sand casting technology, which is applied in the field of sand casting, can solve the problems of poor sand core effect, inability to lay uniformly, poor sand core forming effect, etc., and achieve high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

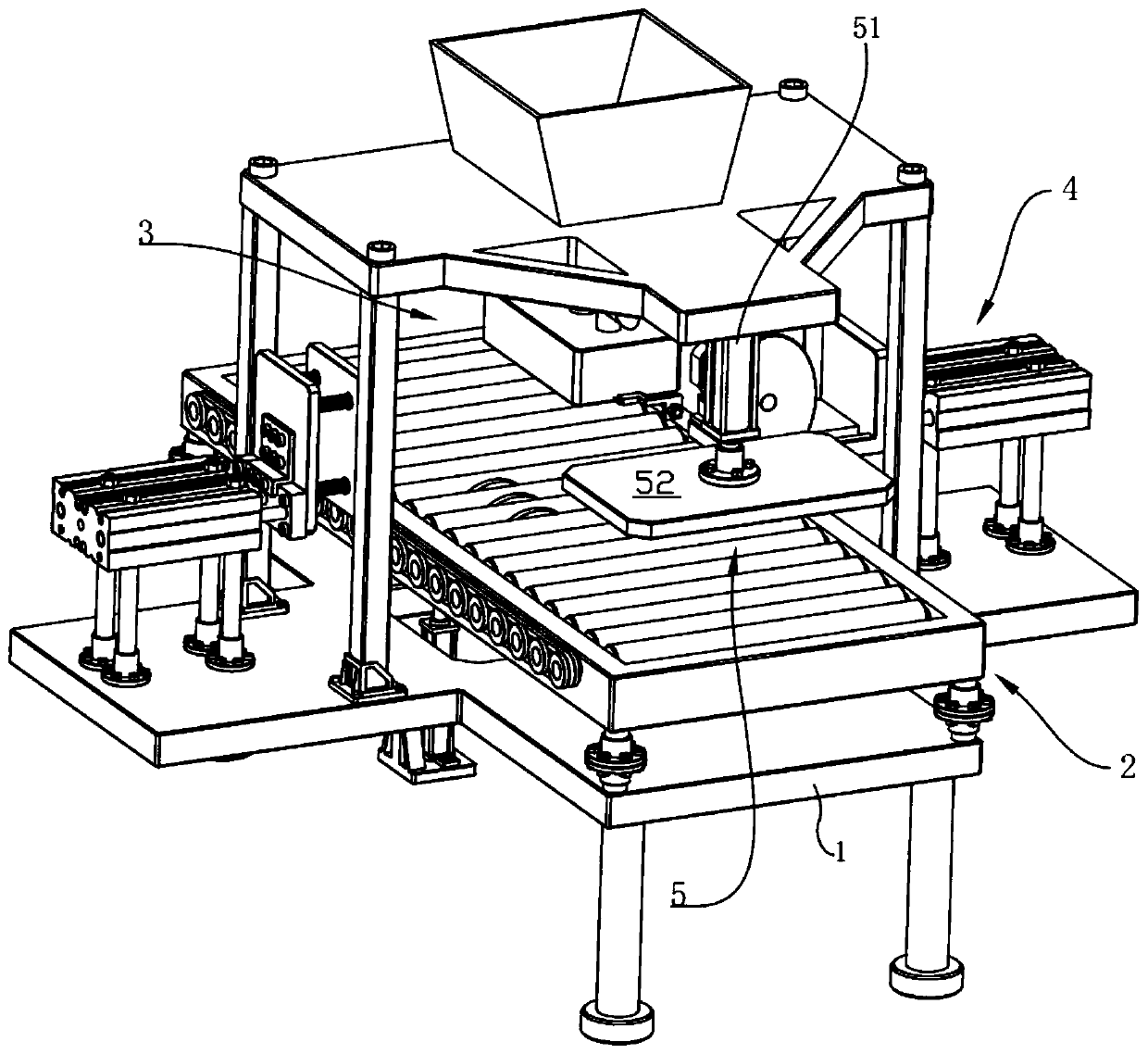

[0028] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0029] A cavity forming device for sand casting, comprising a frame 1, a conveying mechanism 2, a sand output mechanism 3, a shaking mechanism 4 and a compacting mechanism 5, wherein:

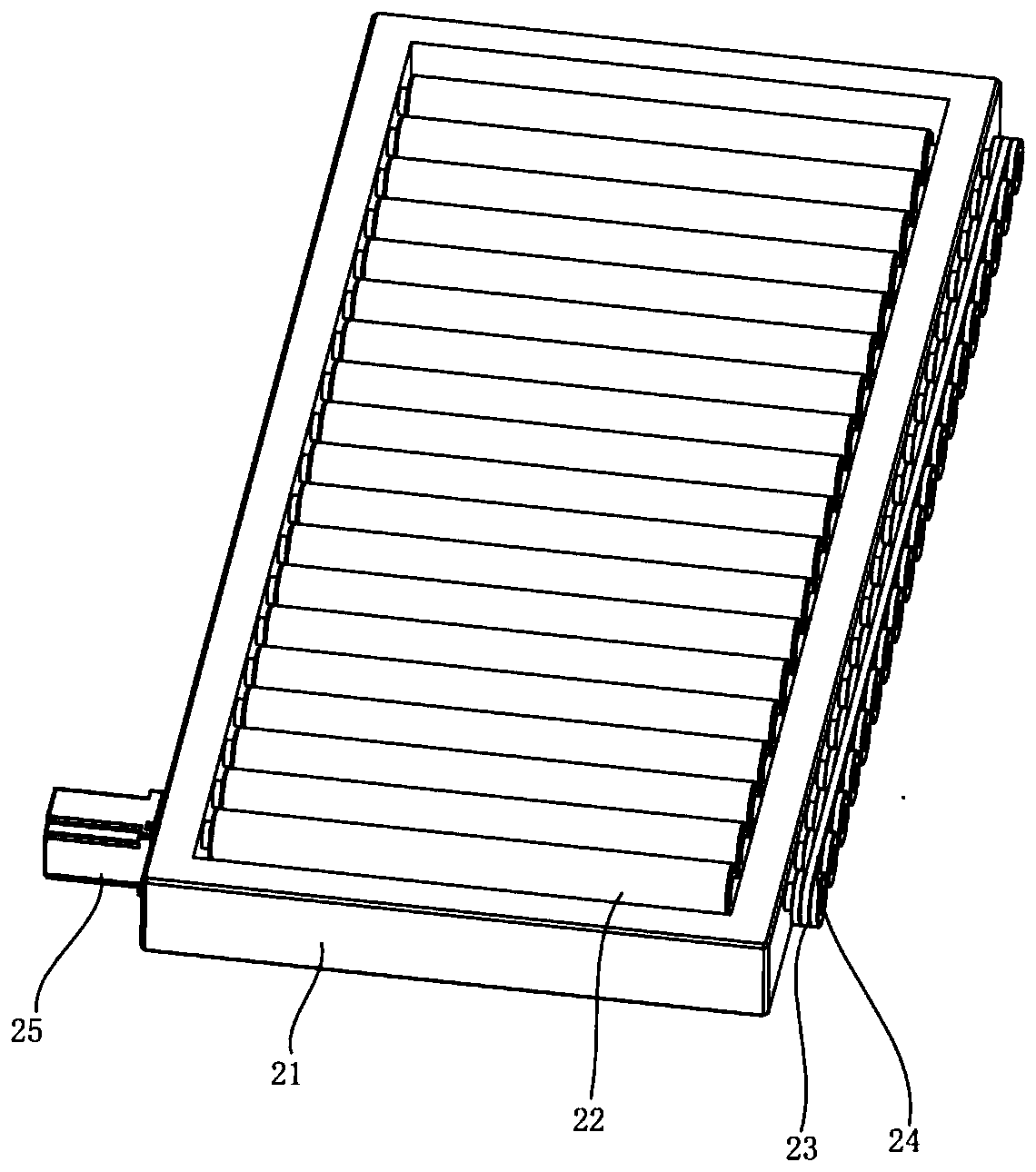

[0030] Conveyor mechanism 2 comprises support 21, rubber roller 22, pulley 23, belt 24 and reduction motor 25, and support 21 is fixedly installed on the frame 1 and is positioned at the below of discharge box 32, and several rubber rollers 22 are equidistantly installed on In the bracket 21, a pulley 23 is sheathed on the rubber roller 22, and the belt 24 is sleeved on several pulleys 23. The reduction motor 25 is fixed on the bracket 21 through bolts, and the power output end of the reduction motor 25 is connected to one of the rubber rollers. 22 are fixedly connected by a coupling;

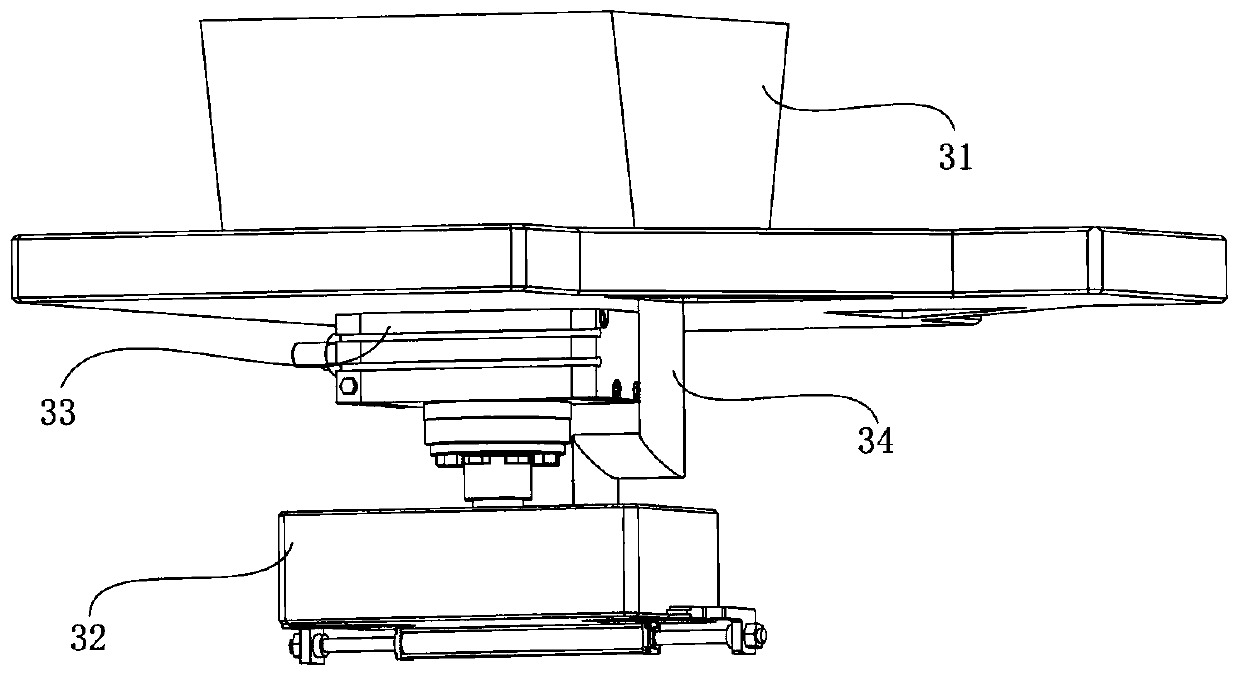

[0031] The sand outlet mechanism 3 includes a hopper 31, a discharge box 32, a rotary cylinder 33, a telescopic hose 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com