Production method of infrared light-emitting diode with high-reliability electrodes

A technology of infrared luminescence and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of easily broken soldering station electrodes and the peeling off of the epitaxial layer of soldering station electrodes, so as to increase the contact surface, increase the current expansion, and improve The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] refer to Figure 1 to Figure 7 As shown, the present invention discloses an infrared light-emitting diode with high-reliability electrodes and the first embodiment of its manufacturing method.

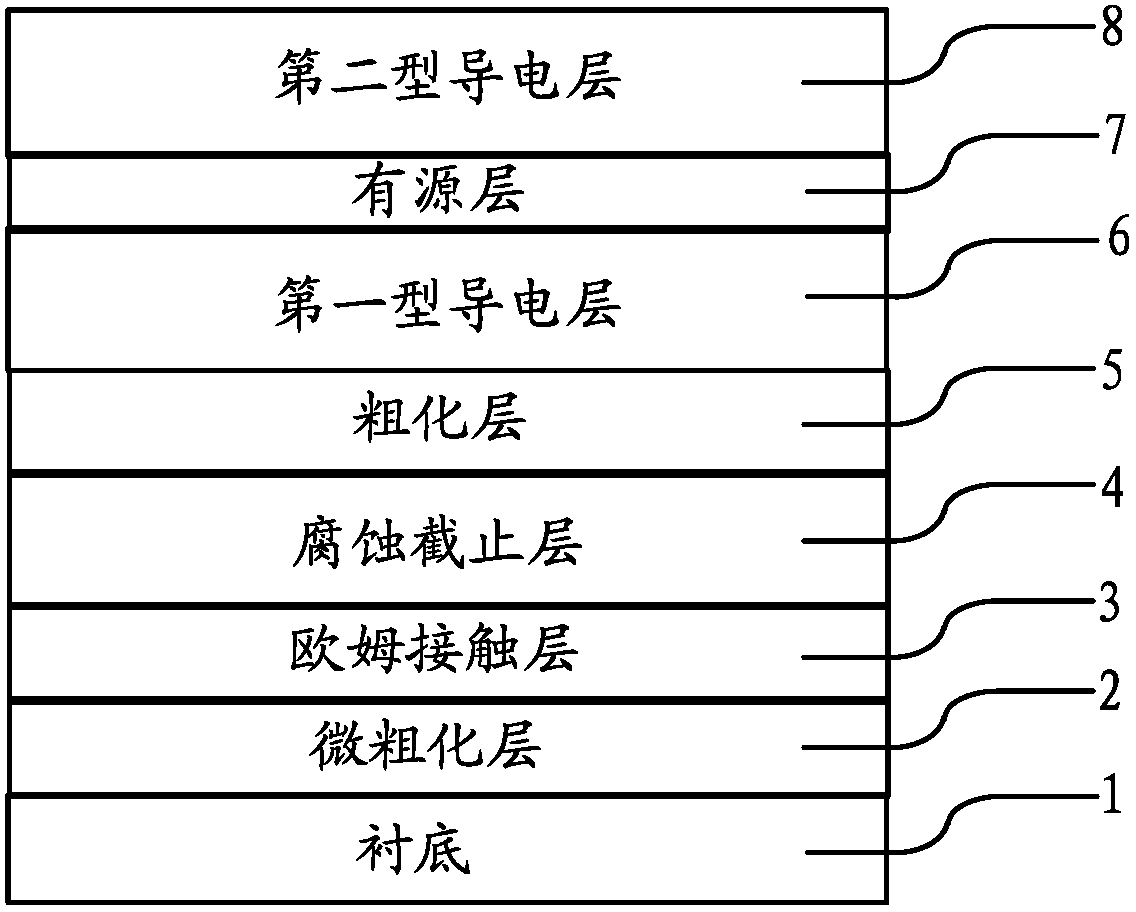

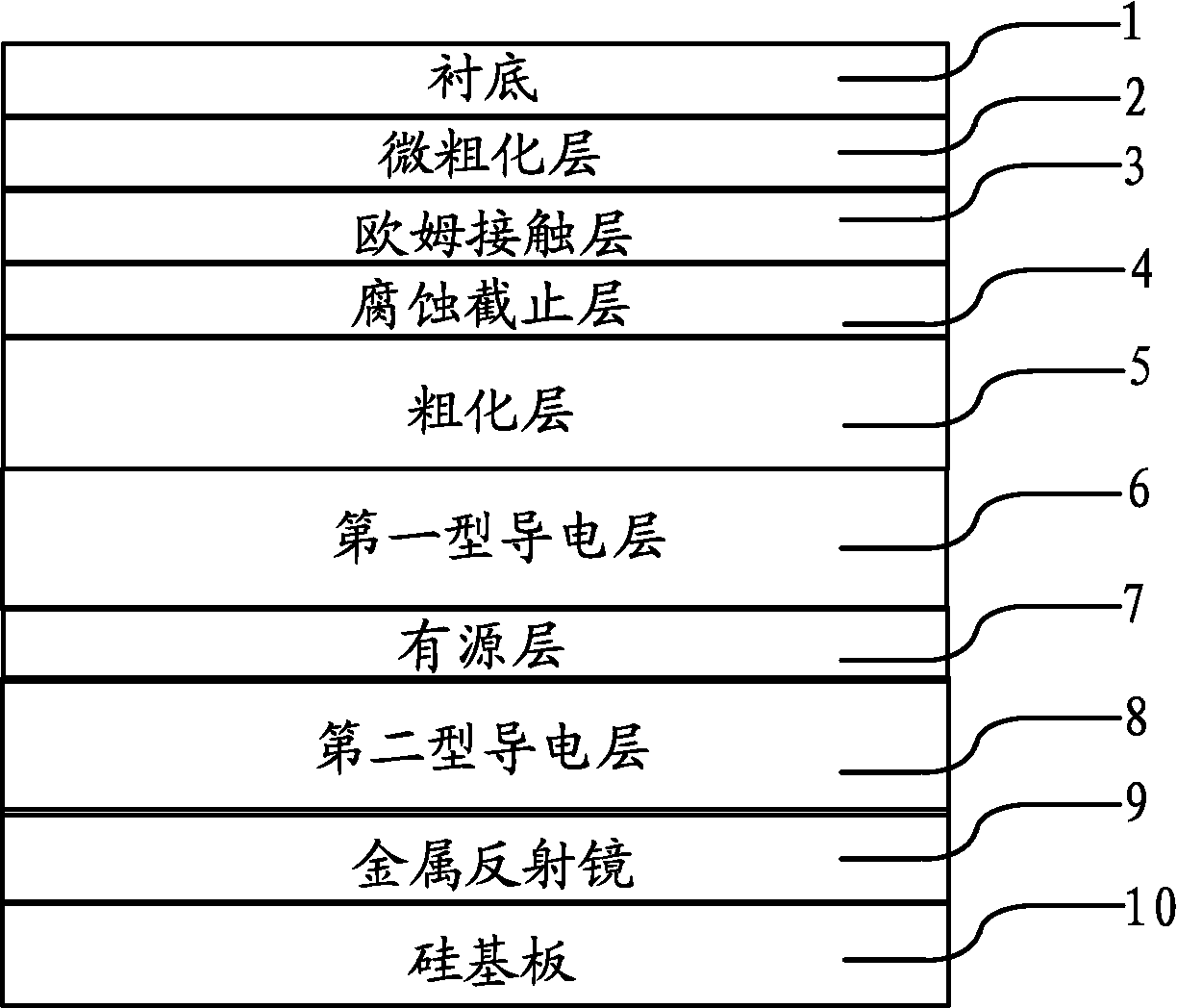

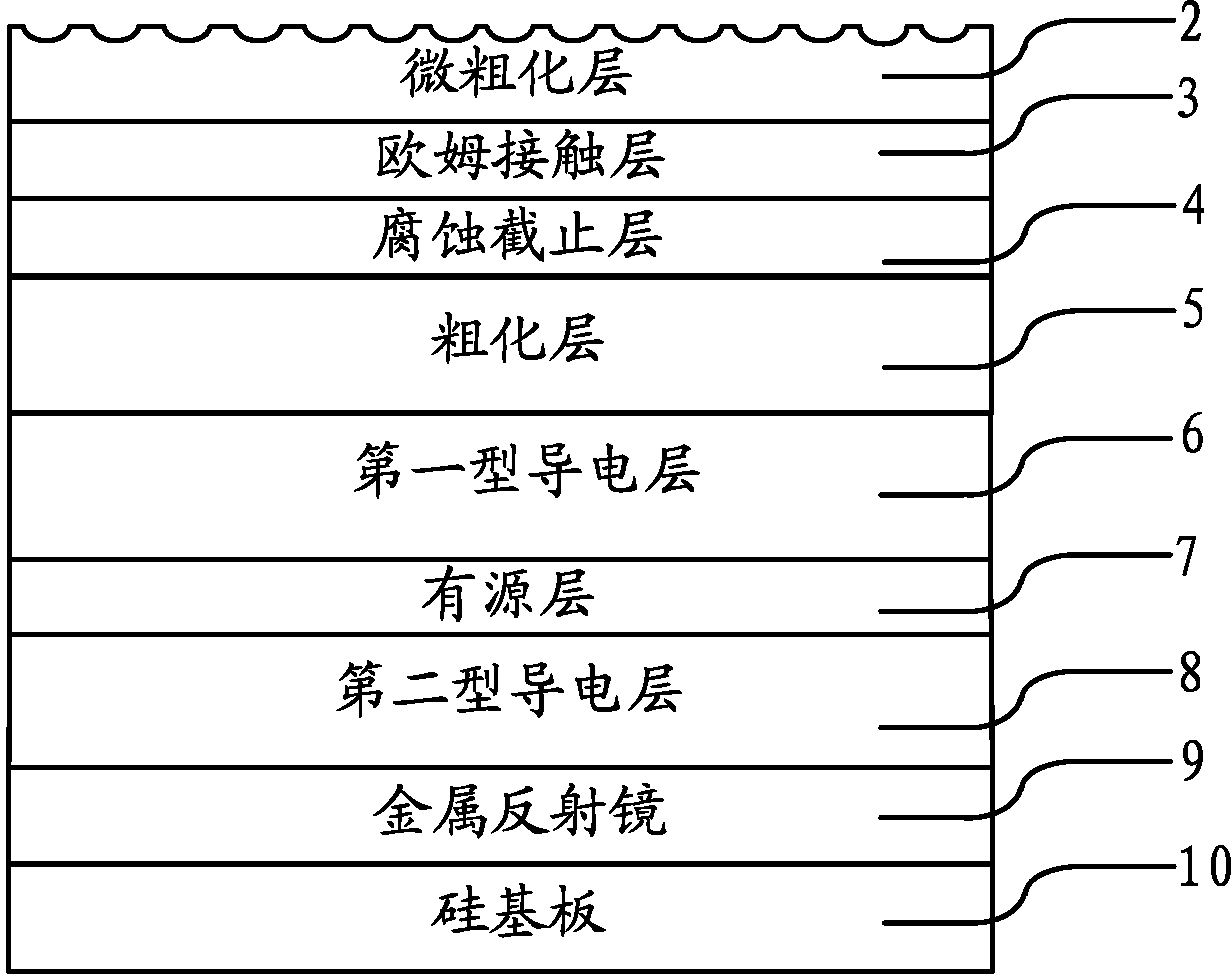

[0050] Such as figure 1 As shown, the upper surface of the GaAs substrate 1 is composed of a micro-roughened layer 2, an ohmic contact layer 3, an etching stop layer 4, a roughened layer 5, a first-type conductive layer 6, an active layer 7, and a first-type conductive layer 6 from bottom to top. Type II conductive layer 8 .

[0051] The material of the micro-roughened layer 2 is (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P three and five compounds, and the thickness of the micro-roughened layer is 200nm.

[0052] The material of the ohmic contact layer 3 is GaAs III-V compound, and the thickness of the ohmic contact layer 3 is 100 nm.

[0053] The material of corrosion stop layer 4 comprises (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P three and five compounds, and the thickness of the corrosion st...

Embodiment 2

[0069] The difference between embodiment two and embodiment one is: the material of the micro-roughened layer 2 is (Al 0.4 Ga 0.6 ) 0.5 In 0.5 P three and five compound, and the thickness of the micro-roughened layer 2 is 300nm.

[0070] The material of the ohmic contact layer 3 is GaAs III-V compound, and the thickness of the ohmic contact layer 3 is 150 nm.

[0071] The material of the corrosion stop layer 4 includes (Al 0.8 Ga 0.2 ) 0.5 In 0.5 P three and five compounds, and the thickness of the corrosion stop layer 4 is 150nm.

[0072] The material of the roughened layer 5 is Al 0.45 Ga 0.55 As III-V compound, and the thickness of the roughened layer 5 is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com