Cable terminating apparatus and method

A technology for cables and equipment, used in the field of termination equipment, to solve problems such as non-flush cutting, contact with shielding or conductive elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

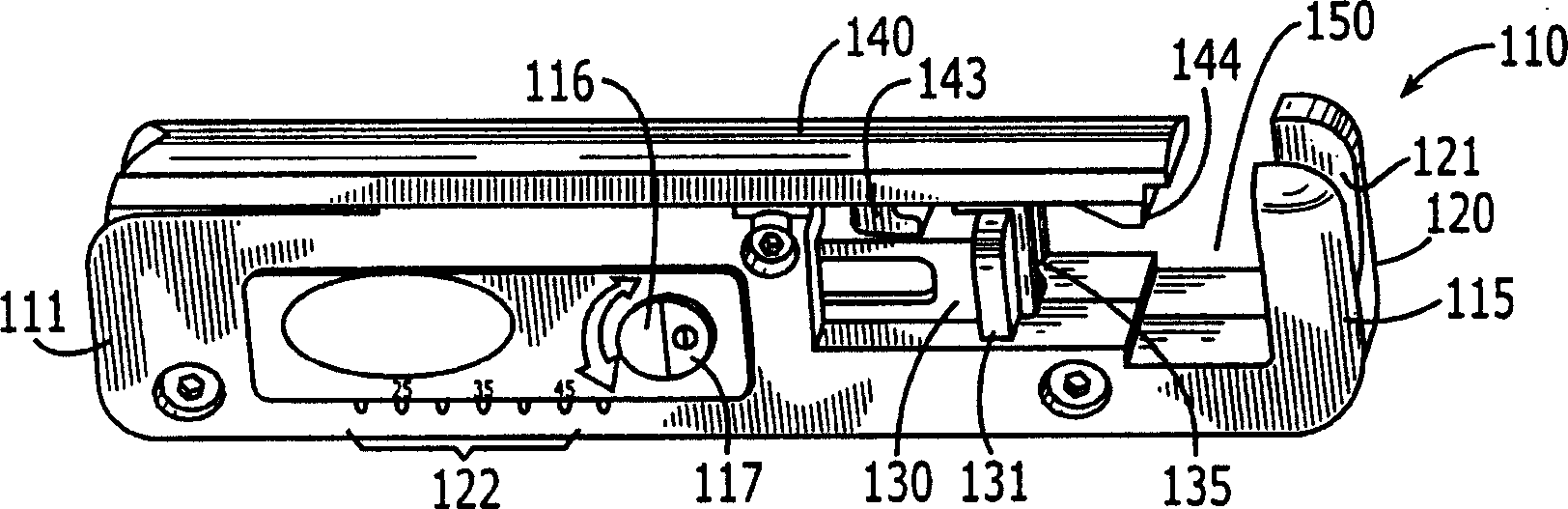

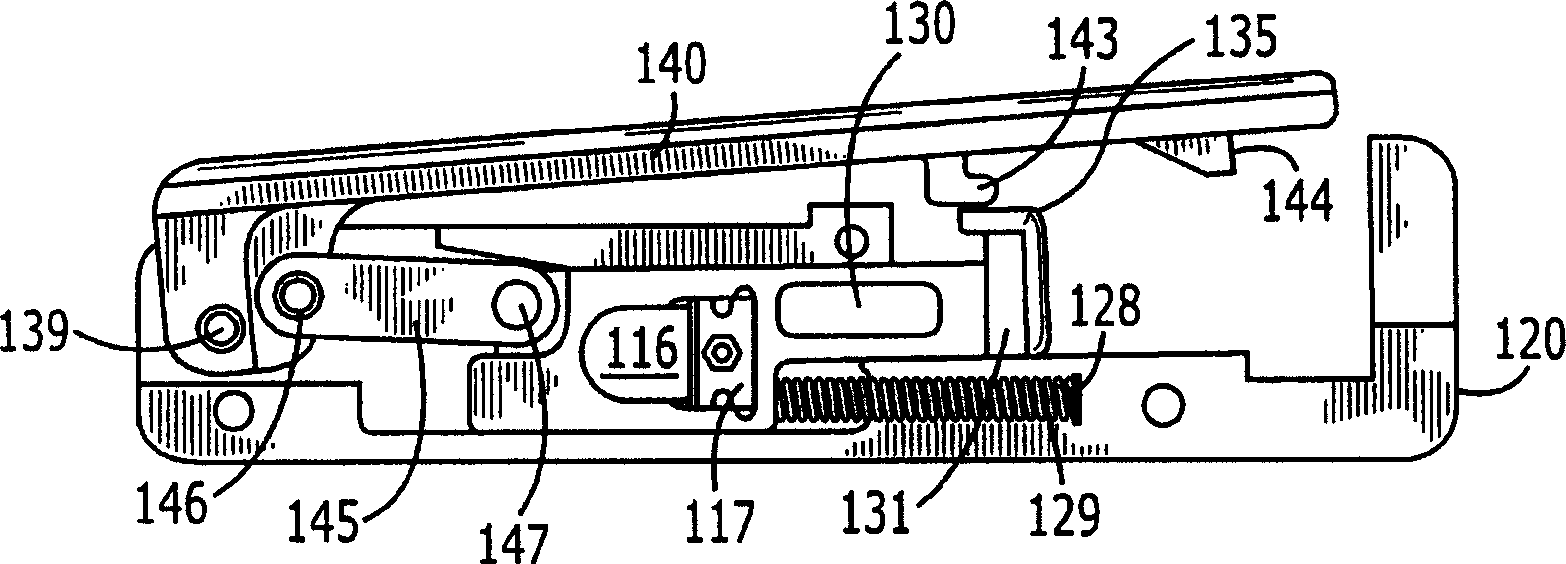

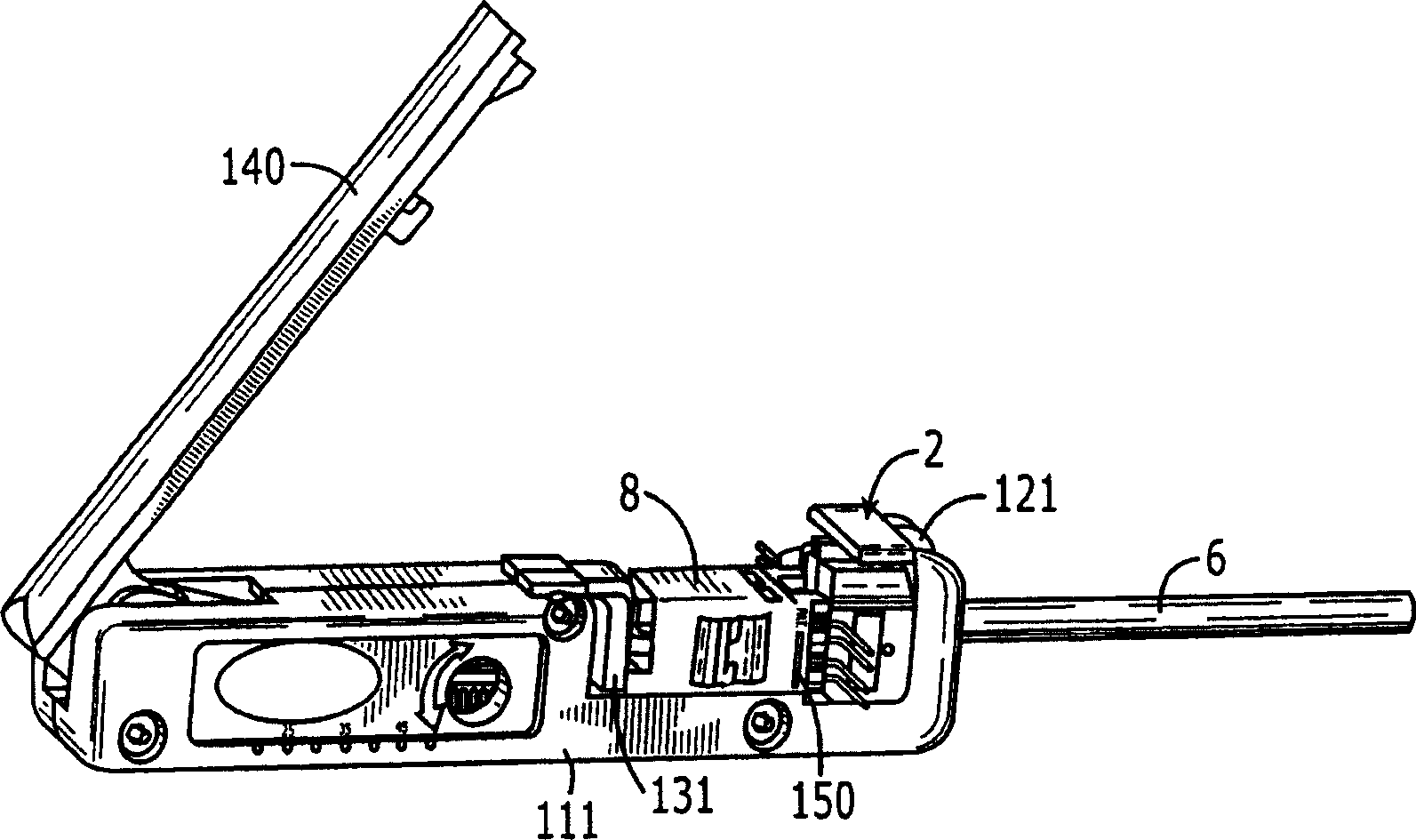

[0024] figure 1 A preferred embodiment of the invention is shown. An example extrusion tool is shown generally at 110 . Body 111 is shown, which includes housings 115 and 120 . The shown wire stripping groove 116 is integral with the body 111 and contains a wire stripping knife 117, which will be further described below. A measuring scale 122 is also shown, used inter alia to measure the stripped length of the cable. Also visible is the action element 130 with a linked finger puller 131 and pusher 135 .

[0025] The handle 140 is shown in the closed position. If desired, the handle 140 can also be placed in a locked position wherein the lug 143 of the handle 140 and the action member 130 are engaged in a mating relationship. Lugs 144 provide base engagement for a cable manager, which will be described further below. The cable channel 121 provides passage for cables, and for mating engagement of cable grippers on the cable manager, described further below.

[0026] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com