A kind of LED chip and its manufacturing method

A technology of LED chip and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of easily damaged structure, poor effect of improving LED luminous efficiency, and not tightly bonded ZnO seeds, etc., so as to improve the current expansion ability , reduced light absorption, effects of high carrier concentration and mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

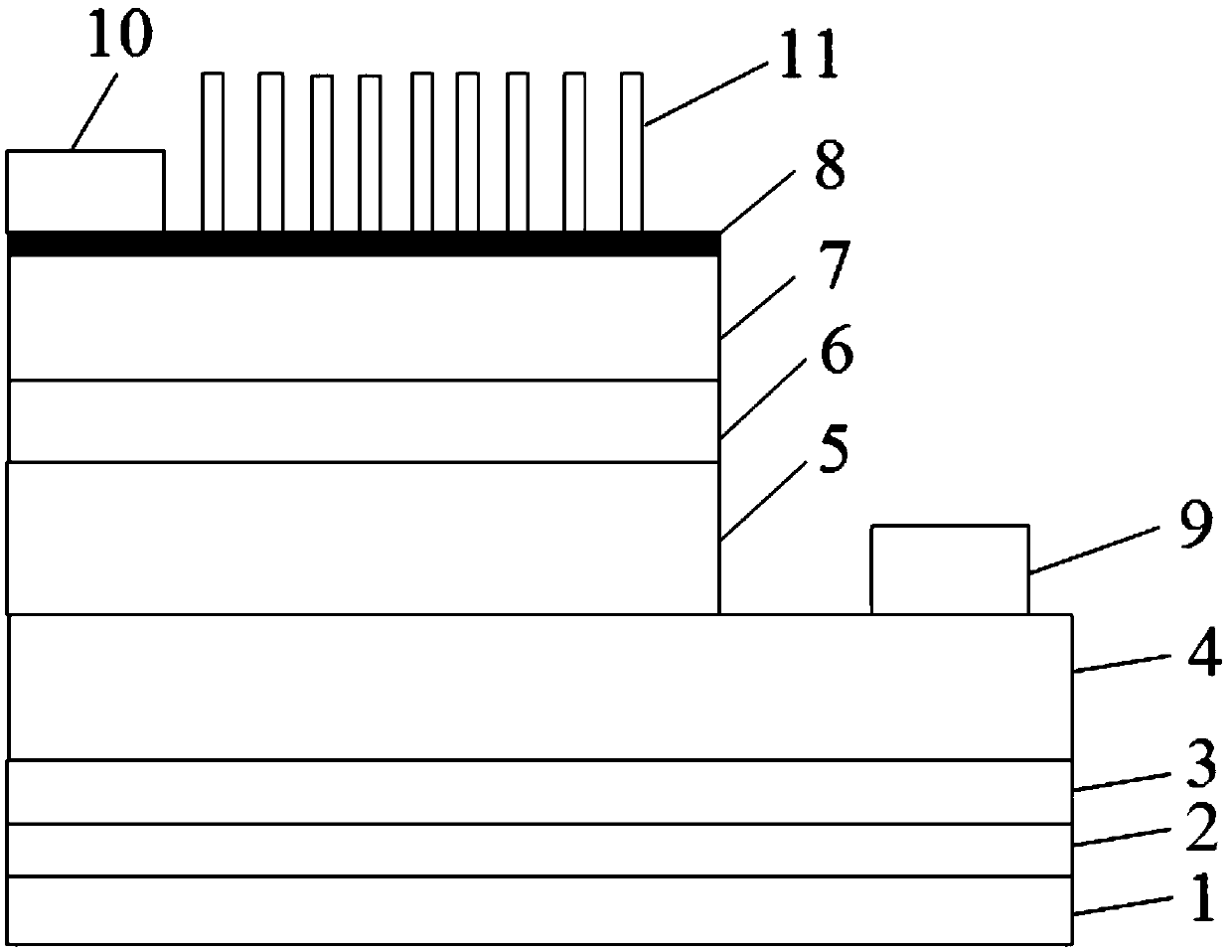

[0042] An embodiment of the present invention provides an LED chip, see figure 1 , the LED chip includes a substrate 1, and an undoped AlN buffer layer 2, an undoped GaN layer 3, an N-type GaN layer 4, a multi-quantum well layer 5, a P-type Al y Ga 1-y N layer 6, P-type GaN layer 7, graphene thin film layer 8, 0.1<y<0.5. The multiple quantum well layer includes alternately stacked InGaN layers and GaN layers. The graphene thin film layer 8 is provided with a groove extending to the N-type GaN layer 4 , the N-type electrode 9 is disposed on the N-type GaN layer 4 , and the P-type electrode 10 is disposed on the graphene thin film layer 8 .

[0043] In this embodiment, the LED chip also includes several TiO 2 nanorods 11, some TiO 2 The nanorods 11 are arranged on the graphene film layer 8 in an array.

[0044] Optionally, TiO 2 The diameter of the nanorods may be 20-80 nm.

[0045] Optionally, TiO 2 The height of the nanorods can be 300-500 nm.

[0046] Optionally, TiO...

Embodiment 2

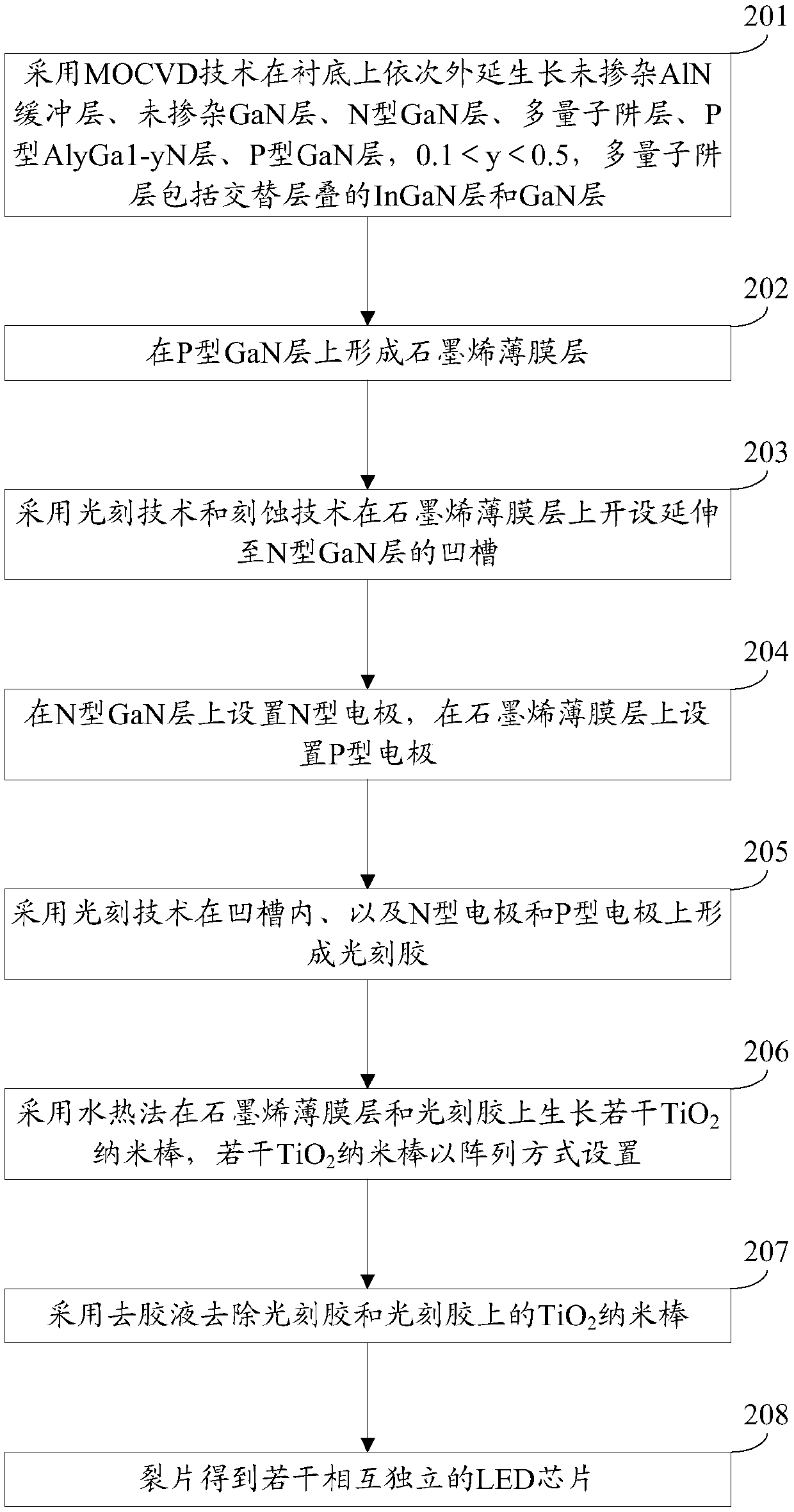

[0050] The embodiment of the present invention provides a method for manufacturing an LED chip, which is suitable for manufacturing the LED chip provided in Embodiment 1, see figure 2 , the production method includes:

[0051] Step 201: Epitaxially grow an undoped AlN buffer layer, an undoped GaN layer, an N-type GaN layer, a multi-quantum Well layer, P-type AlyGa1-yN layer, P-type GaN layer, 0.1<y<0.5, multi-quantum well layer includes alternately stacked InGaN layer and GaN layer.

[0052] Optionally, the substrate may be a GaAs substrate suitable for red and yellow LEDs, or a sapphire substrate, SiC substrate or GaN substrate suitable for blue and green LEDs.

[0053] Step 202: forming a graphene film layer on the p-type GaN layer.

[0054] Specifically, this step 202 may include:

[0055] Using chemical vapor deposition technology (English: Chemical Vapor Deposition), referred to as: CVD) to prepare graphene films on nickel metal substrates;

[0056] Coating the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com