A kind of high-power vertical LED epitaxial structure and its preparation method

A vertical structure and epitaxial structure technology, applied in semiconductor devices, electrical components, nanotechnology, etc., can solve the problems of ohmic contact electrode difficulties, optical and electrical performance limitations, low carrier concentration, etc., to achieve enhanced current expansion, Improving the photoelectric performance and wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

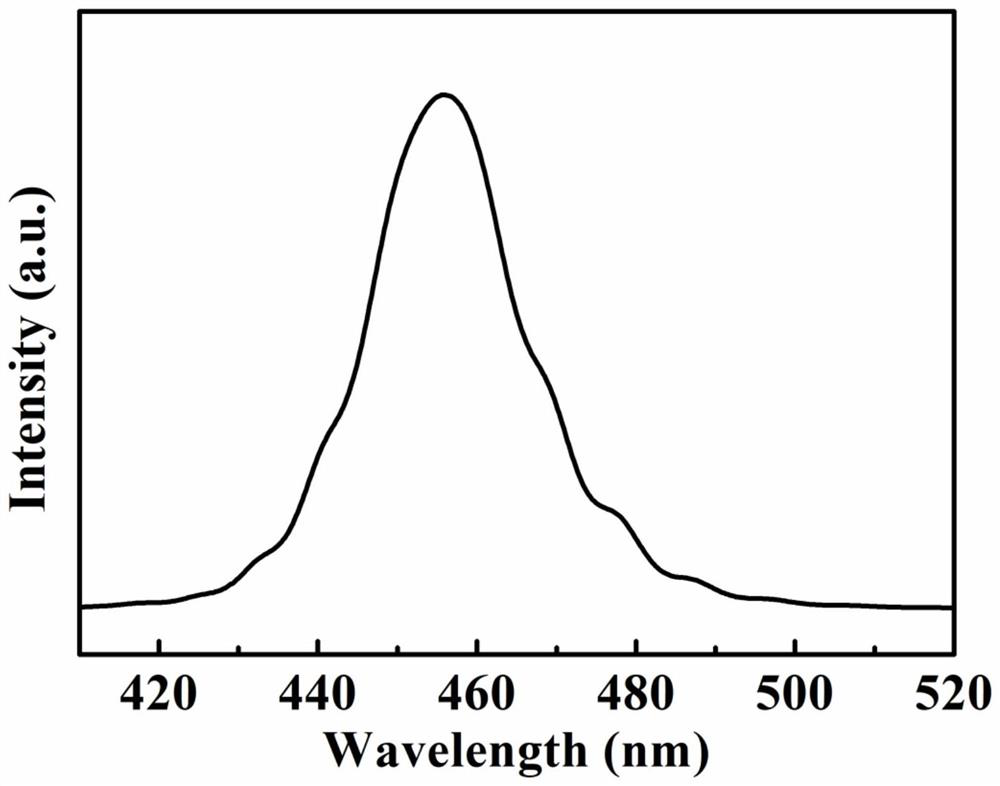

Embodiment 1

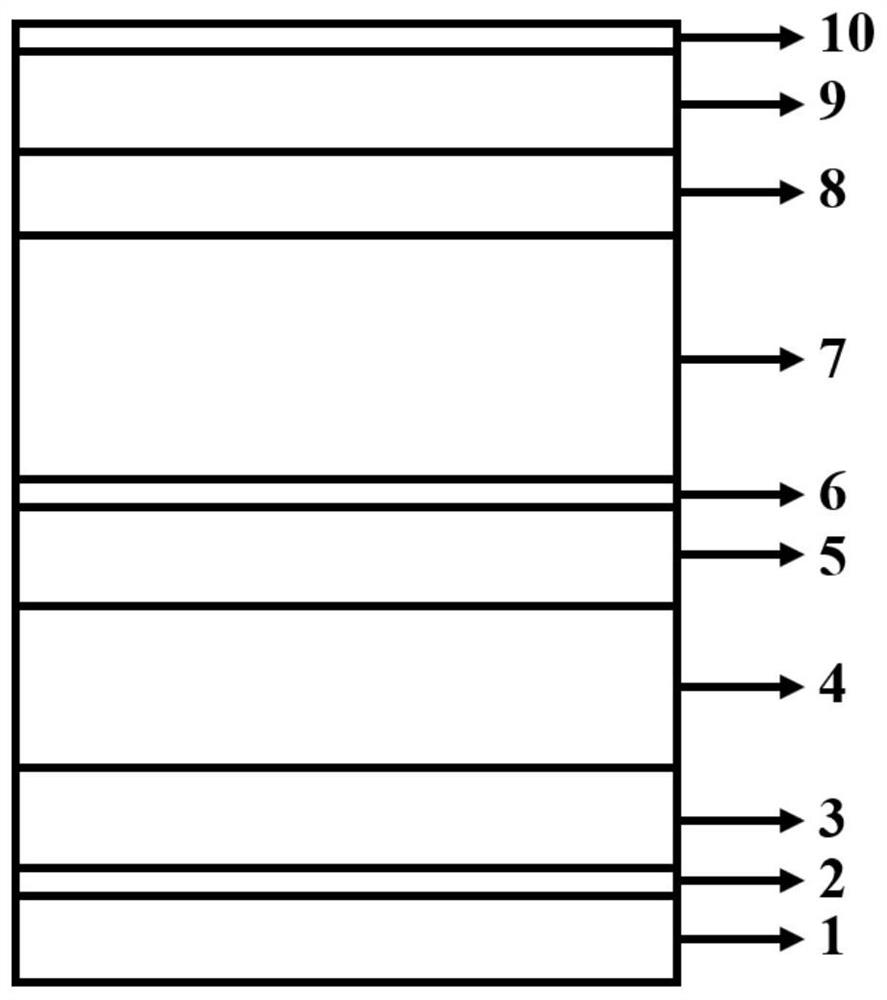

[0036] A method for preparing a high-power vertical structure LED epitaxial structure, comprising the following steps:

[0037] 1) Place the Si substrate 1 in the MOCVD equipment, select the (111) crystal plane of the Si substrate 1, and sequentially deposit a 2nm pre-coated Al layer 2, a 150nm thick AlN buffer layer 3, and a 500nm thick AlGaN buffer layer 4 , a u-type GaN layer 5 with a thickness of 1000nm;

[0038]Specifically, the operating parameters of the pre-laid Al layer 2: the substrate temperature is 950° C., the reaction chamber pressure is 40 Torr, the graphite disk rotation speed is 900 r / min, and the flow rate of TMAl is 250 sccm;

[0039] The operating parameters for depositing the AlN buffer layer 3: the substrate temperature is 1100° C., the reaction chamber pressure is 50 Torr, the graphite disc rotation speed is 1200 r / min, the flow rate of TMAl is 350 sccm, NH 3 The flow rate is 20slm;

[0040] The operating parameters for depositing the AlGaN buffer laye...

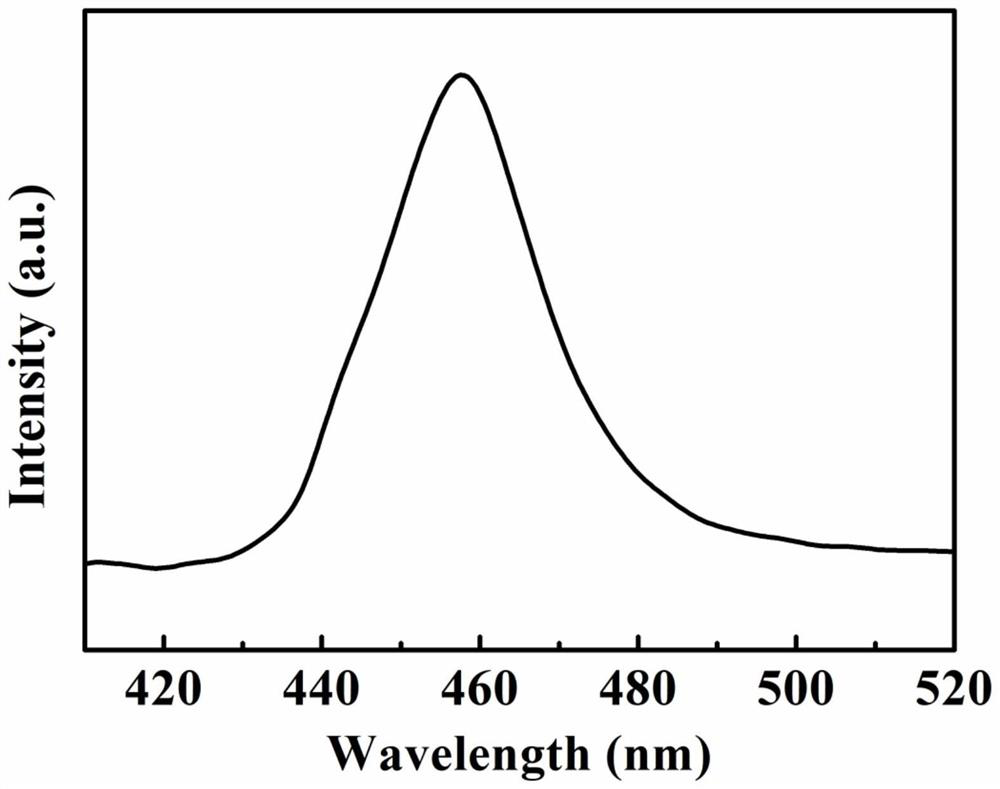

Embodiment 2

[0052] A method for preparing a high-power vertical structure LED epitaxial structure, comprising the following steps:

[0053] 1) Place the Si substrate 1 in the MOCVD equipment, select the (111) crystal plane of the Si substrate 1, and sequentially deposit a 2nm pre-coated Al layer 2, a 150nm thick AlN buffer layer 3, and a 500nm thick AlGaN buffer layer 4 , a u-type GaN layer 5 with a thickness of 1000nm;

[0054] Specifically, the operating parameters of the pre-laid Al layer 2: the substrate temperature is 950° C., the reaction chamber pressure is 40 Torr, the graphite disk rotation speed is 900 r / min, and the TMAl flow rate is 250 sccm;

[0055] The operating parameters for depositing the AlN buffer layer 3: the substrate temperature is 1100° C., the reaction chamber pressure is 50 Torr, the graphite disc rotation speed is 1200 r / min, the flow rate of TMAl is 350 sccm, NH 3 The flow rate is 20slm;

[0056] The operating parameters for depositing the AlGaN buffer layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com