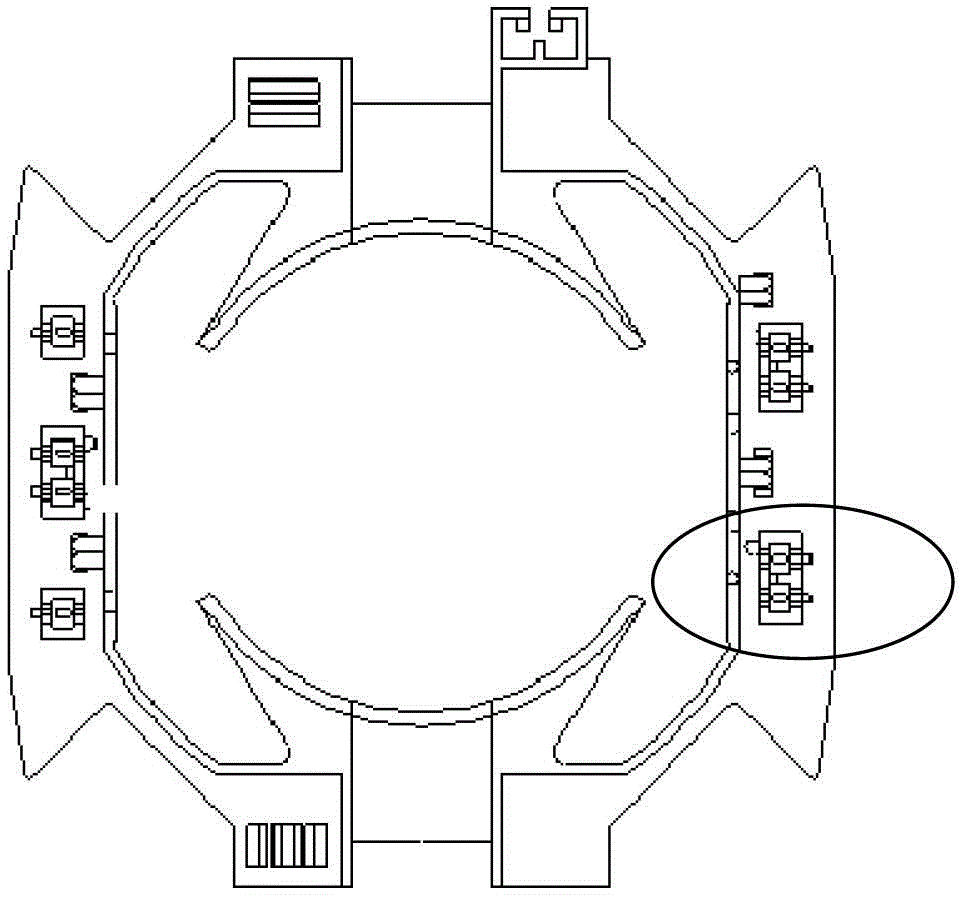

Aluminium wire-contained motor joint and processing method thereof

An aluminum wire motor and aluminum wire technology, which is applied in the field of aluminum wire motor joints and its processing, can solve the problems of reducing the service life of the motor, the difficulty of welding, and the heat shrinkable tube is easy to fall off, so as to prevent corrosion and short circuit and improve the reliability of protection , to ensure the effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

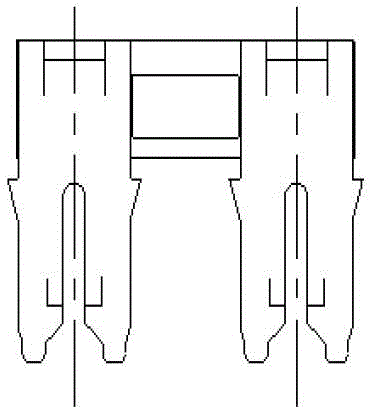

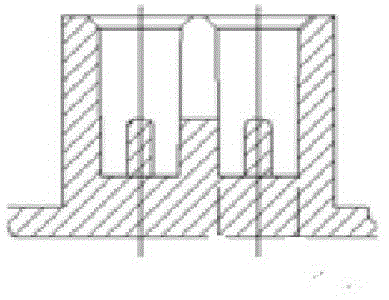

[0043] There is a card slot on the stator insulation end plate of the motor. First press the aluminum enameled wire into the card slot, and then press the terminal into the card slot. The gap in the middle of the terminal pierces the paint film layer of the aluminum enameled wire and then conducts with the aluminum wire. Immediately after that, point EVA hot melt adhesive melted at 100°C to 110°C at the contact point between the terminal and the aluminum enameled wire, and then dry and solidify to complete the connection.

Embodiment 2

[0045] There is a card slot on the stator insulation end plate of the motor. First, press the aluminum enameled wire into the card slot, and then press the copper and aluminum terminals into the card slot. After that, point EVA hot melt glue melted at 100°C to 110°C at the contact point between the terminal and the aluminum enameled wire, and then dry and solidify to complete the connection between the copper lead wire and the aluminum wire.

Embodiment 3

[0047] There is a card slot on the stator insulation end plate of the motor. First press the aluminum enameled wire into the card slot, and then press the terminal into the card slot. The gap in the middle of the terminal pierces the paint film layer of the aluminum enameled wire and then conducts with the aluminum wire. Immediately afterwards, apply UV glue at the contact point between the terminal and the aluminum enameled wire, and then cure and dry by ultraviolet radiation to complete the connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com