Core rod of ultra-high-voltage post composite insulator and manufacturing method thereof

A composite insulator and UHV technology, applied in the mandrel for UHV post composite insulator and its manufacturing field, can solve the problems of easy fracture, affecting the electrical performance and life of the product, and brittle fracture, so as to improve wind resistance and bending resistance Ability, great practical and popularization value, high effect of mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

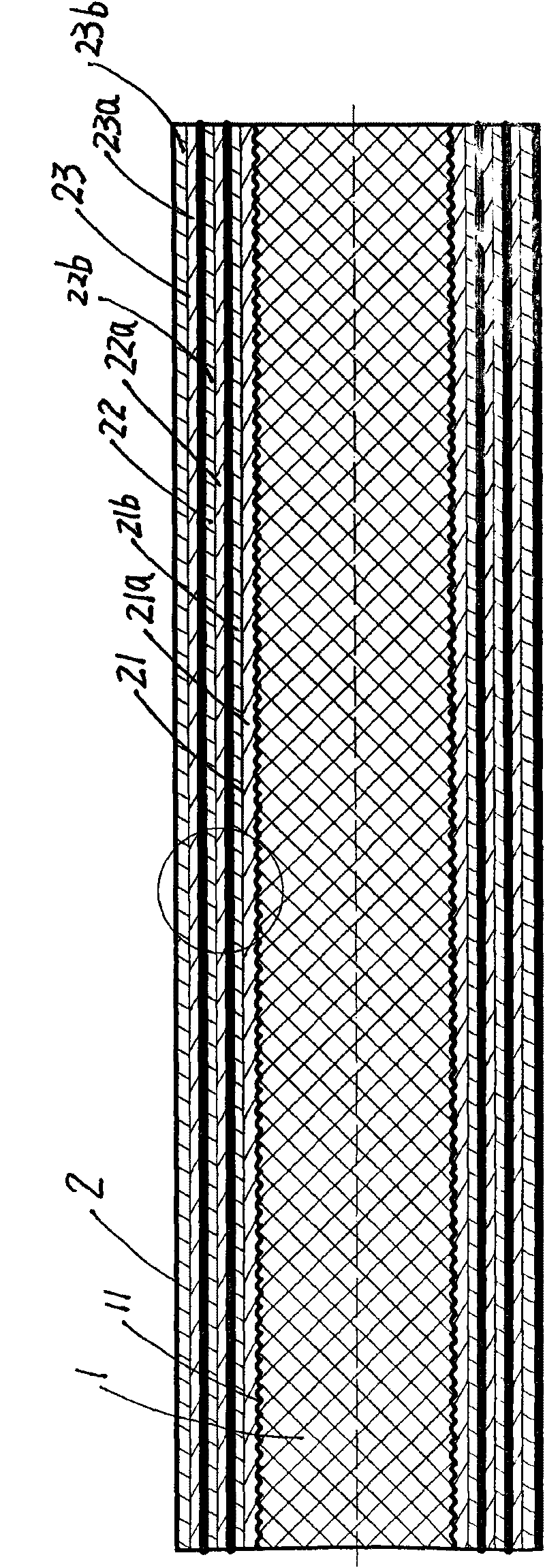

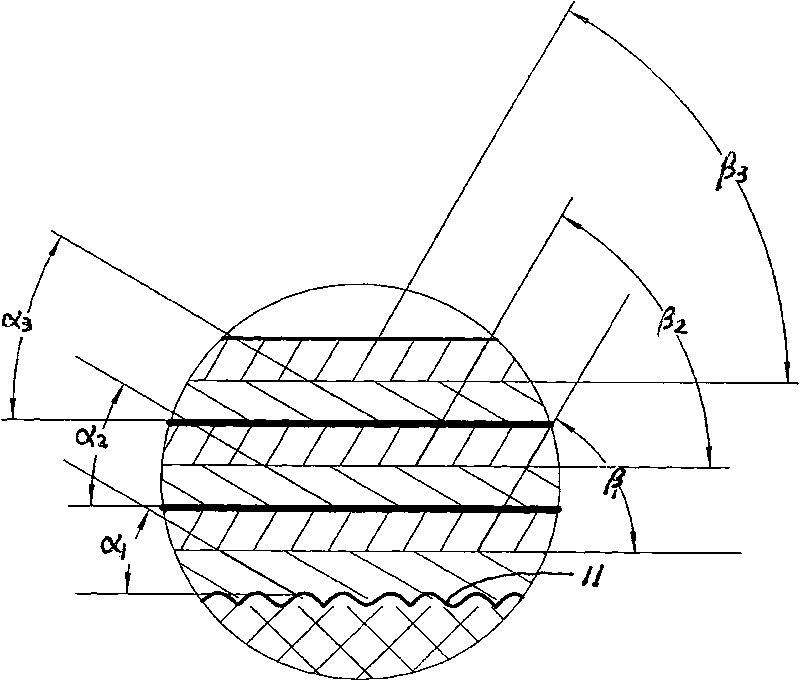

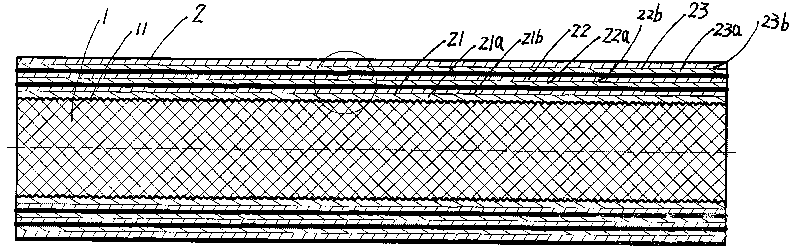

[0039] Refer to attached figure 1 , with figure 2 , the mandrel for ultra-high voltage post composite insulators of the present invention is composed of a rod core 1 and a winding tube 2, the winding tube 2 is arranged on the periphery of the rod core 1, and the winding tube 2 is a tube that is wound and cured by glass fiber yarn impregnated with epoxy resin glue Body, the rod core 1 is a core with a damping groove 11 on the surface, and the damping groove 11 on the rod core 1 is a spiral arc groove. The winding pipe 2 is composed of layer I 21, layer II 22, and layer III 23, and layer I 21, layer II 22, and layer III 23 are respectively wound and cured by glass fiber yarn impregnated with epoxy resin glue , the layer I 21 in the winding pipe 2 is composed of an inner layer I21a and an outer layer I 21b, and the winding angle α of the glass fiber yarn of the inner layer I 21a 1 For: 25°≤α 1 ≤30°; the winding angle β of the glass fiber yarn of the outer layer I 21b 1 For: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com