Chip replacement method

A replacement method and chip technology, which is applied in the field of chip replacement for solder ball array packaged chips, can solve the problems of long BGA chip time consumption and low soldering pass rate, and achieve the effects of short replacement time, high soldering yield, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

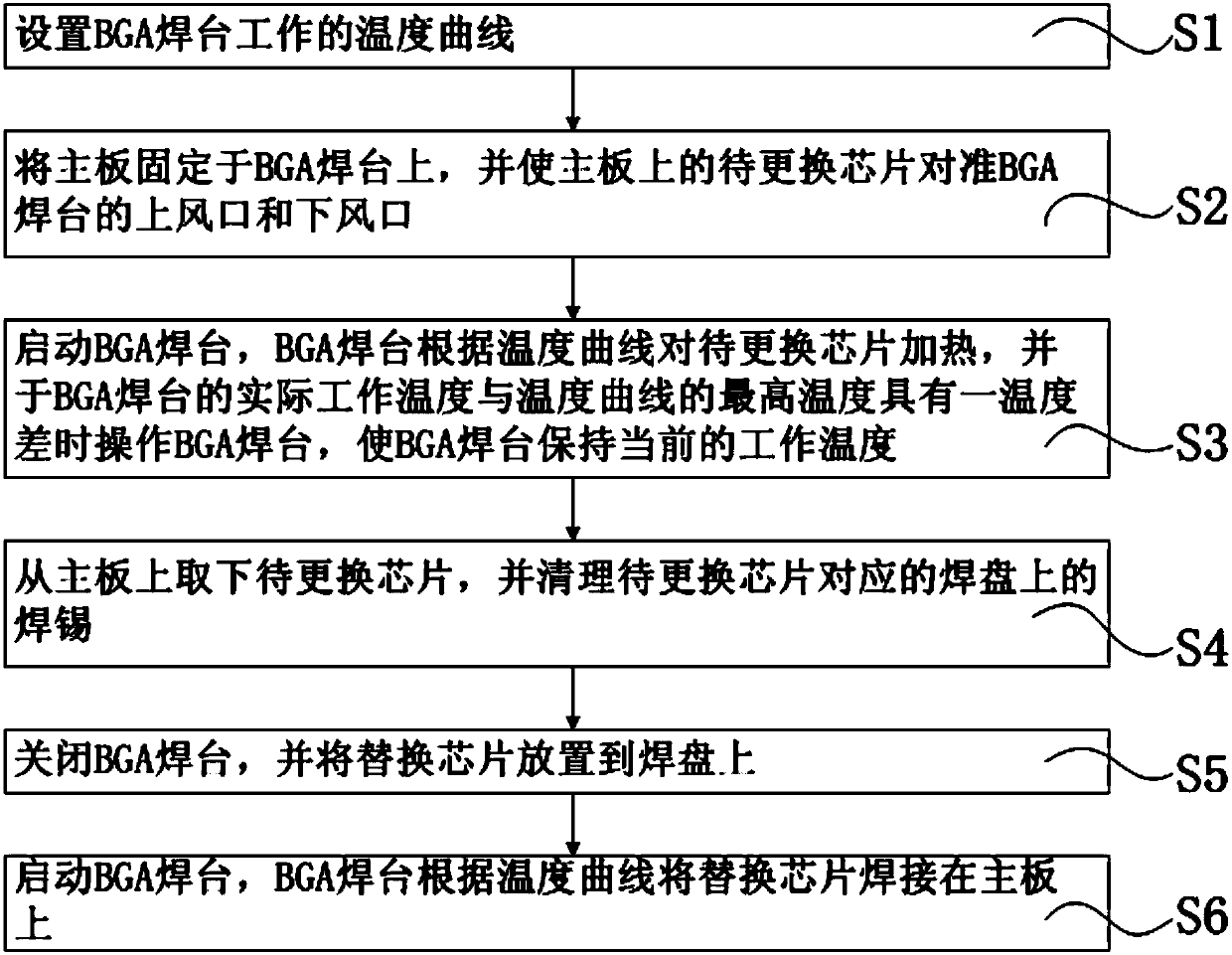

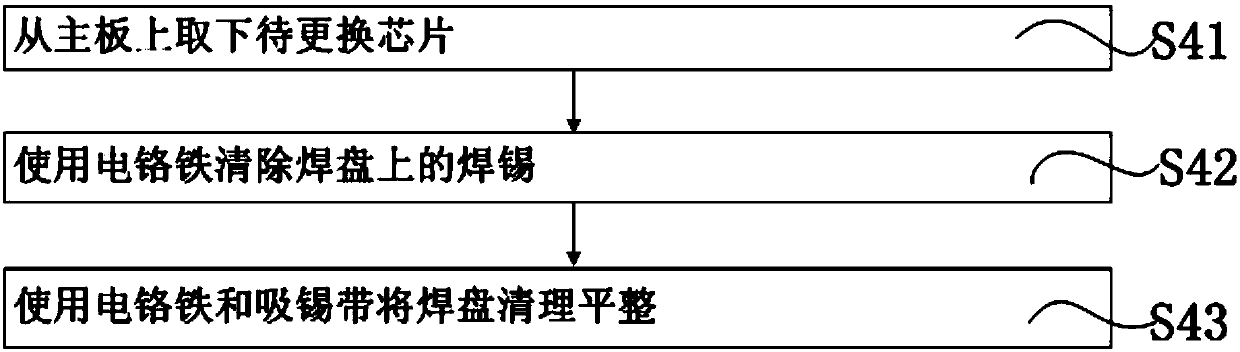

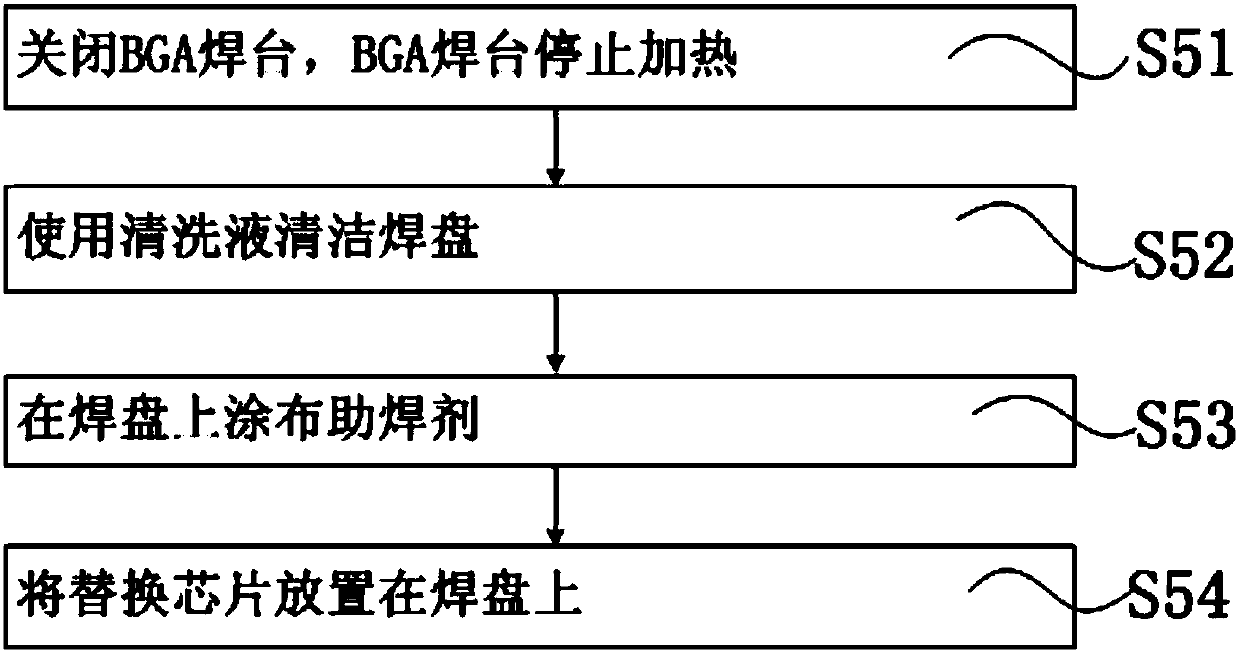

[0033] In a preferred embodiment of the present invention, such as Figure 1-3 As shown, a chip replacement method is provided, which is suitable for replacing a ball array package chip, including the following steps:

[0034] Provide a BGA soldering station for soldering ball array packaged chips;

[0035] Step S1, setting the working temperature curve of the BGA soldering station;

[0036] Step S2, fixing the main board on the BGA soldering station, and aligning the chips to be replaced on the main board with the upper and lower air outlets of the BGA soldering station;

[0037] Step S3, start the BGA soldering station, the BGA soldering station heats the chip to be replaced according to the temperature curve, and operates the BGA soldering station when there is a temperature difference betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com