Power distribution network electrified automatic wiring tool set and robot

A technology of automatic wiring and tool set, applied in the direction of clip connection conductor connection, contact components with insulating cutting blades, etc., can solve problems such as endangering the health of workers, phase-to-phase, phase-to-ground short circuit, high-altitude operation hazards, etc., to achieve convenient grasping The effect of taking and automatic wiring, safe operation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

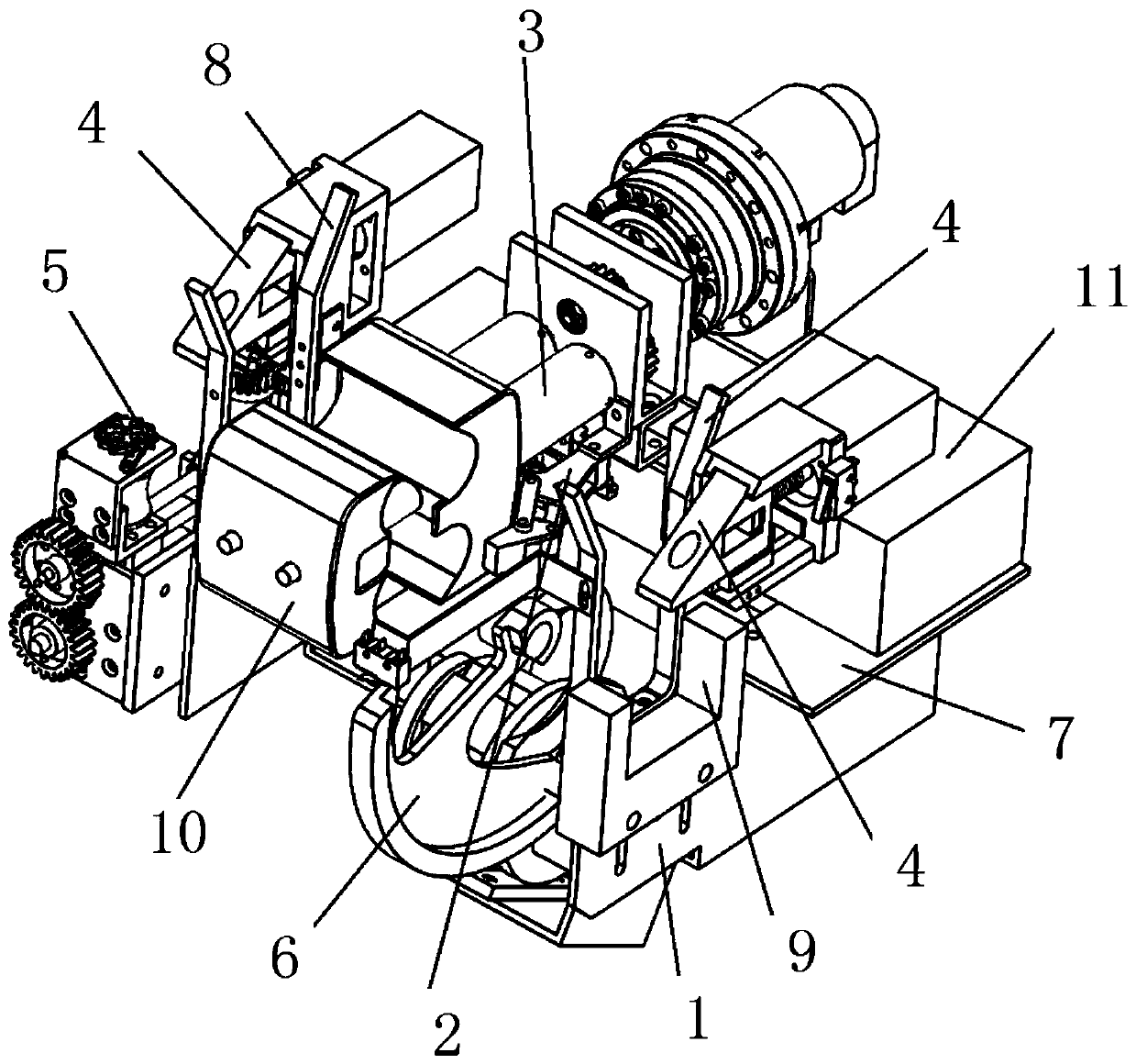

[0028] The distribution network live automatic wiring tool set of this embodiment is suitable for live disconnection / connection of drain wires, such as figure 1 As shown, it includes a frame body 1, a clamping mechanism 2, a clamp tightening mechanism 3, a main line fixing mechanism 4, a branch line fixing mechanism 5, a disconnection mechanism 6, a controller 7 and an induction mechanism 9, wherein the clamping mechanism 2 , the clamp tightening mechanism 3, the main line fixing mechanism 4, the branch line fixing mechanism 5, the disconnection mechanism 6 and the controller 7 are all arranged on the frame body 1. In this embodiment, the puncture wire clip 10 is used as the wiring mechanism connecting the branch wire and the main wire, the puncture wire clip 10 has a main wire groove for installing the main wire, and a branch wire groove for installing the branch wire, and the The main trunking is located above the branch trunking.

[0029] The clamping mechanism 2 is fixedl...

Embodiment 2

[0039] The robot of this embodiment is used for disconnecting / connecting the drain wire with power, and is especially suitable for disconnecting / connecting the drain wire with power such as a 10kV high-voltage distribution network. It includes the distribution network live automatic wiring tool set in Embodiment 1, the first mechanical arm connected to the frame body 1 of the wiring tool set, and the second mechanical arm for grabbing the branch line and pulling the branch line to the branch line fixing mechanism 5 arm.

[0040] During the working process of the robot in this embodiment, the first mechanical arm drives the wiring tool set to move, the clamping mechanism 2 on the wiring tool set clamps the puncture wire clamp 10, and the universal sleeve on the wire clamp tightening mechanism 3 corresponds to the torque nut , when the torque nut stretches into the universal sleeve for a set distance, the clamping mechanism 2 clamps the puncture wire clip 10. The second mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com