Patents

Literature

30results about How to "Improved current scaling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strained superlattice tunnel junction ultraviolet LED (light emitting diode) epitaxial structure and production method thereof

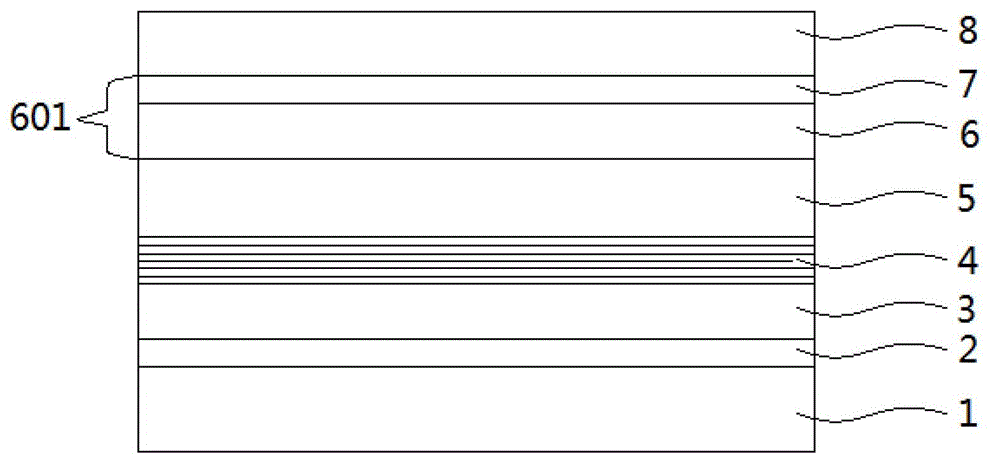

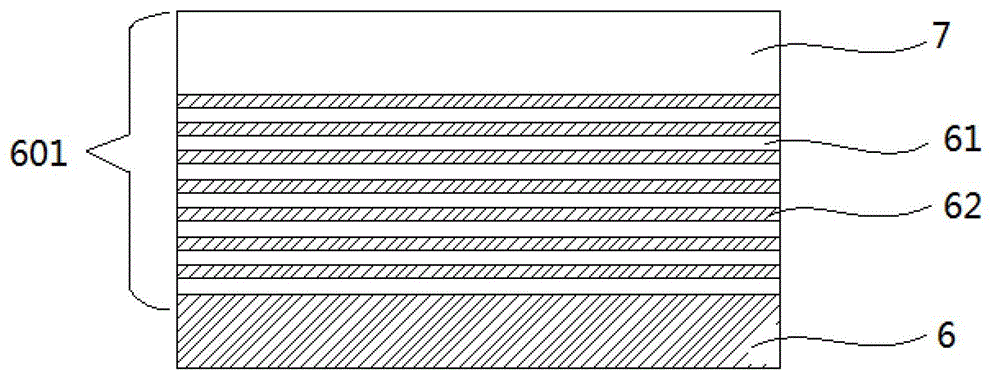

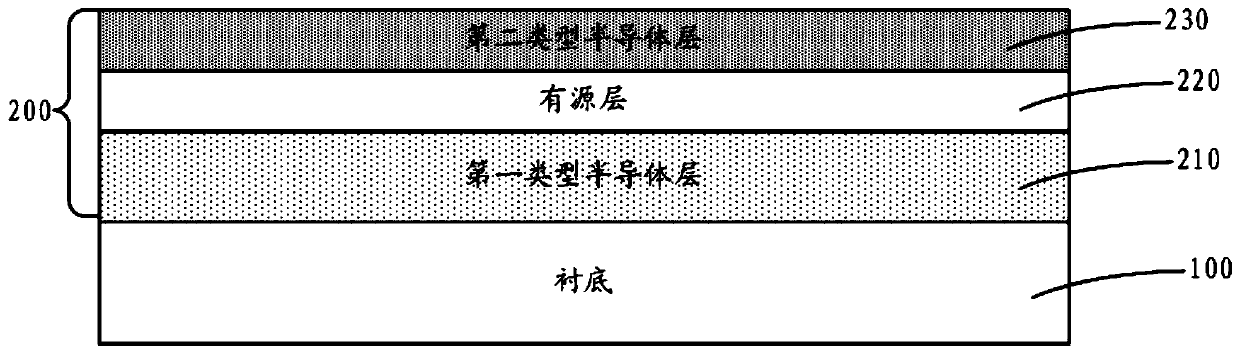

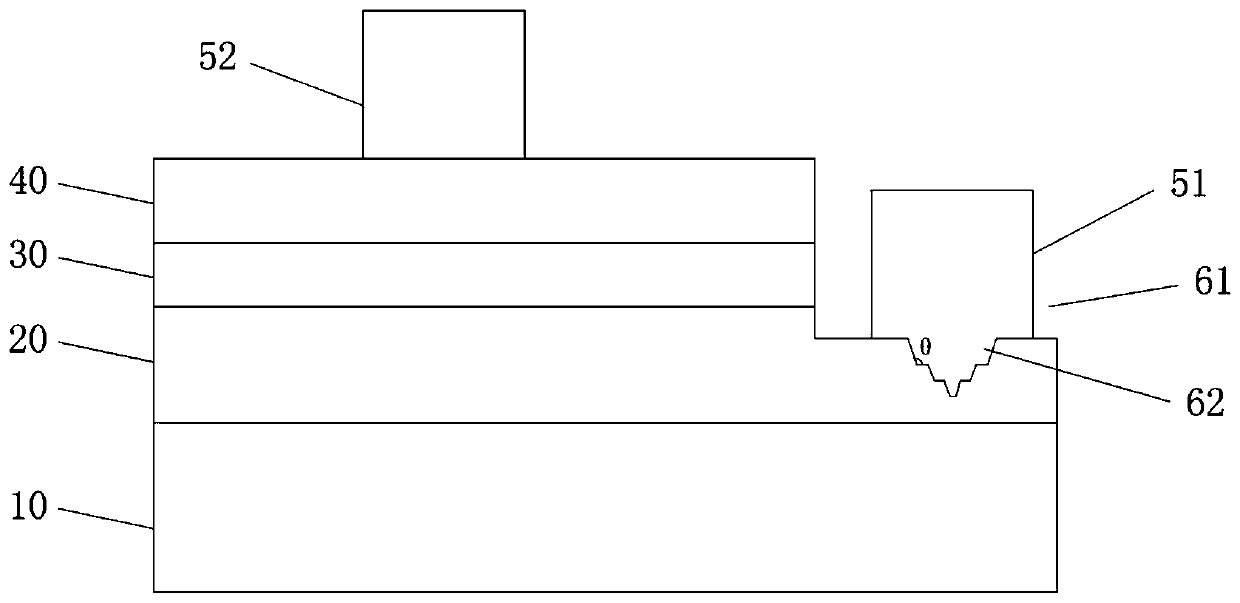

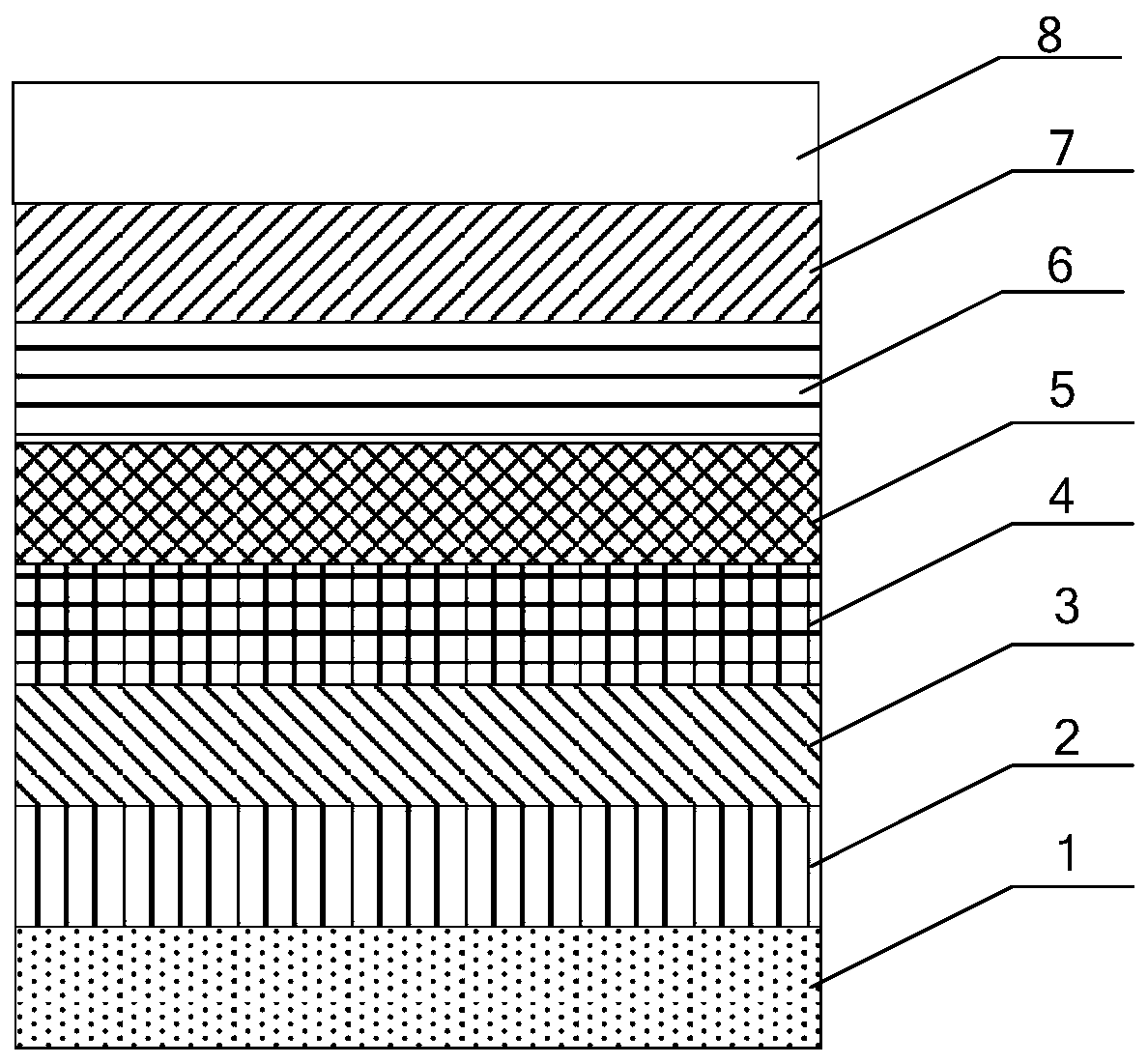

The invention provides a strained superlattice tunnel junction ultraviolet LED (light emitting diode) epitaxial structure and a production method thereof. The epitaxial structure from top to bottom comprises: an epitaxial growth substrate, an AlN buffer layer, an n-type AlGaN layer, a multiple quantum wells, an electron blocking layer, a strained superlattice, an n-type degenerate doped AlGaN layer, and an n-type Si-doped AlGaN layer. The strained superlattice comprises a p-type AlGaN layer and an AlyGa1-yN / AlxGa1-xN. An AlGaN energy band, under effects of a polarized electric field, moves as a whole along a low energy direction. A superlattice structure contacts a heavily doped n-type AlGaN to form a p-AlGaN / SSL / n *-AlGaN tunnel junction. Electrons of a p-type AlGaN valence band, under effects of an external electric field, carried out tunneling through a tunnel effect to one side of the n-type AlGaN, and a hole is formed in the p-type AlGaN. The n-AlGaN is used as the cladding material instead of the p-type AlGaN, so that the problem of the p-type ohmic contact is avoided.

Owner:XI AN JIAOTONG UNIV

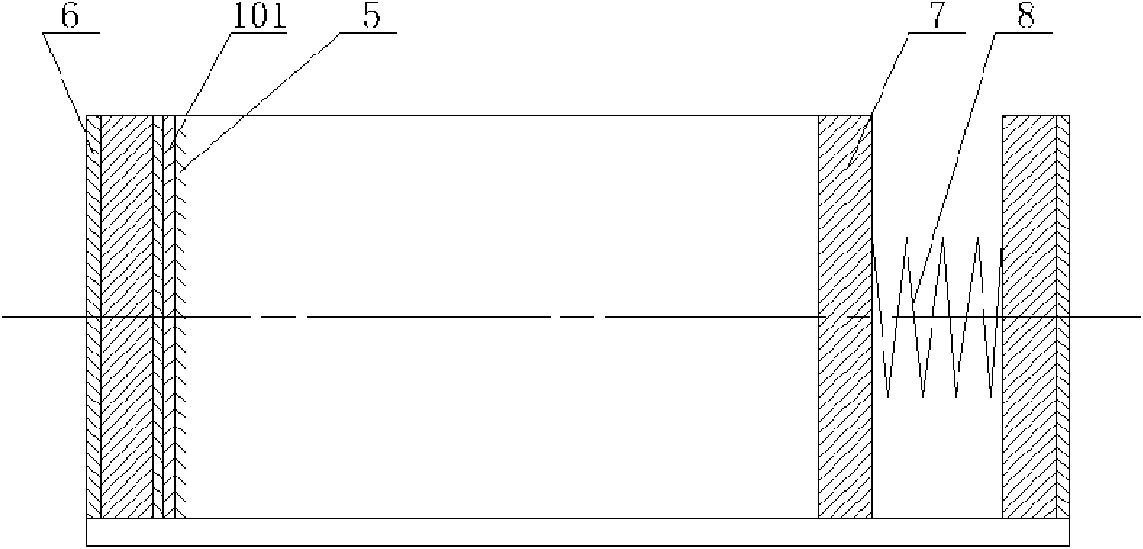

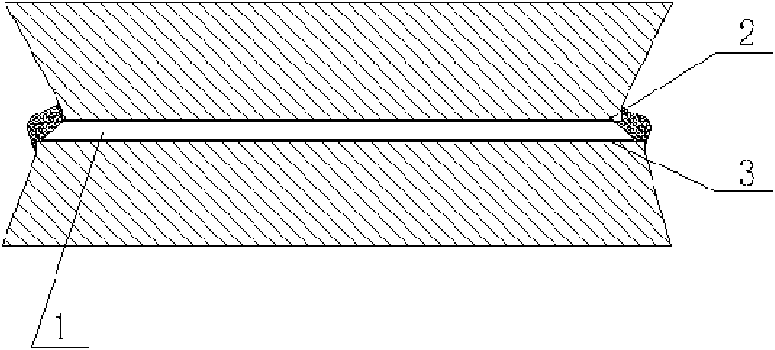

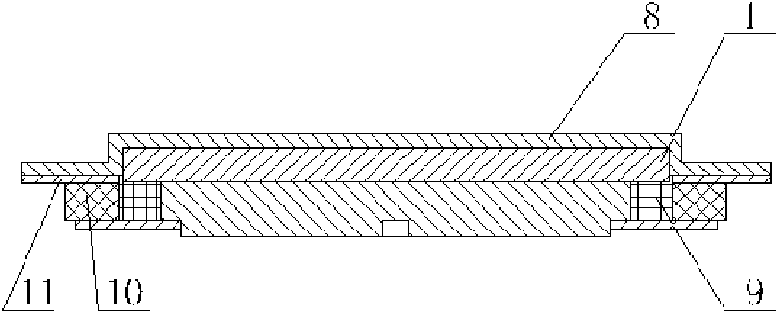

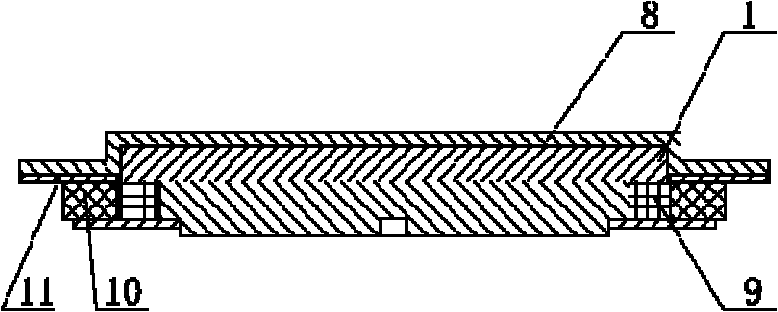

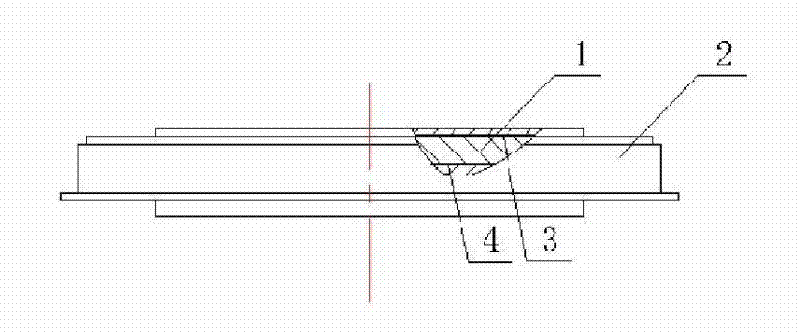

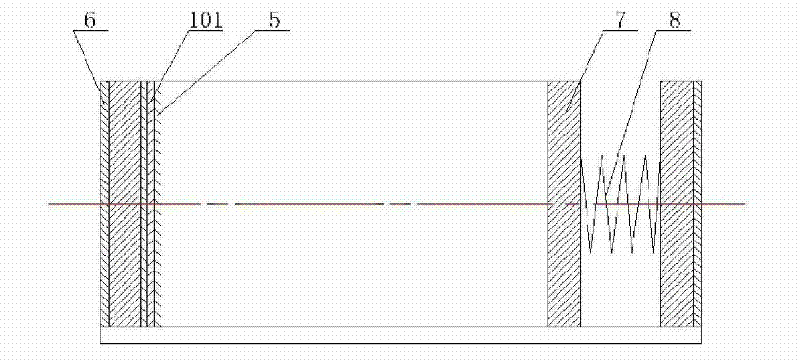

Fast-recovery commutation diode used for high frequency electroplating and production method thereof

ActiveCN101582456AImproved current scaling performanceGuaranteed not to deformSemiconductor/solid-state device manufacturingSemiconductor devicesFurnace temperatureHigh current density

The invention relates to a fast-recovery commutation diode used for high frequency electroplating and a production method thereof, wherein the fast-recovery commutation diode has the high frequency property and is suitable for 30KHz / 2-5KA / (200-400)V high frequency electroplating with both high voltage and high current density. An N-type (100) radial single crystal silicon piece, which has specific resistance Rho n of 5-9 Ohm-cm, diameter of 48-70 mm and thickness of 175-185 microns, is adopted; silicon piece diffusion is conducted, and double-surface once diffusion is carried out at temperature of 1250 DEG C; the diffusion piece detection is carried out; phosphorosilicate glass and borosilicate glass are used for absorption, the temperature is slowly lowered from 1250 DEG C to 1050 DEG C, the speed rate is 1 DEG C per minute, and isothermal absorption is carried out for 2-3 h; slow temperature reduction is continued till furnace temperature is reduced to 600 DEG C, then furnace delivery is carried out, and minority carrier lifetime Tao p is caused to reach 12-16 Mu S; platinum diffusion is carried out at low temperature so that the minority carrier lifetime Tao p is controlled to be 4-6 Mu S; 12 Mev electron irradiation is carried out so that the minority carrier lifetime Tao p of a base region is 0.9-1.1 Mu S; the two surfaces of the silicon piece are plated with titanium-nickel-gold by means of vapor deposition and then undergo table-board spray sand molding, desanding, cleaning, corrosion, passivation protection, intermediate test, shell arrangement and packaging, and after tests testify qualification, the finished product is produced.

Owner:JINZHOU SHENGHE POWER ELECTRONICS

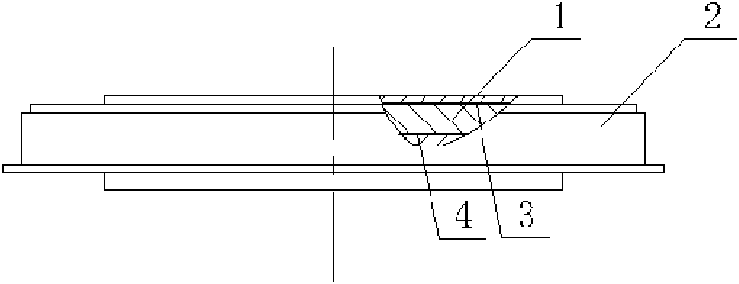

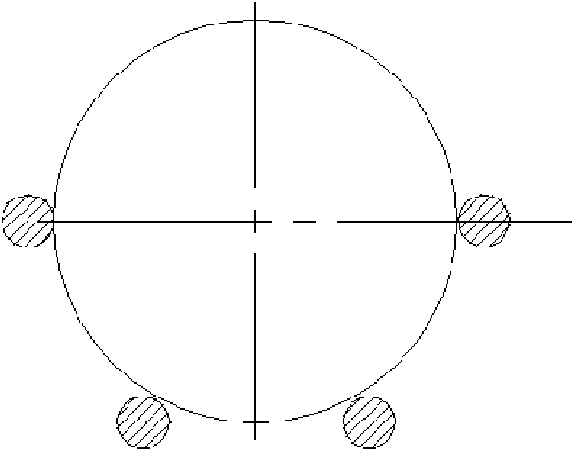

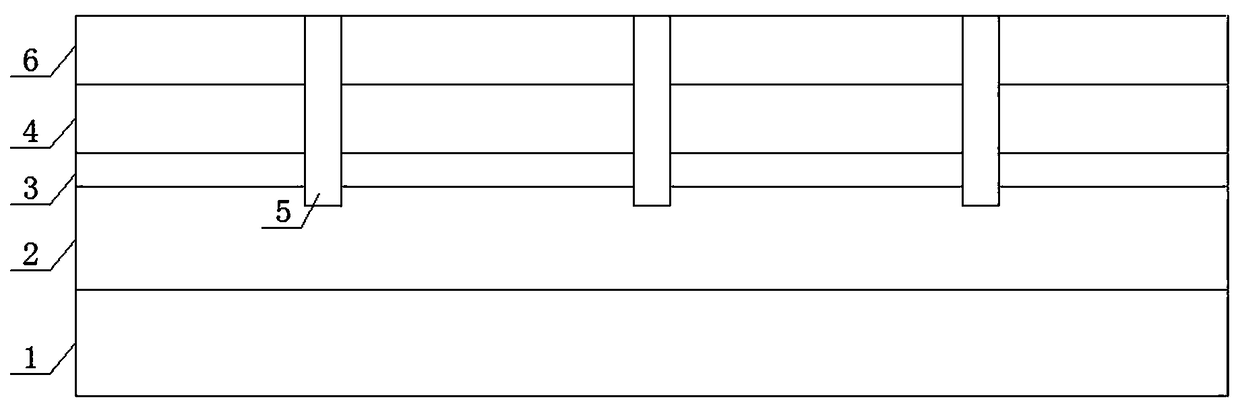

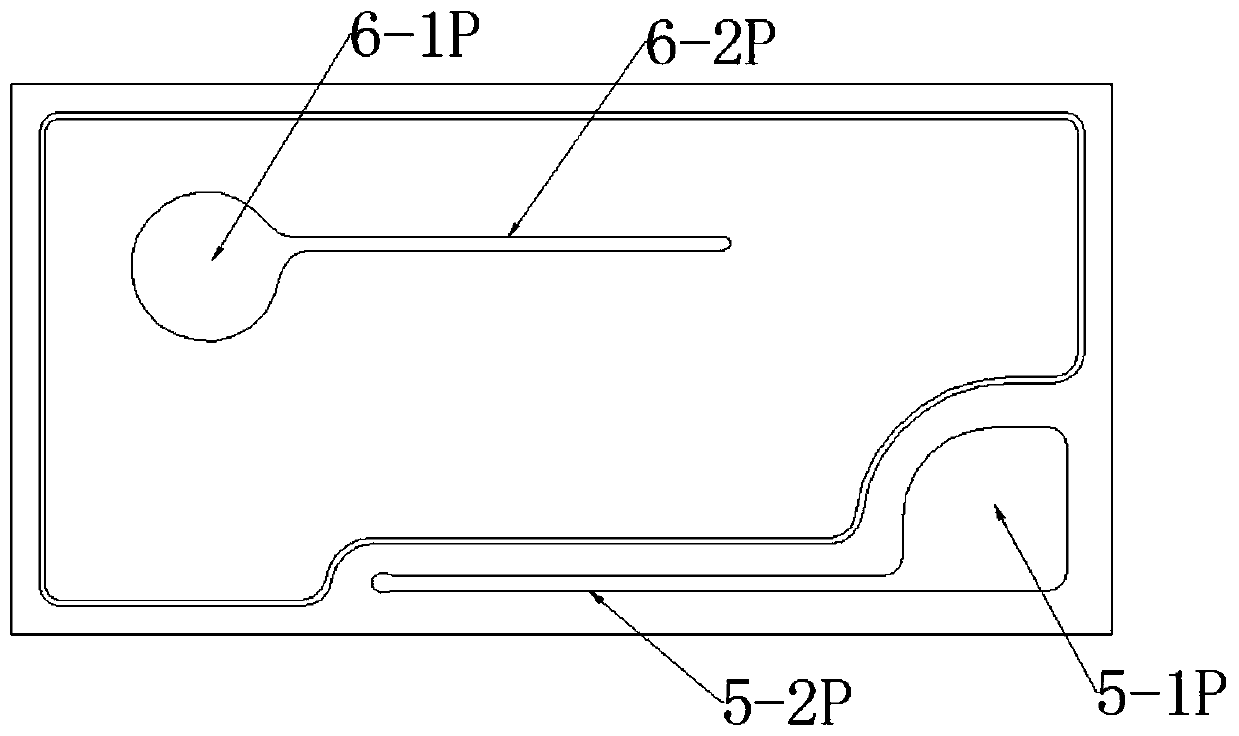

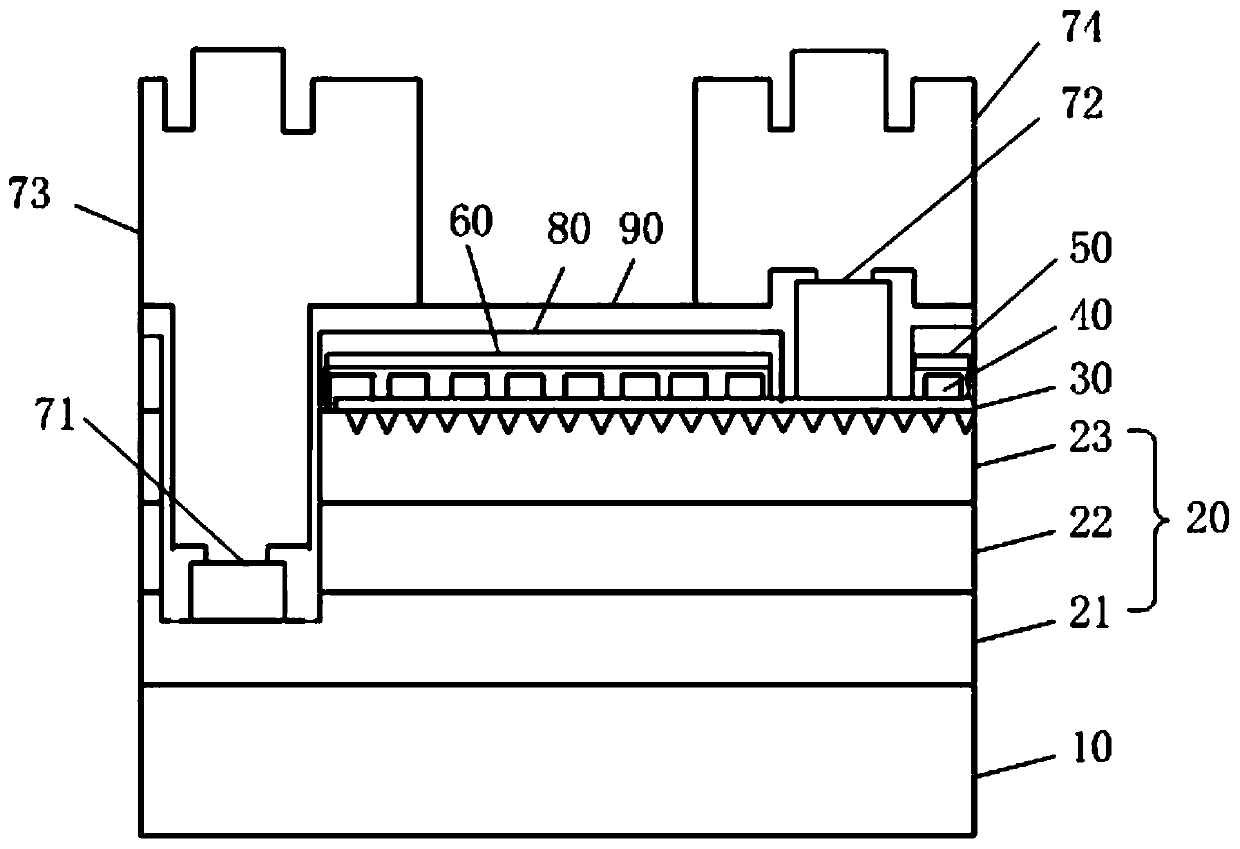

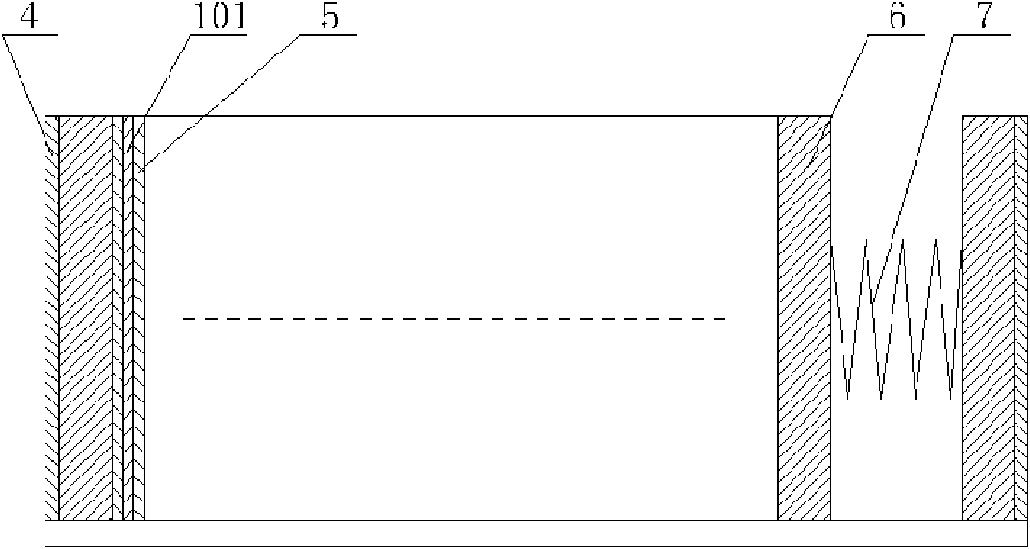

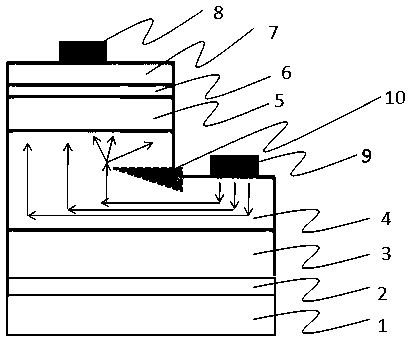

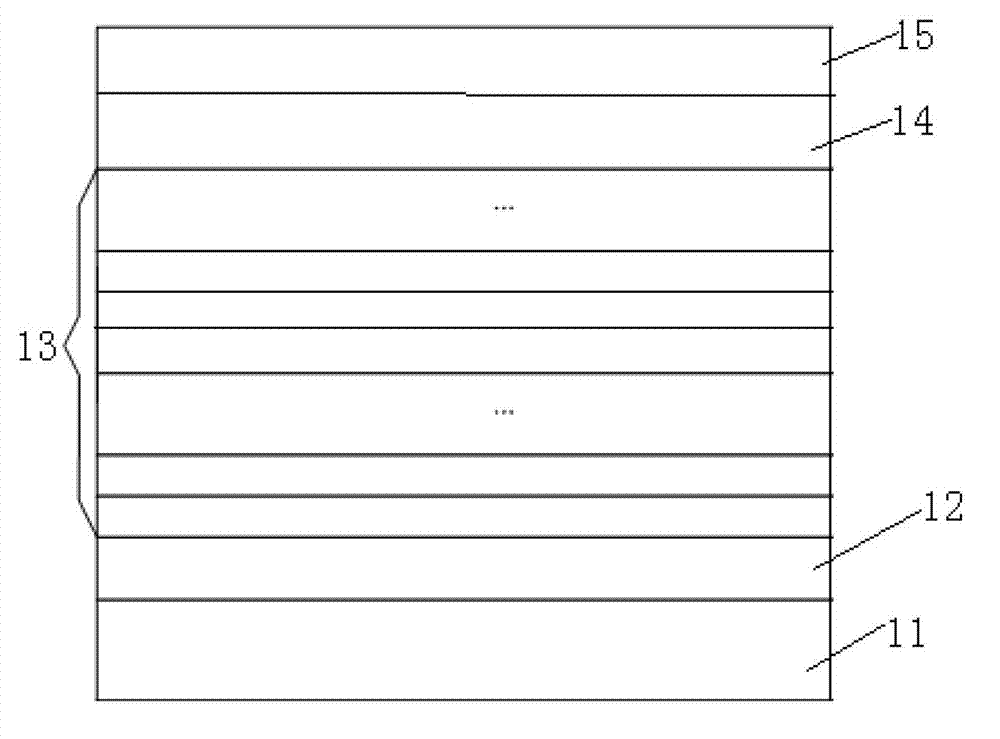

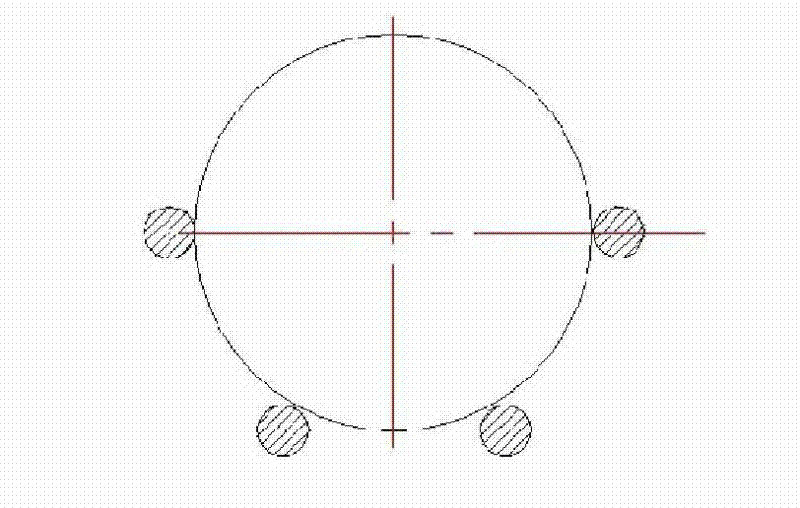

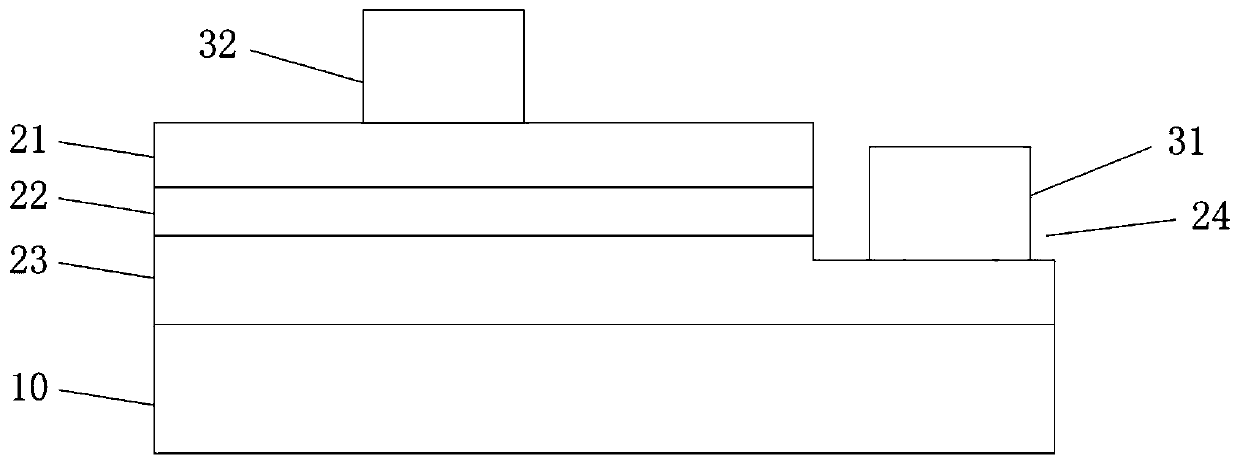

Bimetal-layer annular-interdigital-electrode flip-chip LED chip and manufacturing method thereof

ActiveCN109326688AImproved current scaling performanceReduce constraintsSemiconductor devicesIsolation layerEngineering

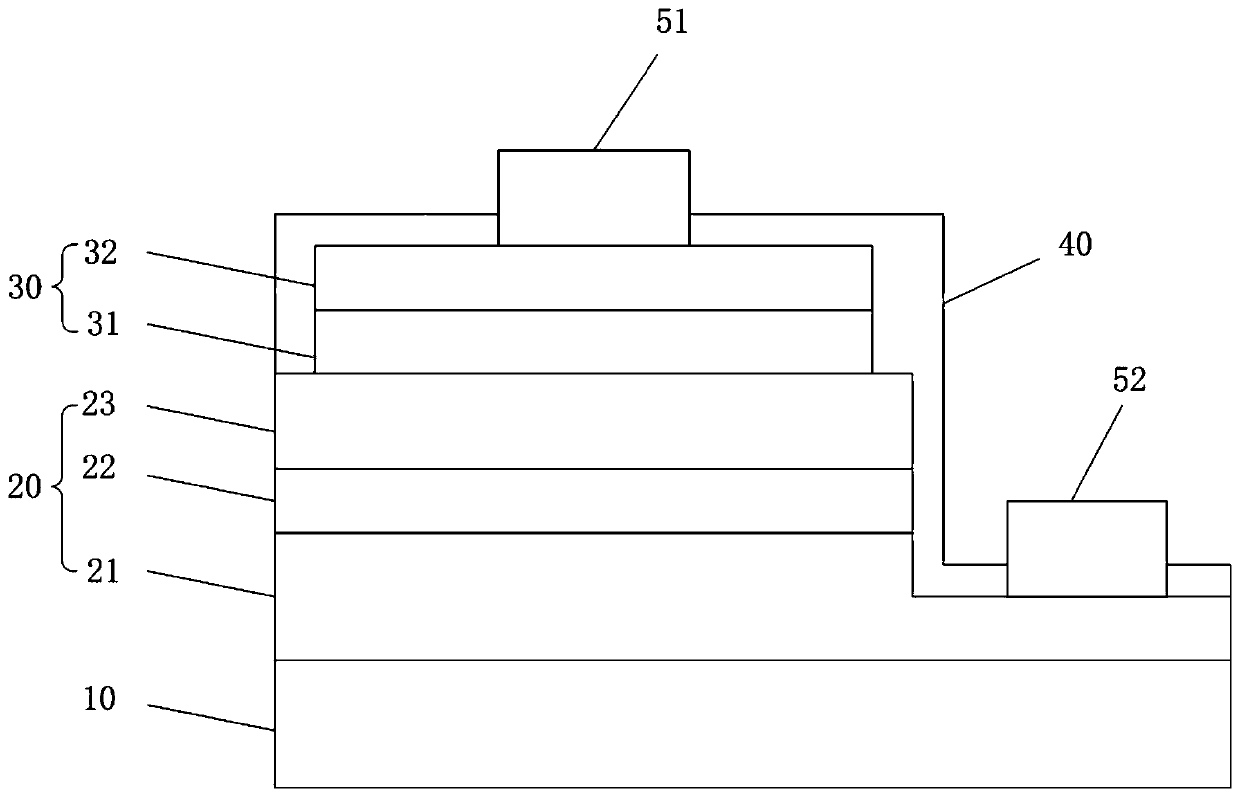

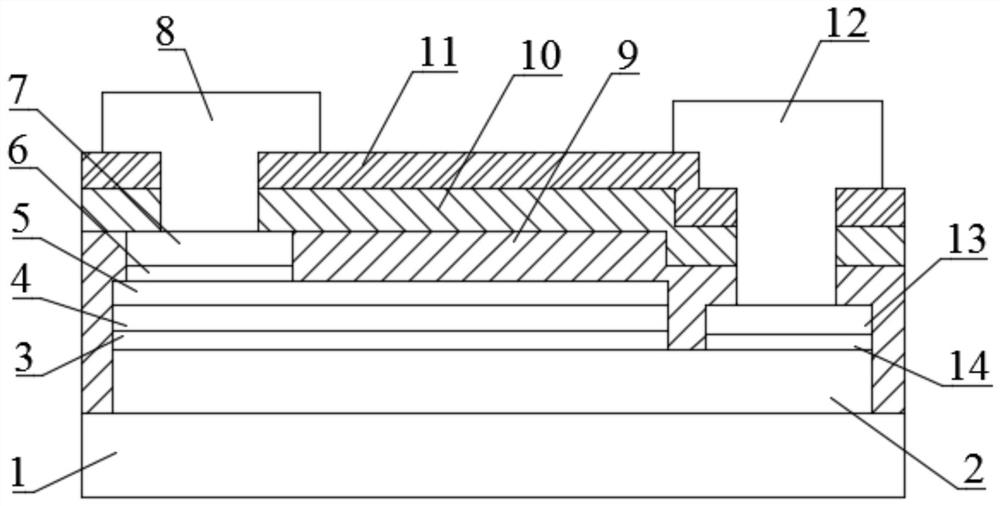

The invention discloses a bimetal-layer annular-interdigital-electrode flip-chip LED chip and a manufacturing method thereof. The chip comprises a substrate, an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer sequentially from bottom to top. The p-type semiconductor layer is provided with a current expanding layer which is provided with a first insulating isolation layer, the first insulating isolation layer is partitioned into a plurality of n-pole annular strips in concentric distribution at equal intervals and a plurality of p-pole annular strips in concentric distribution at equal intervals, and the n-pole annular strips and the p-pole annular strips are alternately arranged to form an annular interdigital structure. Different structural arrangementof the upper half portion and the lower half portion of each electrode is realized, electrode hindrance is sharply reduced, the problem of current gathering around the electrodes is solved, the current expanding performance of the flip-chip LED chip is improved, and accordingly light-emitting efficiency is improved. In addition, a large-area n electrode bonding pad and a p electrode bonding pad onthe upper half portion are realized, and accordingly free configuration is realized to a great extent, smooth implementation of subsequent packaging is facilitated, and the finished product rate is increased.

Owner:JIUJIANG VOCATIONAL & TECHN COLLEGE

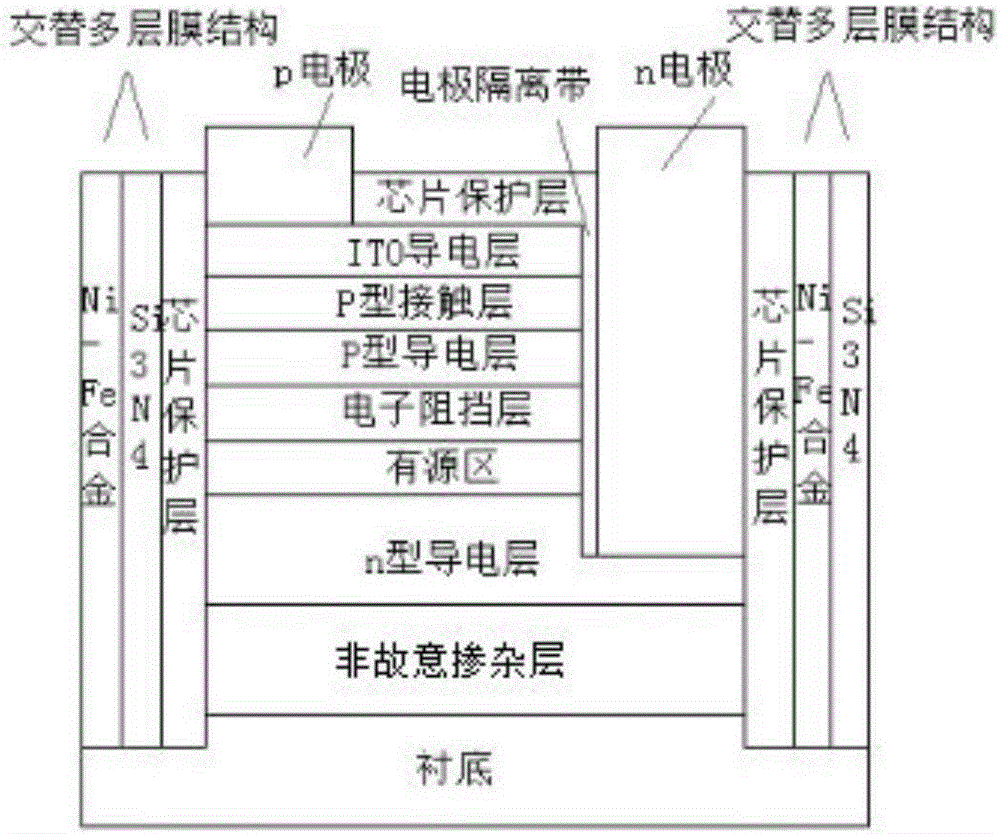

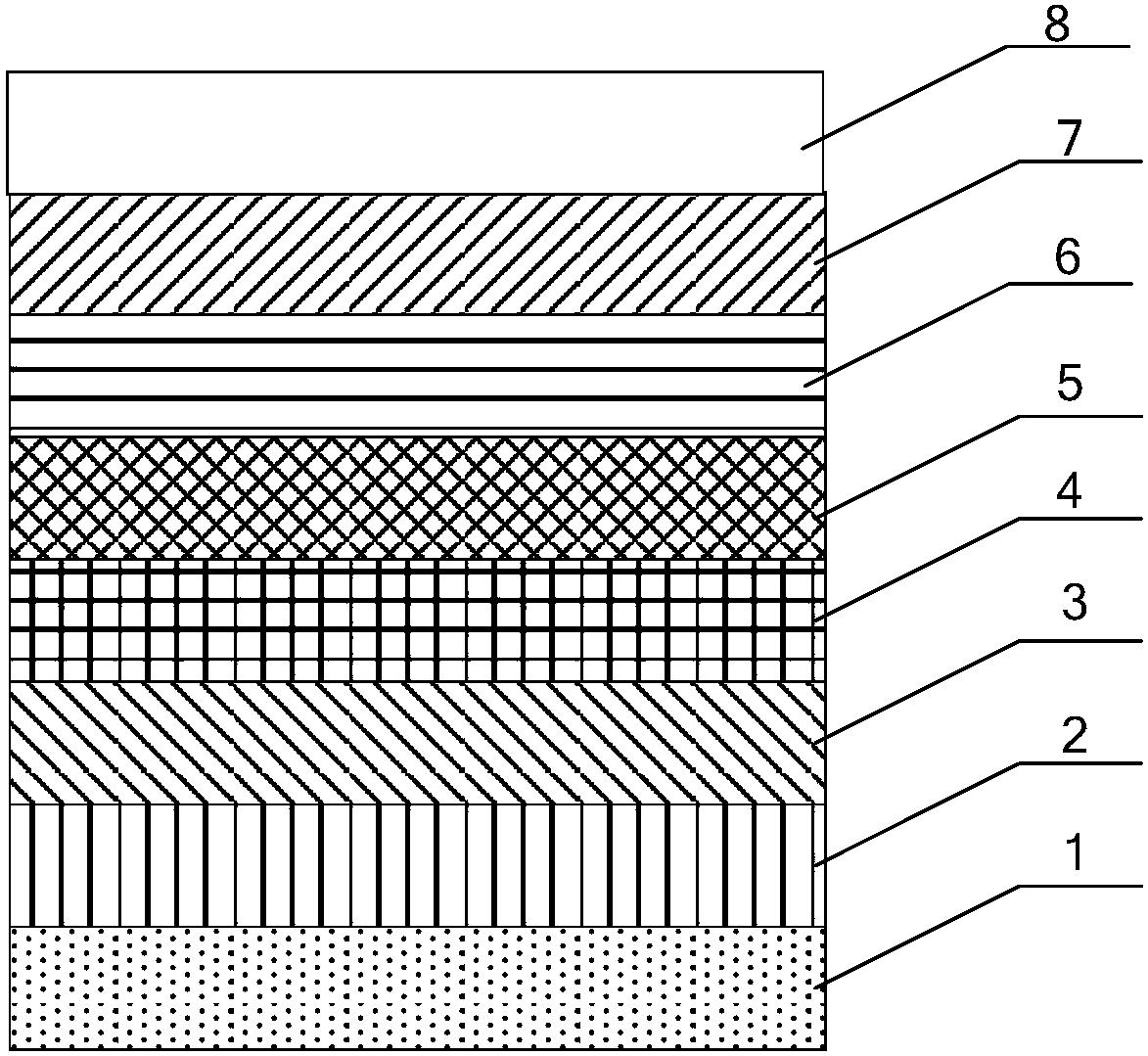

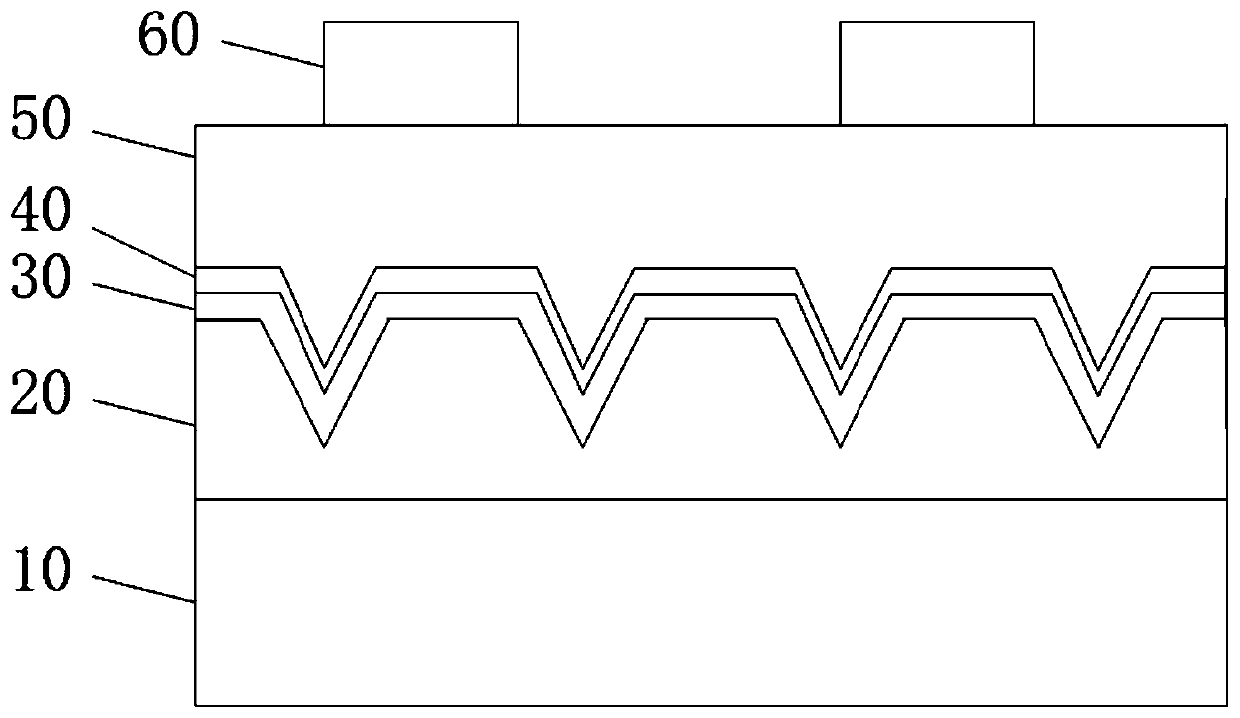

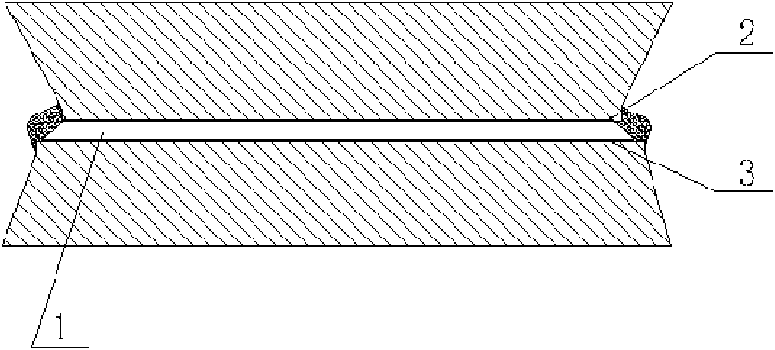

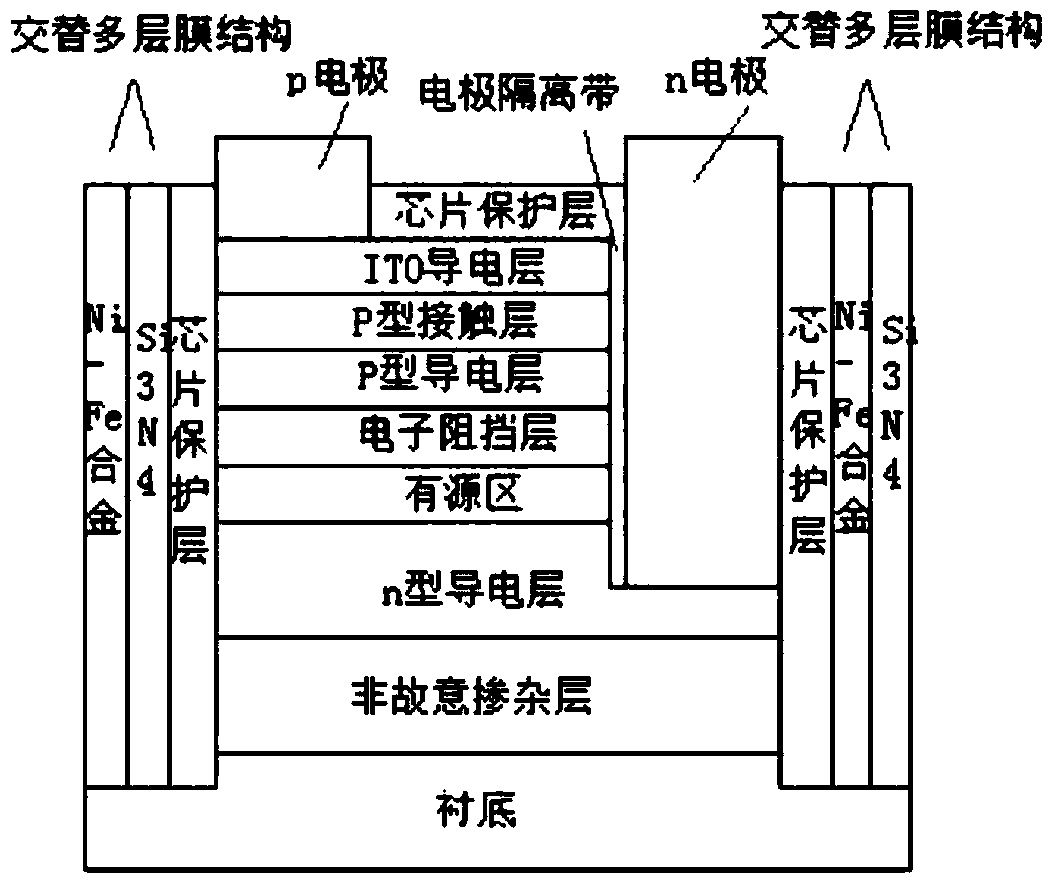

Light-emitting diode with high expanding effect

InactiveCN105226153AAdded outer quantum effectImproved current scaling performancePoint-like light sourceSemiconductor devicesLarge sizeLight-emitting diode

The invention discloses a light-emitting diode (LED) with a high expanding effect. The LED comprises a substrate on which an LED chip epitaxial layer is arranged. The two side surfaces of the LED chip epitaxial layer are provided with first alternate multilayer film structures. The other two side surfaces of the LED chip epitaxial layer are provided with second alternate multilayer film structures. The N-type and P-type current expanding effects of the LED are effectively enhanced. The electrode light-shielding area is not increased. The N-type current expanding effect of a large-size chip is enhanced.

Owner:XIAMEN CHANGELIGHT CO LTD

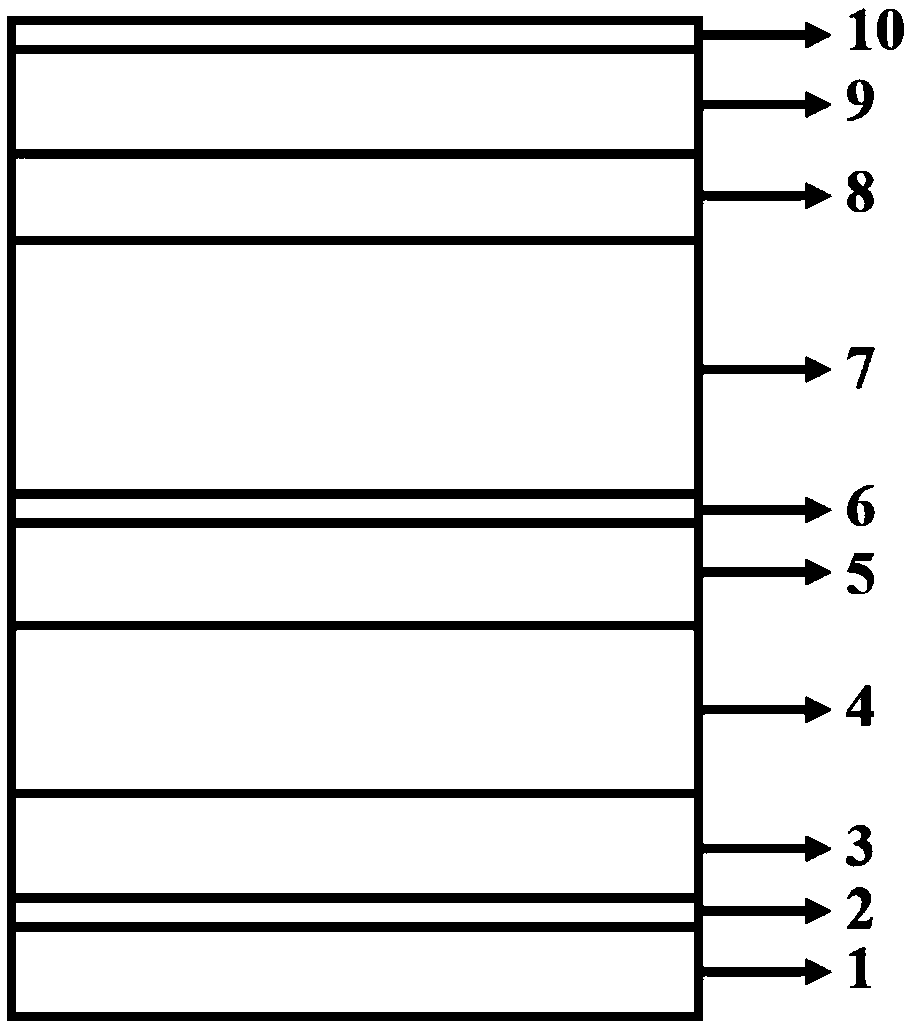

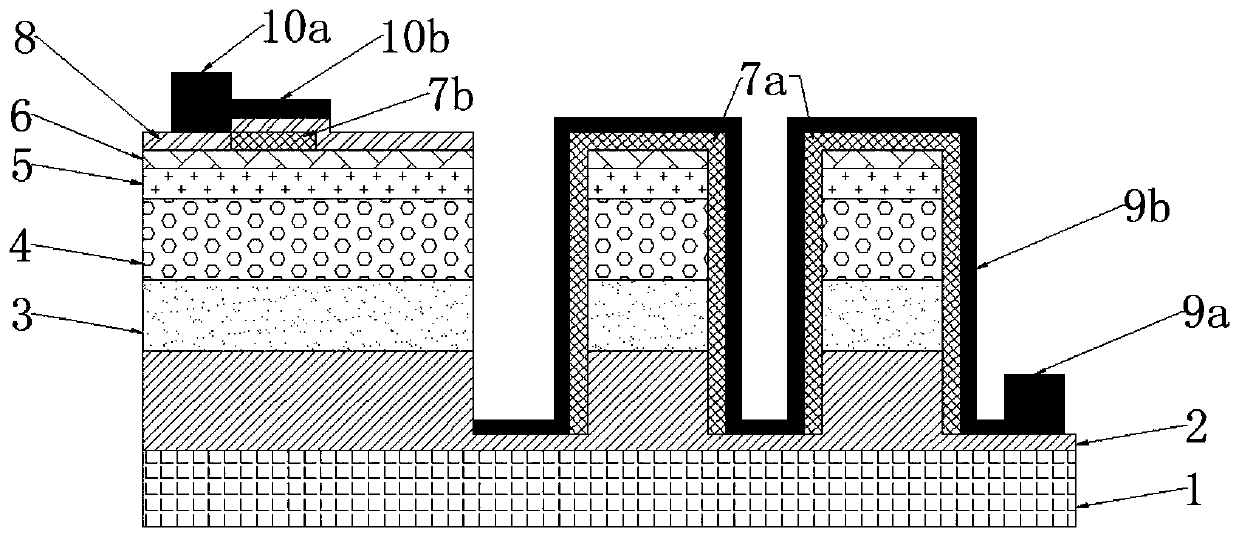

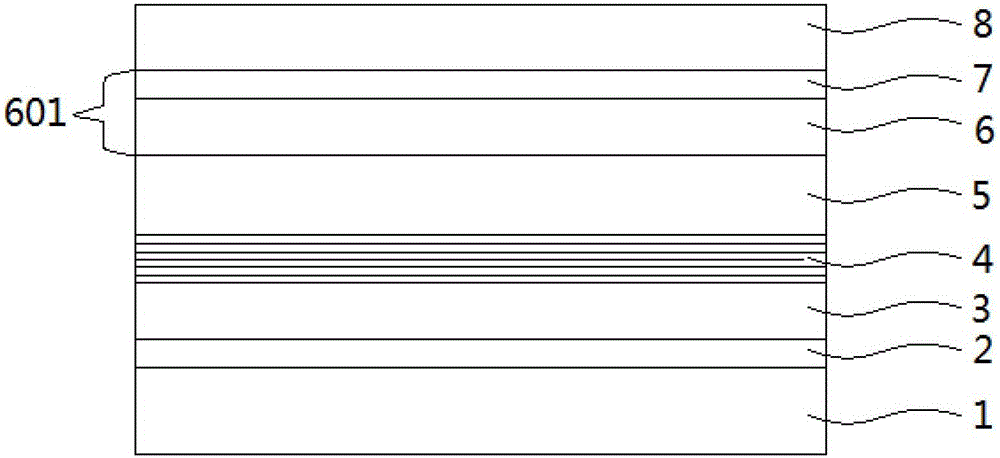

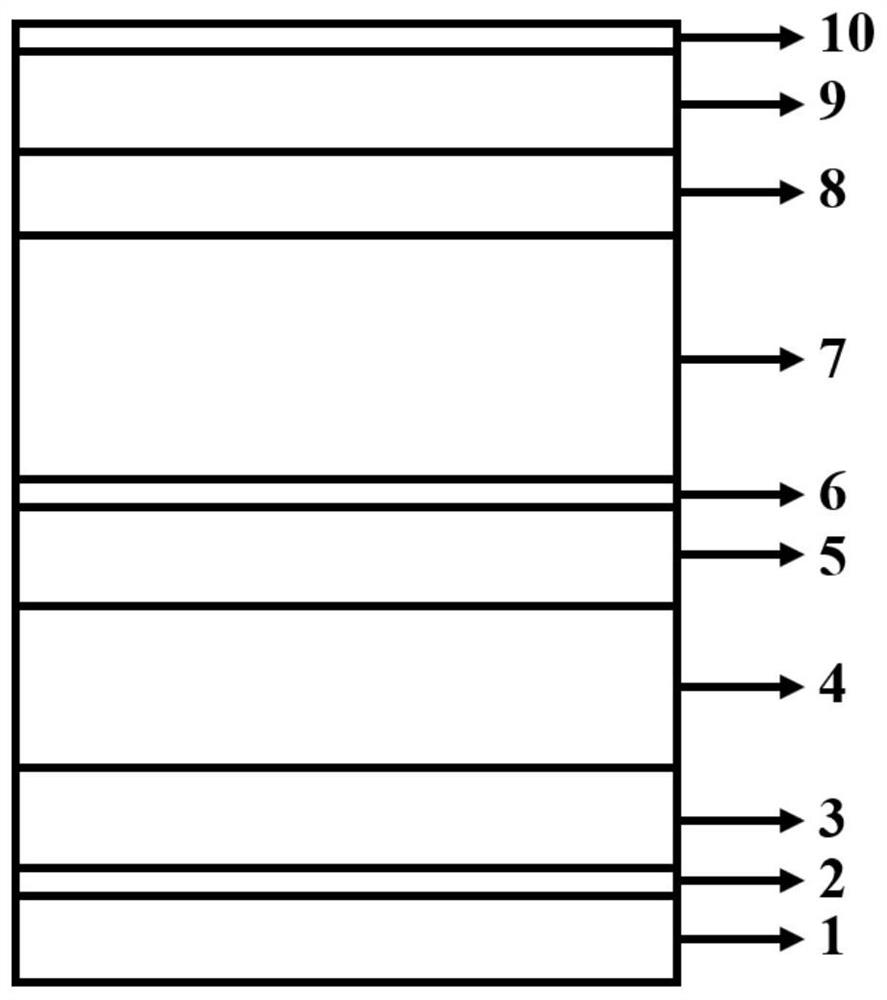

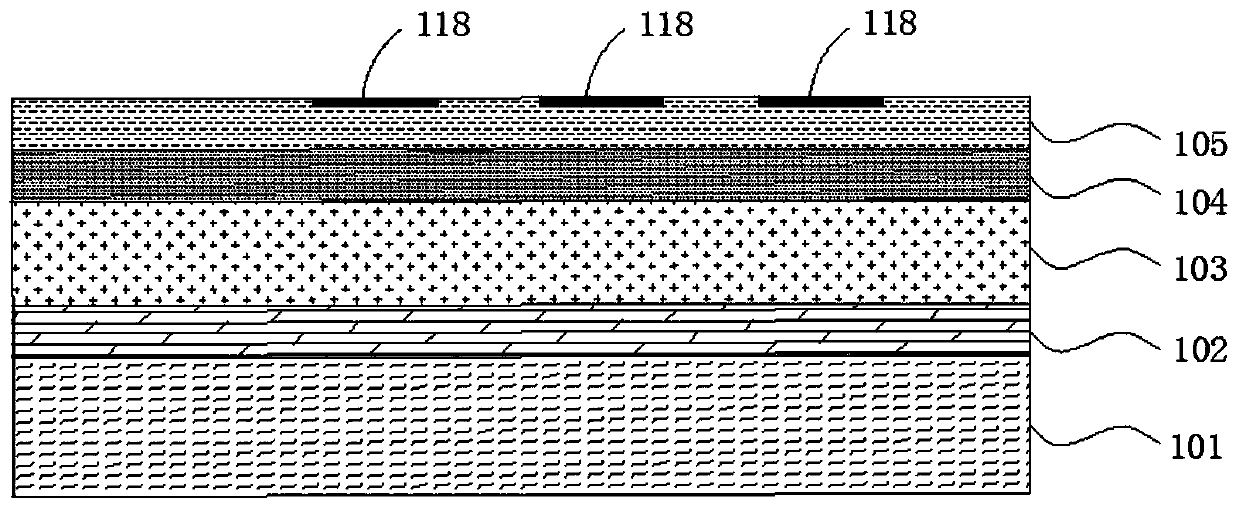

Large-power vertical structure LED epitaxial structure and preparation method thereof

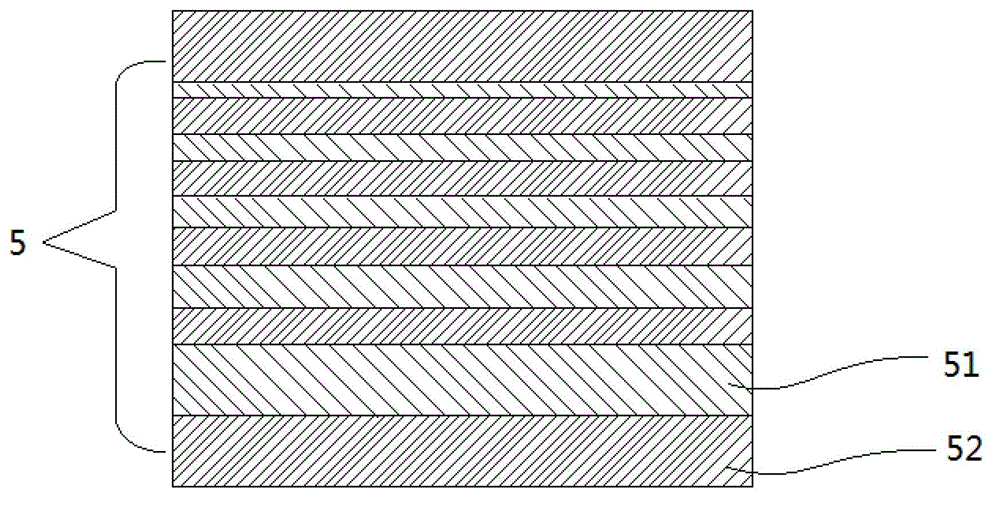

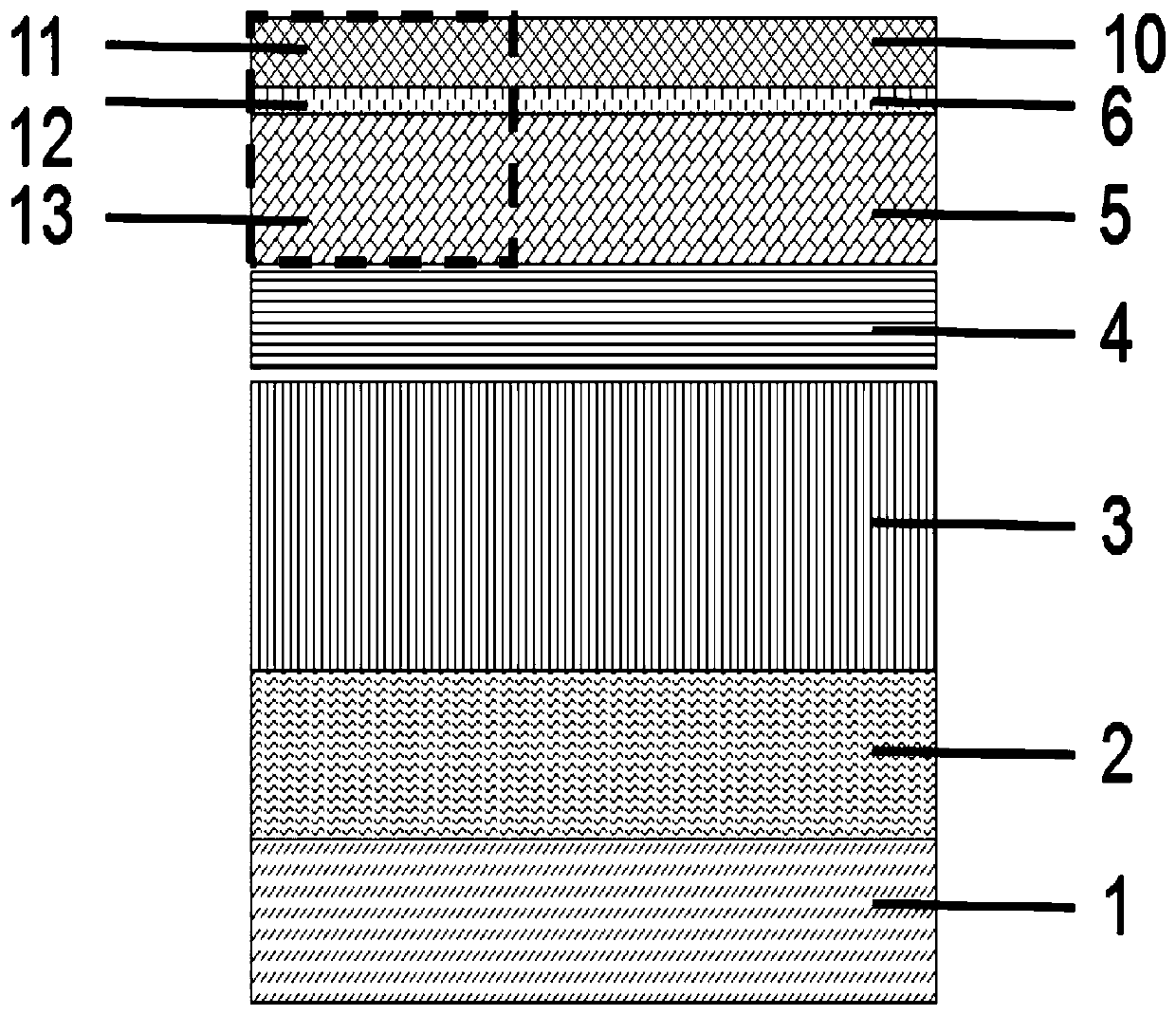

ActiveCN108807627AImproved current scaling performanceImprove conductivityNanotechnologySemiconductor devicesQuantum wellGas phase

The invention discloses a large-power vertical structure LED epitaxial structure. The large-power vertical structure LED epitaxial structure includes a pre-paved Al layer, an AlN buffer layer, an AlGaN buffer layer, a u-type GaN layer, a first graphene layer, an n-type GaN layer, a multi-quantum well, a p-type GaN layer, and a second graphene layer, wherein all the above layers and the multi-quantum well are grown on an Si substrate; and the first graphene layer and the second graphene layer are formed by vapor deposition. The large-power vertical structure LED epitaxial structure has better photoelectric performance and has wide application.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

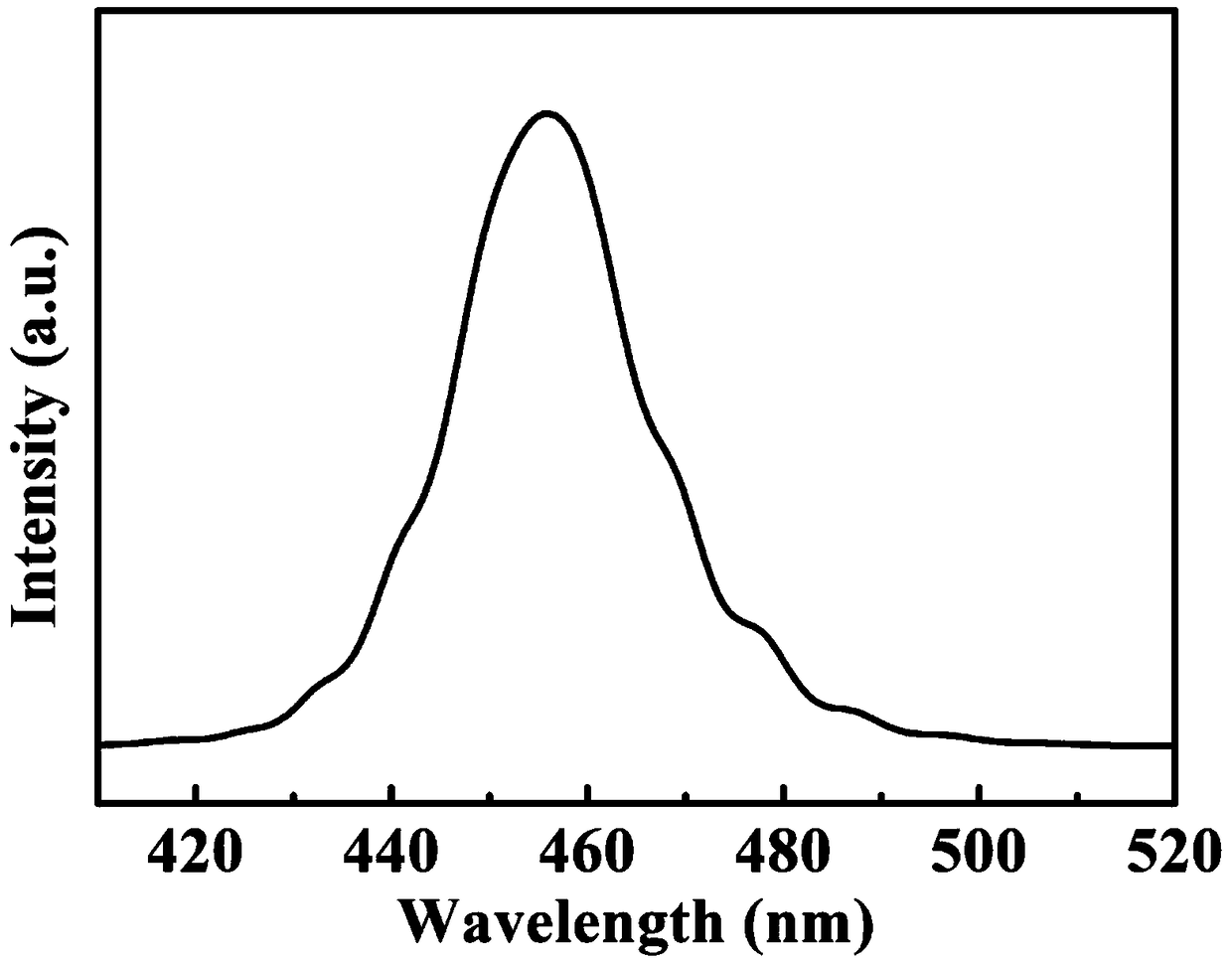

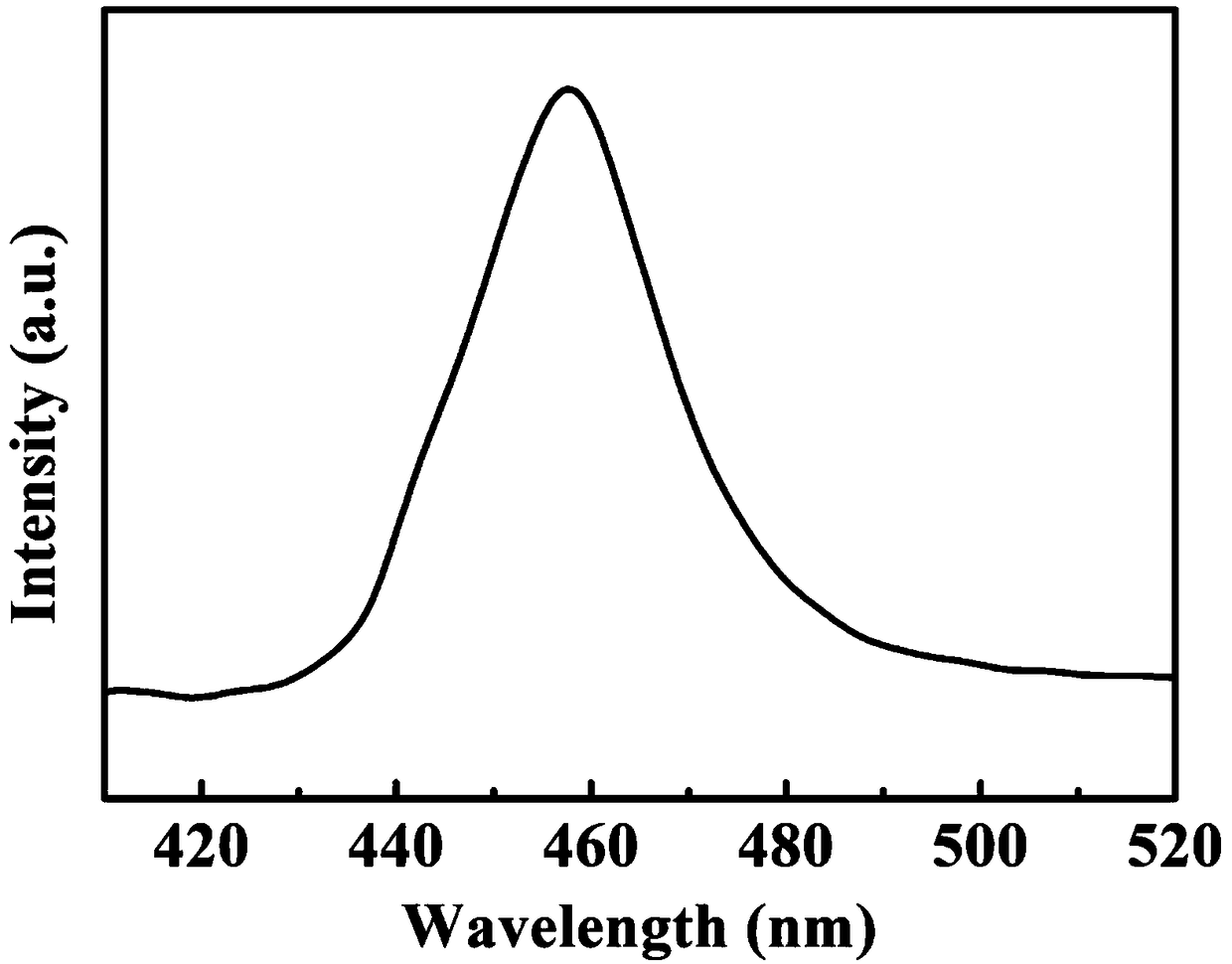

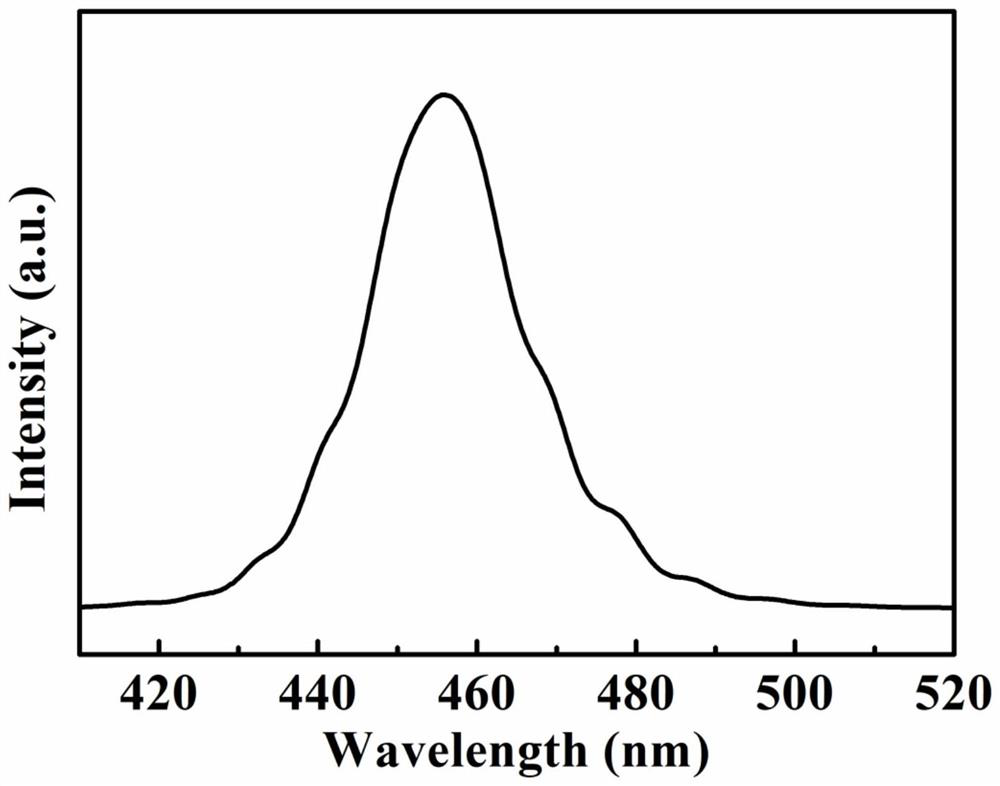

Ultraviolent LED epitaxial structure and growth method thereof

ActiveCN107689405ALower ionization energyIncrease concentrationSemiconductor devicesUltravioletScattering effect

The invention provides a growth method for an ultraviolet LED epitaxial structure, specially a special growth process for multiple quantum wells of an active area, and the special growth process comprises the following steps: growing LP and PAL as an integral superlattice, wherein a growth period is 5-20; adopting roof type gradual doping for doping of Mg, i.e., gradually reducing after doping ofMg firstly gradually increases to reach a peak value, wherein doping is in symmetrical distribution. Through the superlattice growth, ionization energy of Mg can be reduced, hole concentration is improved, the impurity scattering effect on the hole is reduced, and more holes are injected into a light-emitting area, so that light emitting efficiency is improved. The method is an effective method capable of improving efficiency of an ultraviolet LED; and meanwhile, an apparatus has very good light emitting efficiency, so that photoelectric property of the apparatus is improved.

Owner:宁波安芯美半导体有限公司

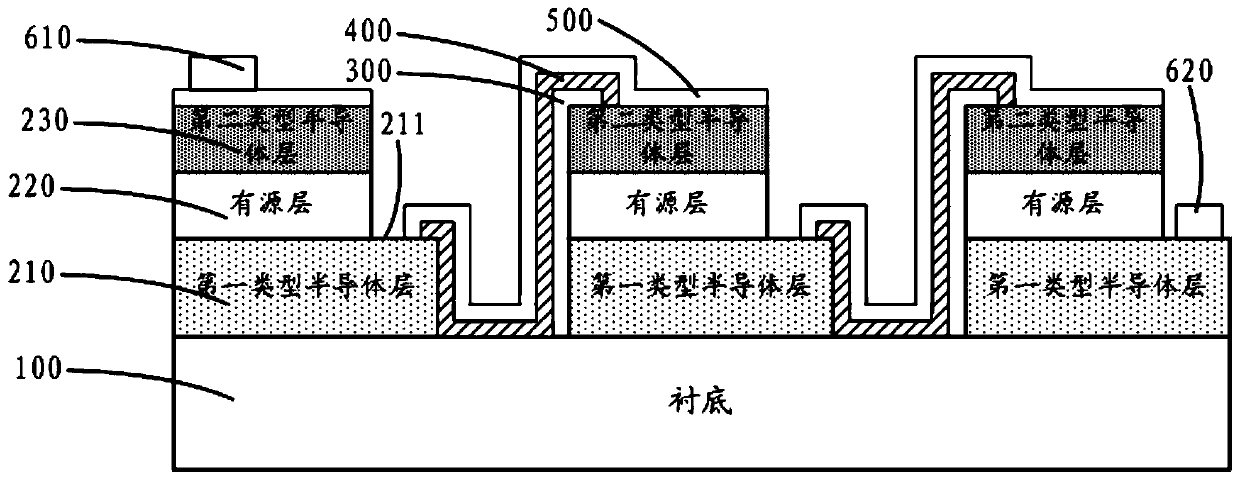

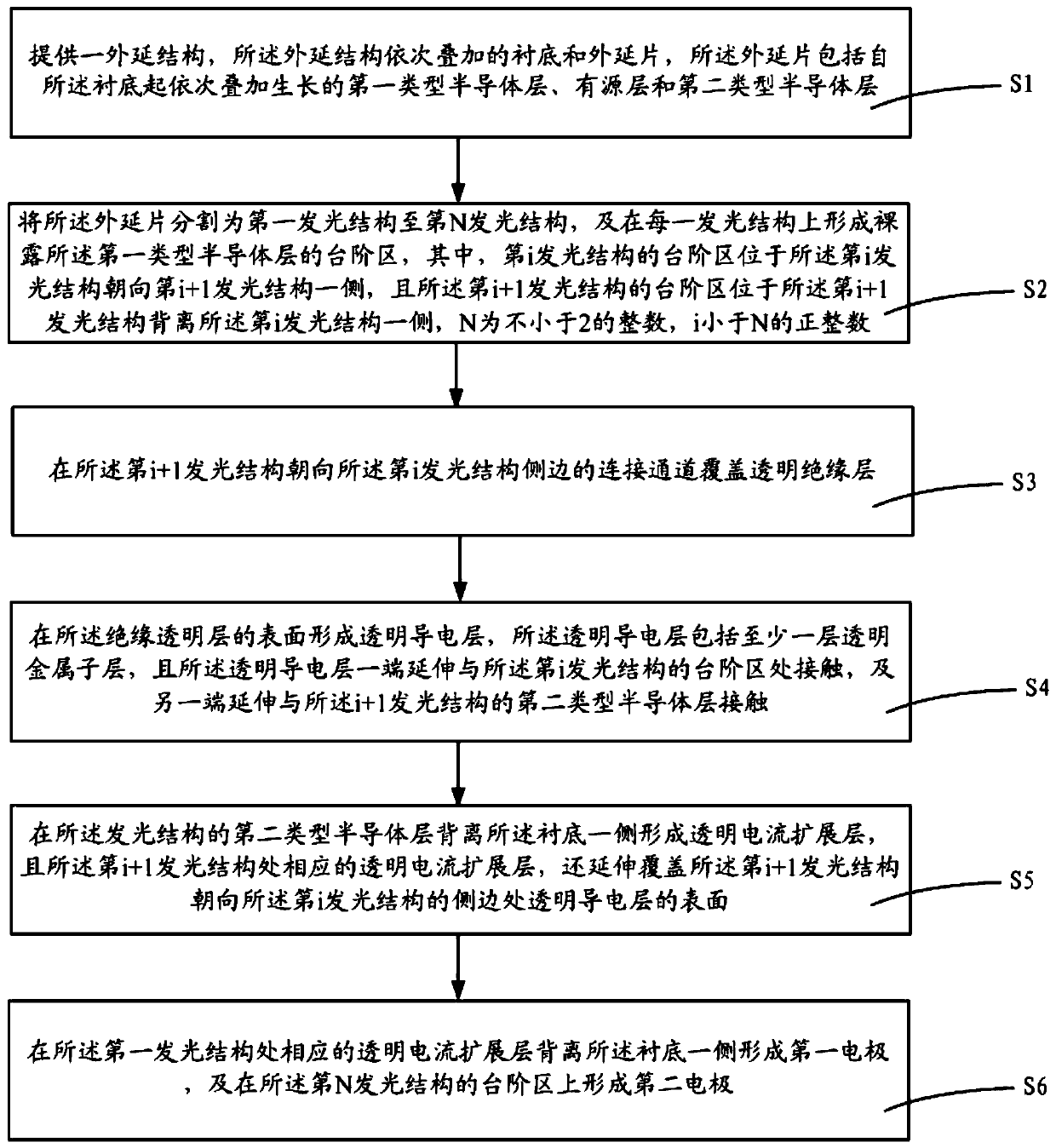

High-voltage light-emitting diode and manufacturing method thereof

InactiveCN110176470AImprove light extraction efficiencyIncrease the side light emitting areaSolid-state devicesSemiconductor devicesPower flowHigh pressure

The invention discloses a high-voltage light-emitting diode and a manufacturing method thereof. In the structures of the high-voltage light-emitting diode, a transparent insulating layer, a part of atransparent current expanding layer and a transparent conducting layer are arranged between the adjacent light-emitting structures; the transparent insulating layer, the part of the transparent current expanding layer and the transparent conducting layer are all of light-permeable structures, so that the light-emitting areas of the side edges of the light-emitting structures are enlarged, and thelight-emitting efficiency of the high-voltage light-emitting diode is improved; and the transparent conducting layer is in contact with the transparent current expanding layer, and the transparent conducting layer is made of metal, so that the resistance of the transparent current expanding layer can be reduced, the current expanding effect is improved, and the light-emitting efficiency of the high-voltage light-emitting diode is further improved.

Owner:XIAMEN CHANGELIGHT CO LTD

Ultraviolet LED chip and manufacturing method thereof

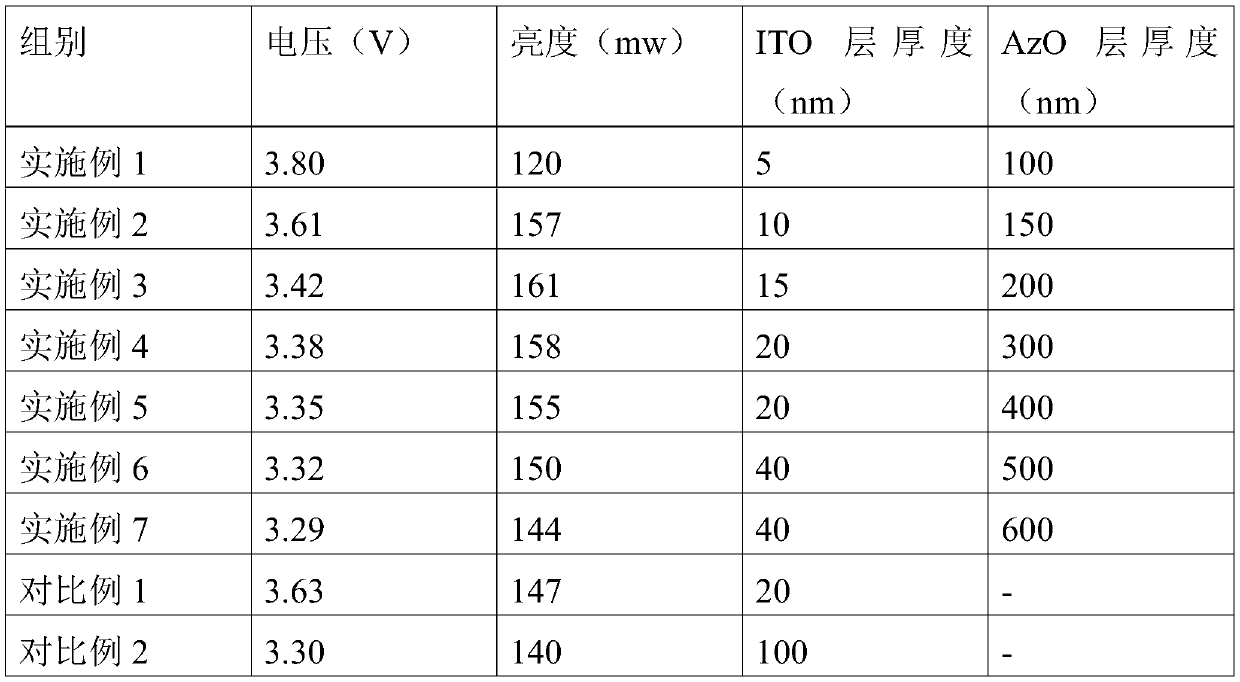

PendingCN111192945AImproved current scaling performanceMake up for bad influenceVacuum evaporation coatingSputtering coatingUltravioletEngineering

The invention discloses an ultraviolet LED chip and a manufacturing method thereof. The chip comprises a substrate, an epitaxial layer arranged on the substrate, a transparent conductive layer and anelectrode structure which are arranged on the epitaxial layer, and a protective layer covering the transparent conductive layer and the epitaxial layer. The LED chip is characterized in that the transparent conductive layer comprises an ITO layer and an AzO layer, the ITO layer is arranged between the epitaxial layer and the AzO layer, the thickness of the ITO layer is 5-20 nm, and the thickness of the AzO layer is 150-500 nm. According to the transparent conductive layer, through mutual cooperation of the ITO layer and the AzO layer, the light emitting efficiency of the chip is effectively improved, and the voltage is effectively reduced.

Owner:FOSHAN NATIONSTAR SEMICON

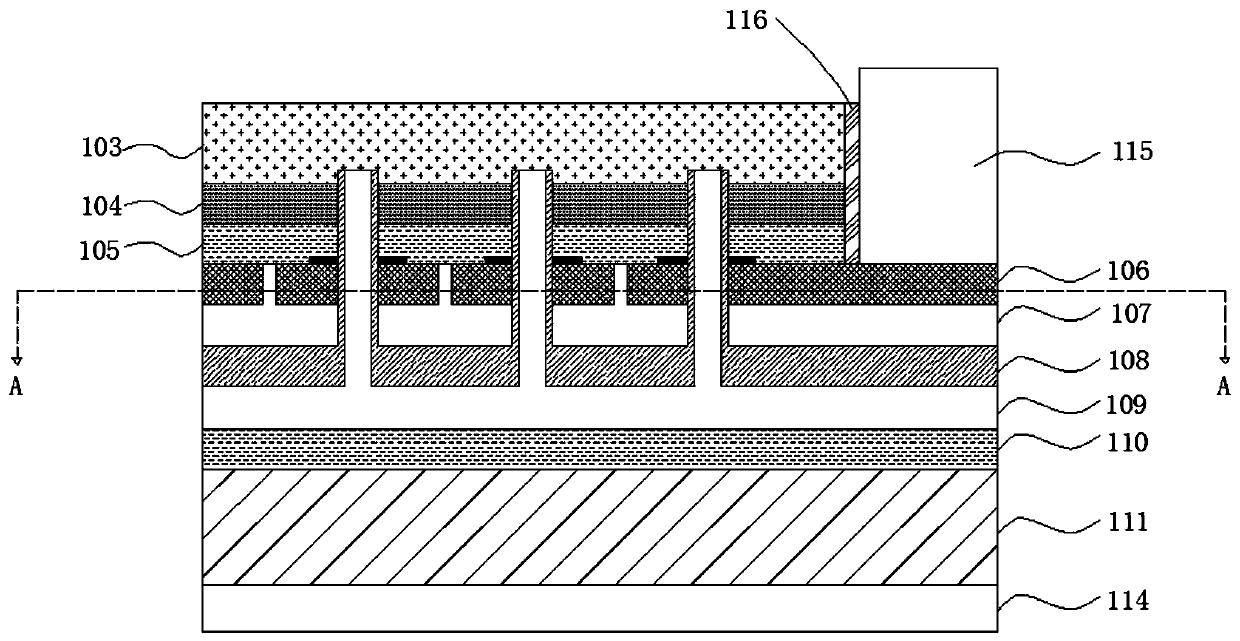

LED chip and manufacturing method thereof

The invention provides an LED chip and a manufacturing method thereof. The epitaxial layer structure of the LED chip comprises: an N-type semiconductor layer, an active region, a P-type semiconductorlayer, a high-doped P-type semiconductor layer and a high-doped tunneling layer which are sequentially overlapped on the substrate. The manufacturing method of the LED chip comprises the steps of: firstly, forming a plurality of light-emitting columns in the N electrode manufacturing area of the epitaxial layer structure, so that the light-emitting area of the LED chip is increased; secondly, arranging a first insulating reflecting layer which comprises an insulating layer and a reflecting layer, wherein the reflecting layer is stacked on the surface of the insulating layer, so that the insulating layer is directly in contact with the high-doped tunneling layer, and lattice matching is performed on the high-doped tunneling layer and the insulating layer to form stress transition, thereby improving the combination degree of the first insulating reflecting layer and the epitaxial layer structure; and finally, insulating an N-type electrode extension strip from a light emitting area through the first insulating reflecting layer, so that the electric leakage of the LED chip can be effectively avoided.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

Flip LED chip

PendingCN111180565AImprove light extraction efficiencyEliminate the effects ofSemiconductor devicesMirror reflectionEngineering

The invention discloses a flip LED chip, which comprises a substrate, an epitaxial layer, a transparent conductive layer, a filling and leveling layer, an adhesive layer, a reflecting layer and an electrode structure, wherein the epitaxial layer is arranged on the substrate; the transparent conductive layer is arranged on the epitaxial layer, the filling and leveling layer is arranged on the transparent conductive layer and fills the concave-convex structure of the epitaxial layer, the filling and leveling layer is provided with a plurality of first holes, the adhesion layer is arranged on thefilling and leveling layer and fills the first holes to form conductive connection with the transparent conductive layer, and the reflecting layer is arranged on the adhesion layer. The filling and leveling layer is formed on the transparent conductive layer of the flip LED chip; the concave-convex structure of the epitaxial layer is filled and leveled up to form a flat surface, and the reflecting layer arranged on the filling and leveling layer forms full mirror reflection, so that light emitted by the epitaxial layer can be emitted from the back surface of the substrate in a centralized manner after being reflected by the reflecting layer, and the light emitting efficiency of the chip is further improved.

Owner:FOSHAN NATIONSTAR SEMICON

Large-sized light-emitting diode

InactiveCN105226158AImprove current spreading effectReduce light blocking areaSemiconductor devicesManufacturing cost reductionLight-emitting diode

The invention discloses a large-sized light-emitting diode. The large-sized light-emitting diode includes a p region, an n region and an active region, wherein the active region is arranged between the p region and the n region, the p region is provided with a first electrode, and the n region is provided with a second electrode. The large-sized light-emitting diode is characterized in that the p region is provided with a composite multilayer ohmic contact layer structure; an ITO electric conduction layer is formed on the composite multilayer ohmic contact layer structure through evaporation; and the first electrode is arranged on the ITO electric conduction layer. According to the large-sized light-emitting diode of the invention, the current expansion effect of the ITO electric conduction layer can be improved, and the light shielding area of the expansion electrodes can be reduced, and therefore, the luminous efficiency of the light-emitting diode can be improved, and manufacturing cost can be reduced.

Owner:XIAMEN CHANGELIGHT CO LTD

Avalanche commutation diode special for 16000A/200-400V welding machine and preparation method thereof

ActiveCN101582455AImprove current expansion capabilityImprove high current capacitySemiconductor/solid-state device manufacturingSemiconductor devicesCorrosionOhm

The invention relates to an avalanche commutation diode special for a 16000A / 200-400V welding machine and a preparation method thereof. The invention solves the problems that an avalanche commutation diode special for a single welding machine has small capacity and that parallel connection and flow equalization are needed during the use of the avalanche commutation diode. An N-type (100) radial single crystal silicon piece, which has specific resistance Rho n of 5-10 Ohm-cm, diameter of 70 mm and thickness of 0.17-0.19 mm, is adopted; at the temperature of 1250 DEG C, double-surface once diffusion is carried out; the surface concentration of a surface higher-concentration region of a diffusion region is 0.06-n A, a junction depth X jP is 58-62 microns, and residual minority carrier lifetime Tao p of a base region is 9-13 Mu S; cathode-anode titanium-nickel-gold undergoes ohmic contact; a cathode table surface undergoes spray sand molding, corrosion, cleaning, passivation protection and intermediate test; and a shell is arranged, the thickness of a pipe is 5-6 mm, cold pressure welding packaging is conducted under the protection of nitrogen gas, and the thickness of the pipe is 5-6 mm after the packaging. The avalanche commutation diode has stronger current expansion capability, larger capacity, better quality, higher reliability and lower use cost.

Owner:JINZHOU SHENGHE POWER ELECTRONICS

Strained superlattice tunnel junction ultraviolet led epitaxial structure and its preparation method

Owner:XI AN JIAOTONG UNIV

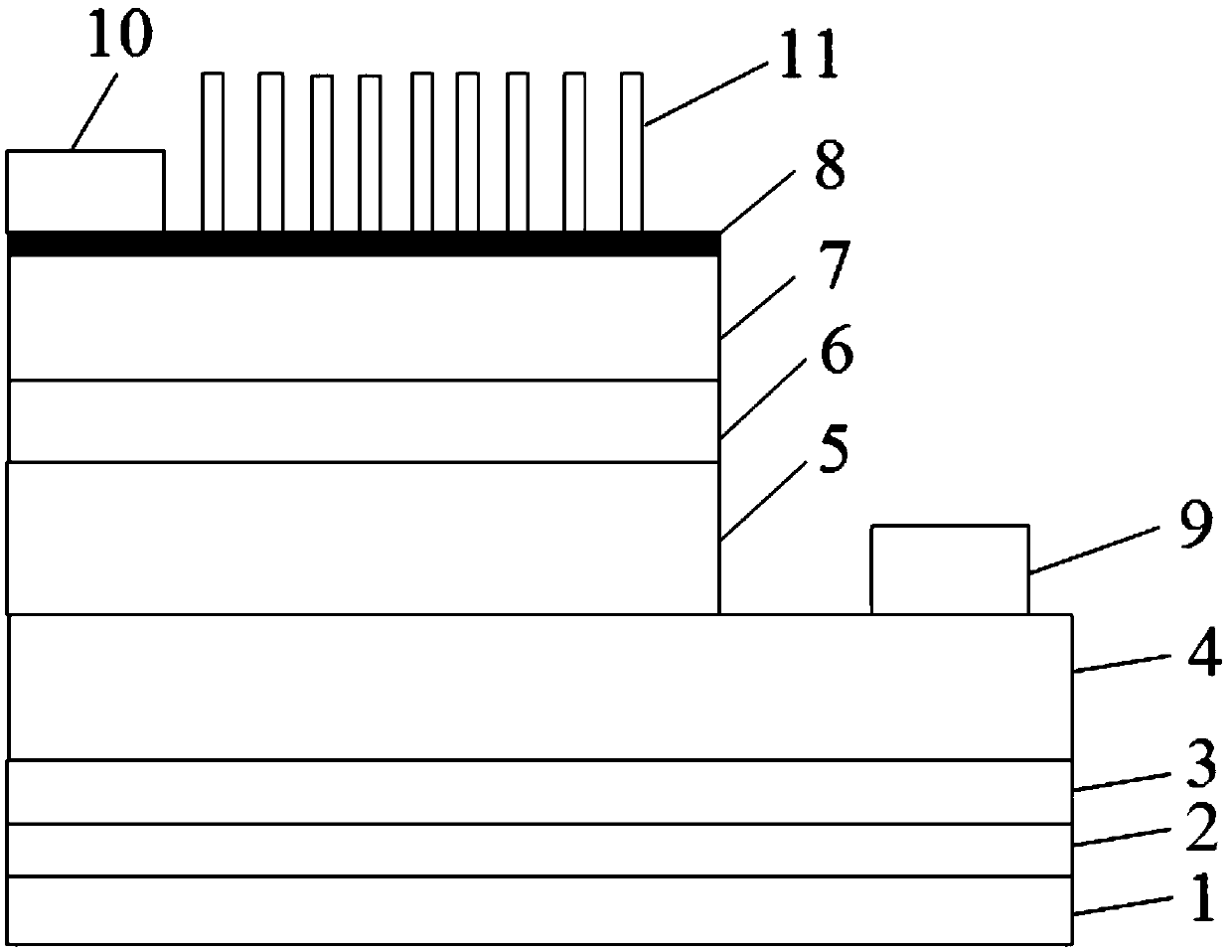

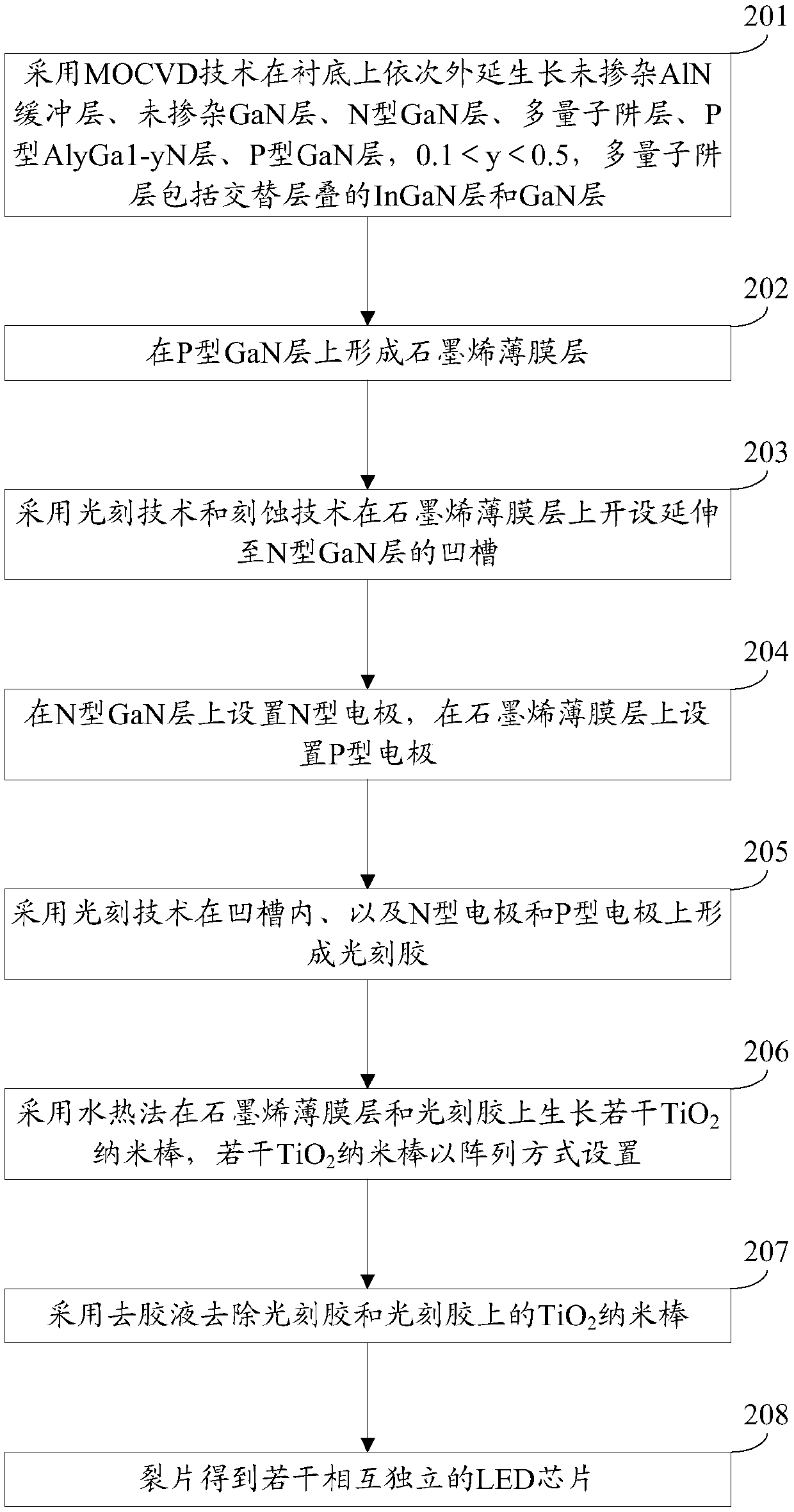

A kind of LED chip and its manufacturing method

ActiveCN106653973BImprove luminous efficiencyHigh catalytic activitySemiconductor devicesQuantum wellGraphene

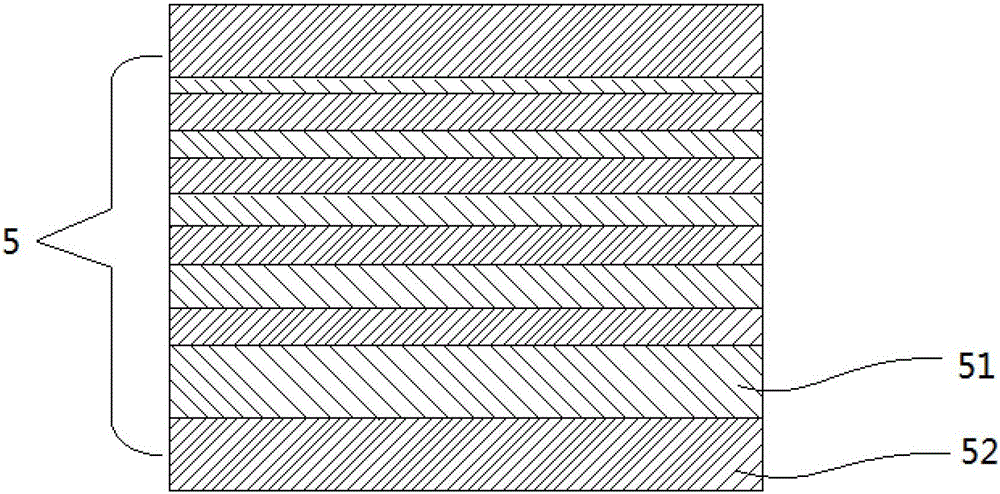

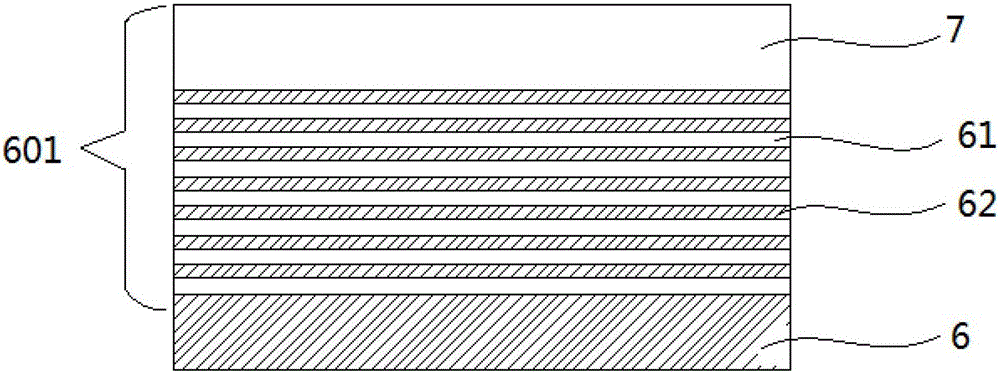

The invention discloses an LED chip and a preparation method thereof, and belongs to the technical field of semiconductors. The LED chip comprises a substrate, an undoped AlN buffer layer, an undoped GaN layer, an N-type GaN layer, a multi-quantum well layer, a P-type Al<y>Ga<1-y>N layer, a P-type GaN layer and a graphene film layer, wherein the undoped AlN buffer layer, the undoped GaN layer, the N-type GaN layer, the multi-quantum well layer, the P-type Al<y>Ga<1-y>N layer, the P-type GaN layer and the graphene film layer are sequentially stacked on the substrate; y is smaller than 0.5 and greater than 0.1; the multi-quantum well layer comprises an InGaN layer and a GaN layer which are alternately stacked; a groove which extends to the N-type GaN layer is formed in the graphene film layer; an N-type electrode is arranged on the N-type GaN layer; a P-type electrode is arranged on the graphene film layer; and multiple TiO2 nanorods are arranged on the graphene film layer in an array manner. The graphene film layer can be directly adopted as a seed layer through formation of the TiO2 nanorods, and the seed layer is tightly combined and is not easily destroyed, so that the light-emitting efficiency of an LED can be obviously improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Avalanche commutation diode special for 16000A/200-400V welding machine and preparation method thereof

ActiveCN101582455BImproved current scaling performanceGuaranteed not to deformSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationNitrogen gas

Owner:JINZHOU SHENGHE POWER ELECTRONICS

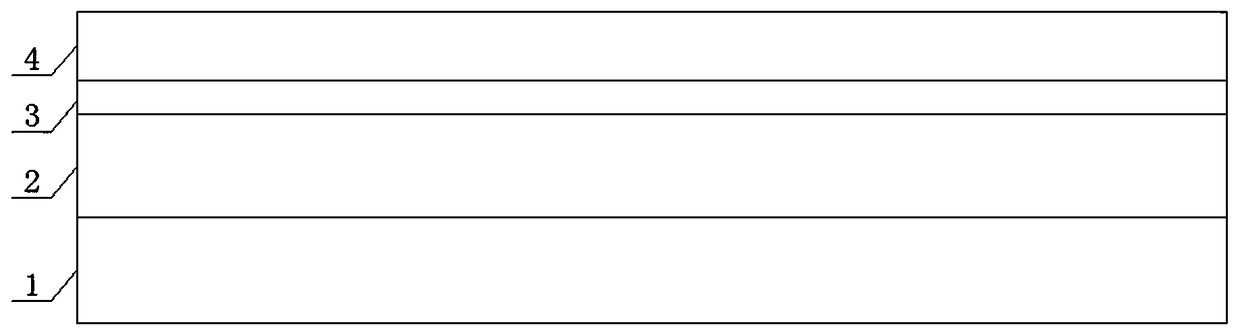

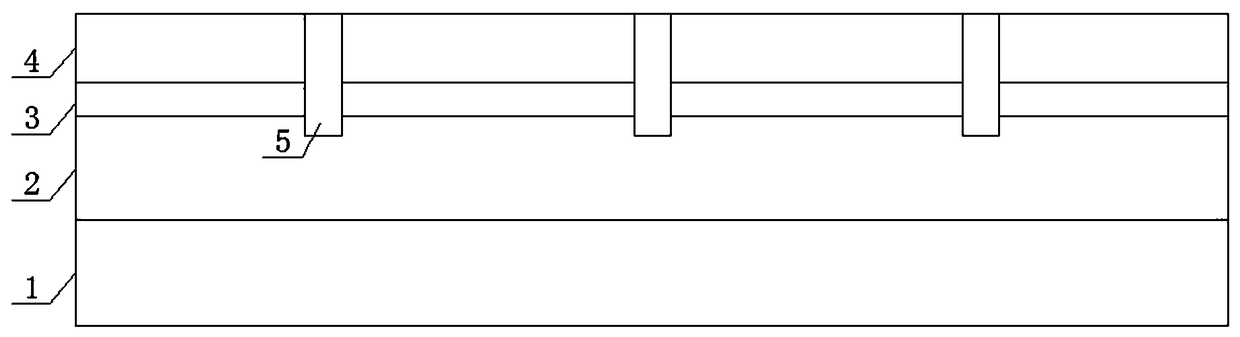

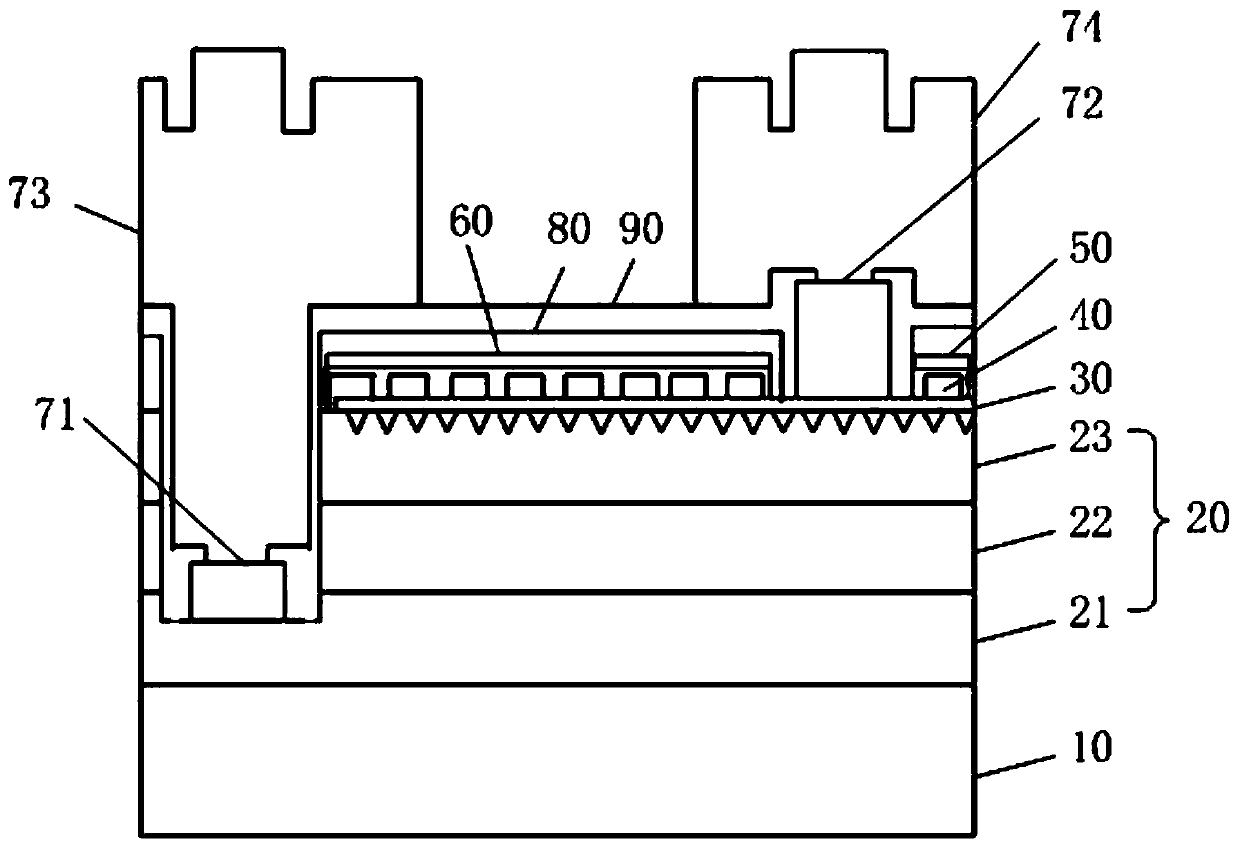

Light-emitting diode and method of making the same

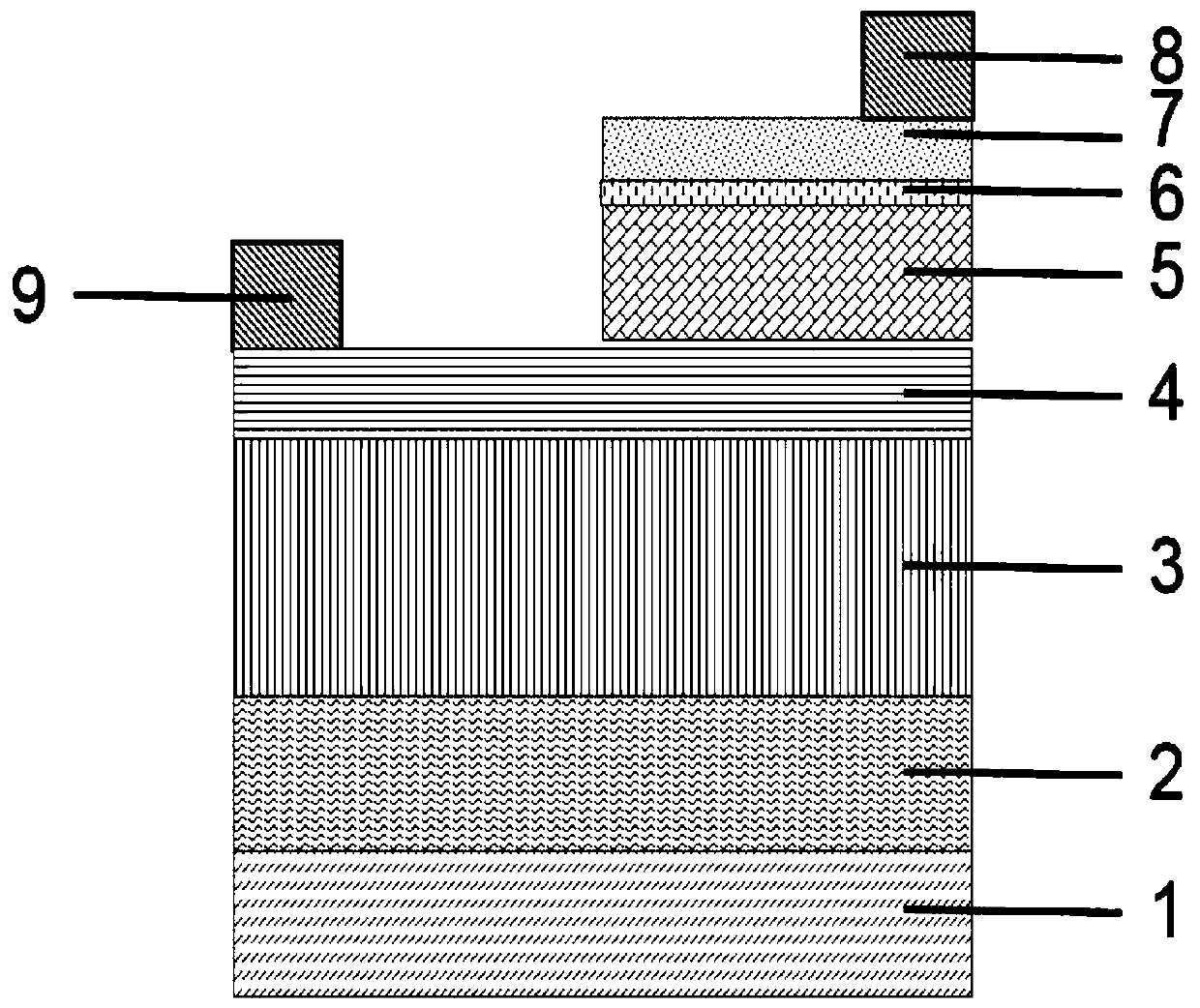

ActiveCN105428483BUniform light outputReduce aggregation effectSemiconductor devicesLuminous intensityLight-emitting diode

The invention provides a diode structure design with uniform luminous intensity. An epitaxial wafer structure comprises a substrate, an N-type layer, a multi-quantum well active region and a P-type layer from bottom to top; preparation of a chip technology is carried out; a current adjusting structure is arranged at the position, close to an N electrode, in the N-type layer; a resistance value of a region at the position, close to the N electrode, in the N-type layer is increased by the current adjusting structure; the current carrier aggregation effect of the position close to the N electrode is reduced by controlling the summarized occupied volume and the transverse and longitudinal etching depths of the current adjusting structure in the N-type layer; relatively multiple current carriers flow to the position close to a P electrode; the number of electrons which flow to the position close to the P electrode in the N-type layer is increased; different positions of a same LED chip are relatively uniform in light-emitting; and meanwhile, the current carrier aggregation effect is relieved, so that the reliability of an LED is further improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

LED chip and preparation method thereof

The present invention relates to a LED chip and a preparation method thereof. The method comprises the following steps of: providing a LED chip main body; forming a metal layer on the surface of the chip main body by employing a physical vapor deposition mode; and performing annealing treatment for the chip main body after deposition of the metal layer to obtain a crystalline state metallic oxidethin film. The prepared LED chip comprises a chip main body and a crystalline state metallic oxide thin film protection layer formed on the surface of the chip main body. The crystalline state metallic oxide thin film protection layer can provide better water vapor isolation capability for the LED chip, in the annealing process, part of metal atoms are diffused into a tin indium oxide layer to increase the number of free electrons of the tin indium oxide layer so as to improve the current expansion capability of the current extension layer, reduce the working voltage of the LED chip and improve the photoelectric converting efficiency of the LED chip.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

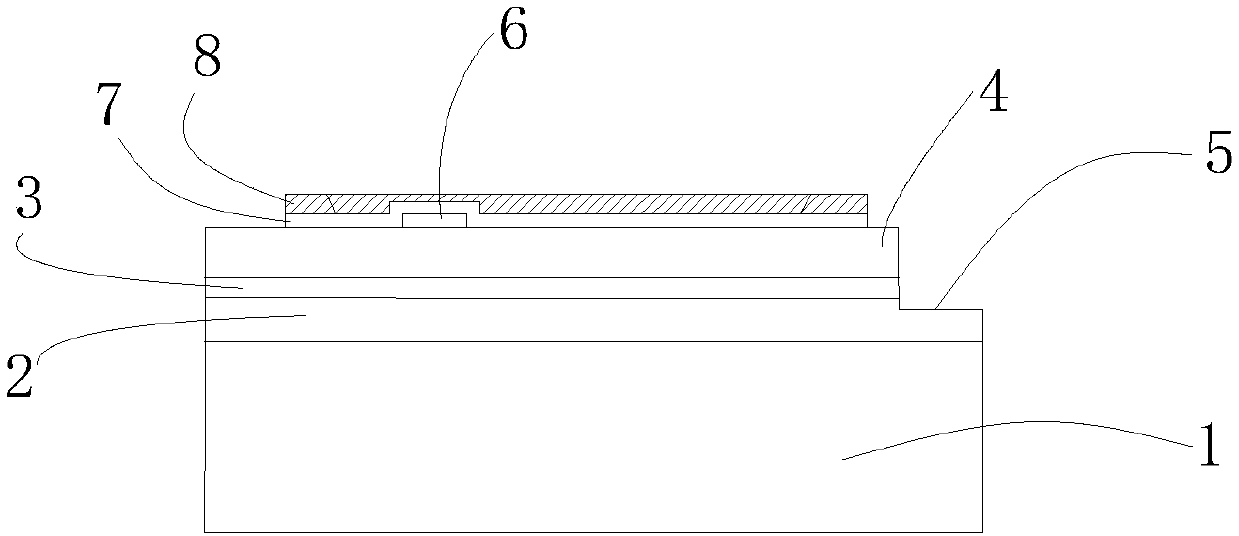

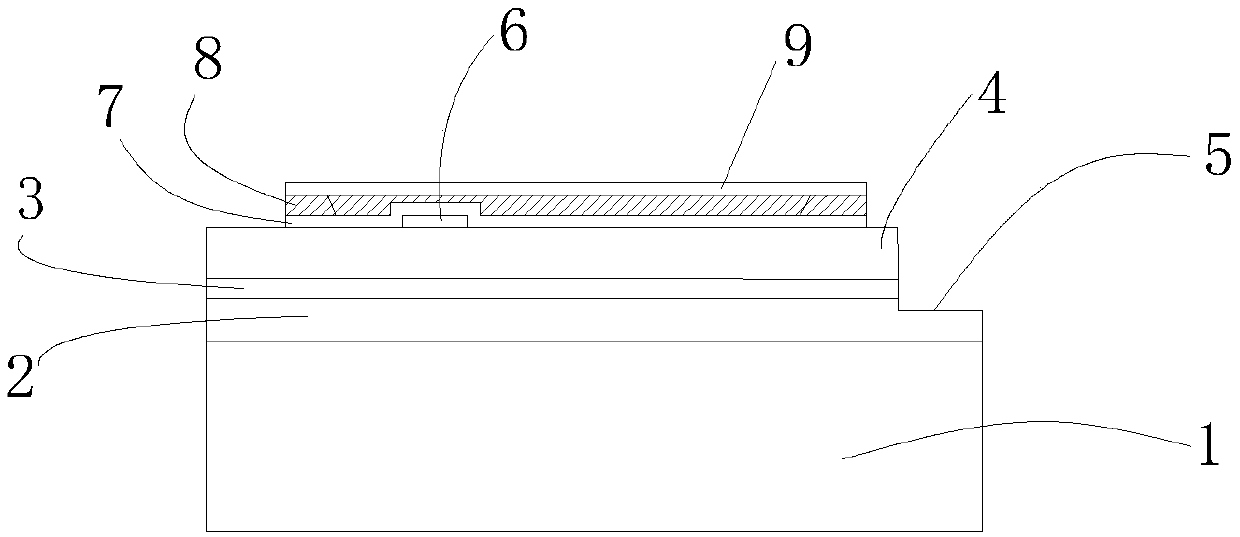

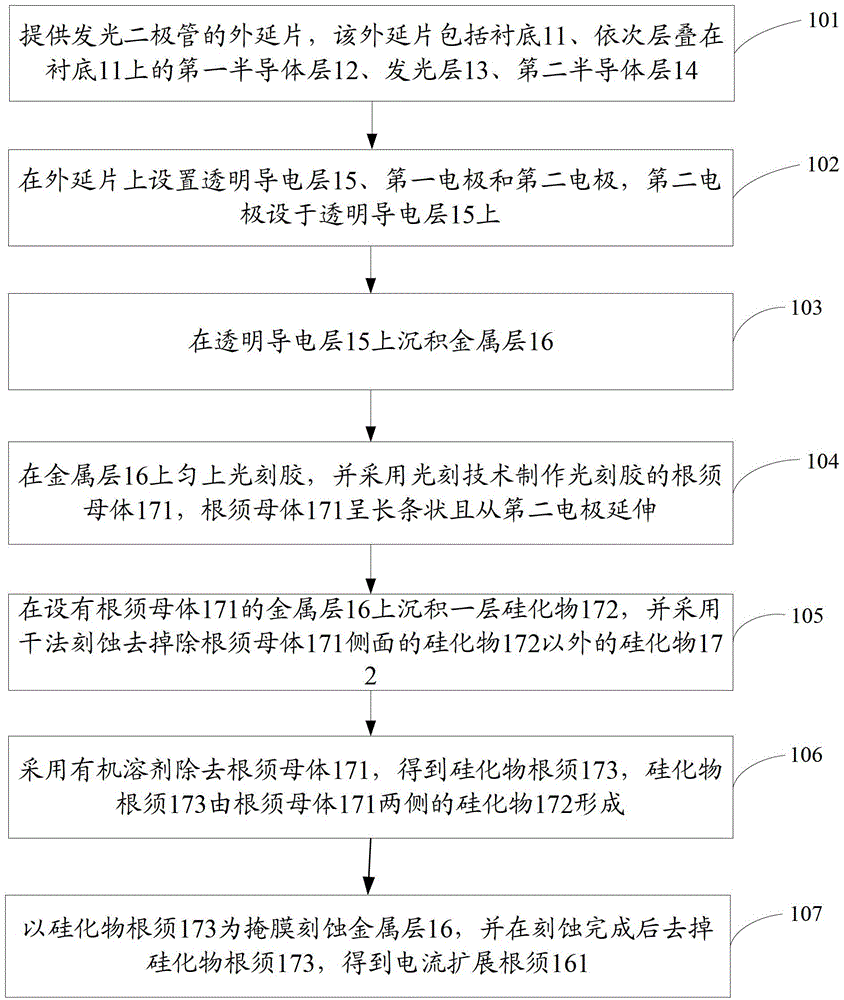

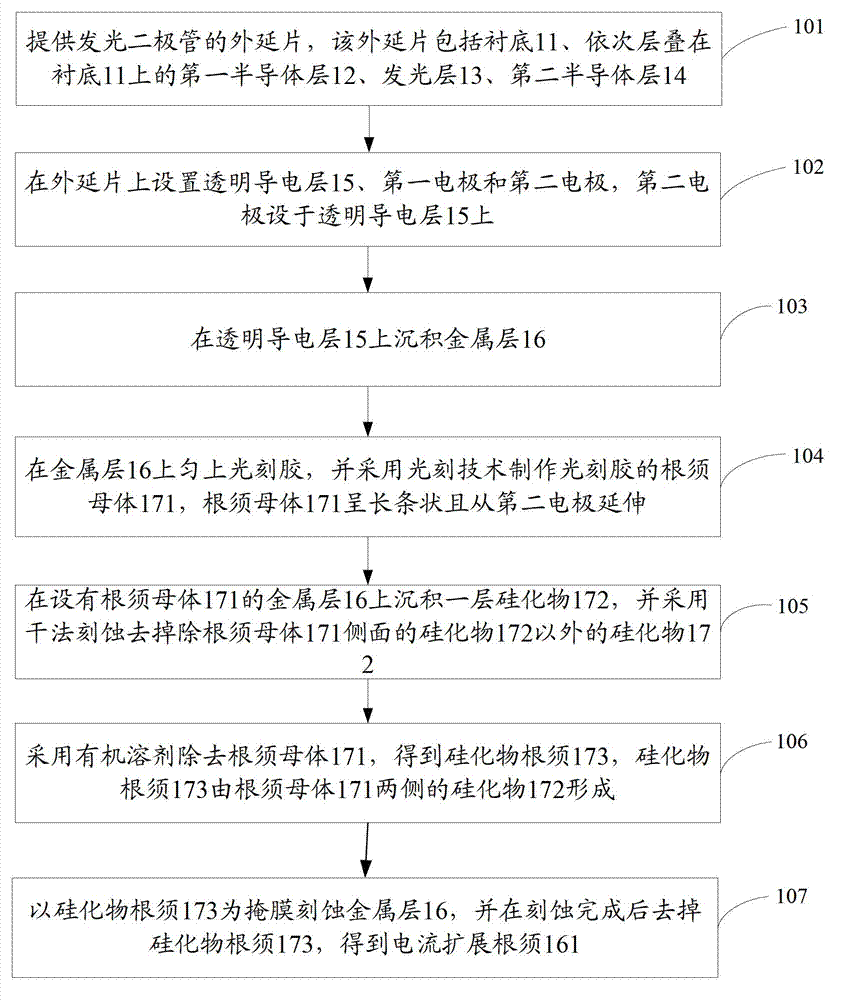

Light emitting diode chip and preparation method thereof

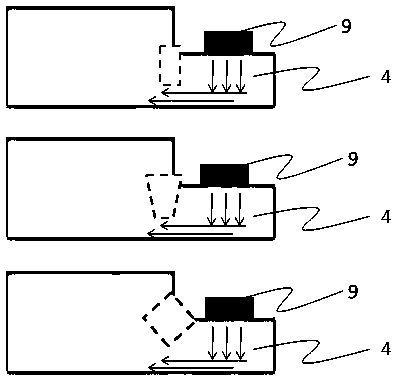

ActiveCN103035796BReduce widthImproved current scaling performanceSemiconductor devicesLight-emitting diodePhotoresist

The utility model discloses a light emitting diode chip and a preparation method thereof, and belongs to the technical field of semiconductors. The preparation method includes that an epitaxial wafer of the light emitting diode chip is provided, a transparent conducting layer, a first electrode and a second electrode are arranged on the epitaxial wafer, the second electrode is arranged on the transparent conducting layer, a metal layer is arranged on the transparent conducting layer in a depositing mode, photoresist is evenly coated on the metal layer, a root hair matrix of the photoresist can be manufactured by using of photoetching technique, and the root hair matrix is in a long strip shape and extend from the second electrode. A layer of silicide is coated on the metal layer which is provided with the root hair matrix in a depositing mode. Silicide except silicide on the side face of the root hair matrix is removed by using dry etching. The dry etching is removed by using organic solvent so that silicide root hairs are obtained. The silicide root hairs are formed by the silicide on two sides of the root hair matrix and used as covering films to etch the metal layer and removed after etching is finished, so that current expanding root hairs are obtained. Through the scheme, current expanding capacity is improved.

Owner:HC SEMITEK CORP

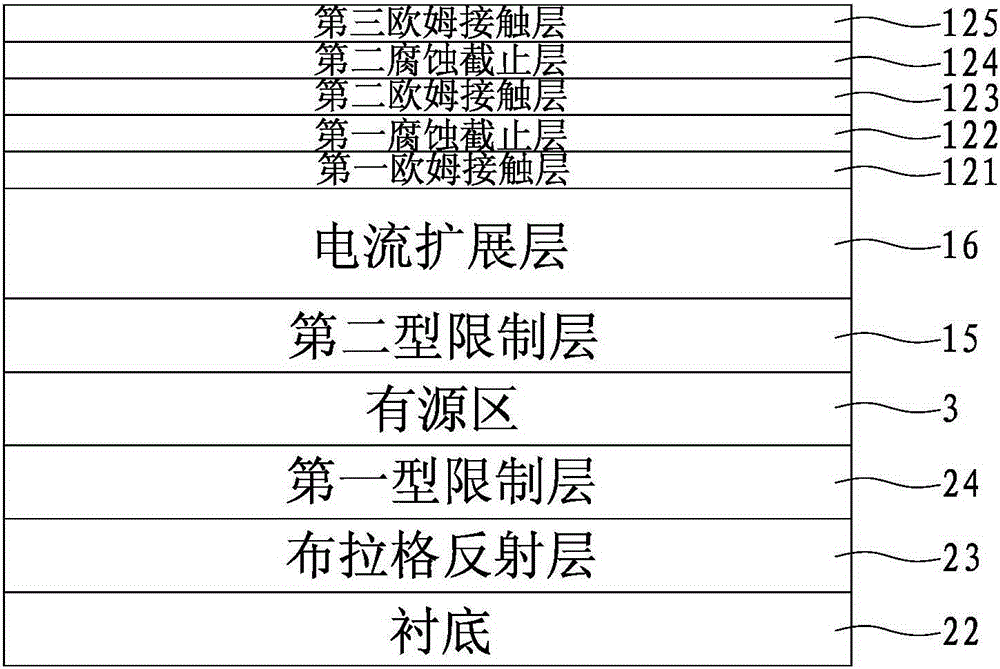

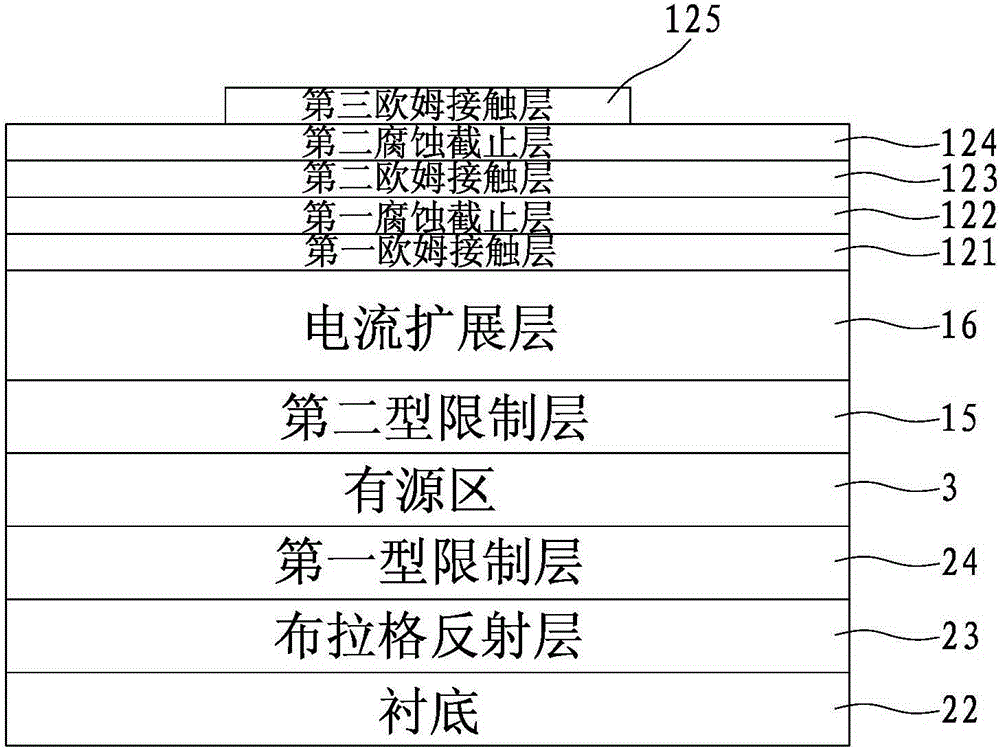

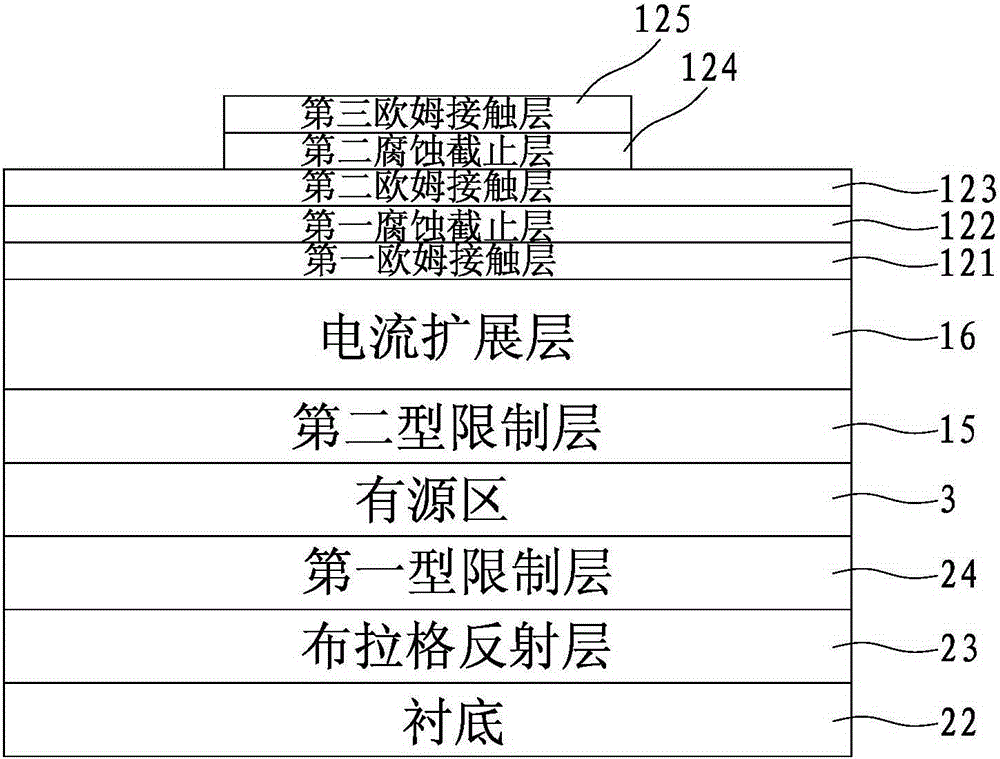

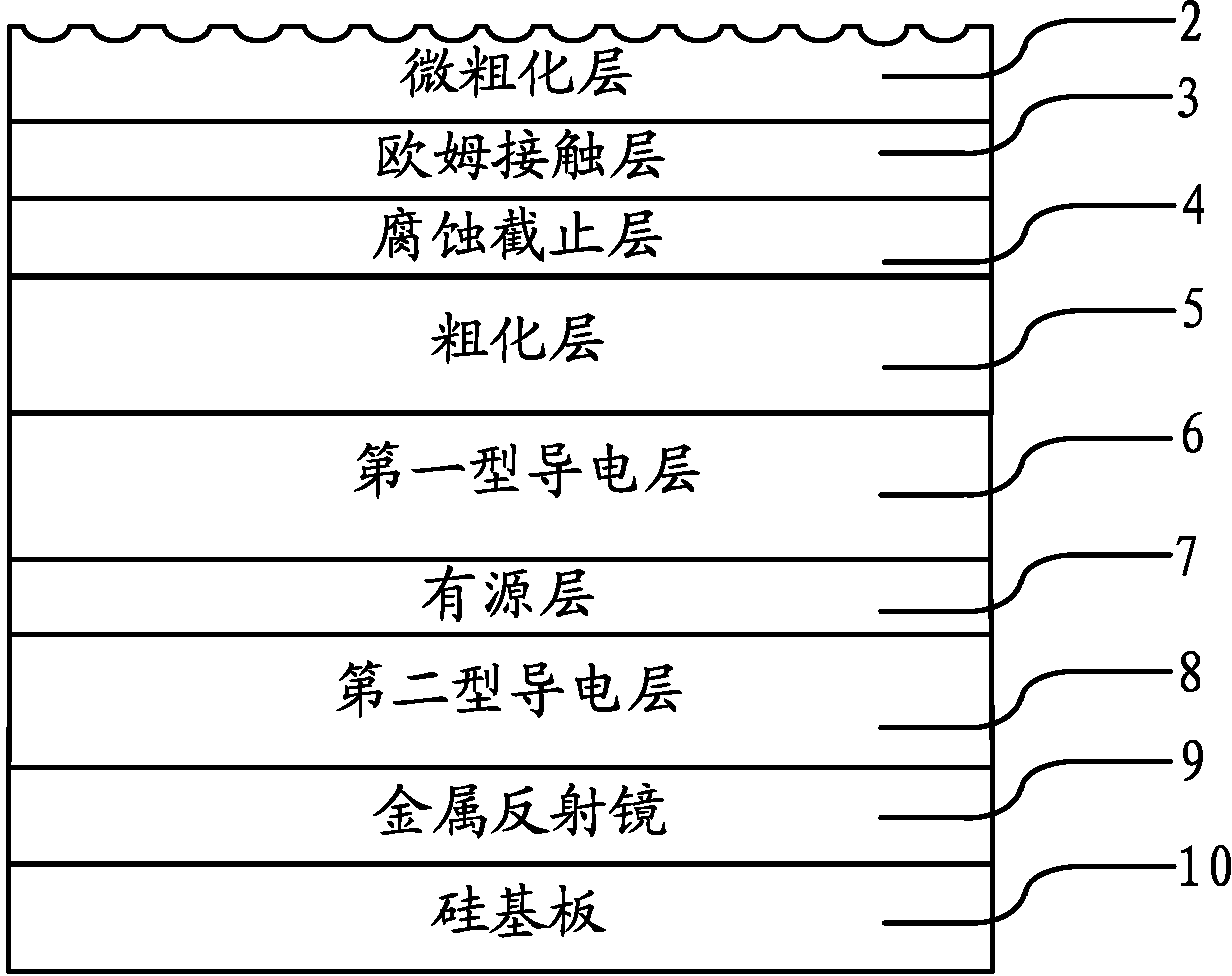

Infrared light-emitting diode with high-reliability electrodes

InactiveCN104201265AIncrease contact surfaceImprove adhesionSemiconductor devicesOhmic contactSolder station

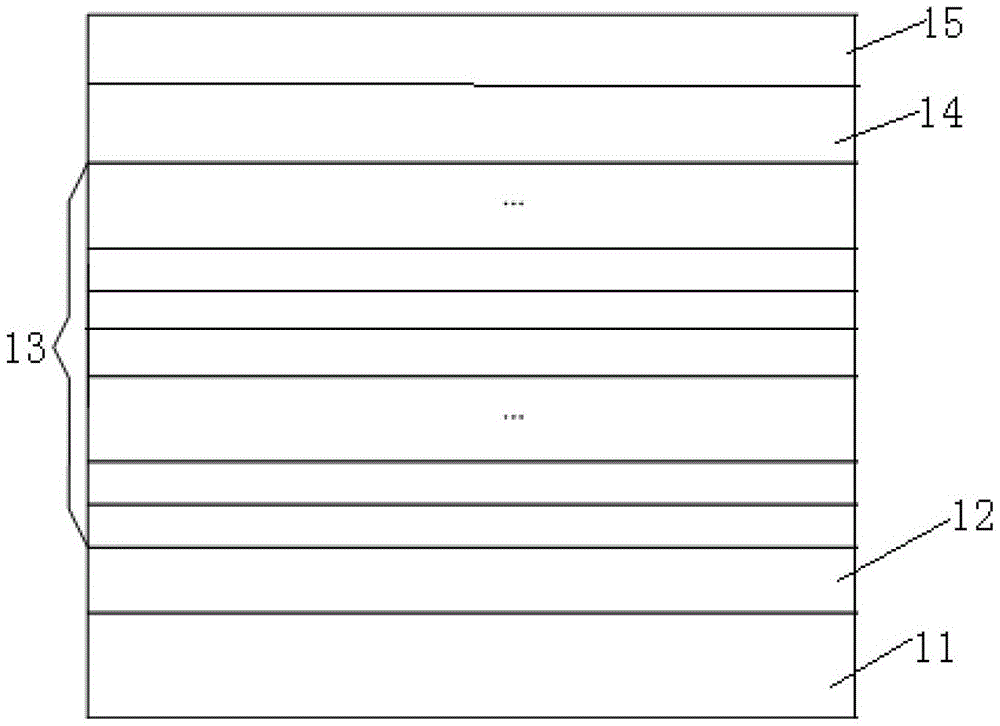

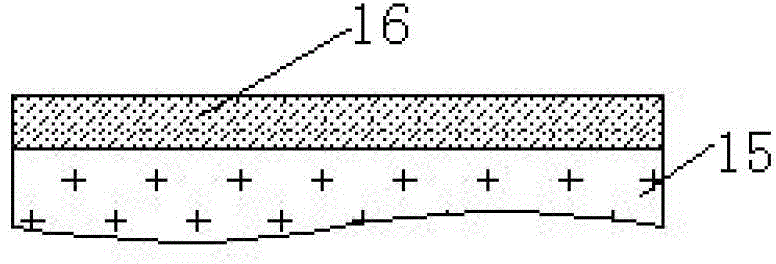

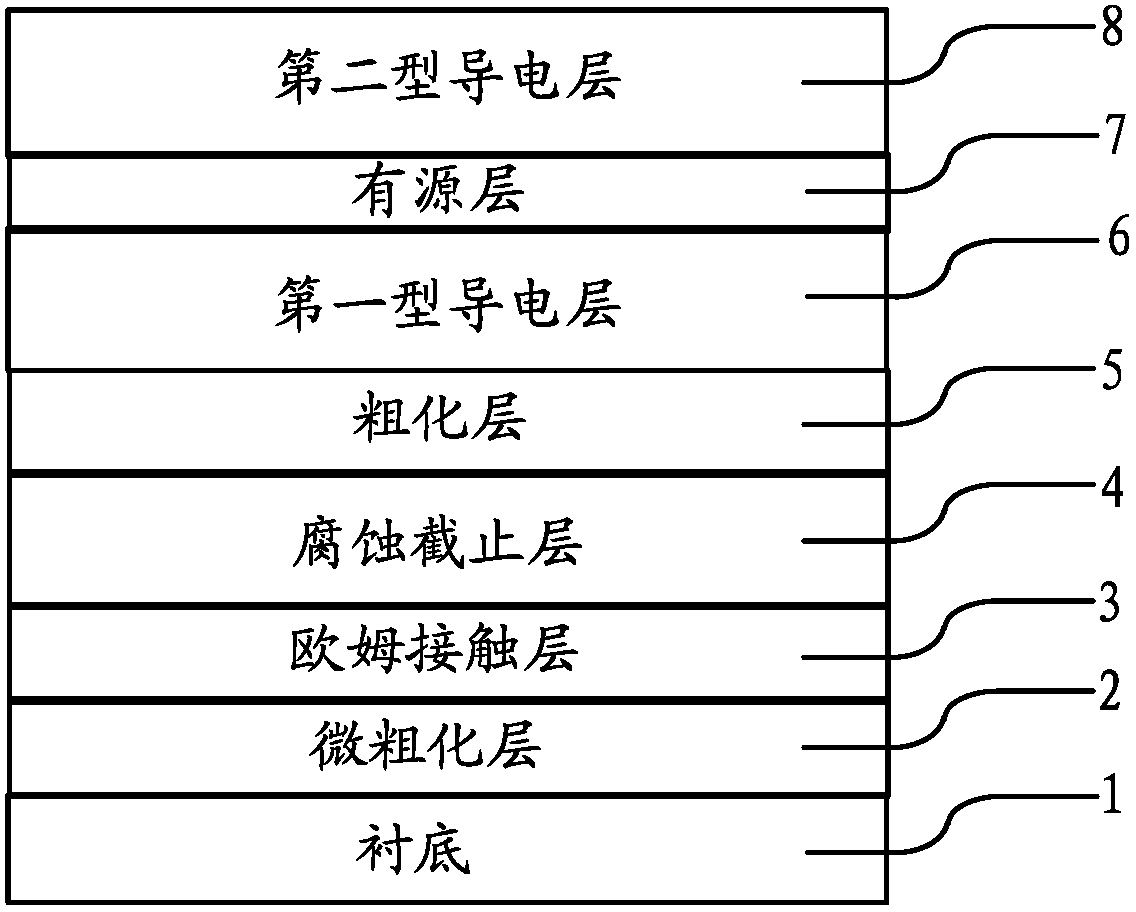

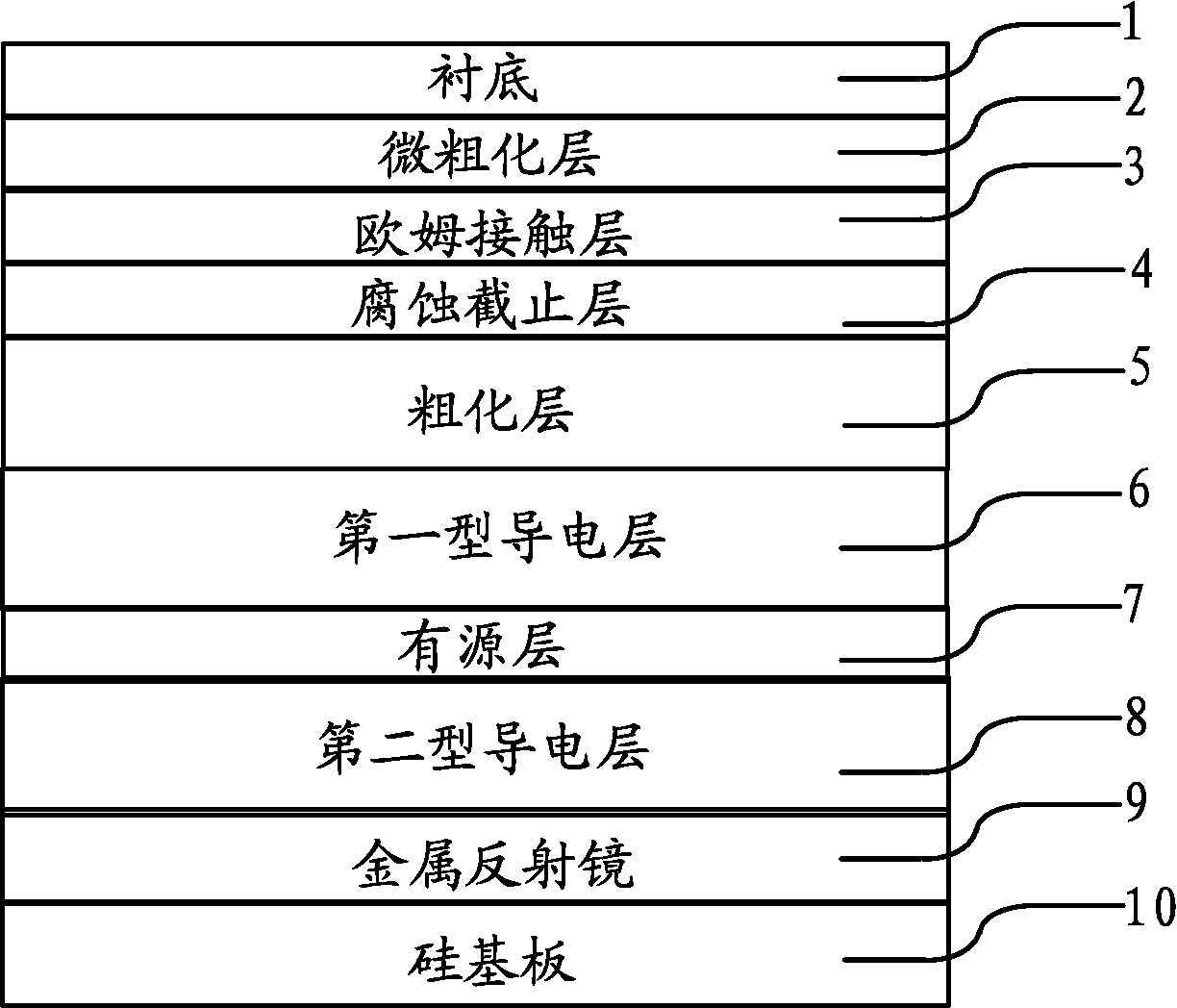

The invention discloses an infrared light-emitting diode with high-reliability electrodes. A roughening layer is arranged on one side of an epitaxial light-emitting structure, a corrosion stop layer is arranged on the roughening layer, an ohmic contact layer is arranged on the corrosion stop layer, extension electrodes are formed on the surface of the ohmic contact layer, a micro roughening layer is arranged on the ohmic contact layer, and a bonding pad electrode is arranged on the micro roughening layer and connected with the extension electrodes; a metal reflector is arranged on the other side of the epitaxial light-emitting structure, a substrate is arranged on the metal reflector, and a back electrode is arranged on the substrate. Reliability of soldering station electrodes is improved effectively, the problem that soldering station electrodes are prone to falling off due to poor adhesion is solved, and the packaging problem that the epitaxial layer under the soldering station electrodes is easy to break up during wire bonding is solved as well.

Owner:XIAMEN CHANGELIGHT CO LTD

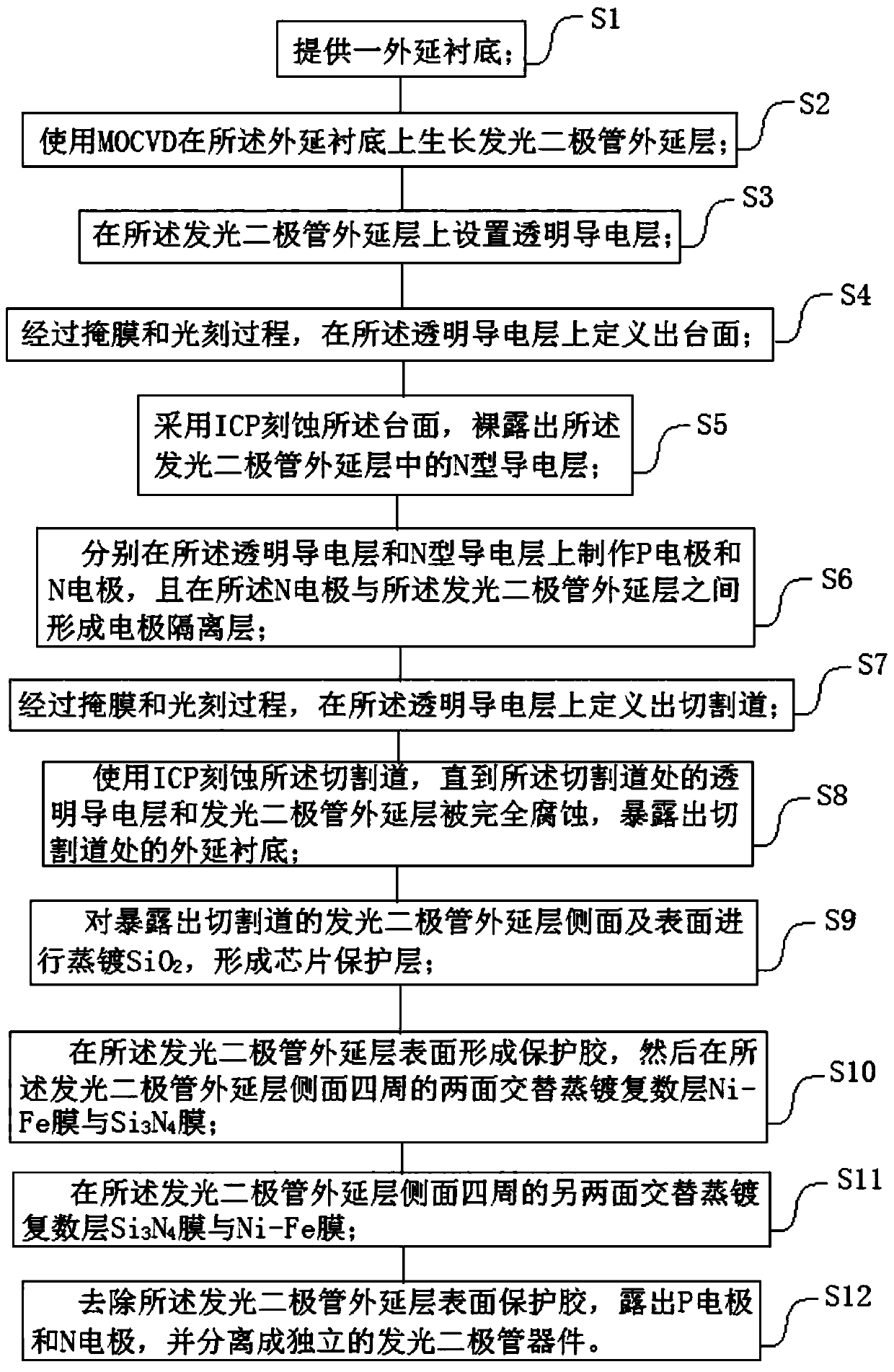

A kind of manufacturing method of light-emitting diode with high spreading effect

ActiveCN105304771BAdded outer quantum effectImproved current scaling performanceSemiconductor devicesAlloyLarge size

The present invention discloses a manufacture method of a light emitting diode having a high extension effect. The manufacture method comprises the following steps: providing an epitaxial substrate; growing the epitaxial layer of the light emitting diode through adoption of MOCVD; forming protection glue at the surface of the epitaxial layer of the light emitting diode, and performing alternate vacuum evaporation of a plurality of layers of Ni-Fe alloy membranes and Si3N4 membranes at two of four side faces of the epitaxial layer of the light emitting diode; performing alternate vacuum evaporation of a plurality of layers of Si3N4 membranes and Ni-Fe alloy membranes at the other two of four side faces of the epitaxial layer of the light emitting diode; and removing the protection glue at the surface of the epitaxial layer of the light emitting diode, exposing a p electrode and a n electrode, and forming an independent light emitting diode device through separation of epitaxial wafers. According to the invention, N-type and P-type current expansion of a light emitting diode is effectively enhanced without increasing the light blocking area of electrodes, and the N-type current expansion effect of a large-size chip is improved.

Owner:江西乾照光电有限公司

A kind of high-power vertical LED epitaxial structure and its preparation method

ActiveCN108807627BImproved current scaling performanceImprove conductivityNanotechnologySemiconductor devicesEngineeringGraphite

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Light emitting diode chip and preparation method thereof

ActiveCN103035796AReduce widthImproved current scaling performanceSemiconductor devicesLight-emitting diodePhotoresist

The utility model discloses a light emitting diode chip and a preparation method thereof, and belongs to the technical field of semiconductors. The preparation method includes that an epitaxial wafer of the light emitting diode chip is provided, a transparent conducting layer, a first electrode and a second electrode are arranged on the epitaxial wafer, the second electrode is arranged on the transparent conducting layer, a metal layer is arranged on the transparent conducting layer in a depositing mode, photoresist is evenly coated on the metal layer, a root hair matrix of the photoresist can be manufactured by using of photoetching technique, and the root hair matrix is in a long strip shape and extend from the second electrode. A layer of silicide is coated on the metal layer which is provided with the root hair matrix in a depositing mode. Silicide except silicide on the side face of the root hair matrix is removed by using dry etching. The dry etching is removed by using organic solvent so that silicide root hairs are obtained. The silicide root hairs are formed by the silicide on two sides of the root hair matrix and used as covering films to etch the metal layer and removed after etching is finished, so that current expanding root hairs are obtained. Through the scheme, current expanding capacity is improved.

Owner:HC SEMITEK CORP

Flip-over type light emitting diode chip and preparation method thereof

InactiveCN109638124AImproved current scaling performanceEvenly distributedSemiconductor devicesLight-emitting diodeSemiconductor

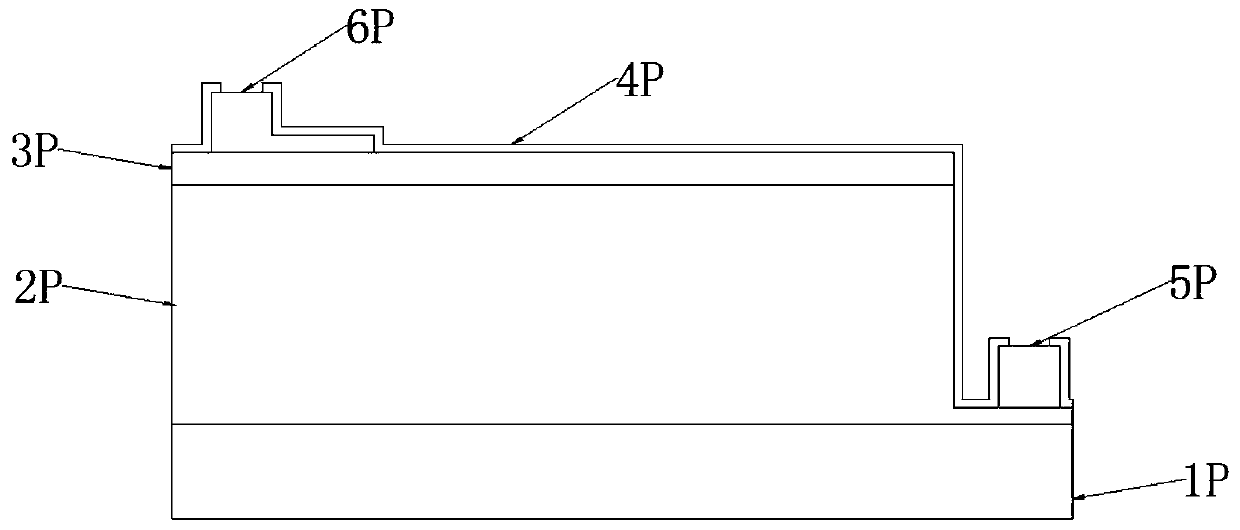

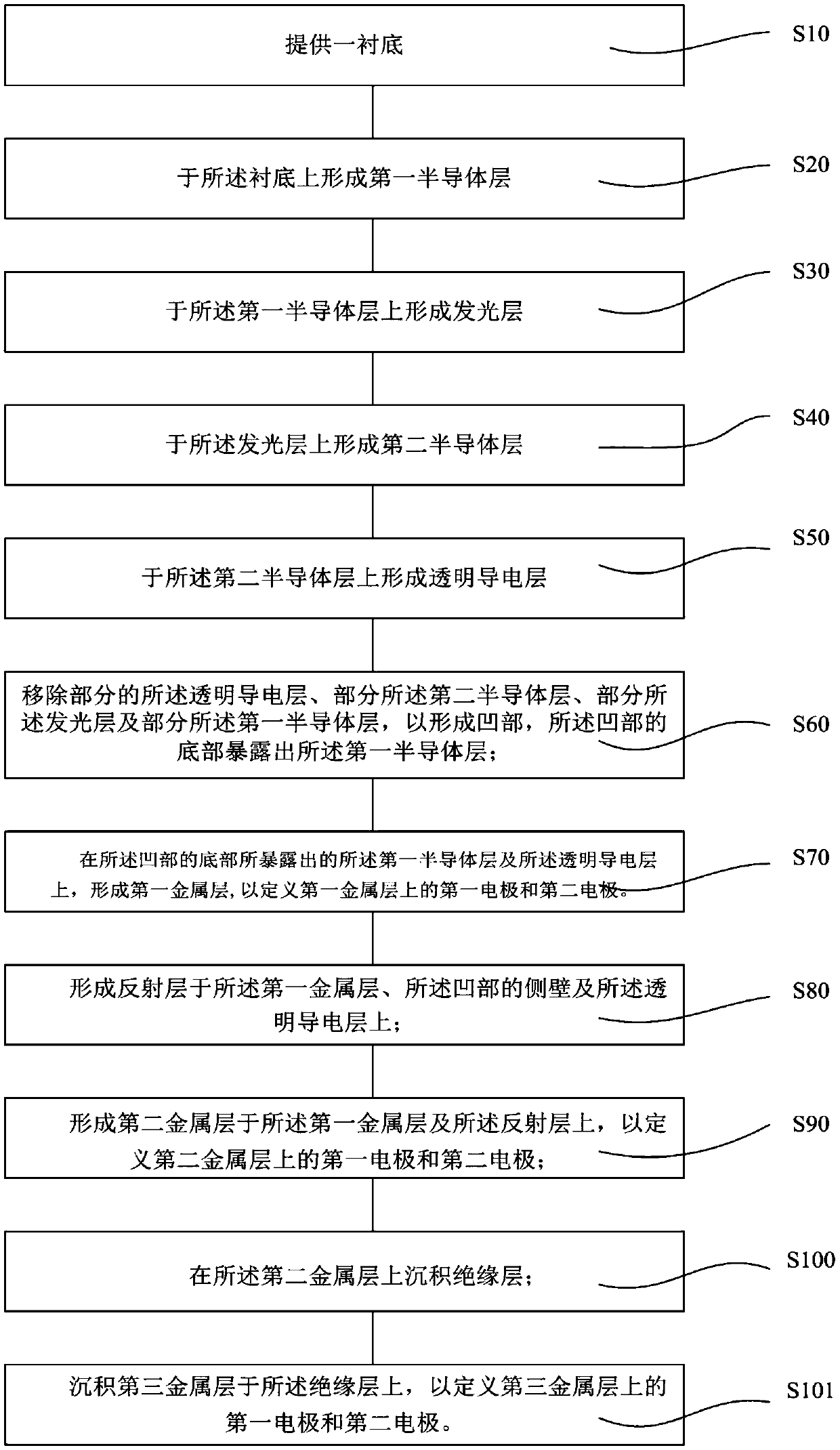

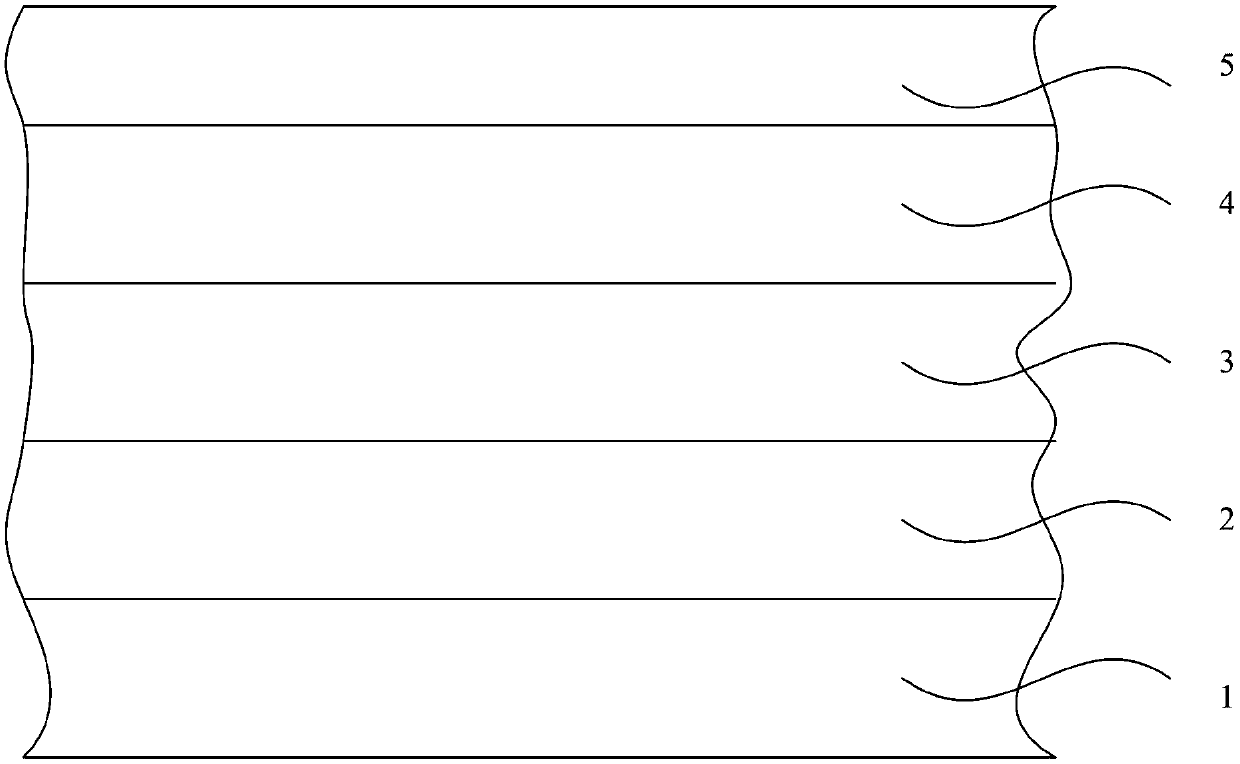

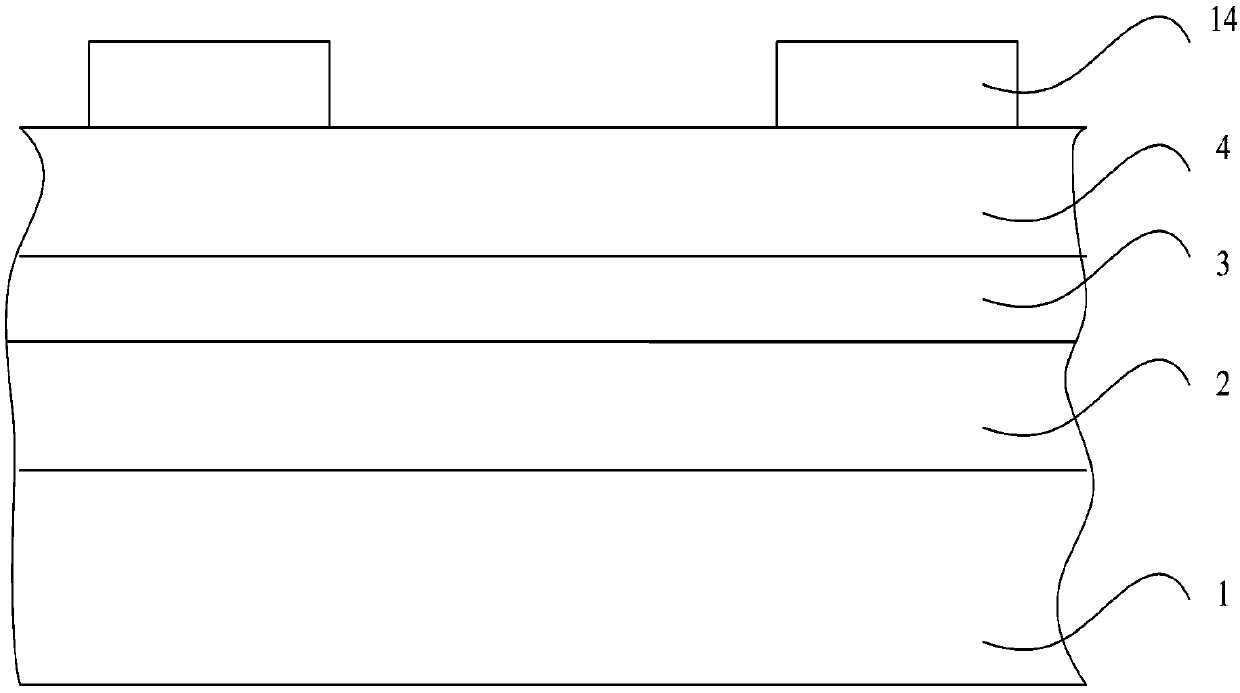

The invention provides a preparation method of a flip-over type light emitting diode chip. The preparation method comprises the steps of: providing a substrate and forming a first semiconductor layer,a light emitting layer, a second semiconductor layer and a transparent conducting layer on the substrate in sequence; removing a part of the transparent conducting layer, the second semiconductor layer, the light emitting layer and the first semiconductor layer to form a concave part, wherein the bottom of the concave part is exposed from the first semiconductor layer; forming first metal layerson the first semiconductor layer, from which the bottom of the concave part is exposed, and the transparent conducting layer so as to define first electrodes and second electrodes of the first metal layers; forming reflection layers on the first metal layers, the side wall of the concave part and the transparent conducting layer; forming second metal layers on the first metal layers and the reflection layers so as to define first electrodes and second electrodes of the second metal layers; depositing insulating layers on the second metal layers; and depositing third metal layers on the insulating layers so as to define first electrodes and second electrodes of the third metal layers. The chip prepared by the method is high in product yield.

Owner:合肥彩虹蓝光科技有限公司

Fast-recovery commutation diode used for high frequency electroplating and production method thereof

ActiveCN101582456BImproved current scaling performanceGuaranteed not to deformSemiconductor/solid-state device manufacturingSemiconductor devicesFurnace temperatureHigh current density

The invention relates to a fast-recovery commutation diode used for high frequency electroplating and a production method thereof, wherein the fast-recovery commutation diode has the high frequency property and is suitable for 30KHz / 2-5KA / (200-400)V high frequency electroplating with both high voltage and high current density. An N-type (100) radial single crystal silicon piece, which has specificresistance Rho n of 5-9 Ohm-cm, diameter of 48-70 mm and thickness of 175-185 microns, is adopted; silicon piece diffusion is conducted, and double-surface once diffusion is carried out at temperature of 1250 DEG C; the diffusion piece detection is carried out; phosphorosilicate glass and borosilicate glass are used for absorption, the temperature is slowly lowered from 1250 DEG C to 1050 DEG C,the speed rate is 1 DEG C per minute, and isothermal absorption is carried out for 2-3 h; slow temperature reduction is continued till furnace temperature is reduced to 600 DEG C, then furnace delivery is carried out, and minority carrier lifetime Tao p is caused to reach 12-16 Mu S; platinum diffusion is carried out at low temperature so that the minority carrier lifetime Tao p is controlled to be 4-6 Mu S; 12 Mev electron irradiation is carried out so that the minority carrier lifetime Tao p of a base region is 0.9-1.1 Mu S; the two surfaces of the silicon piece are plated with titanium-nickel-gold by means of vapor deposition and then undergo table-board spray sand molding, desanding, cleaning, corrosion, passivation protection, intermediate test, shell arrangement and packaging, and after tests testify qualification, the finished product is produced.

Owner:JINZHOU SHENGHE POWER ELECTRONICS

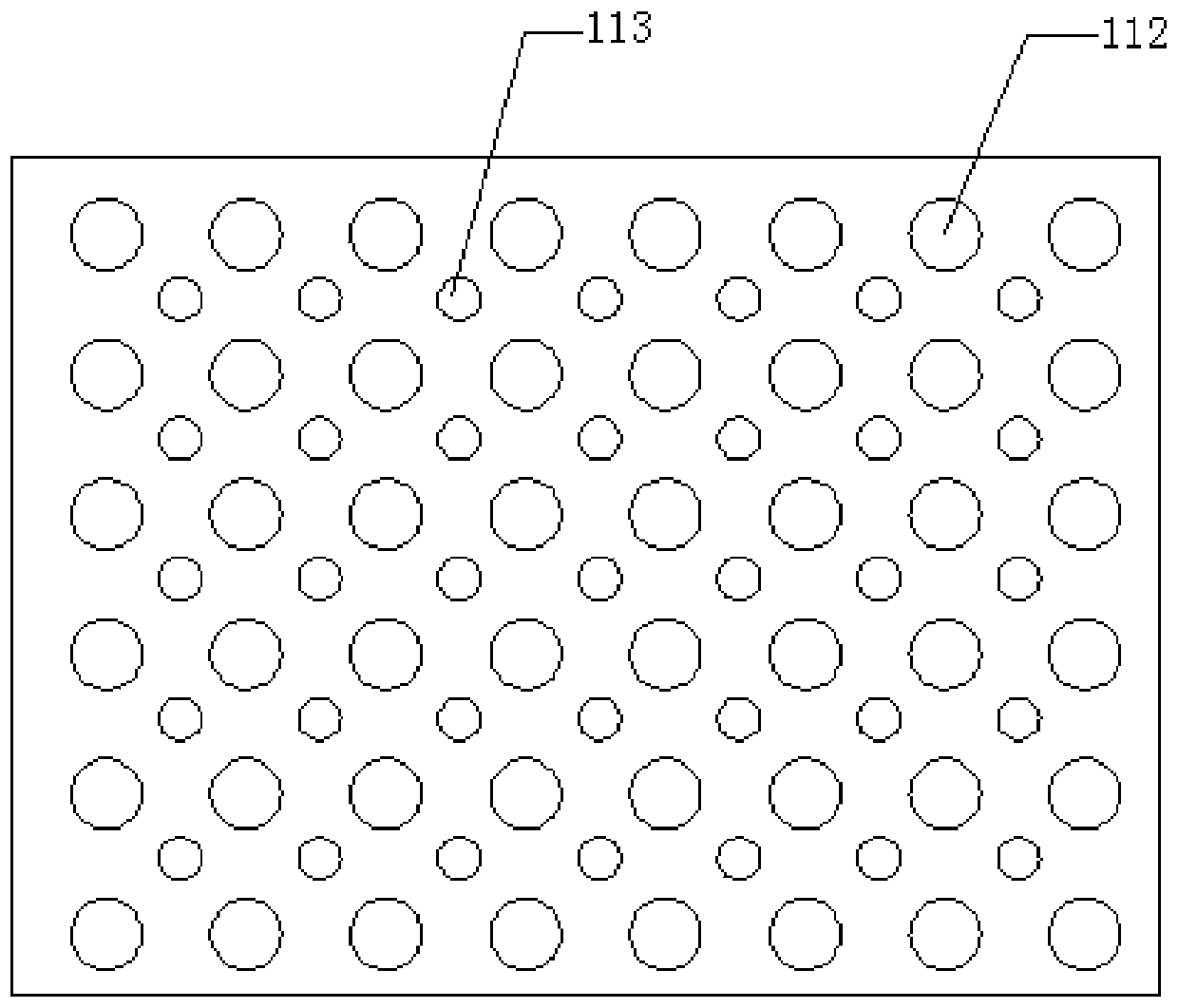

A high-power ultraviolet light-emitting diode and its manufacturing method

ActiveCN109994583BImproved current scaling performanceReduce in quantitySemiconductor devicesOhmic contactUltraviolet lights

The invention provides a high-power ultraviolet light emitting diode and a manufacturing method thereof. Firstly, N-type through holes are arranged to electrically connect a conductive layer with a first conductive layer, which improves the current expansion capability of the ultraviolet light emitting diode. Secondly, uniformly-distributed expanded through-holes are formed in a transparent conductive layer to make the transparent conductive layer, a metal mirror and a second conductive layer form ohmic contact. The N-type through holes and the extended through holes are arranged in a staggered manner along the vertical direction of the transparent conductive layer. The number of the N-type through holes is reduced while the effect of current expansion is guaranteed, and the area loss of the active layer caused by too many through holes is avoided.

Owner:XIAMEN CHANGELIGHT CO LTD

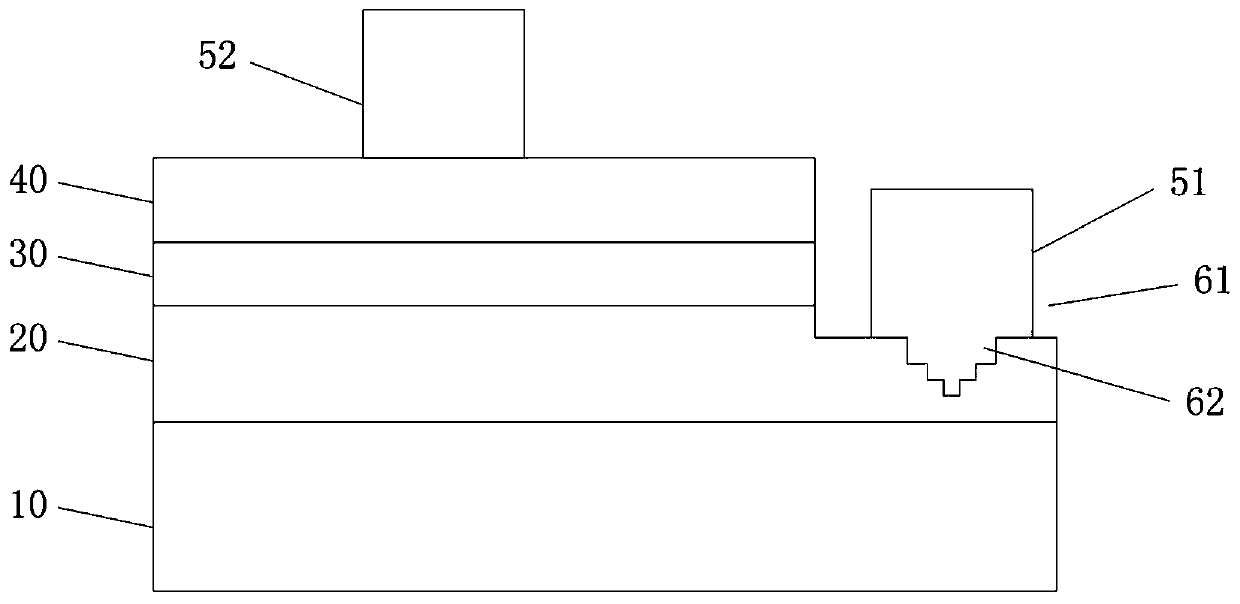

LED chip and manufacturing method thereof

PendingCN110491977AIncrease contact areaImprove current spreading effectSemiconductor devicesElectrical conductorPower flow

The invention discloses an LED chip and a manufacturing method thereof. The LED chip includes a substrate, wherein a first semiconductor layer, a active layer, a second semiconductor layer, and a first electrode and a second electrode are sequentially arranged on the substrate; the semiconductor device further comprises an exposed area and n holes, n is larger than or equal to 2, the n holes forma stepped structure, the diameters of the first hole to the nth hole are sequentially decreased progressively, the first electrode is arranged on the exposed first semiconductor layer and extends intothe n holes, and the second electrode is arranged on the second semiconductor layer. According to the invention, the contact area of the first electrode and the first semiconductor layer is increasedthrough the n holes, so that the first electrode and the first semiconductor layer are combined more firmly, the reliability of subsequent packaging and routing is improved, and the current expansioncapability of a chip is improved.

Owner:FOSHAN NATIONSTAR SEMICON

A kind of mini LED chip and manufacturing method

ActiveCN111081832BStable reliabilityGuaranteed reliabilitySemiconductor devicesEngineeringSolder paste

The invention discloses a Mini LED chip and a manufacturing method, comprising a GaN substrate, a P-type contact surface and a current stabilization layer, a P-type current injection layer, a P-type welding interface metal layer, a buffer insulating layer, a stress Release layer, insulating full-spectrum reflective layer, N-type welding interface metal layer, N-type current injection layer, N-type contact surface and current stabilization layer; the present invention uses P-type contact surface and current stabilization layer, P-type current injection layer, The use of special functional layers such as buffer insulation layer, stress release layer, N-type current injection layer, N-type contact surface and current stabilization layer solves the problems of current resistance, insulation layer stress, insulation layer adhesion and pad and The problem of the adhesion of the solder paste makes the Mini LED chip have excellent reliability and various performances, and at the same time, it can ensure the production efficiency and production yield of the Mini LED chip.

Owner:FUJIAN PRIMA OPTOELECTRONICS CO LTD

Mis-structured UV LED based on localized surface plasmon enhancement and its preparation method

ActiveCN110165028BImprove internal quantum efficiencyHigh luminous intensitySemiconductor devicesLuminous intensityUltraviolet lights

The invention relates to an MIS structured ultraviolet LED based on local surface plasmon enhancement and a preparation method thereof. According to the invention, silver metal nanoparticles are introduced into the MIS structured ultraviolet LED to form a local surface plasmon; the MIS structured LED adopts a graphene film to serve as a conductive layer so as to enhance the current expansibility and improve the ultraviolet light emitting rate of the device; and the metal nanoparticles are arranged on the graphene layer, and emitted photons are enabled to have resonance coupling with the metalnanoparticles by using the local surface plasmon enhancement effect, so that the internal quantum efficiency of the device is improved, and the light emitting intensity of the device is enhanced. TheMIS structured ultraviolet LED based on the local surface plasmon enhancement provided by the invention has the advantages of simple structure, simple and convenient preparation and easy production.

Owner:XIAMEN UNIV

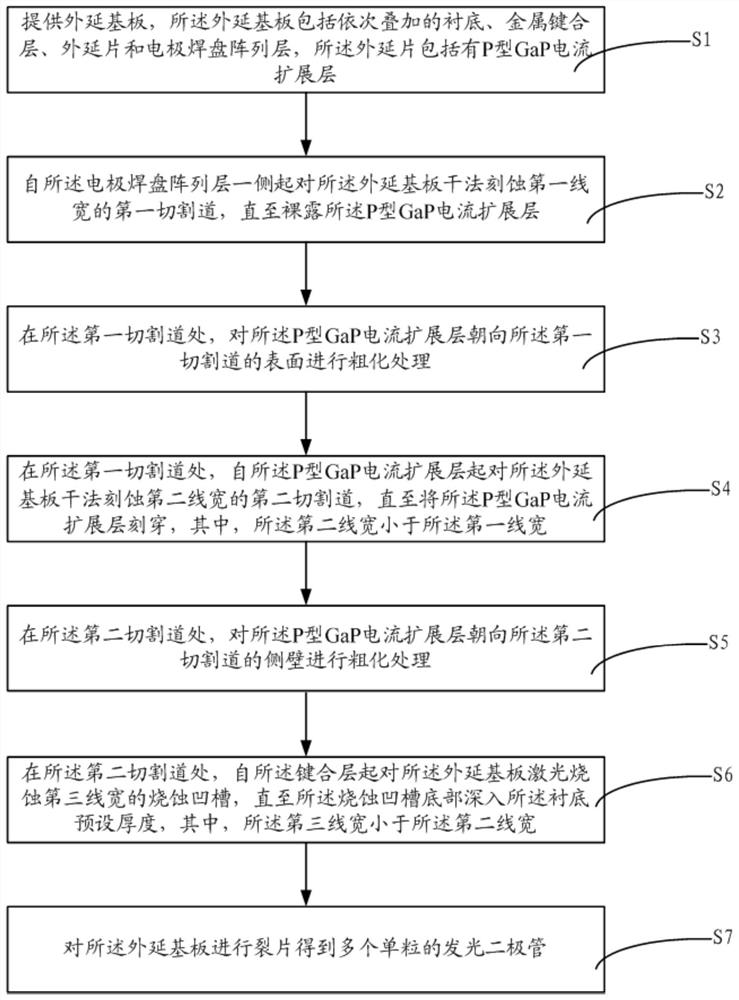

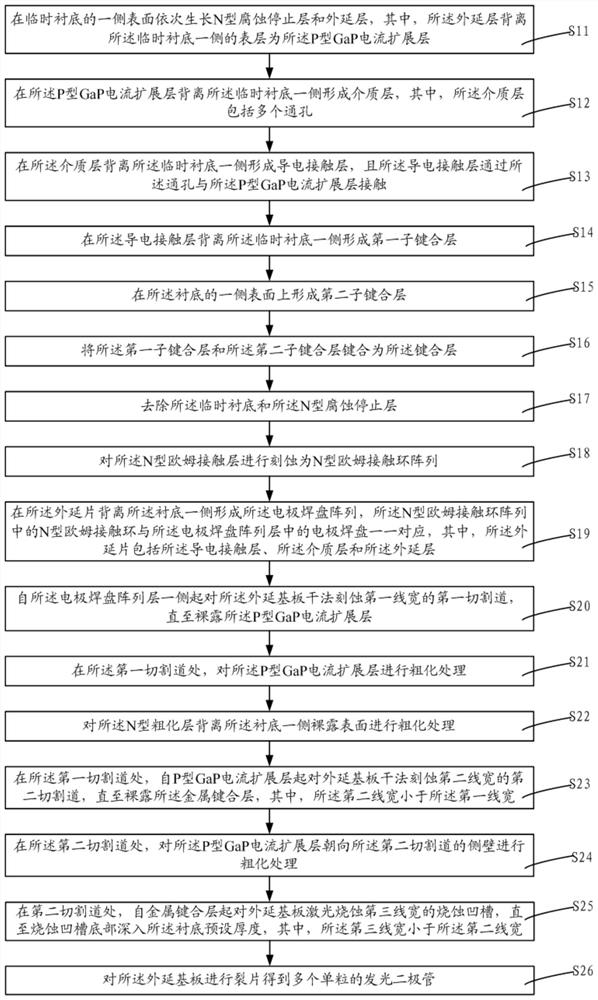

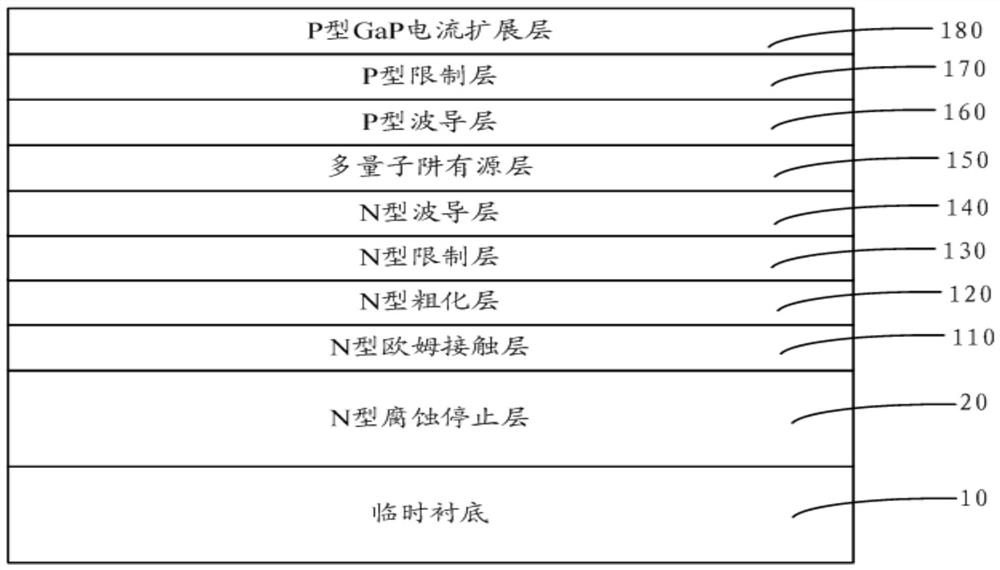

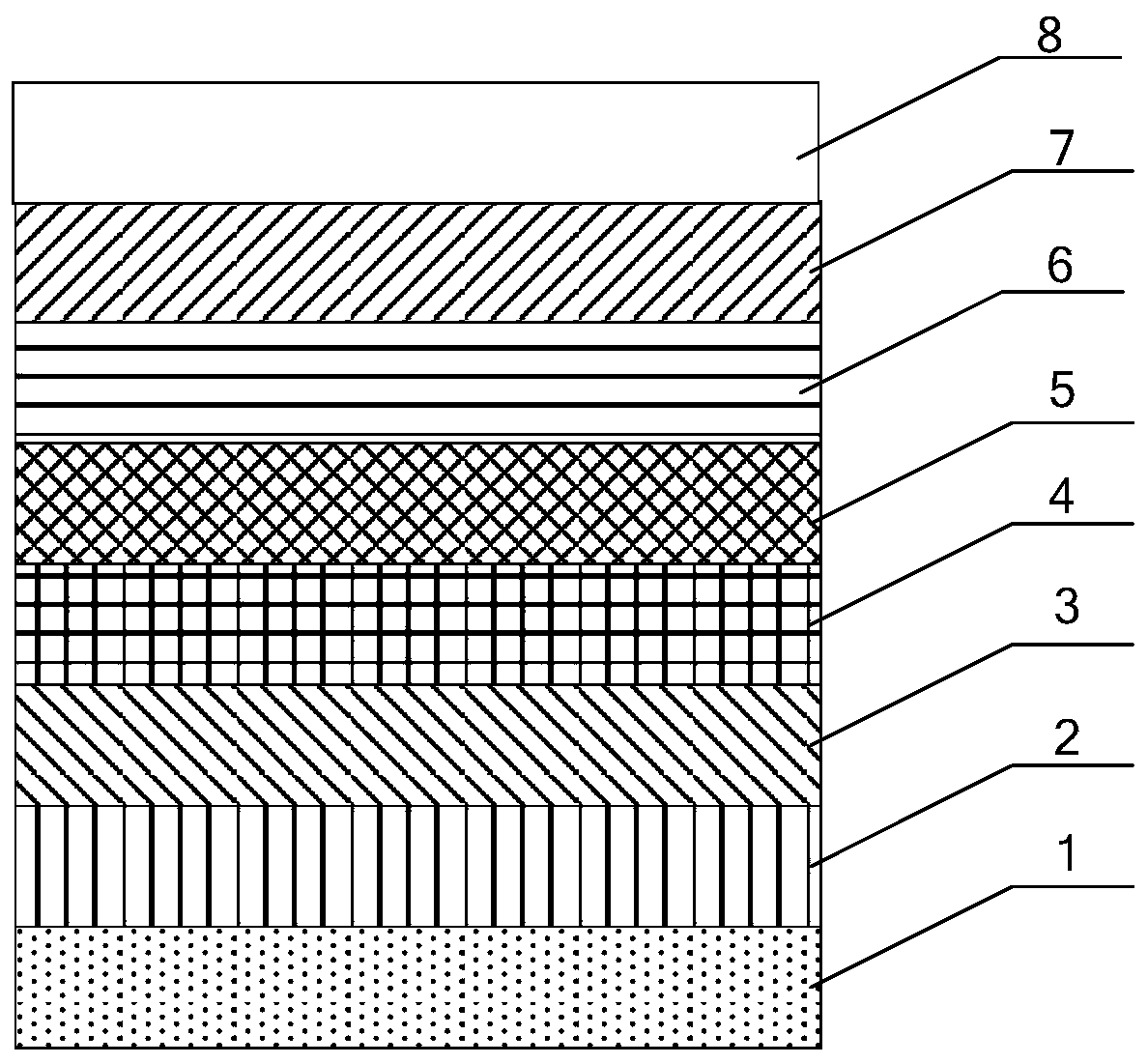

A light emitting diode and its manufacturing method

ActiveCN110660888BReduce the area removed by etchReduce absorption lossSemiconductor devicesLine widthPhysical chemistry

The invention discloses a light-emitting diode and a manufacturing method thereof. Firstly, a first scribe line with a first line width is etched on an epitaxial wafer, and then a second scribe line with a second line width is etched at the first scribe line. The width is smaller than the first line width, thereby reducing the area to be removed by etching the P-type GaP current spreading layer, and improving the current spreading ability; When the ablation groove of the third line width is laser ablated at the track, the melt produced by the ablation of the laser on the P-type GaP current spreading layer is reduced, thereby reducing the absorption loss of the melt on the light emitted by the light-emitting diode, and improving the efficiency of the light-emitting diode. luminous efficiency. And, roughen the exposed surface of the P-type GaP current spreading layer away from the substrate and its sidewall, thereby reducing the total reflection phenomenon in this region and increasing the edge luminous efficiency.

Owner:YANGZHOU CHANGELIGHT

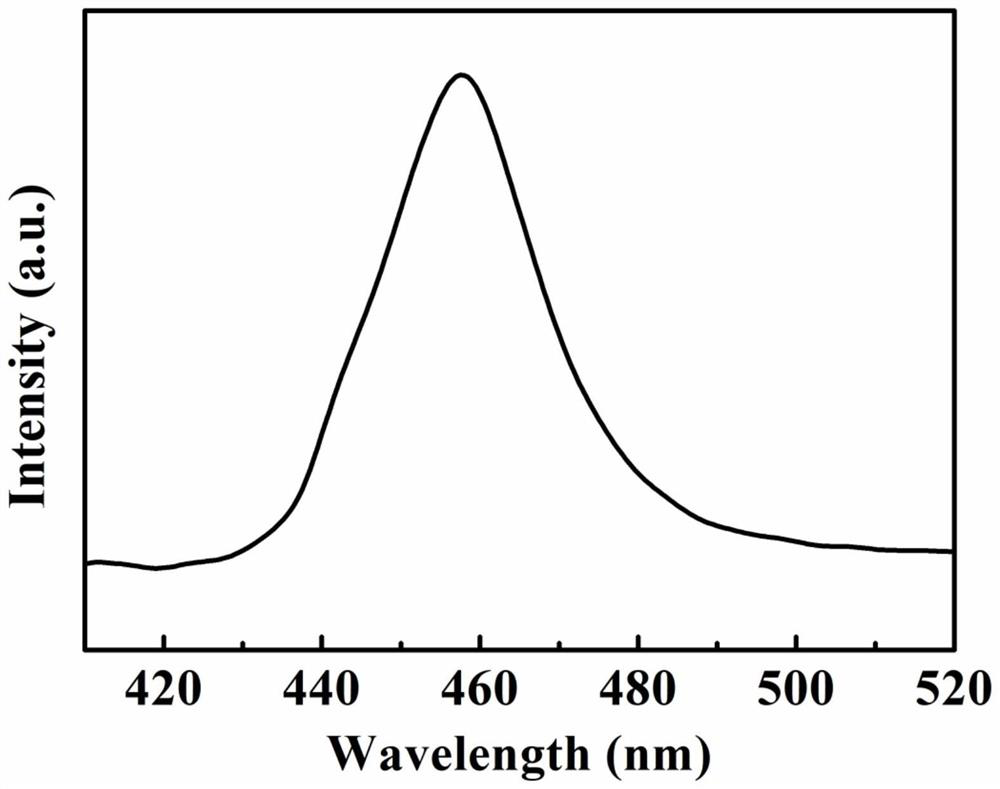

Ultraviolet led epitaxy structure and its growth method

ActiveCN107689405BLower ionization energyIncrease concentrationSemiconductor devicesUltravioletScattering effect

The invention provides a growth method for an ultraviolet LED epitaxial structure, specially a special growth process for multiple quantum wells of an active area, and the special growth process comprises the following steps: growing LP and PAL as an integral superlattice, wherein a growth period is 5-20; adopting roof type gradual doping for doping of Mg, i.e., gradually reducing after doping ofMg firstly gradually increases to reach a peak value, wherein doping is in symmetrical distribution. Through the superlattice growth, ionization energy of Mg can be reduced, hole concentration is improved, the impurity scattering effect on the hole is reduced, and more holes are injected into a light-emitting area, so that light emitting efficiency is improved. The method is an effective method capable of improving efficiency of an ultraviolet LED; and meanwhile, an apparatus has very good light emitting efficiency, so that photoelectric property of the apparatus is improved.

Owner:宁波安芯美半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com