Touch soldering station

A soldering station and touch technology, applied in welding equipment, auxiliary equipment, metal processing equipment, etc., can solve the problems of inconvenient operation and unintuitive comparison of temperature parameters, and achieve the effect of simple appearance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

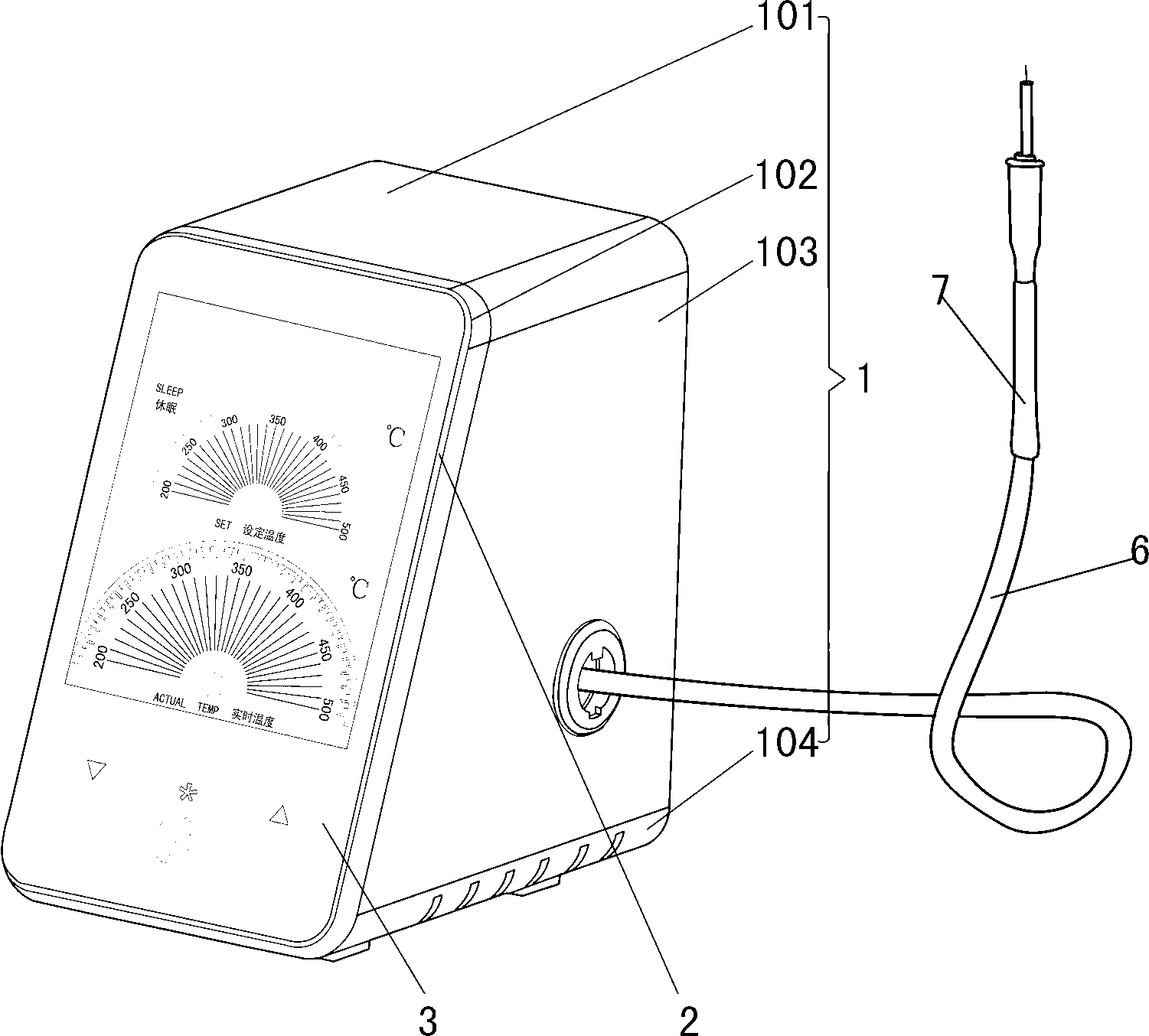

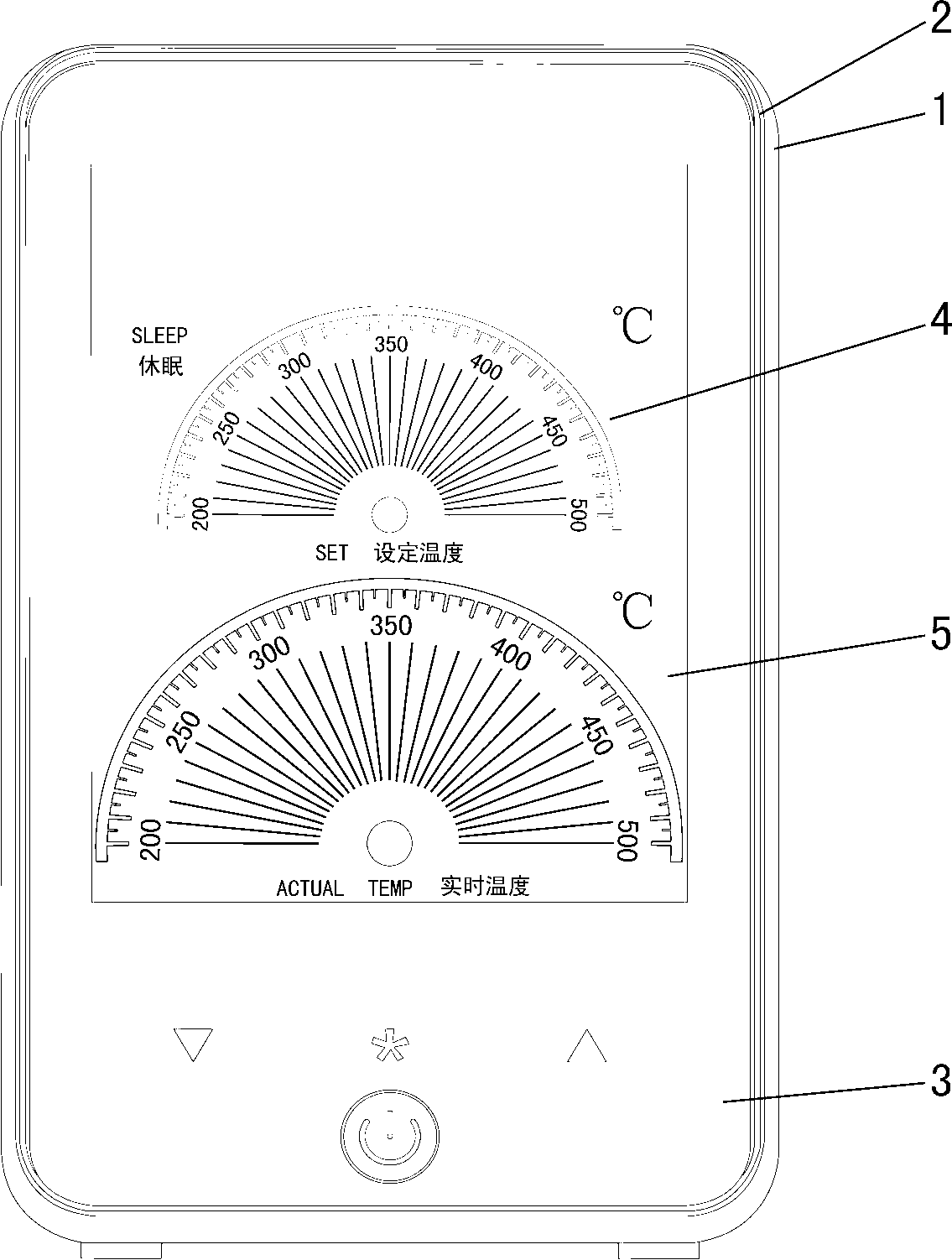

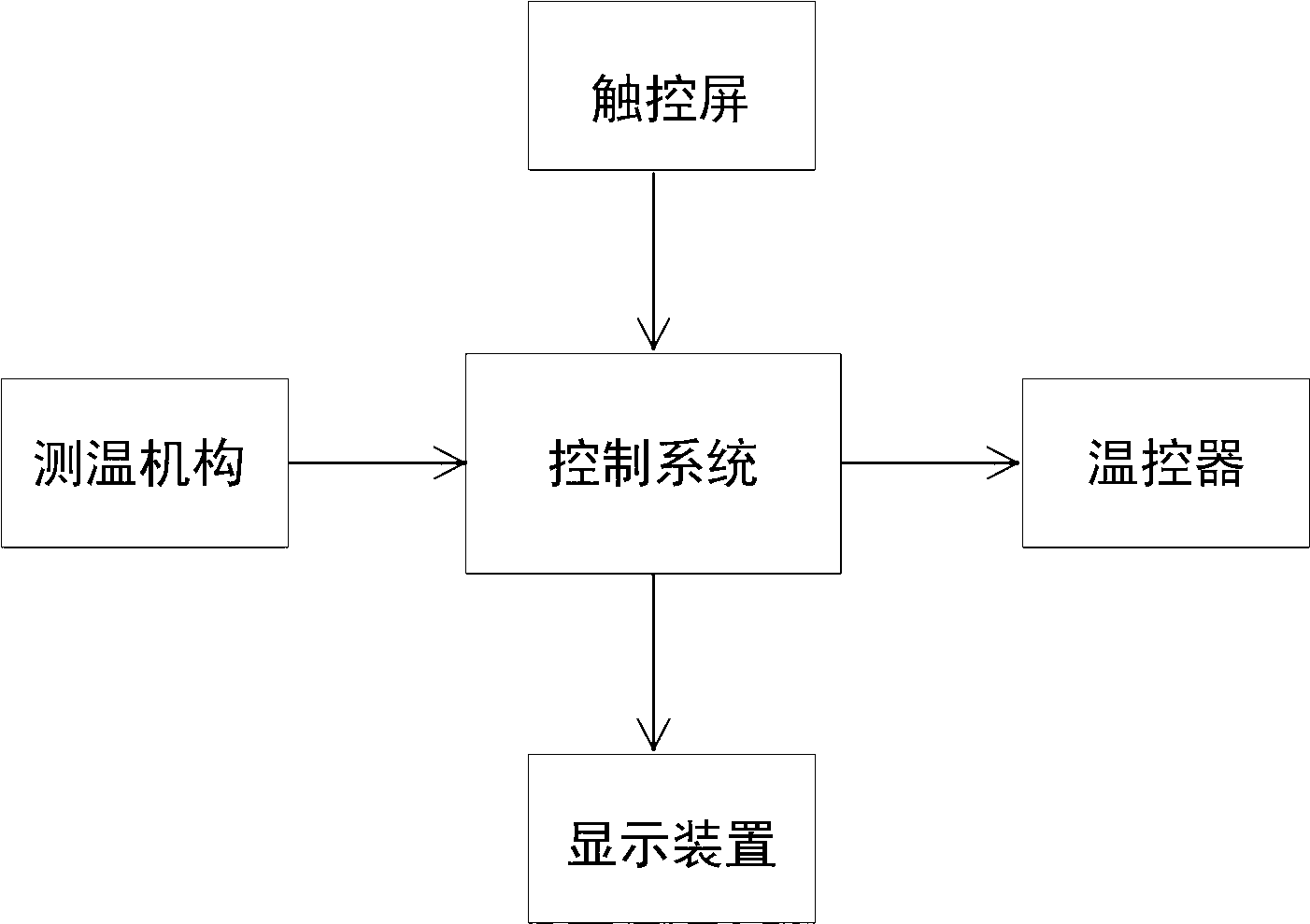

[0018] Such as Figure 1-3 As shown, the touch soldering station in this preferred embodiment includes a handle 7, a housing 1, a control system inside the housing 1, and a temperature controller. The handle 7 is electrically connected to the temperature controller through a connecting cable.

[0019] The handle 7 includes an insulating handle housing, a heating core, a temperature measuring mechanism and a soldering iron tip, and the heating core, temperature measuring mechanism and soldering iron tip are installed in the insulating handle housing.

[0020] The housing 1 includes a top panel 101, a front side panel 102, a left side panel (not visible in the figure), a rear side panel (not visible in the figure), a right side panel 103 and a bottom panel 104, the left side panel, Rear side panel, right side panel 103, front side panel 102 are arranged along the periphery of bottom panel 104 successively, and top panel 101 is installed on left side panel, rear side panel, right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com