Patents

Literature

39results about How to "Speed up shedding" patented technology

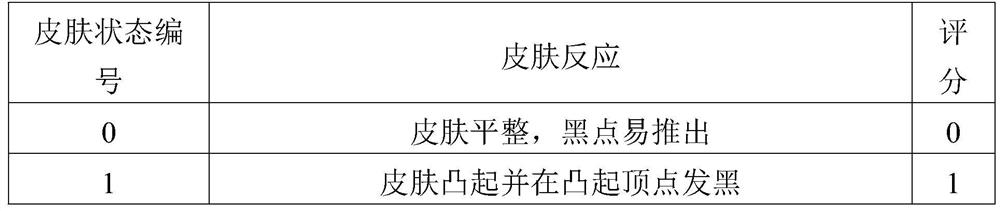

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

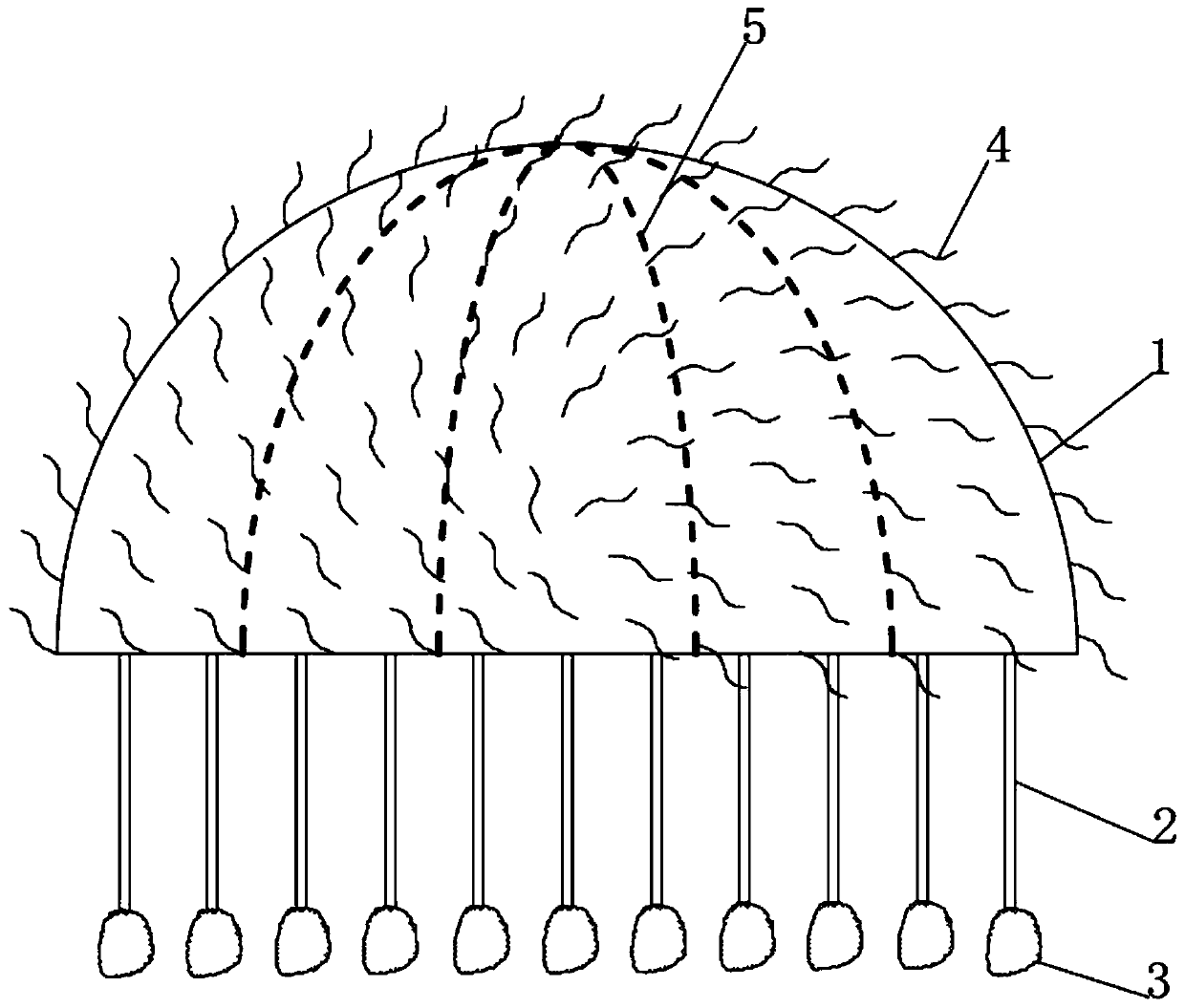

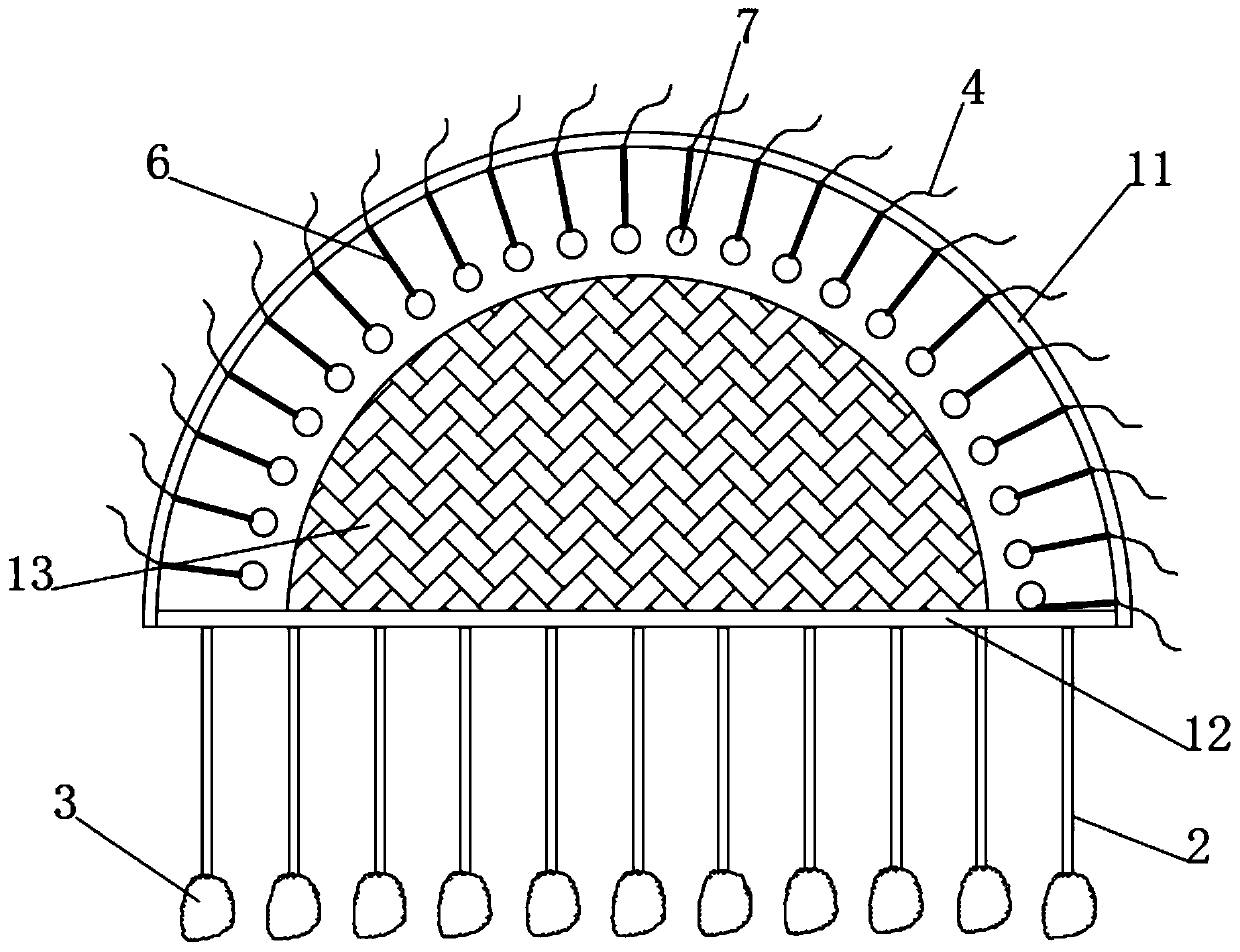

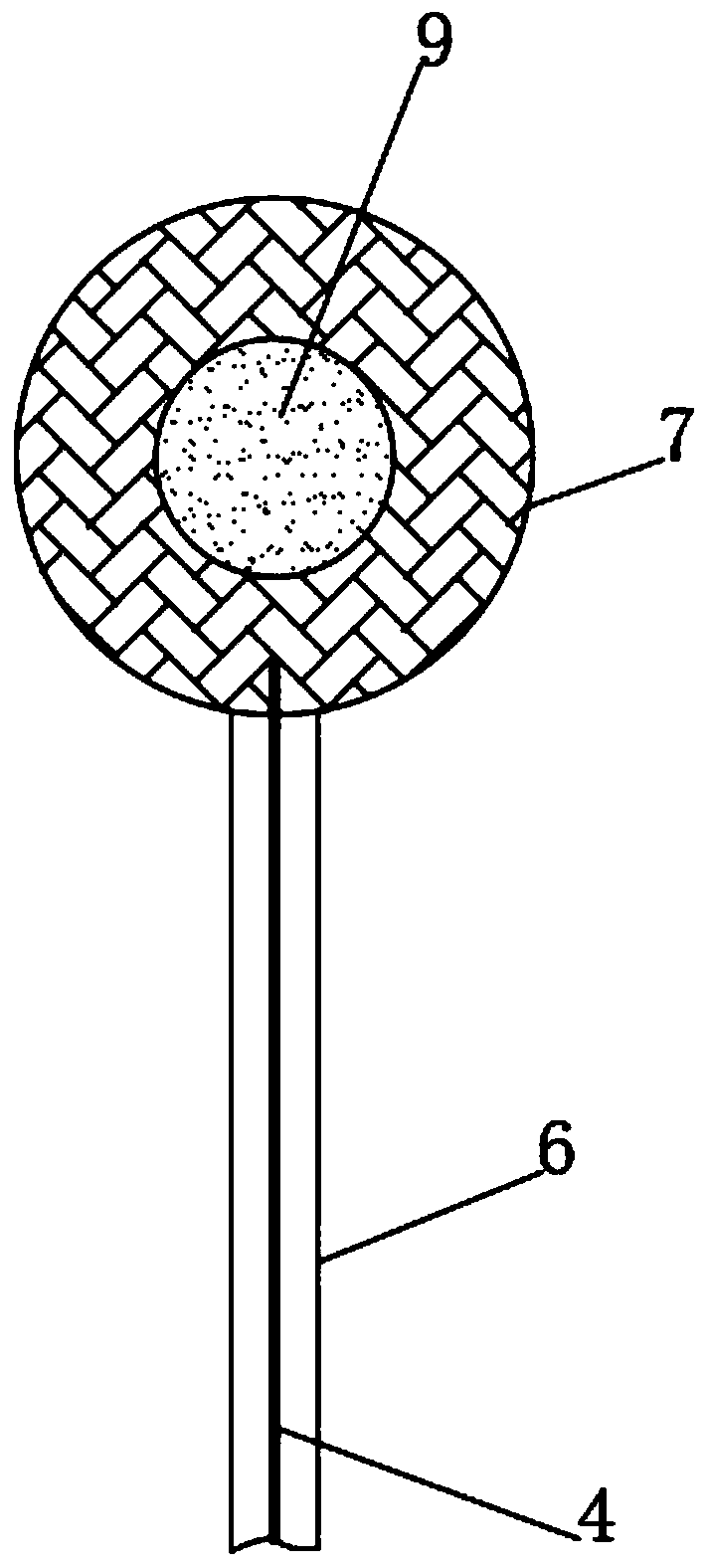

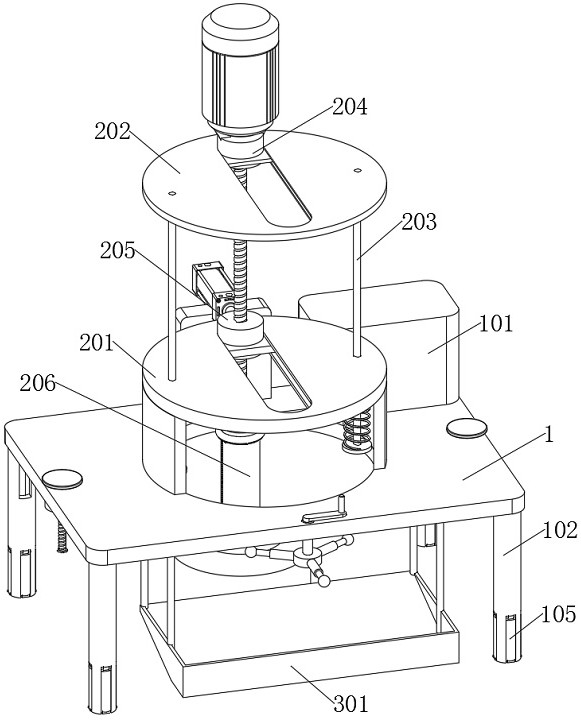

Cyclone separation falling type sewage remediation hemisphere

InactiveCN111533280AIncrease contact areaReduce gravityFatty/oily/floating substances removal devicesLiquid separationMicroorganismSludge

The invention discloses a cyclone separation falling type sewage remediation hemisphere, and belongs to the field of water body remediation. When the cyclone separation falling type sewage remediationhemisphere is used in sewage, the particles are pneumatically dissociated to fall into water and gas can be instantly released, the released gas can generate larger impact force to enable the hemisphere to fall off from the paddling zone and release a microbial strain, finally, the pneumatic dissociation particles fall into the water bottom to be embedded into underwater sludge, pores in the sludge can be enlarged in the process of continuously generating the gas, and thus the decomposition efficiency of microorganisms on harmful substances in the sludge is improved; besides, after the pneumatic dissociation particles fall off, the gravity of the remediation hemisphere is reduced, and the dissociation layer is dissolved so that the remediation hemisphere can rapidly float and be unfoldedto be attached to the water surface, the contact area with the water body is effectively increased, the remediation efficiency and effect are improved, sewage and sludge at the bottom of the sewage can be remediated at the same time, and the remediation efficiency is remarkably improved.

Owner:鲍永强

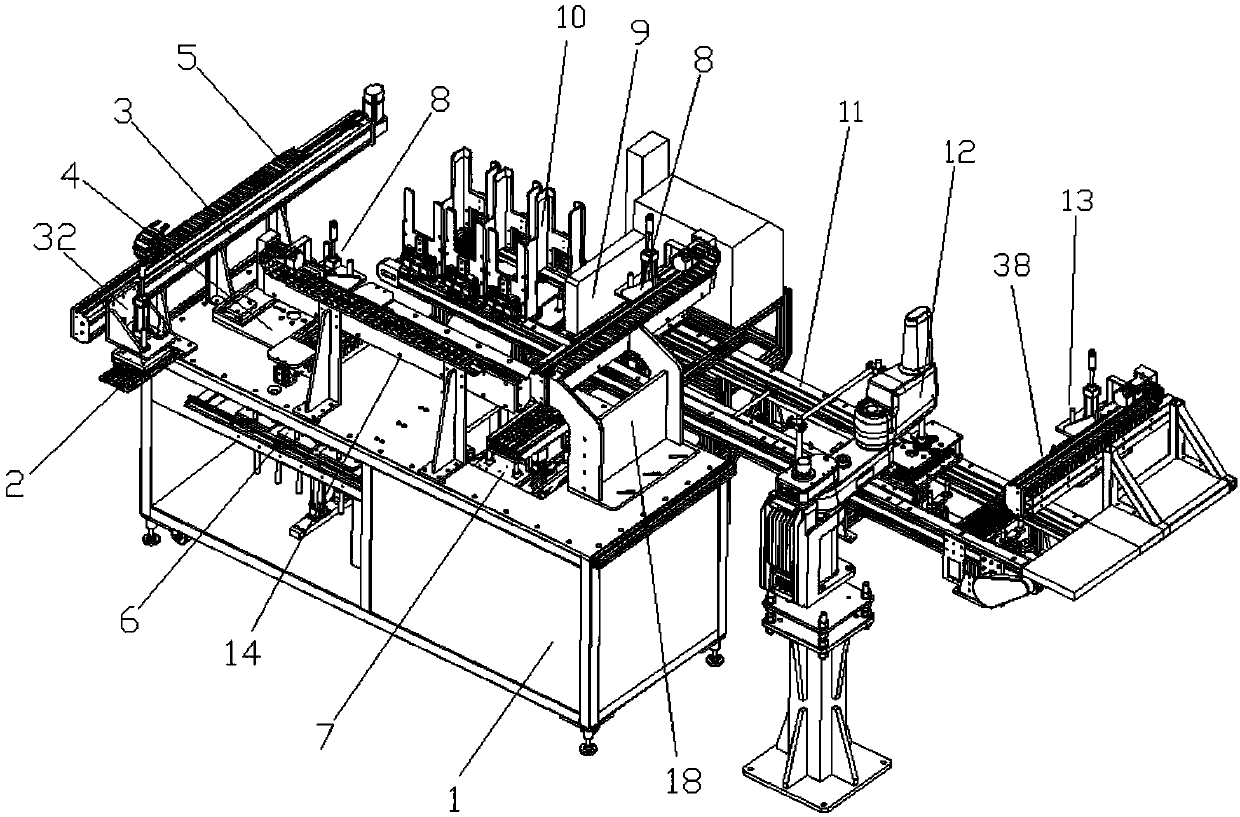

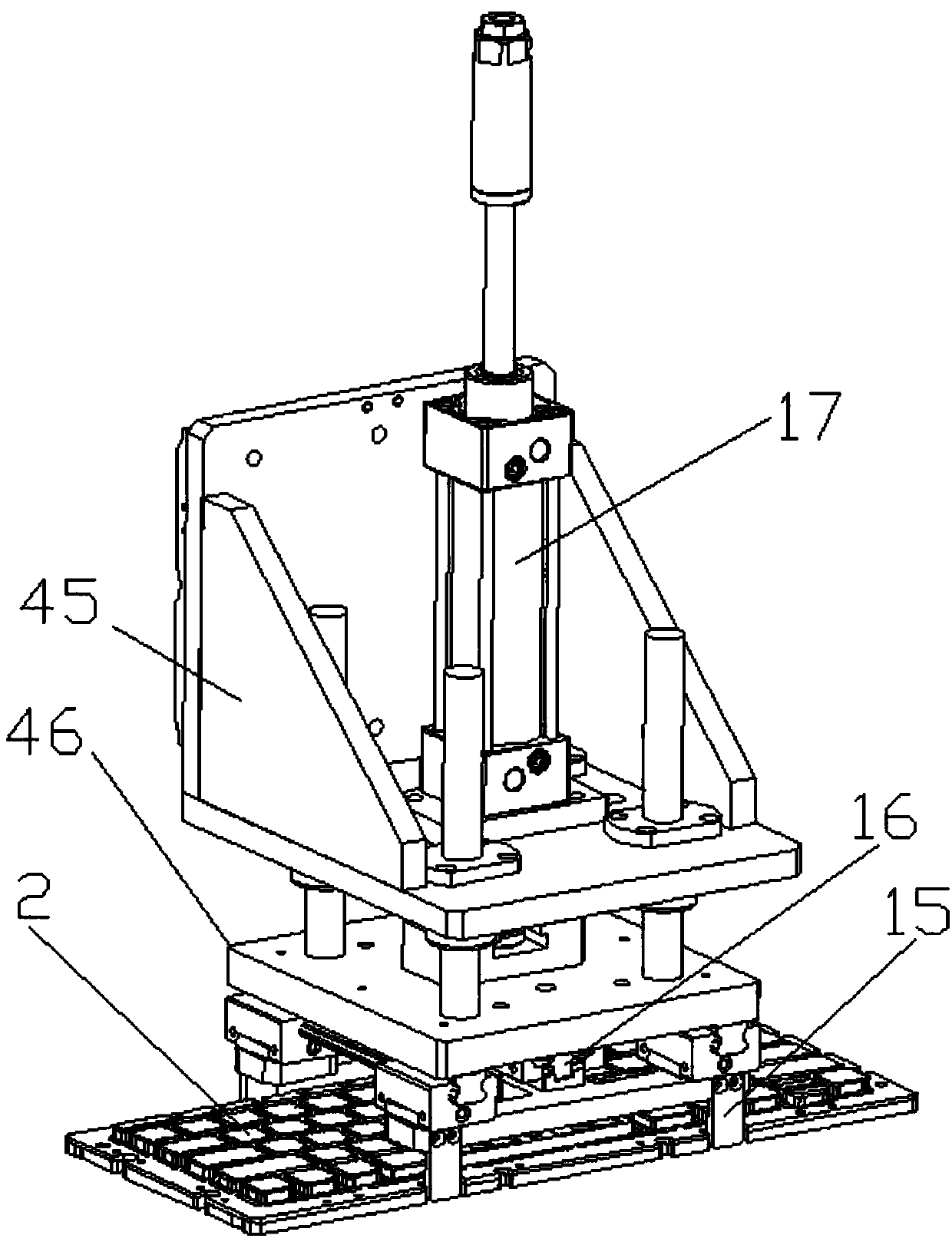

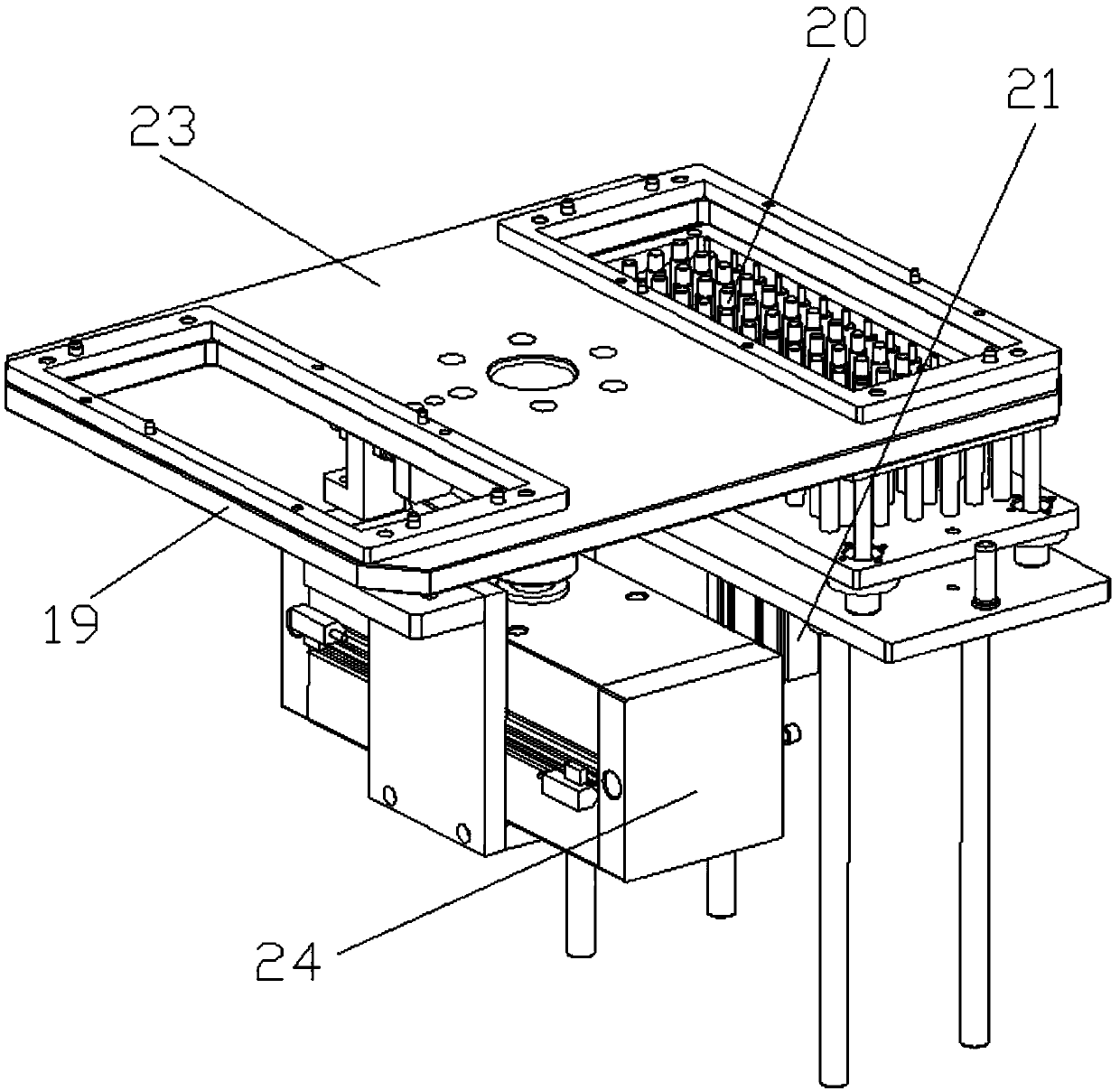

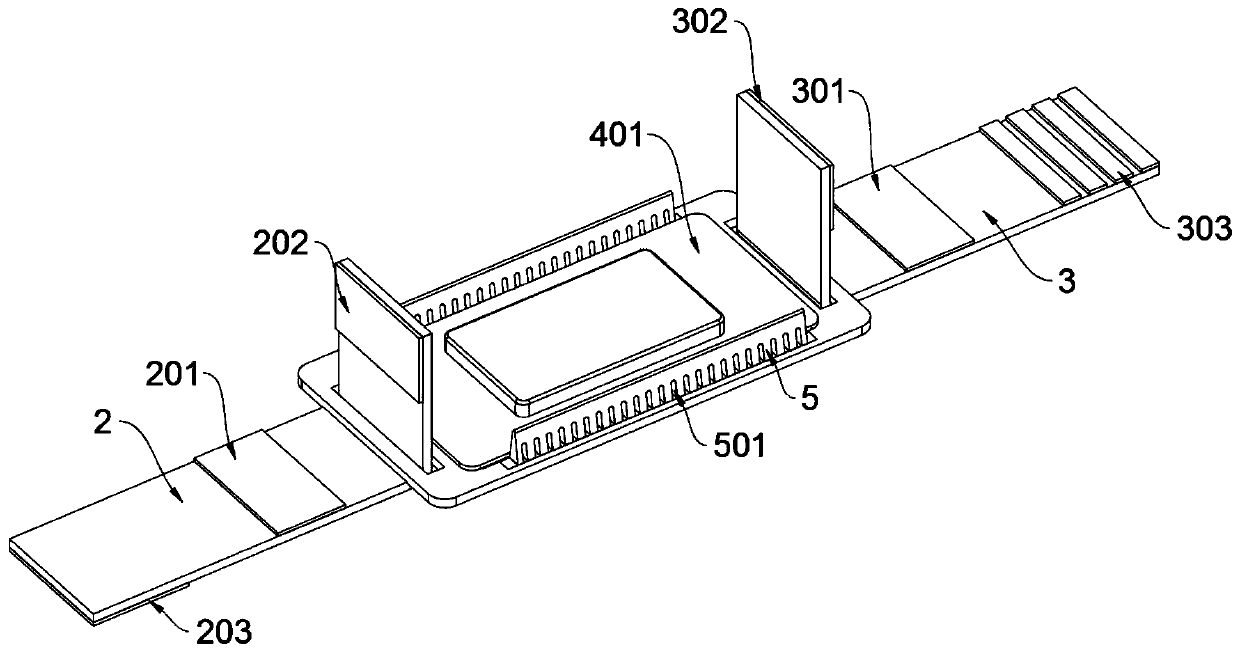

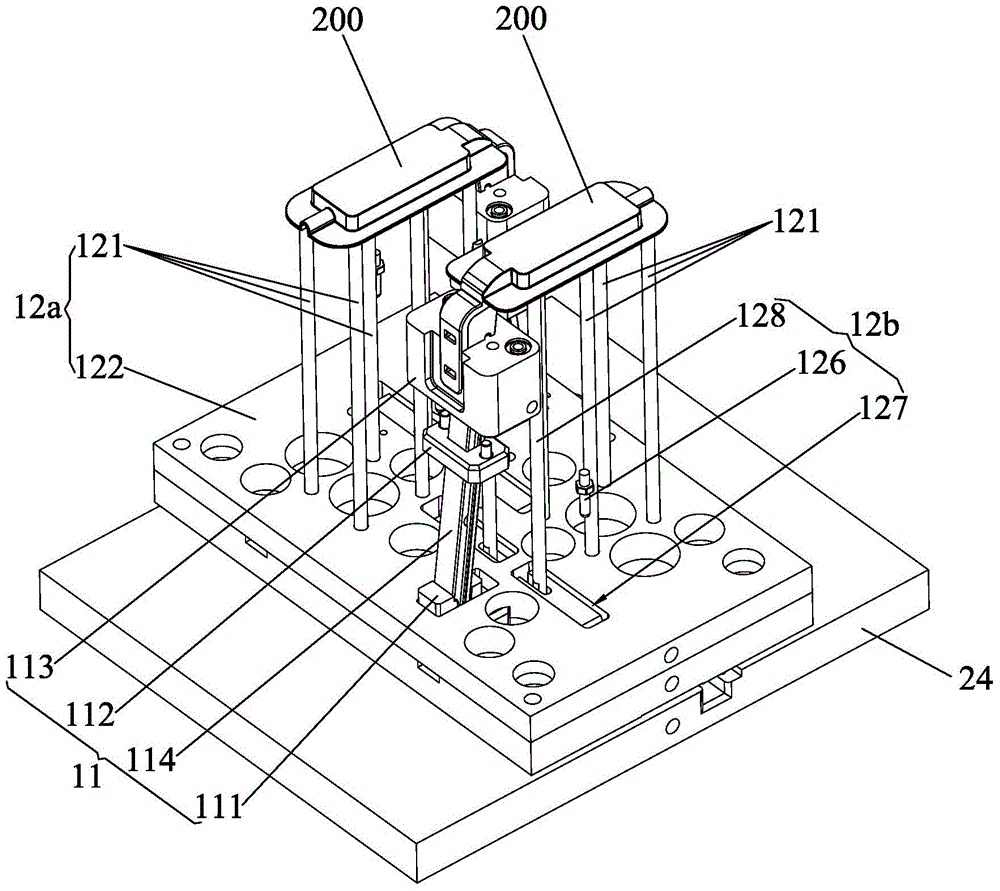

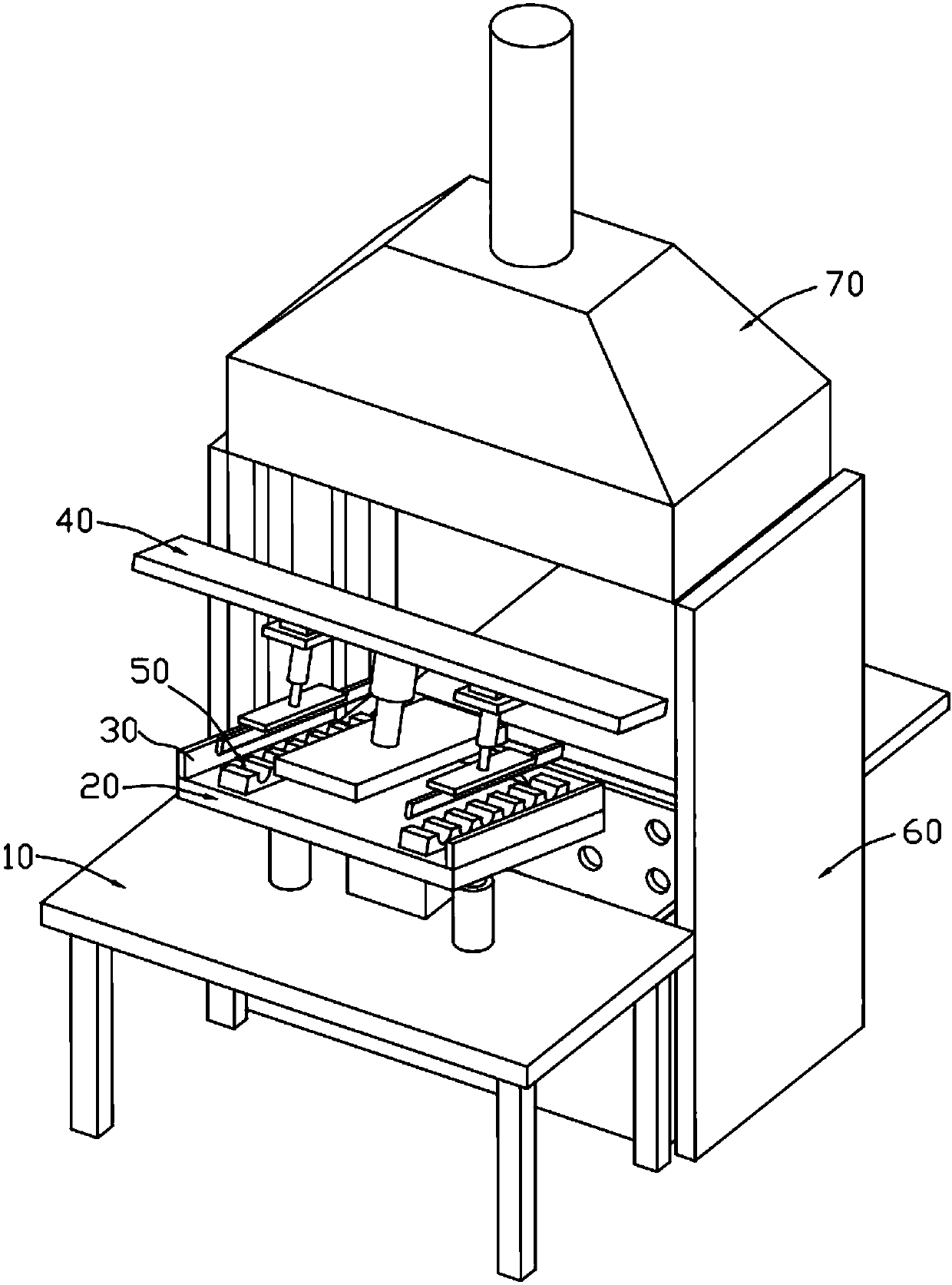

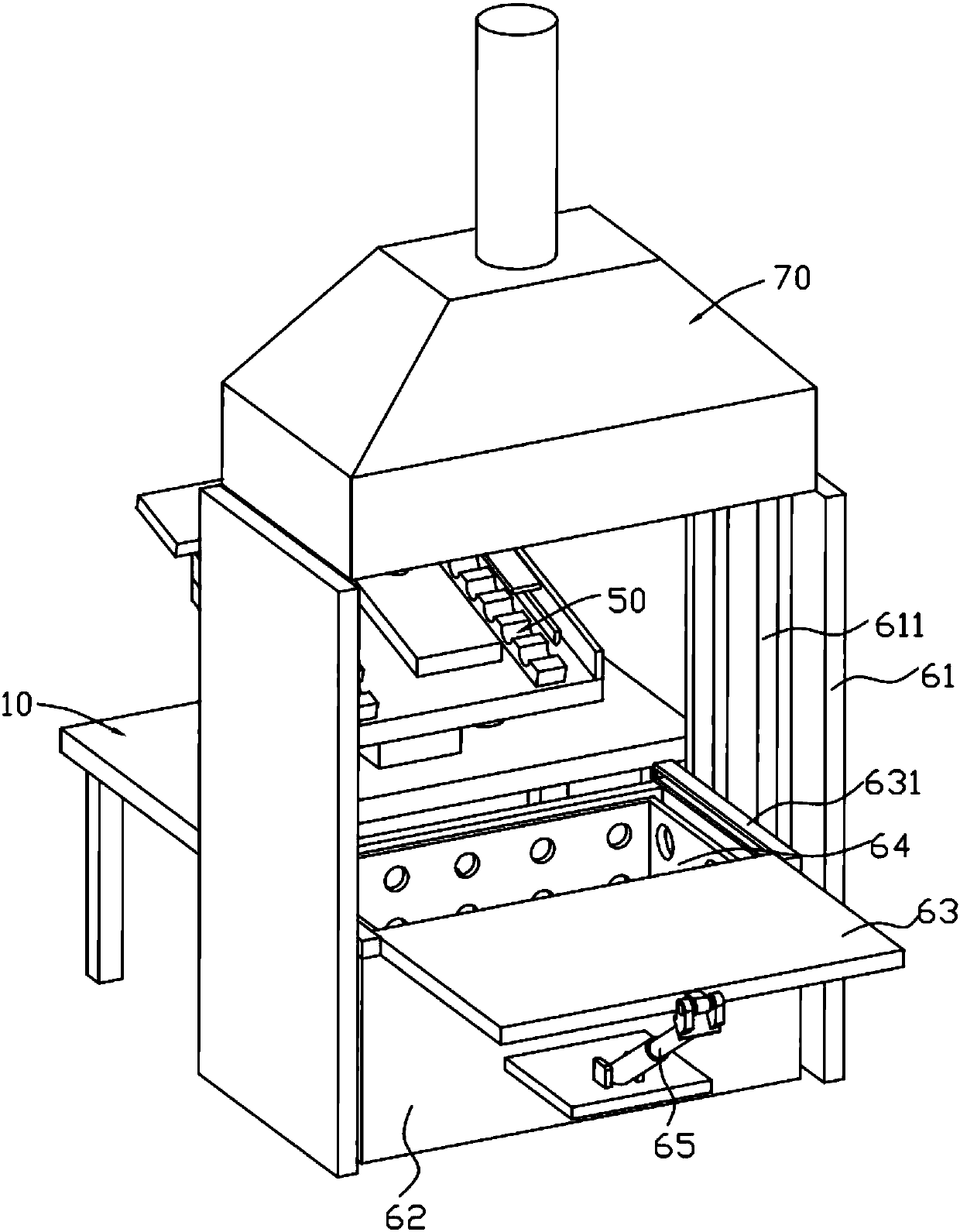

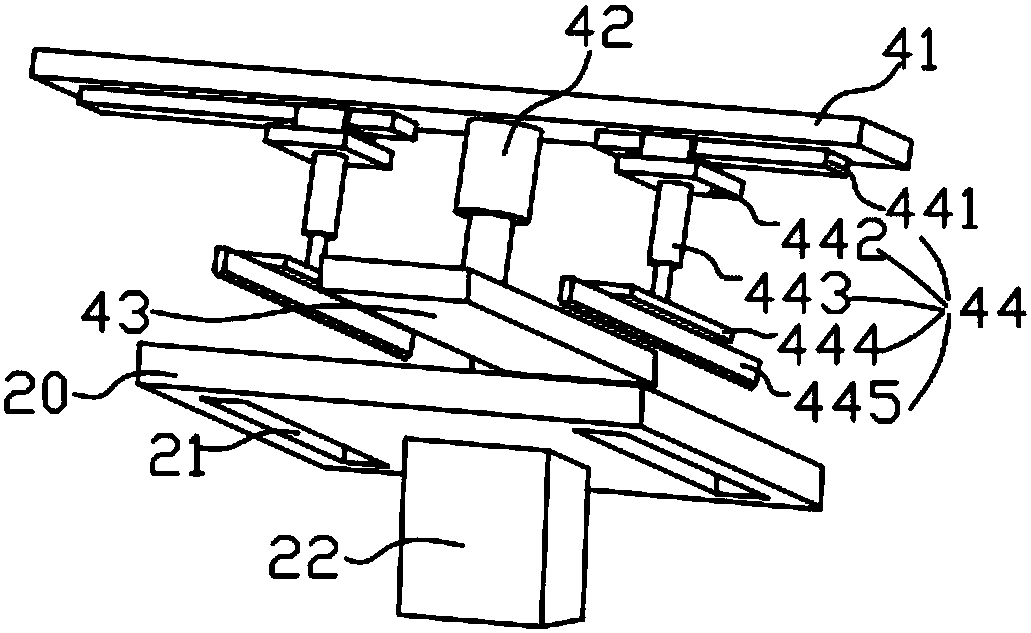

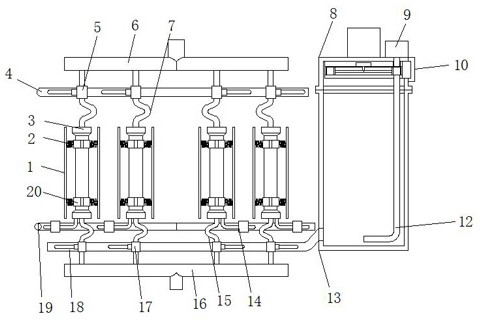

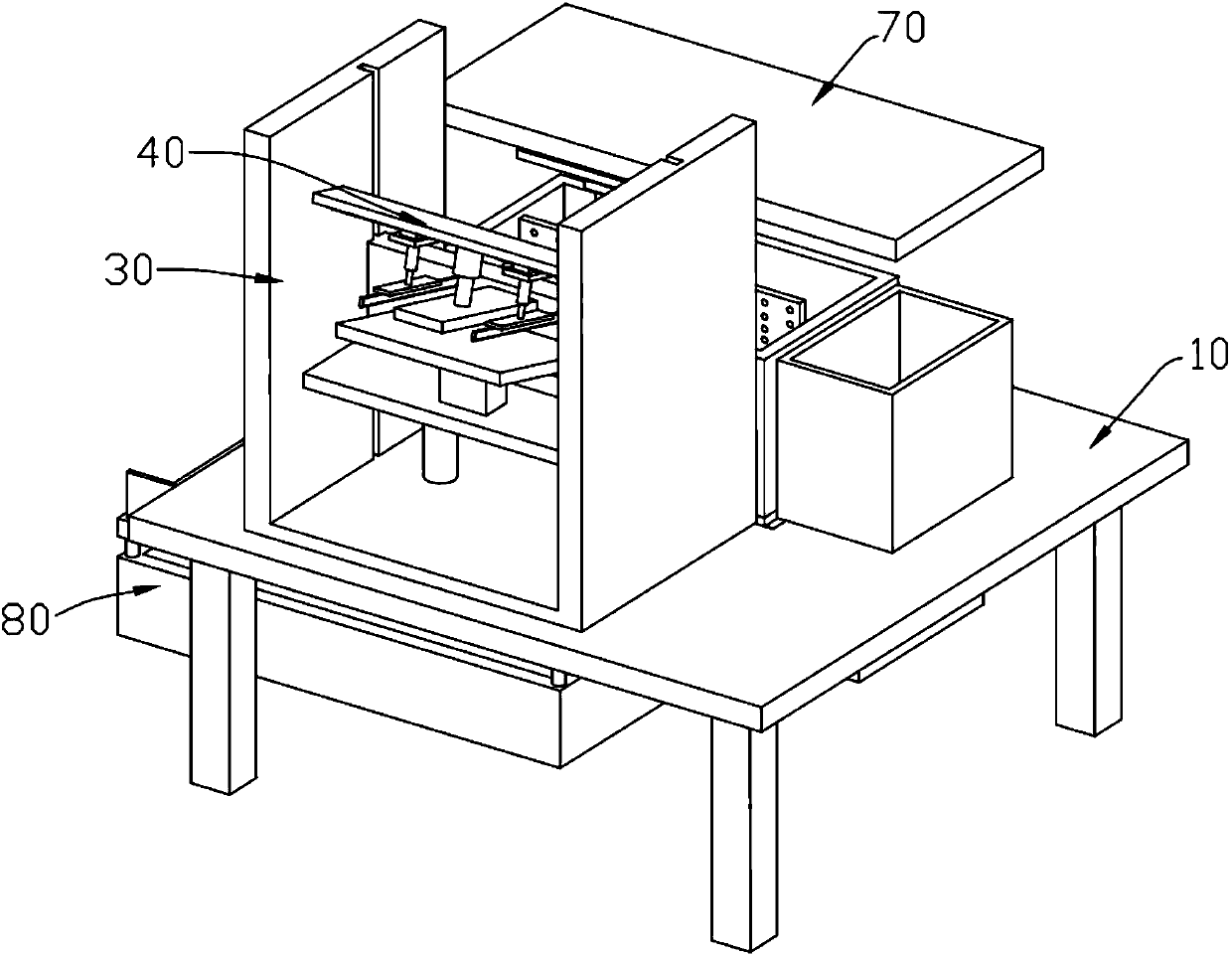

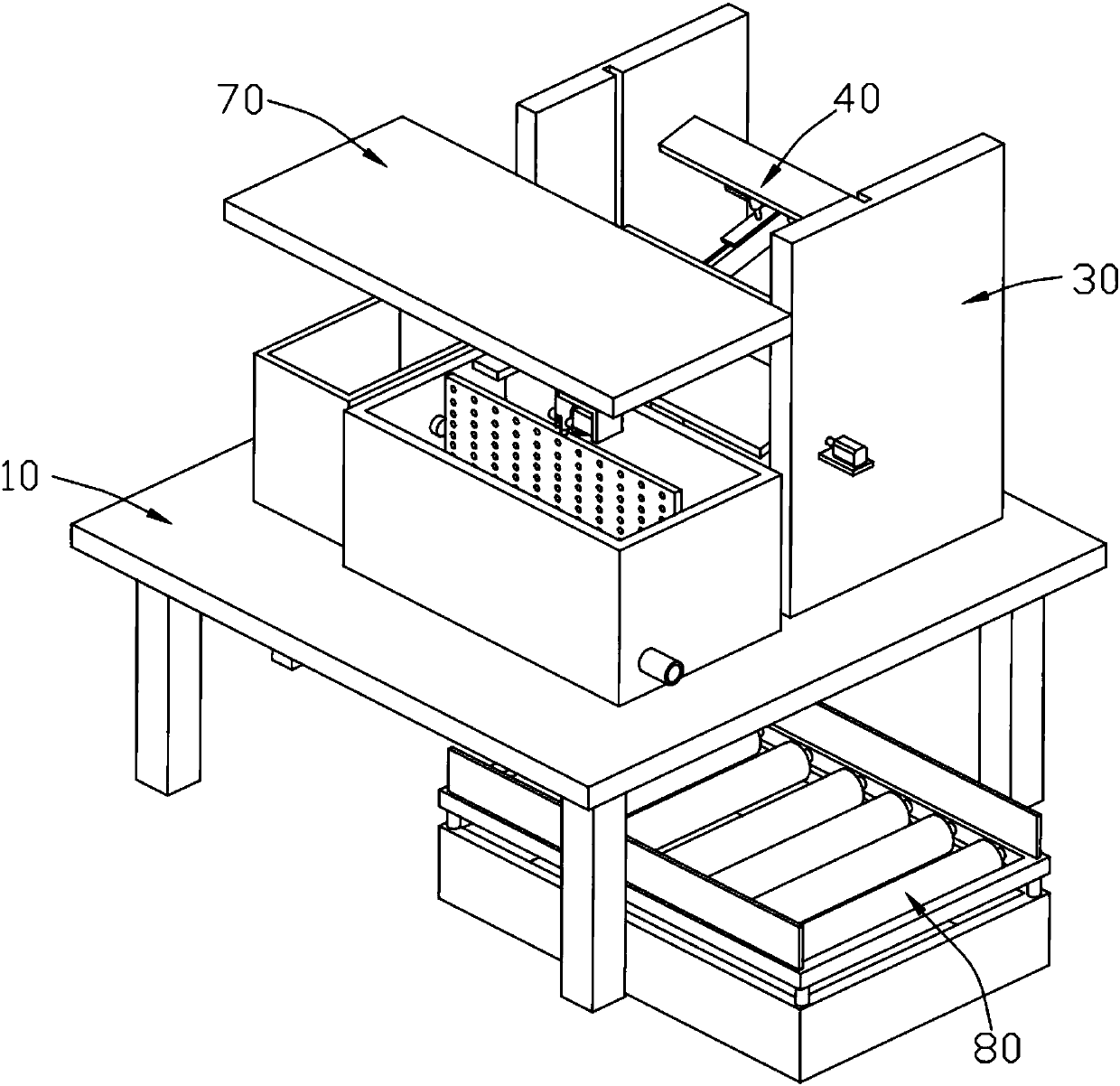

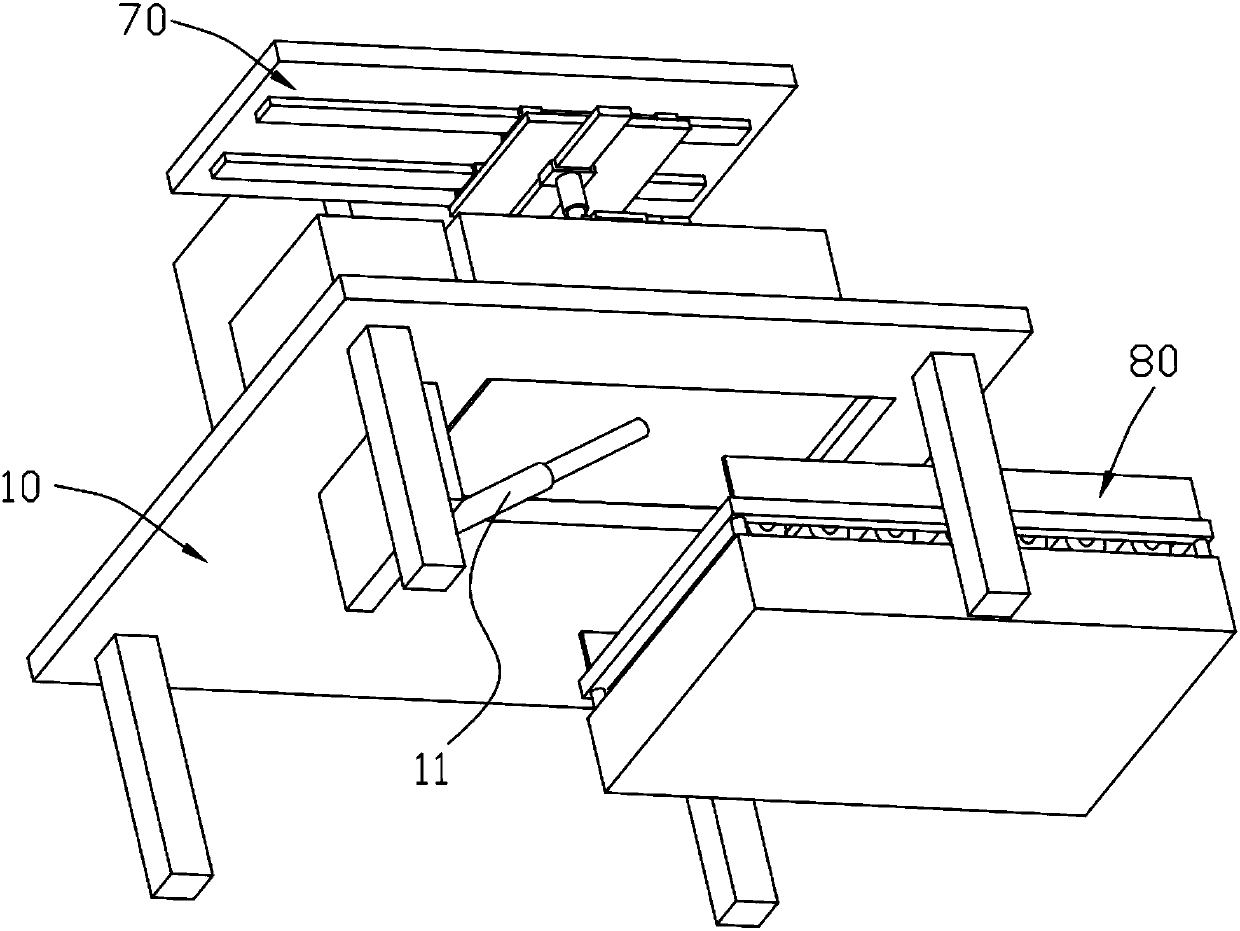

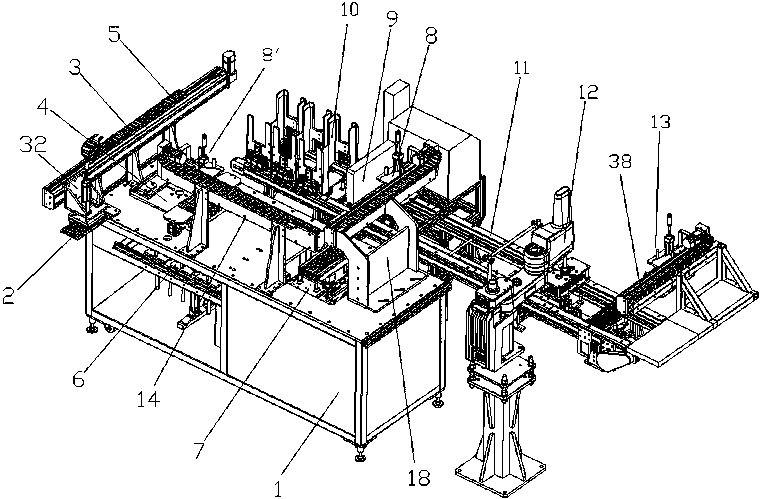

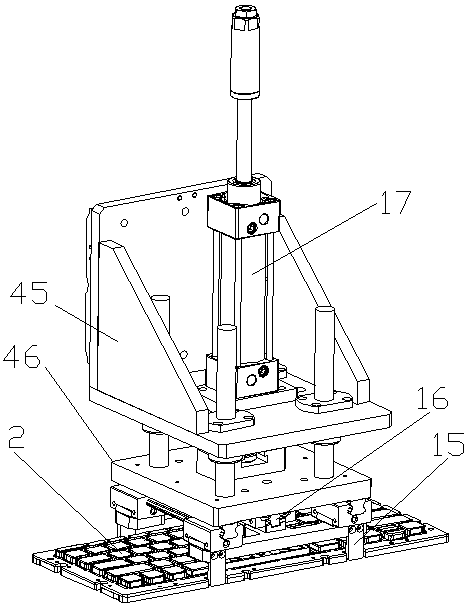

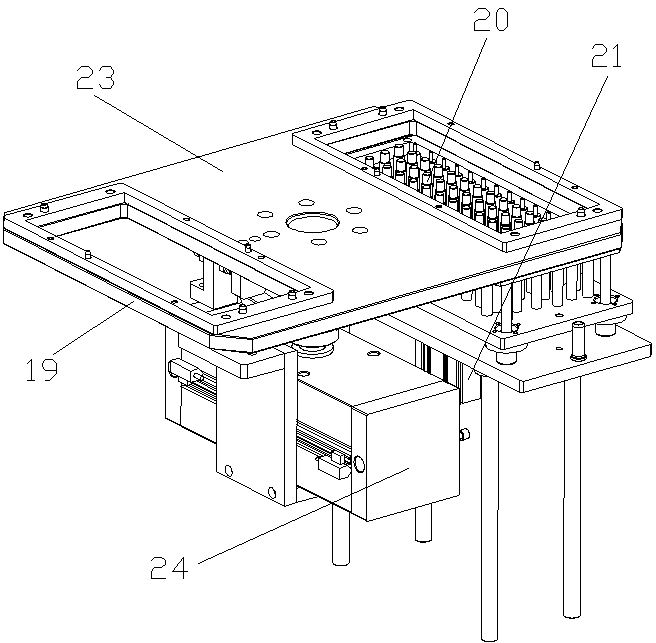

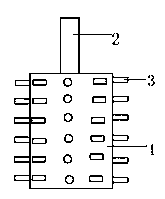

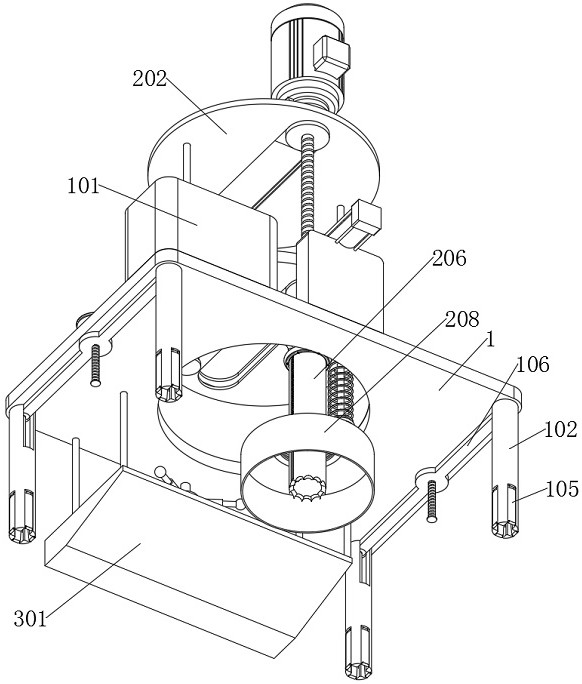

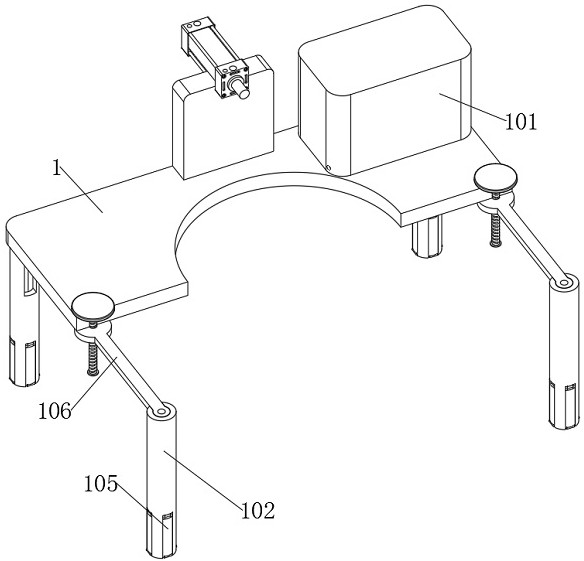

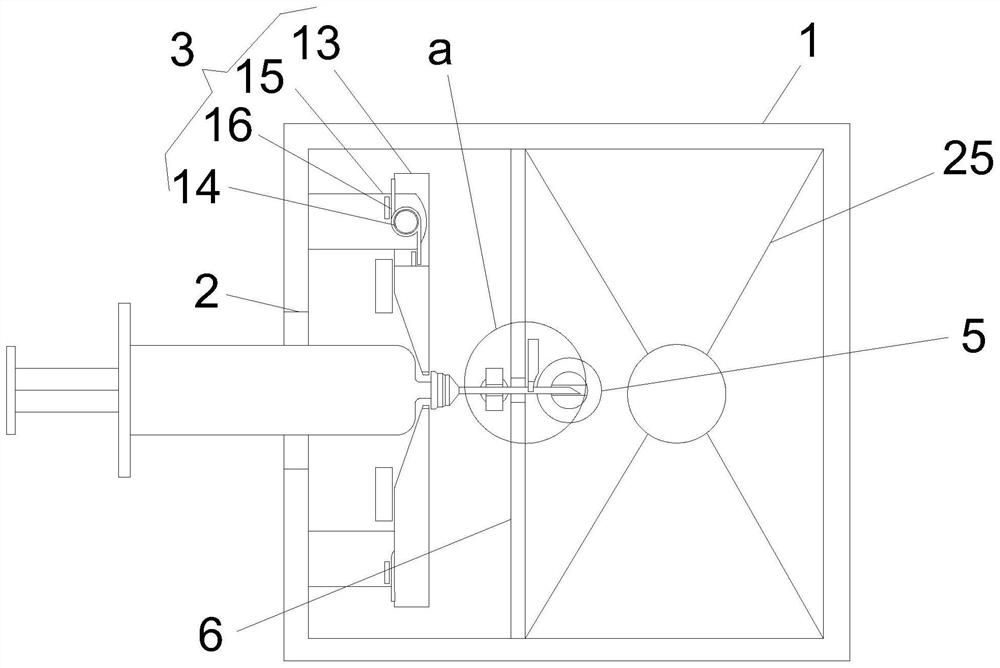

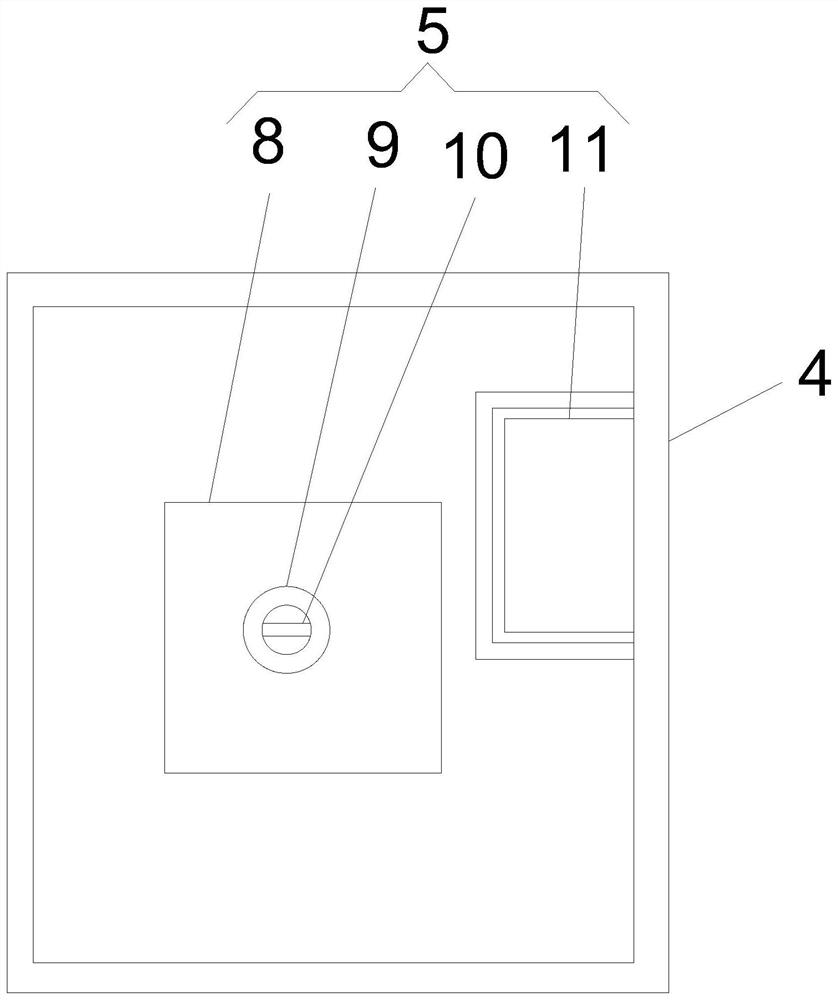

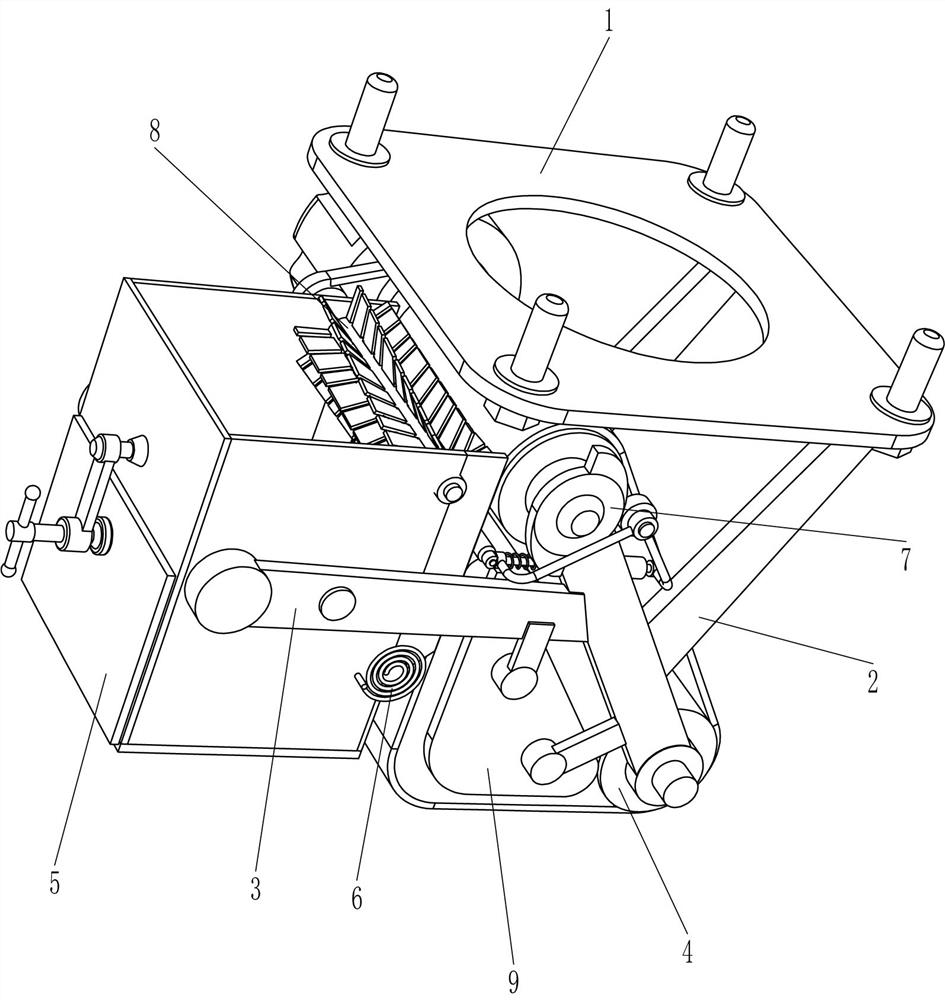

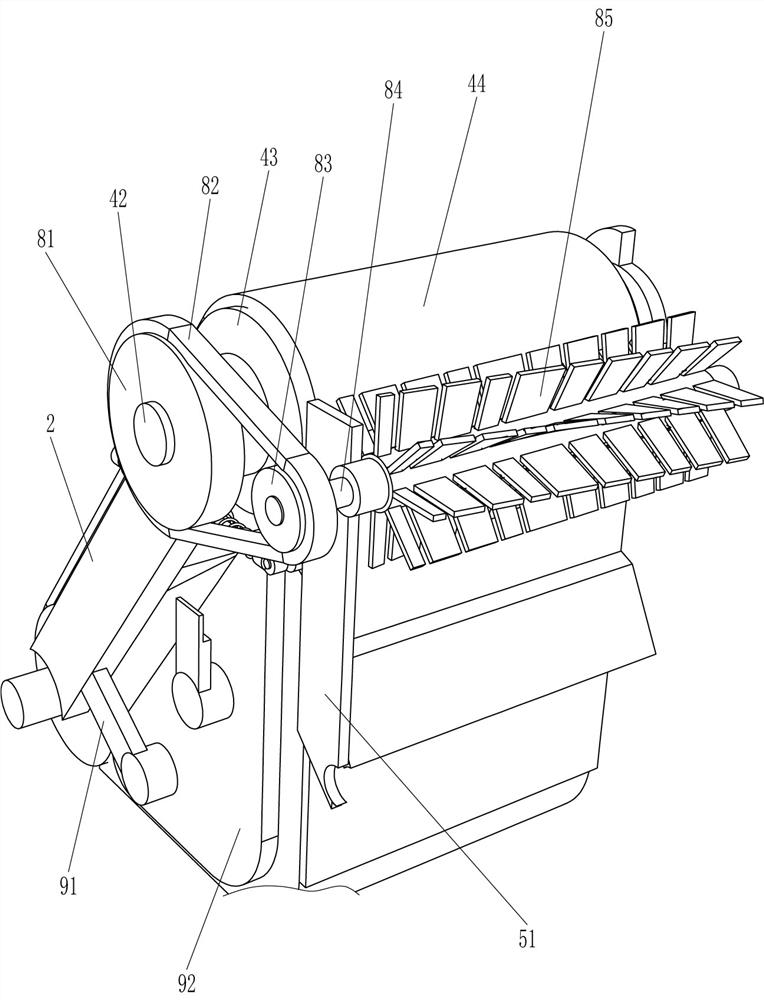

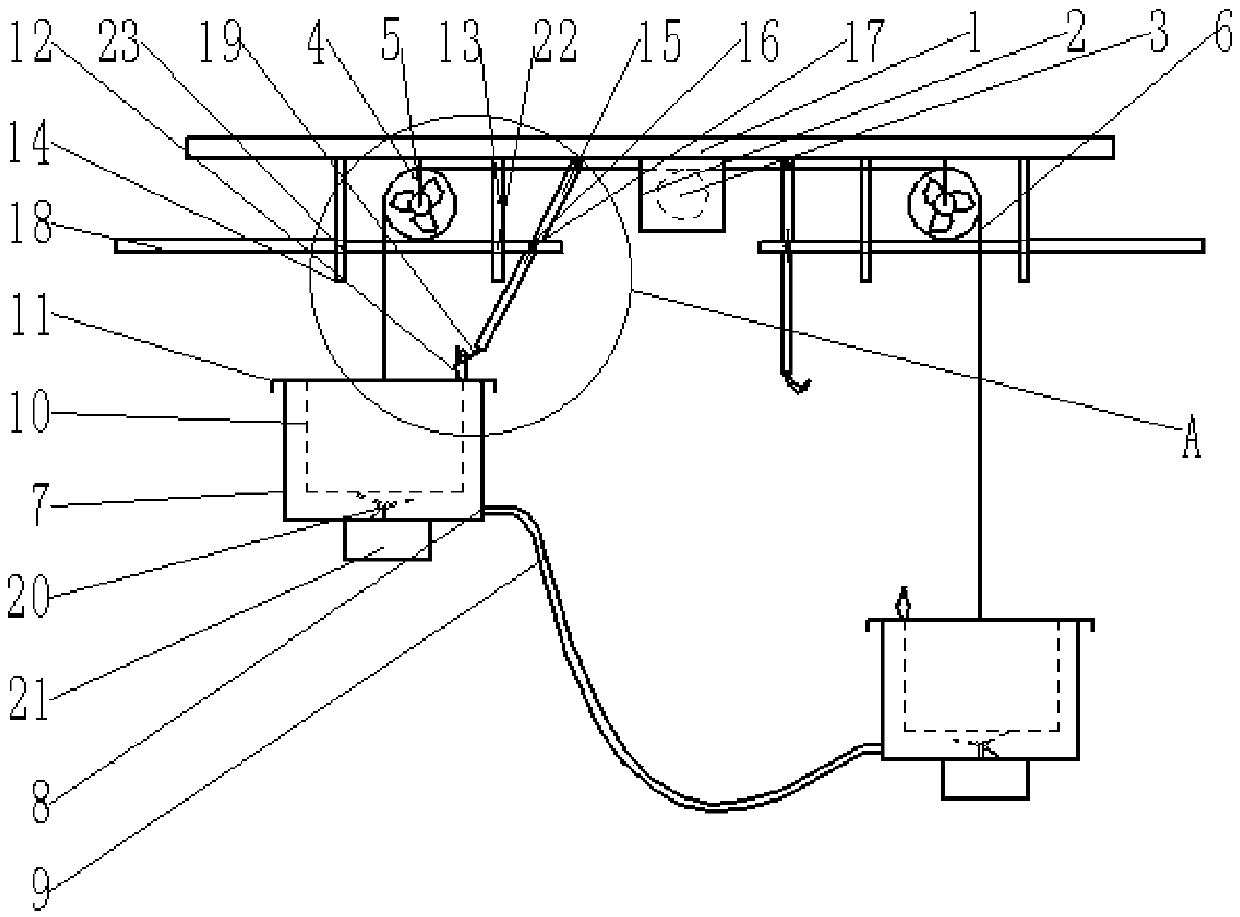

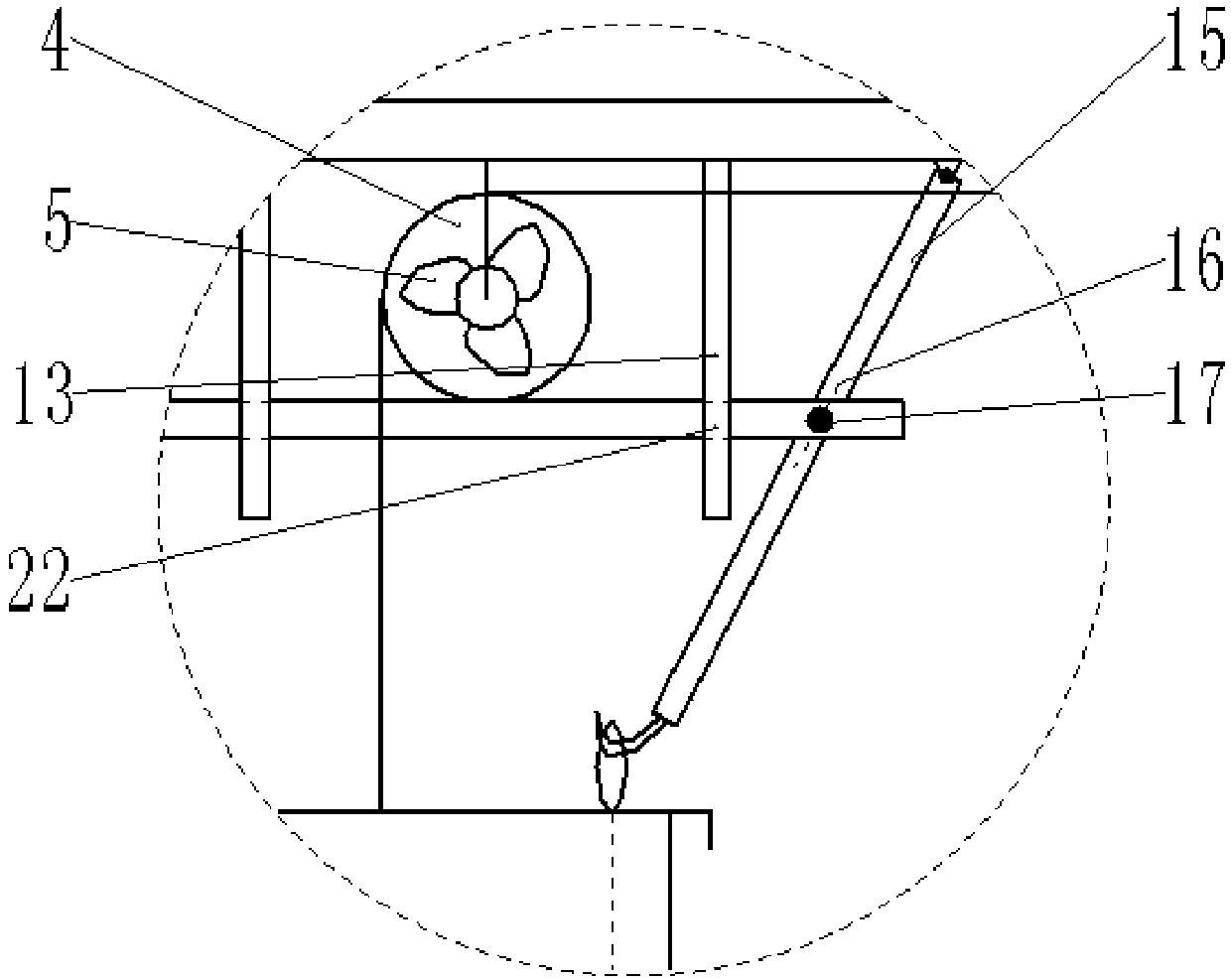

Full-automatic keyboard disassembling and cleaning machine

ActiveCN107737774ARealize fully automatic disassemblyImprove processing efficiencyCleaning using gasesSortingEngineeringManipulator

The invention discloses a full-automatic keyboard disassembling and cleaning machine. The machine comprises a control box, wherein a feeding device, a rotating disc device and a keycap detaching device and a keycap falling device are arranged on the table surface of the control box in sequence from one end to the other end; the feeding device comprises a feeding manipulator arranged on a first electric guide rail; a second electric guide rail is arranged between the keycap detaching device and the keycap falling device; a movable conveying manipulator is arranged on the second electric guide rail; an optical detector is arranged at the rear end of the control box; a third electric guide rail is arranged between the optical detector and the keycap falling device; the conveying manipulator is further arranged on the third electric guide rail; a conveyor belt is arranged below the optical detector; a stacking device is arranged at one end of the conveyor belt, and a dust collecting deviceand a discharging device are arranged at the other end; the discharging device comprises a fourth electric guide rail arranged above the conveyor belt; and a discharging manipulator is arranged on the fourth electric guide rail. The full-automatic keyboard disassembling and cleaning machine can realize full-automatic disassembling, cleaning and sorting of keyboards, thereby being high in automation degree and processing efficiency.

Owner:平邑县经发企业服务有限公司

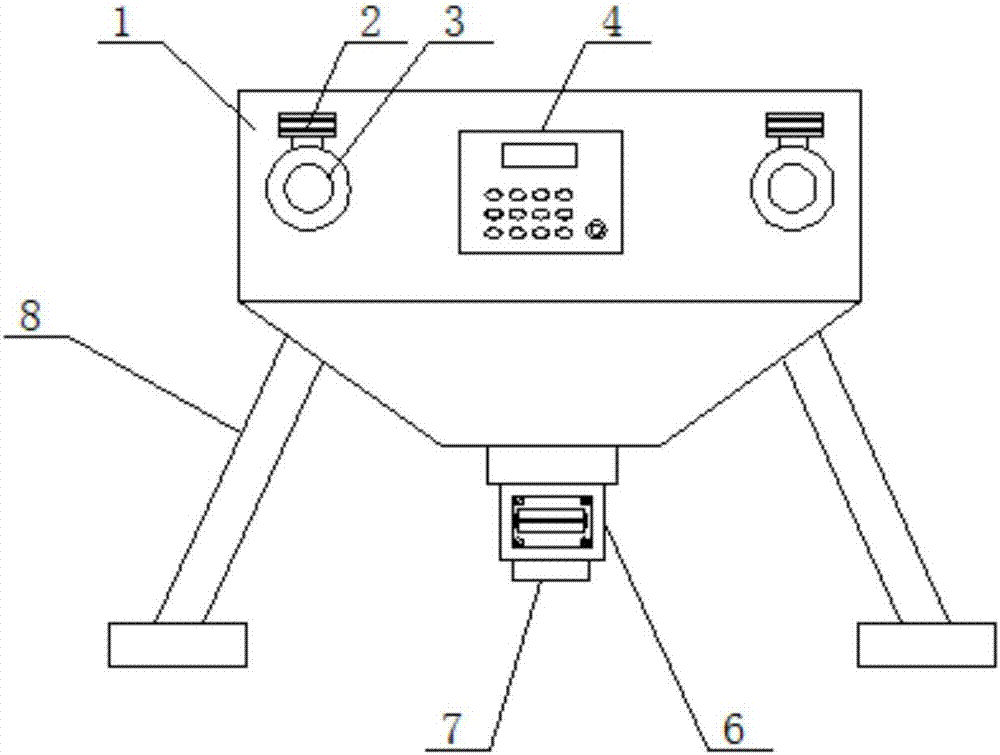

Special tool for removing labels

InactiveCN107470290AImprove removal efficiencySpeed up sheddingHollow article cleaningEngineeringBottle

The invention discloses a special tool for removing labels. The special tool for removing the labels comprises a label-removing container. A drainage pipe is arranged at the center of the bottom of the label-removing container, a second electromagnetic valve is installed on the drainage pipe, a water injection pipe is arranged on the front surface of the label-removing container, and a first electromagnetic valve is installed on the water injection pipe; and a controller is arranged on the position, on one side of the water injection pipe, of the front surface of the label-removing container, and container placing troughs are formed in the label-removing container. According to the special tool for removing the labels, the multiple container placing troughs are formed, the container is placed in the container placing troughs, tilting or flat lying of a bottle body caused by water impact force cannot occur in the water injecting process, therefore broken label paper cannot pollute a bottle opening in the immersing process, a special clamp is not needed to conduct clamping and fixing, a glass material of a heat transfer plate can rapidly transmit heat energy of a heating core rod into water, falling off of the labels is accelerated, and further the efficiency of removing the labels is improved.

Owner:LIUZHOU YIJIAN TECH

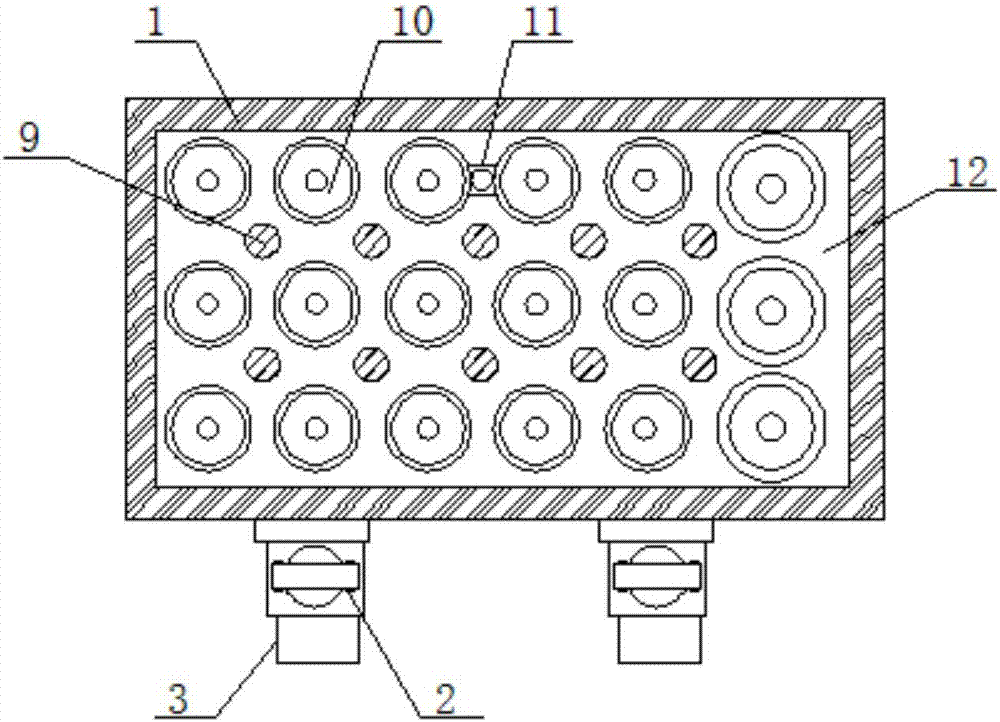

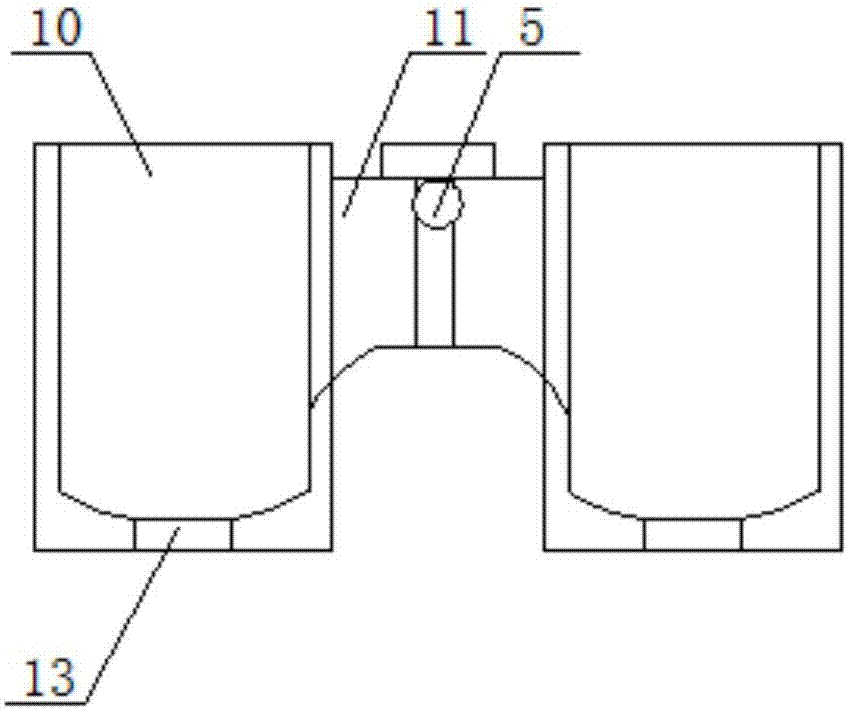

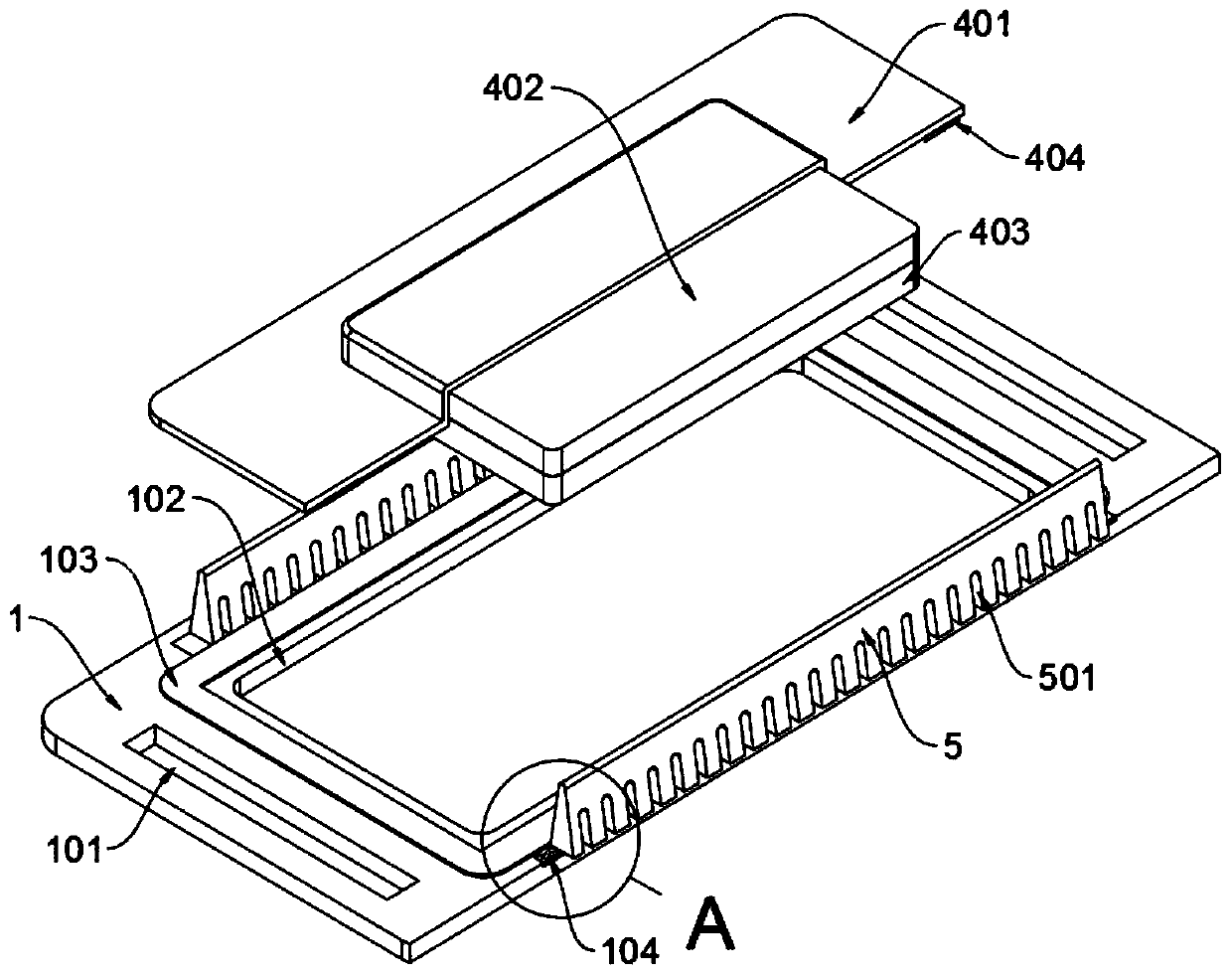

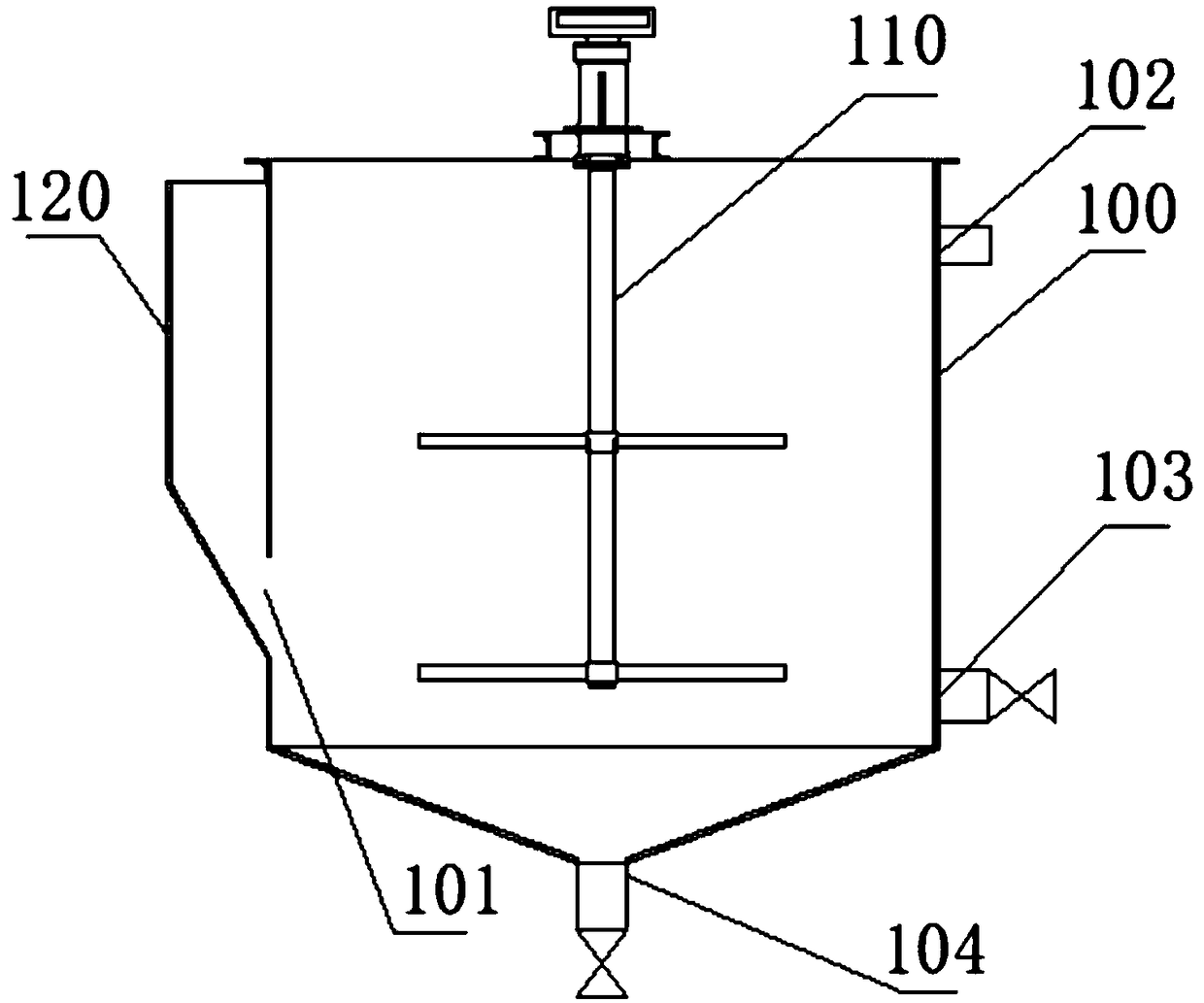

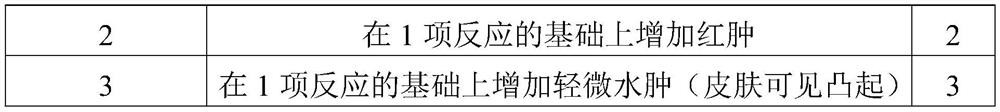

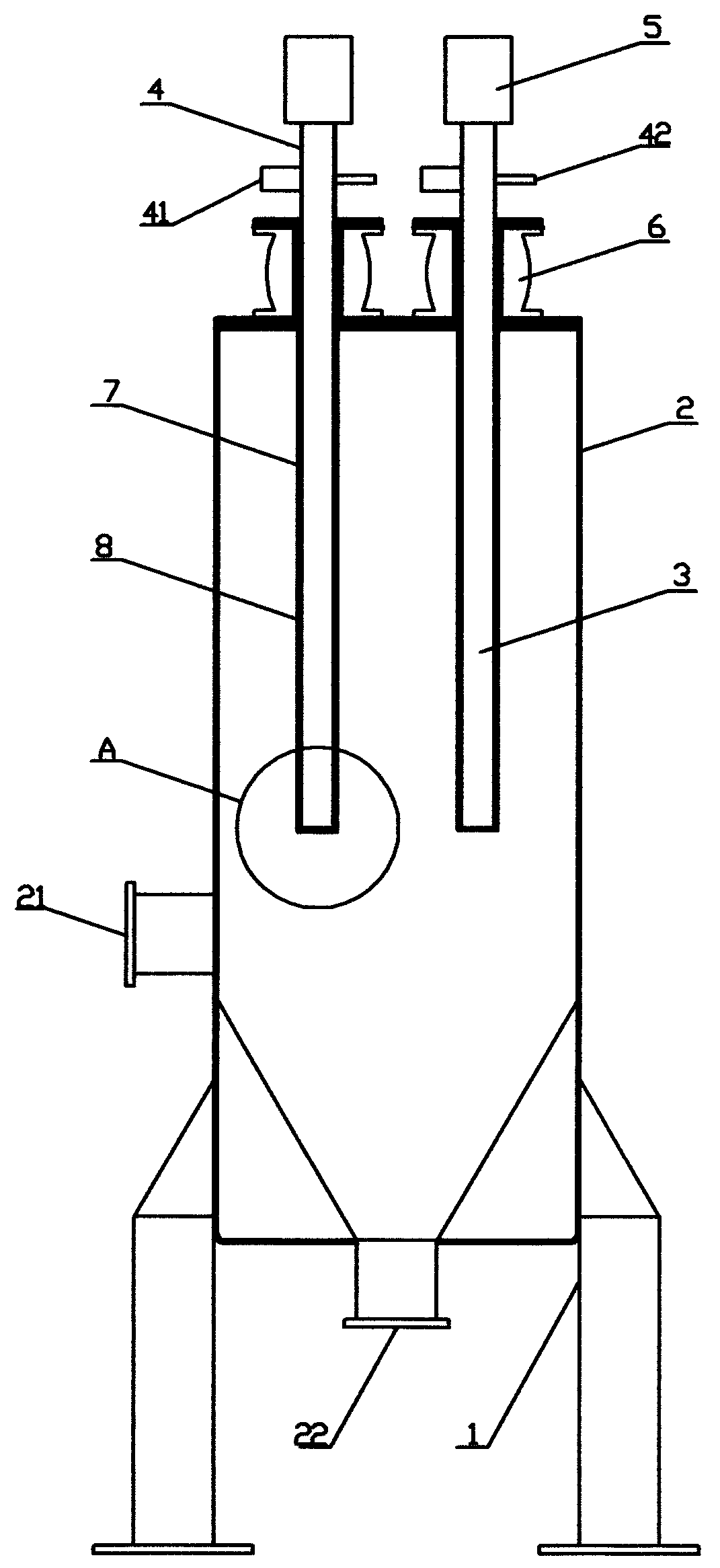

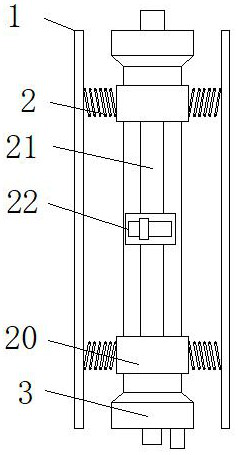

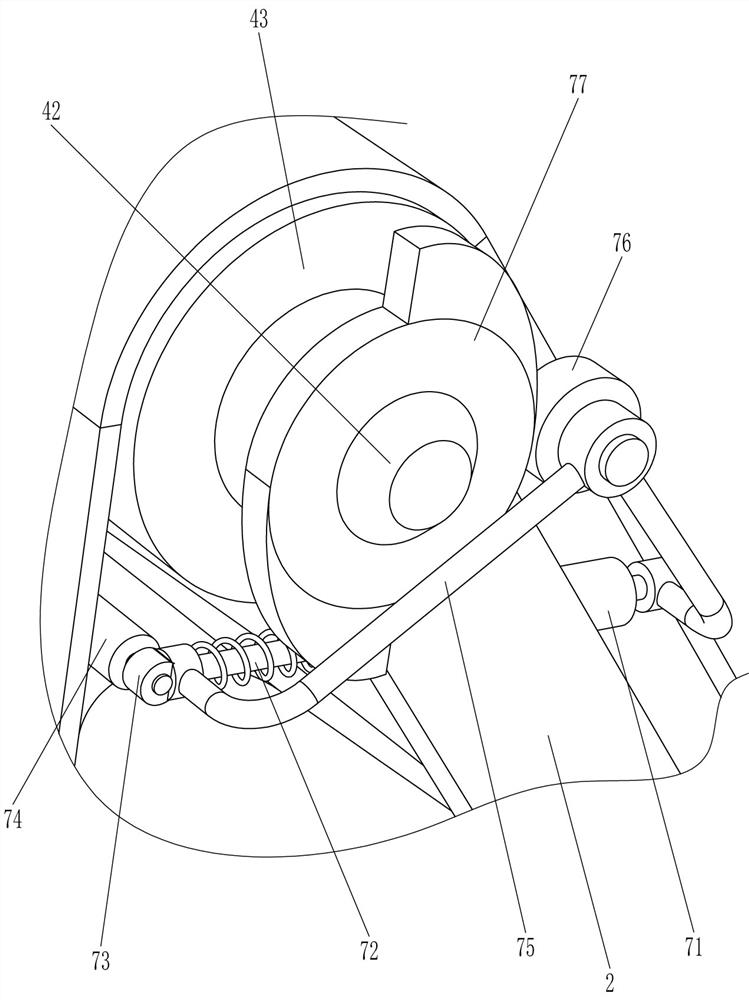

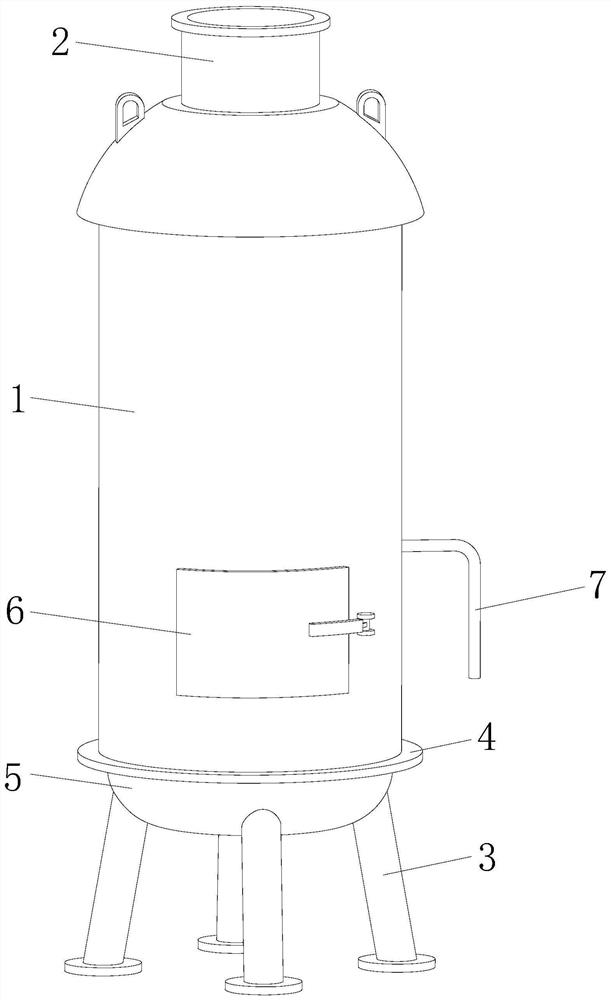

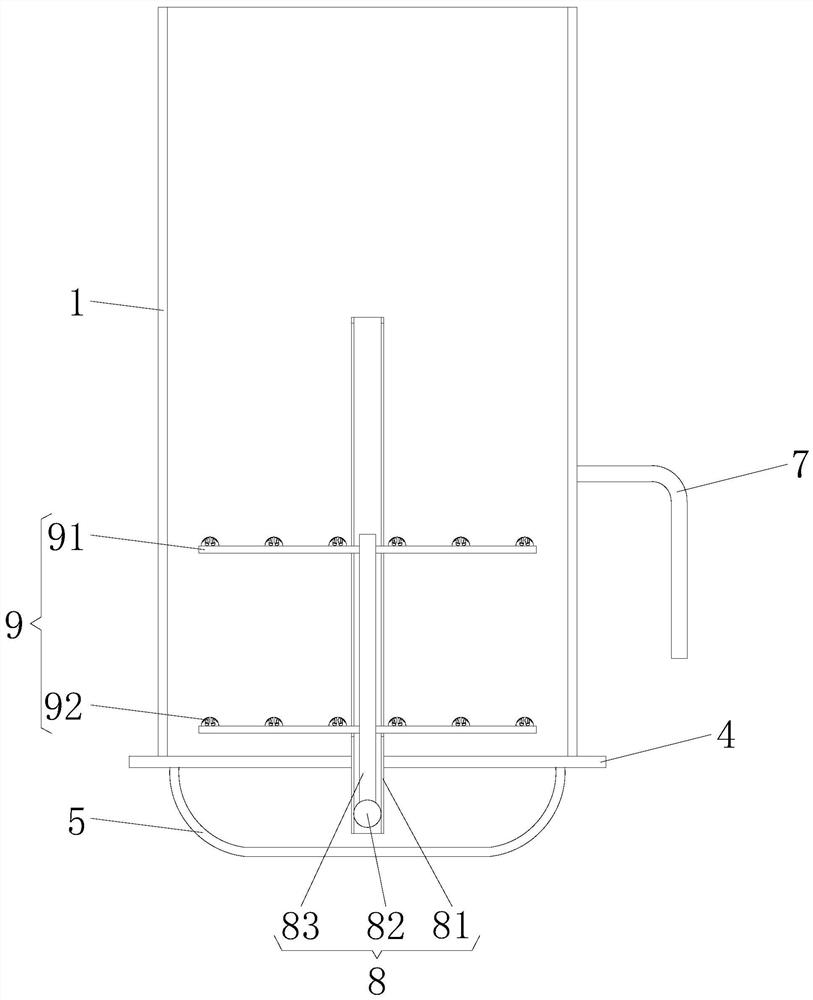

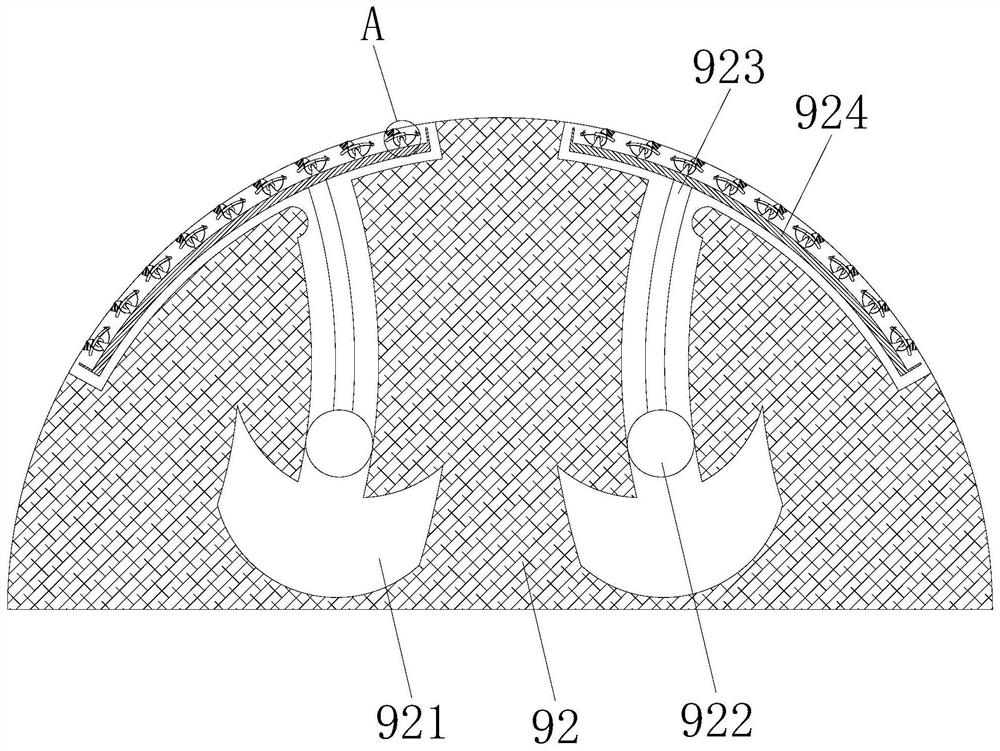

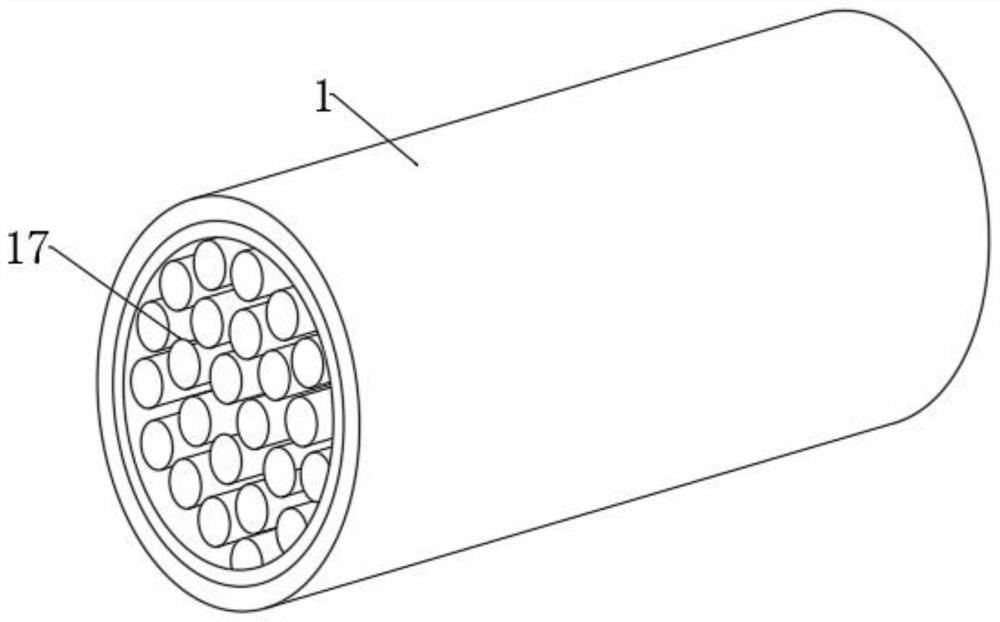

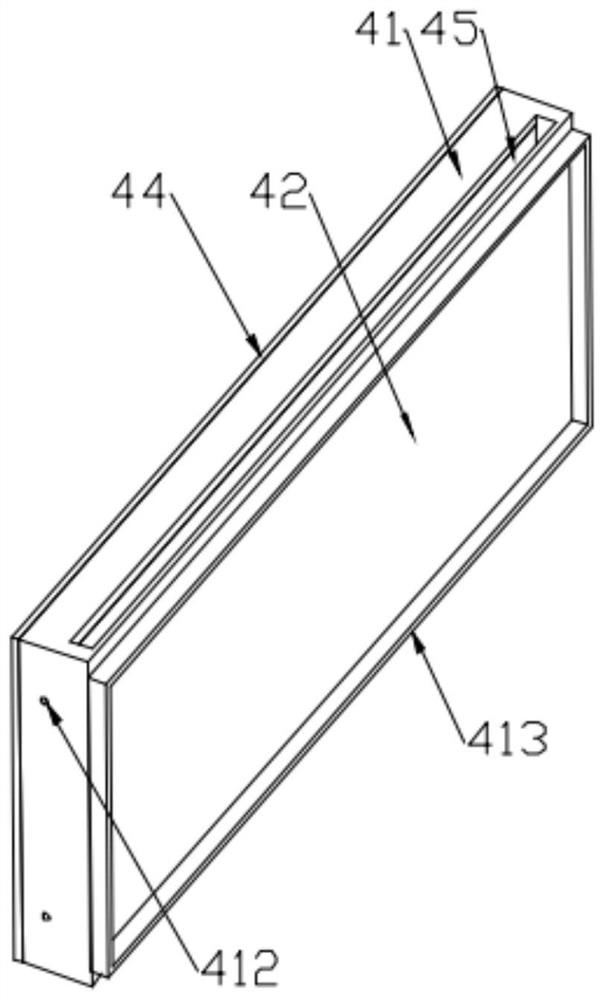

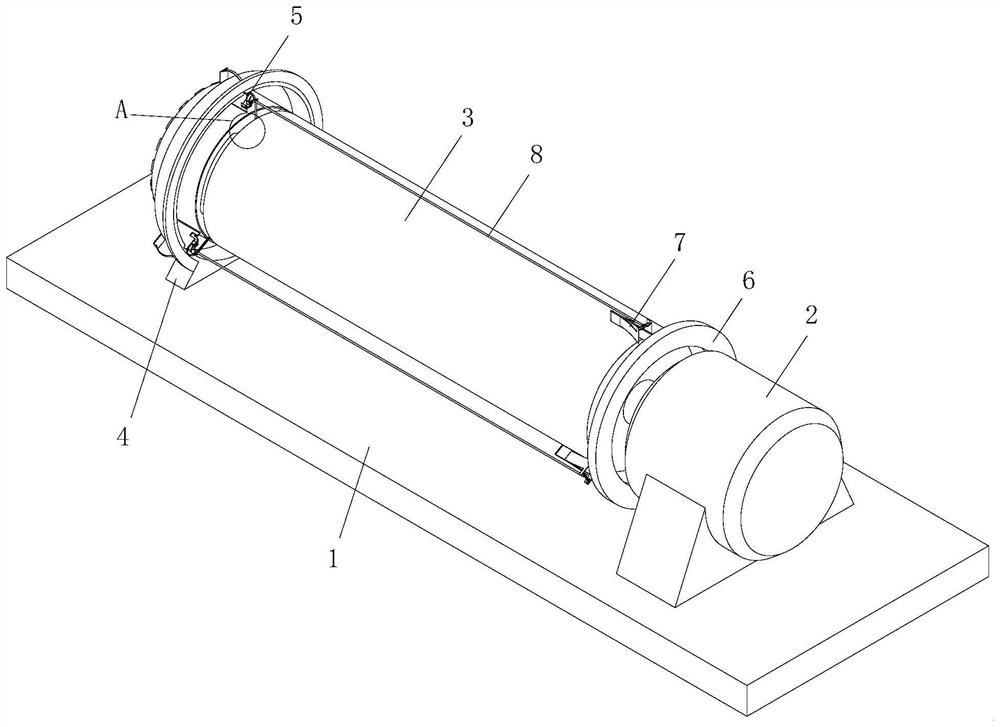

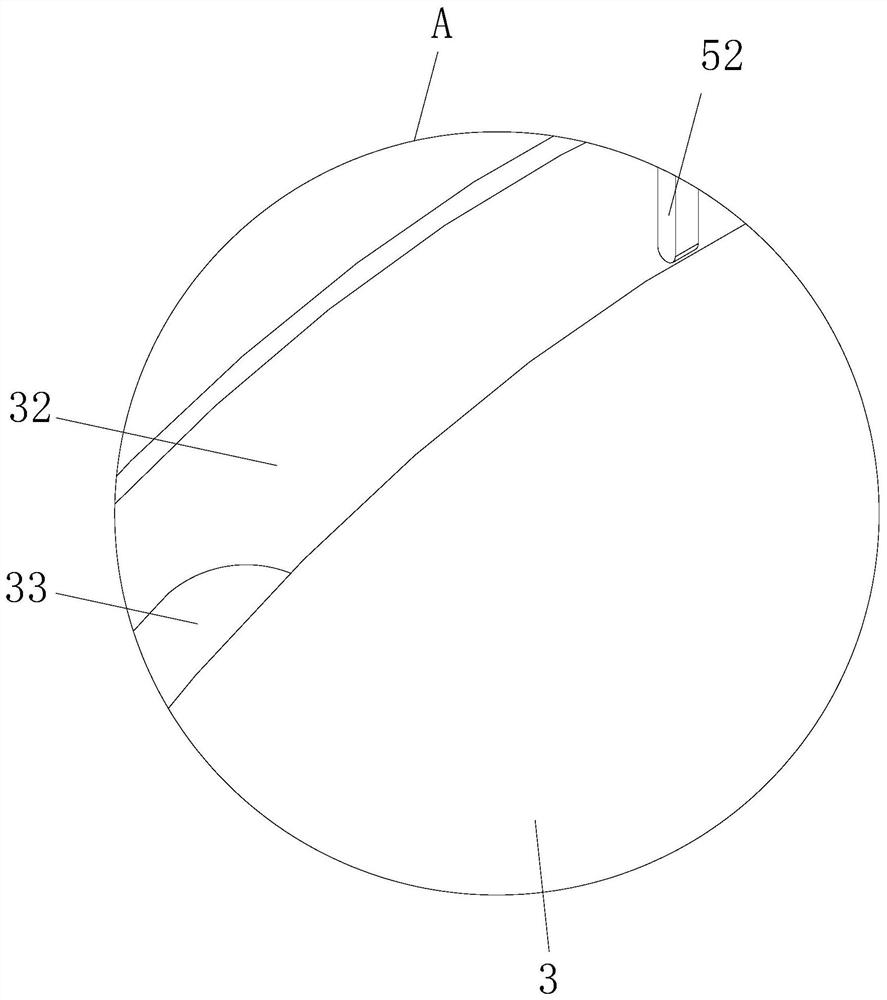

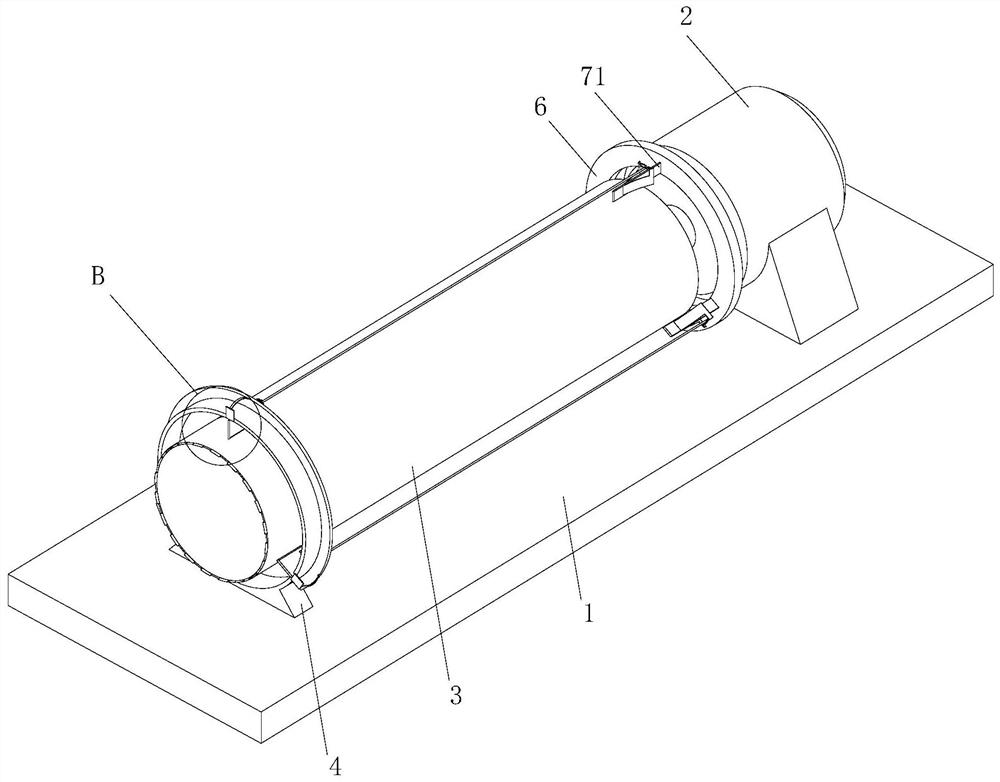

A tubular concentration device

ActiveCN104056479BSpeed up sheddingQuick and complete sheddingStationary filtering element filtersSludgePapermaking

Owner:杭州安永环保科技有限公司

Multifunctional post-PCI operative limb blood vessel protection safety belt

PendingCN111297433AReduce elastic stretchAvoid squeezingPlastersAdhesive dressingsPhysical medicine and rehabilitationWound site

The invention provides a multifunctional post-PCI operative limb blood vessel protection safety belt, relates to the field of medical instruments and solves the problems that the wound part cannot besupported and protected by structural improvement, and the anti-bacterial capacity is reduced because the support and protection structure is subjected to edge warping after being placed; the use costcannot be reduced by replacing the disinfection part alone in dressing; and binding fixation is difficult to achieve due to reduction of adhesion of velcro, which is easily caused by repeated disassembly. The multifunctional post-PCI operative limb blood vessel protection safety belt comprises a main body seat; and a first strap and a second strap are bound on the main body seat. Because a plurality of rectangular grooves are formed in the bottom end face of the protection structure, and are in a compressed state after being bound and fixed, elastic stretch force of the protection structure can be reduced, and further, reduction of the anti-bacterial capacity due to edge warping of the main body seat, which is caused by elastic stretch force of the protection structure, can be prevented.

Owner:郑璐

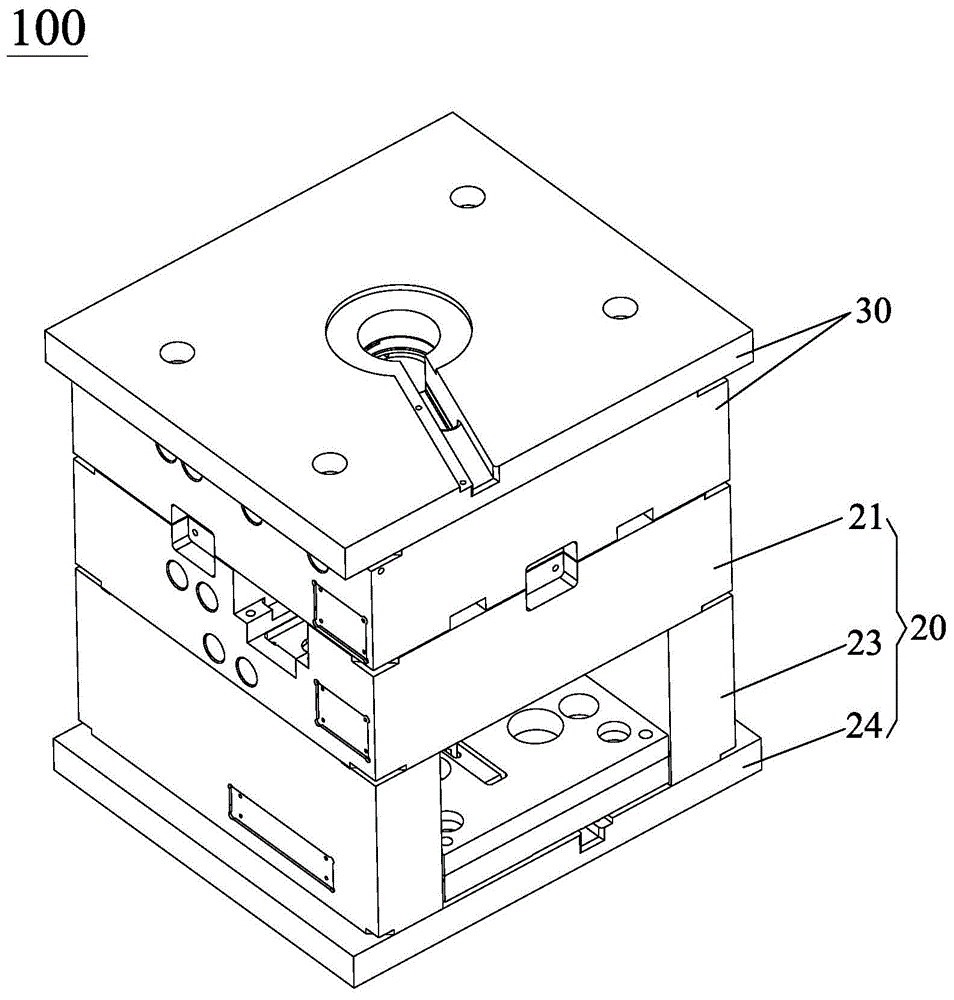

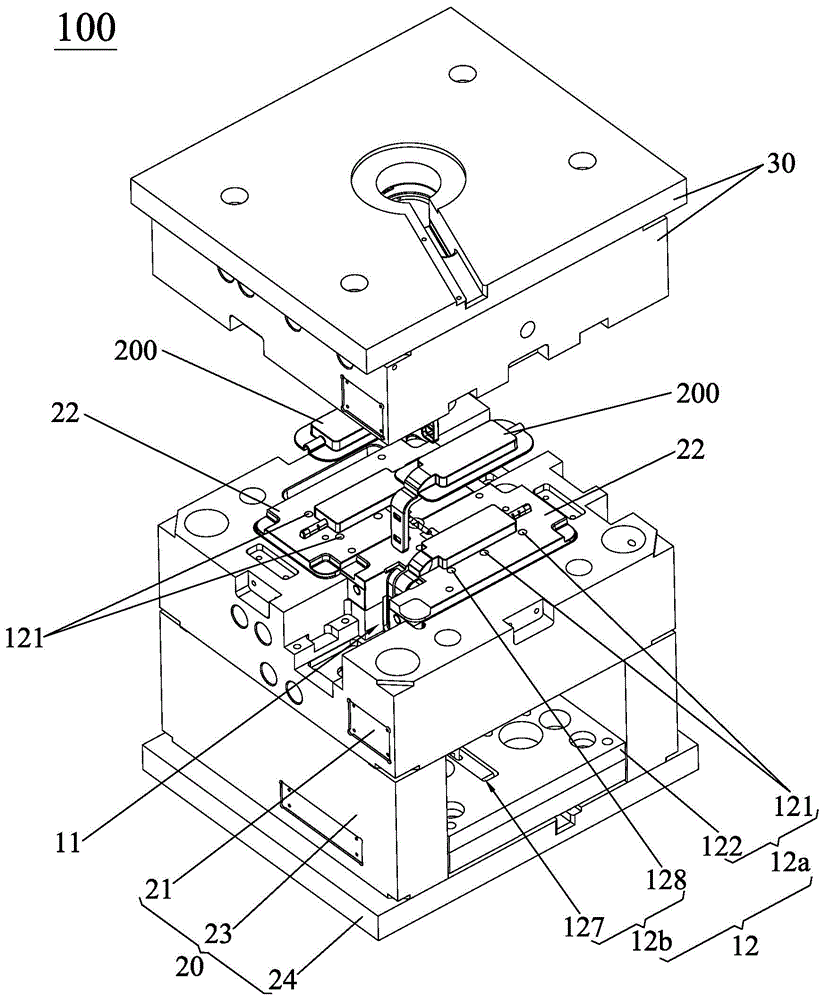

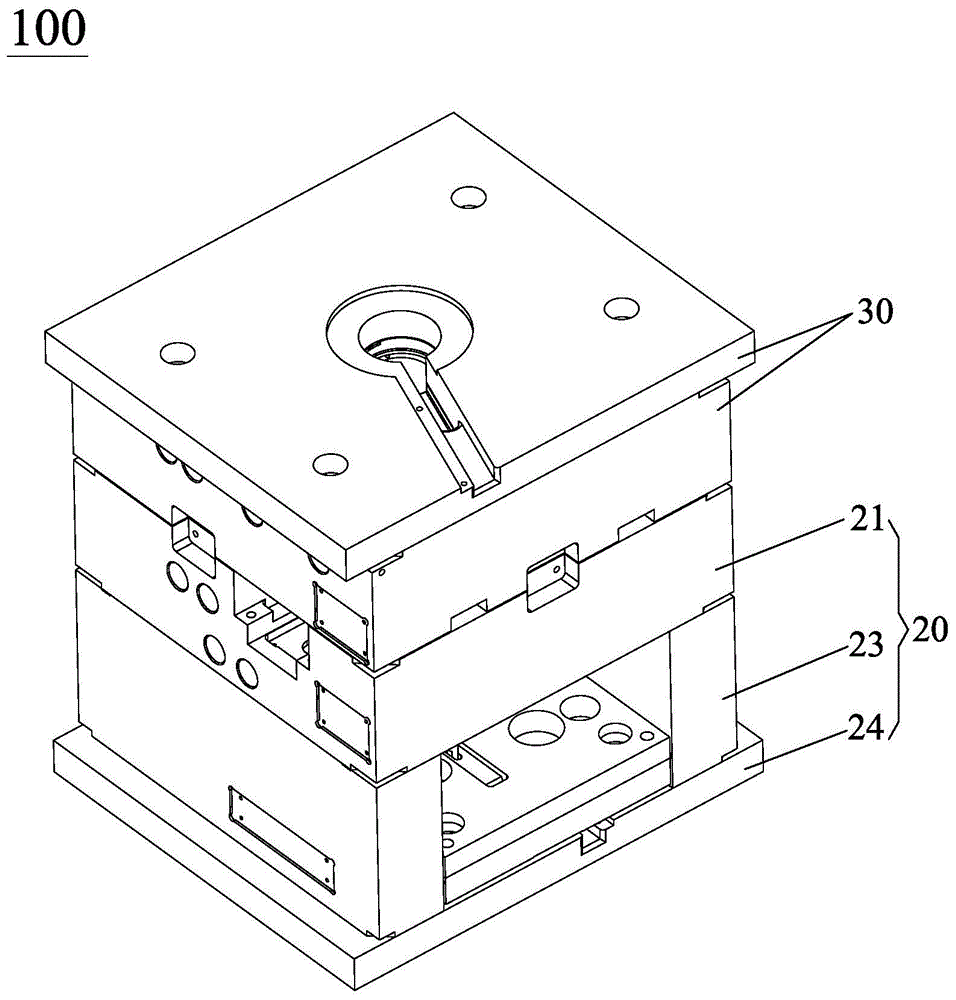

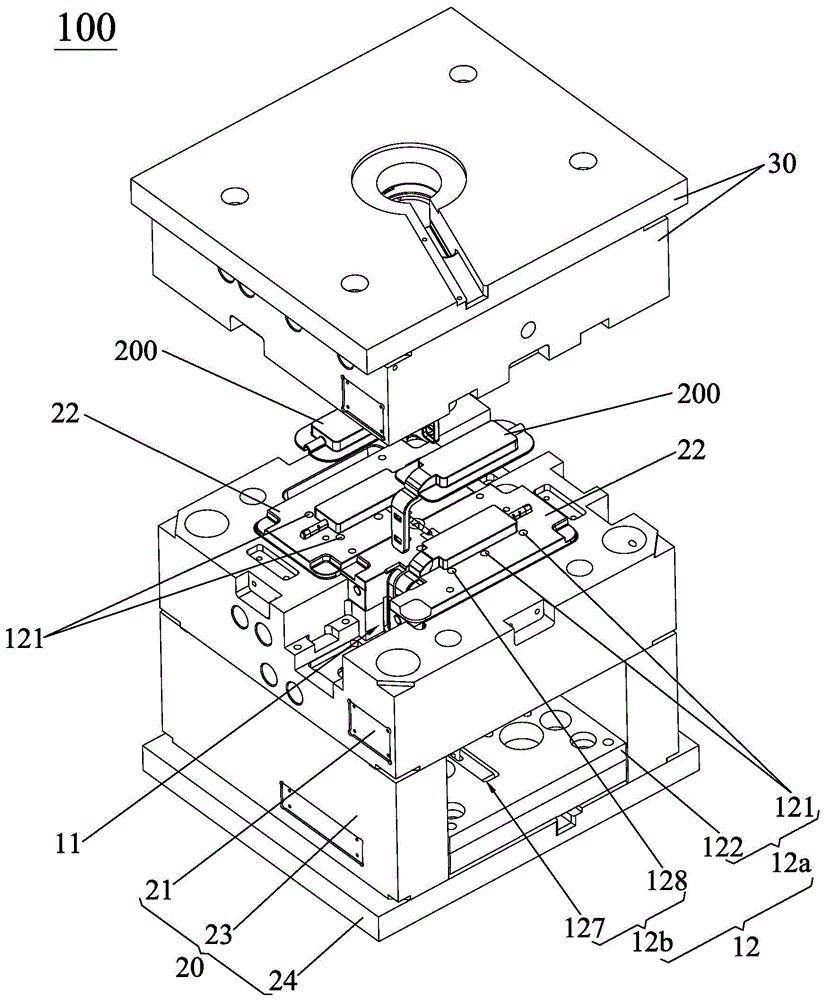

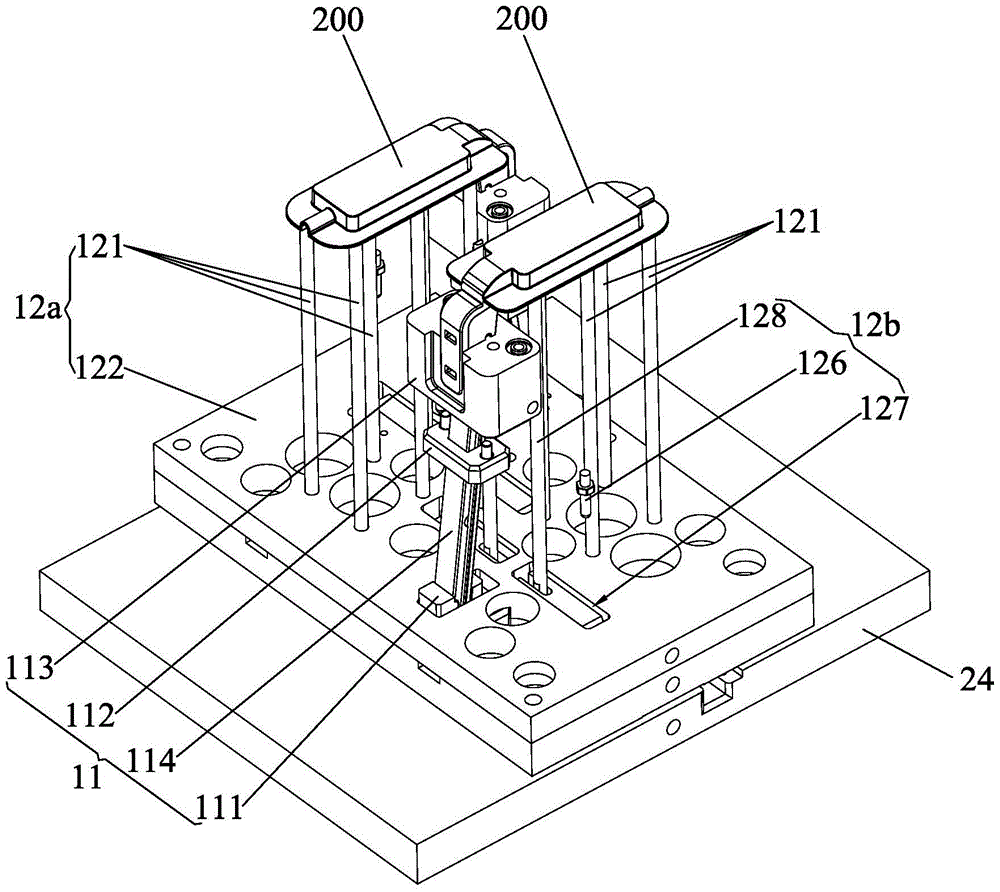

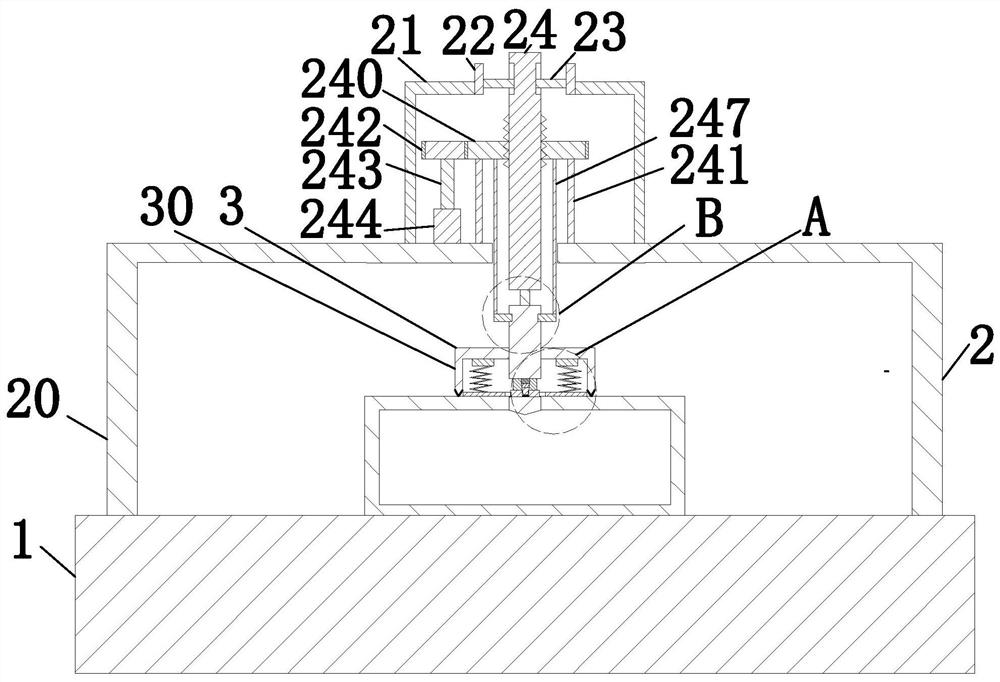

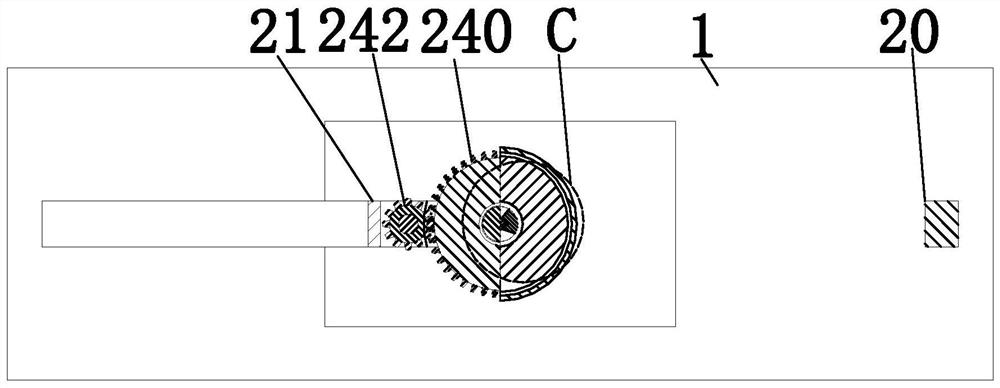

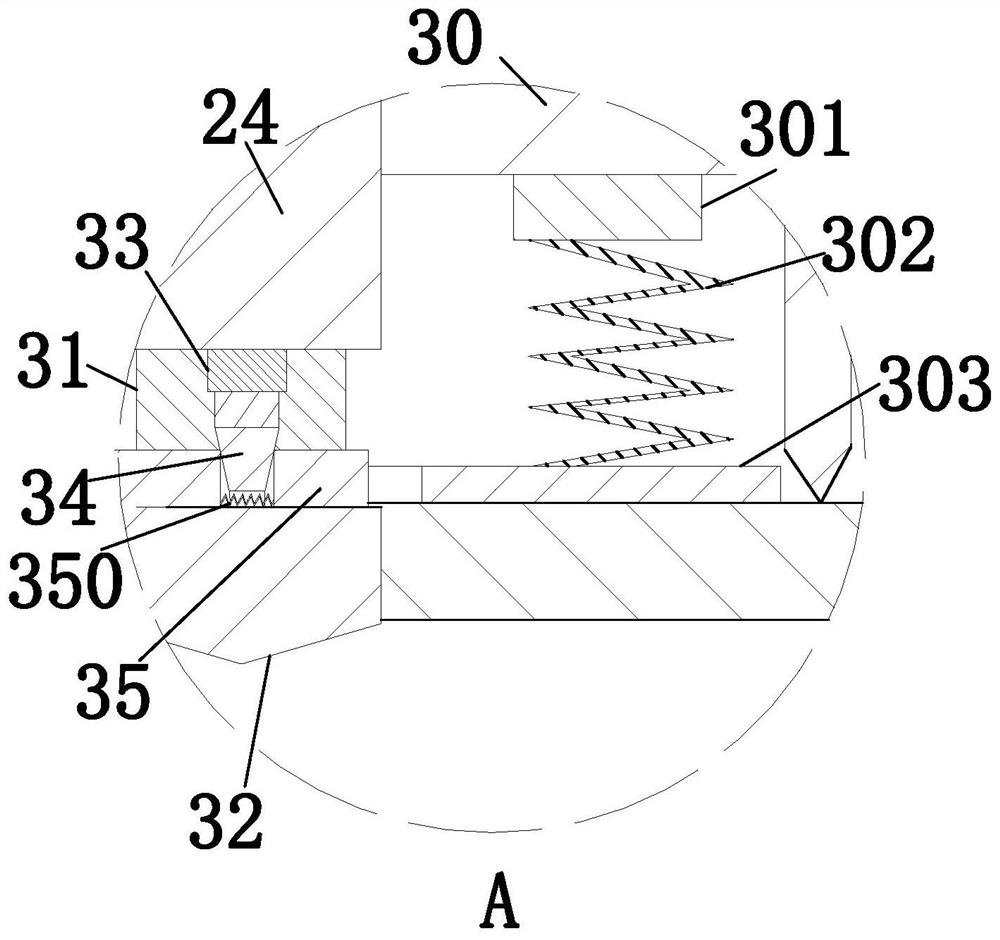

Side pulling and ejection device and injection mold

InactiveCN104149294ASpeed up sheddingAchieve the purpose of free fallEngineeringMechanical engineering

Owner:DONGGUAN WELLMEI MOLD MFG CO LTD

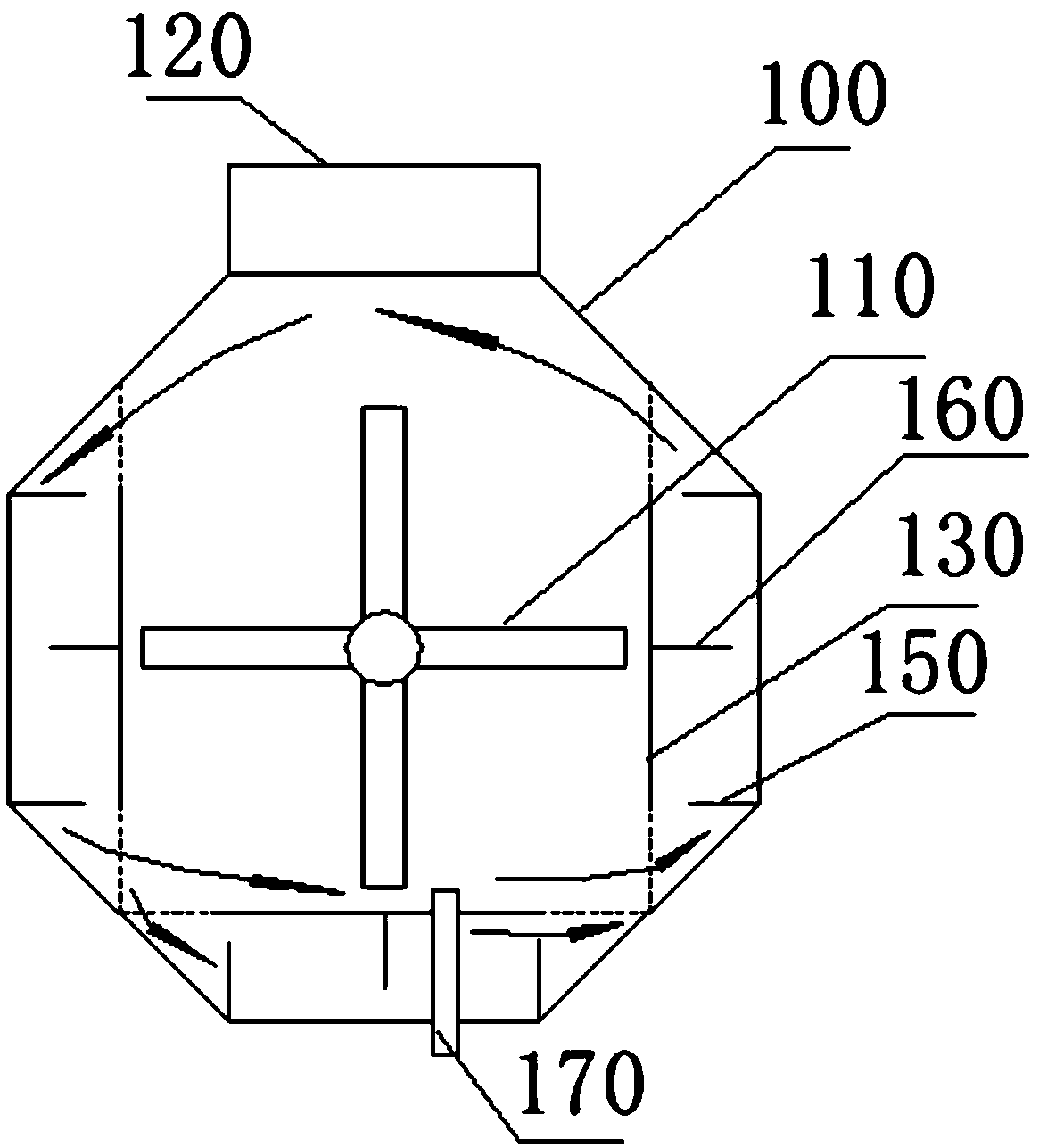

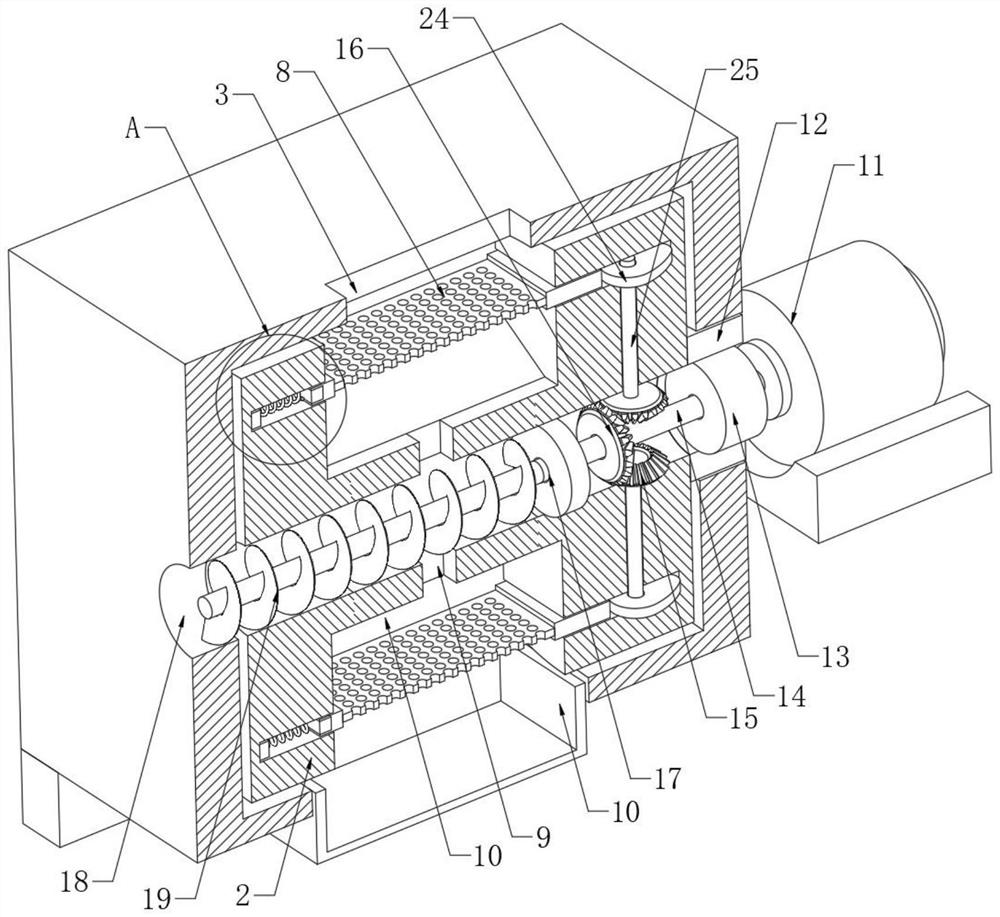

Carbon washing groove and production method of low-ash-content water purification activated carbon

ActiveCN108940201ASpeed up sheddingIncrease separation speedOther chemical processesCombustible gas purificationActive carbonMaterials science

The invention discloses a carbon washing groove and a production method of low-ash-content water purification activated carbon. The carbon washing groove comprises a groove body and a stirring device,wherein the groove body is provided with a feeding opening, a water inlet, a slurry outlet and a sand grain outlet; the sand grain outlet is located below the slurry outlet; and the stirring device is arranged in the groove body. The production method of the low-ash-content water purification activated carbon comprises the following steps: pre-heating a crushed carbonized material, carrying out water steam activation and cooling; then crushing; washing through the carbon washing groove; after carrying out sand removal and mud removal on a washed material, adding the material into a modification container; then adding water to immerse the material; then adding an acidic or alkaline modifying agent and stirring to enable the pH (Potential of Hydrogen) value of the water to be 6.5 to 7.5; and rinsing, dehydrating and drying the modified material in sequence. The carbon washing groove provided by the invention can be used for rapidly washing the activated carbon to reduce the impurity andash content of the activated carbon. The activated carbon produced by the method disclosed by the invention has low ash content, developed micro-pores and high iodine absorption value and the adsorption capability of the activated carbon is improved.

Owner:BEIHAI HERONG ACTIVE CARBON TECH +1

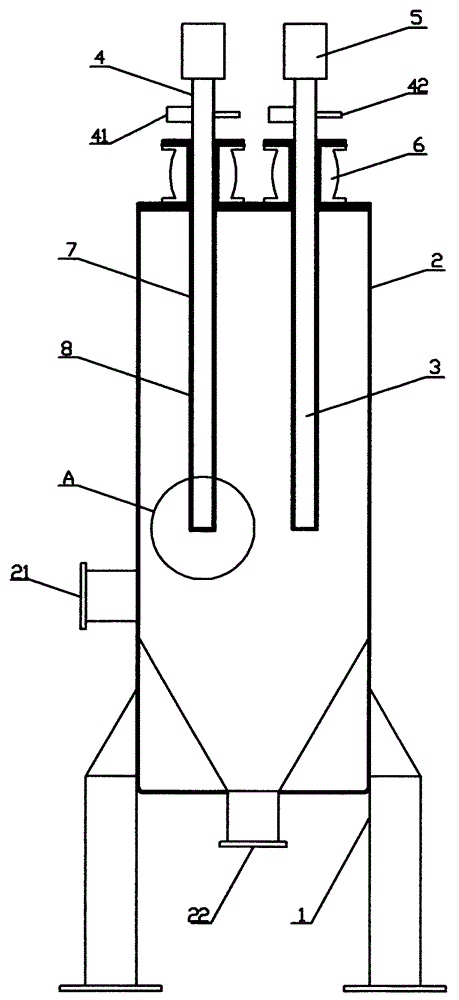

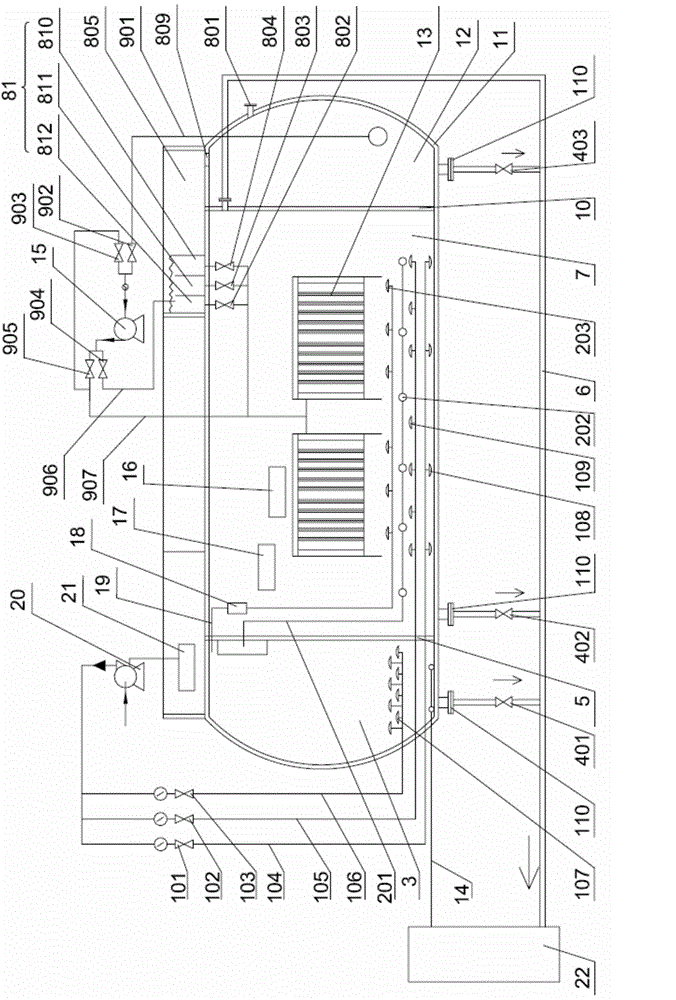

Anaerobic membrane bioreactor for sewage treatment and composite cleaning method of membrane module

ActiveCN103803763BReduce pollutionLess sludgeSemi-permeable membranesTreatment with anaerobic digestion processesOxygenPollution

The invention discloses an anaerobic membrane bioreactor for sewage treatment and a composite cleaning method of a membrane module. An aerobic reaction zone, an anaerobic reaction zone and a recycle water zone are arranged inside a membrane bioreactor shell disclosed by the invention; sewage input by a sewage input pipe enters the bottom of the aerobic reaction zone, a gas of the aerobic reaction zone and sewage after aerobic reaction are input to the bottom of the anaerobic reaction zone; the membrane module is arranged inside the anaerobic reaction zone; the water after anaerobic reaction enters the recycle water zone through a physical nitrogen and phosphorus removal zone; and the recycle water zone outputs the processed sewage. By adopting the sewage processor disclosed by the invention, the membrane module reacts under an anaerobic environment, the residual sludge can be obviously reduced, meanwhile, pollution of the membrane module can be retarded, energy consumption is reduced, and the sludge quantity and the sludge concentration are reduced. By adopting the composite cleaning method disclosed by the invention, the pollution layer can be more deeply cleaned by carrying out recycle water backflush cleaning and chemical and physical combined backflush cleaning on the member module, the dropping speed of a pollutant is accelerated, and the effect is greatly higher than that of soaking cleaning by a single drug.

Owner:CHONGQING NAIDE MACHINERY EQUIP

Soaking type peeling device

InactiveCN108040596AImprove peeling efficiencyGood peeling effectHarvestersAgricultural engineeringWater tanks

The invention discloses a soaking type peeling device. The device comprises a rack, a bearing plate arranged on the rack through a stand column in an inclined mode, a pair of vacuum adsorption platesarranged on the opposite side edges of the bearing plate, a cutting unit installed over the bearing plate and a pair of limiting units penetrating through the bearing plate, a water tank unit locatedon one side of the bearing plate and used for bearing cut corn ears conveyed by the bearing plate, and a draught fan unit arranged over the water tank unit for sucking away dried subtending leaves. Agroove through which the limiting units run is formed in the bearing plate. The corn ear peeling efficiency can be effectively improved, and the soaking type peeling device has the advantages of beingsimple in structure and convenient to use.

Owner:SUZHOU JIAMING MACHINERY MFG

Acne-removing composite acid essence solution and preparation method thereof

InactiveCN113181069AImprove difficult problemsIncrease contentCosmetic preparationsToilet preparationsEpitheliumSalicylic acid

The invention discloses an acne-removing composite acid essence solution and a preparation method thereof. The acne-removing composite acid essence solution is prepared from, by weight, 1-3 parts of nano-liposome salicylic acid, 5-7 parts of azelaic acid, 5-7 parts of lactic acid, 0.2-1.5 parts of phenethyl resorcinol, 0.1-1 part of hexamidine, 8-12 parts of tea oil and 0.2-0.8 part of blumea balsamifera oil. Nano-liposome salicylic acid, azelaic acid, lactic acid, phenylethyl resorcinol, hexamidine, tea oil and blumea balsamifera oil are mixed to serve as an essence solution, and after the essence solution is smeared on a closed acne area, the content of linoleic acid in sebum secreted in the area can be effectively improved, so that the content of fatty acid in follicular epithelium is increased, the epithelial cell falling speed of the hair follicle opening in the area is increased, the problem that the aperture of the hair follicle opening is reduced is solved, pollutants in the hair follicle can be conveniently removed, the problem that the closed acne is difficult to treat is effectively solved, and the acne-removing composite acid essence solution is particularly suitable for users with the closed acne caused by reduction of the local sebum linoleic acid content.

Owner:云南昭药健康产业有限公司

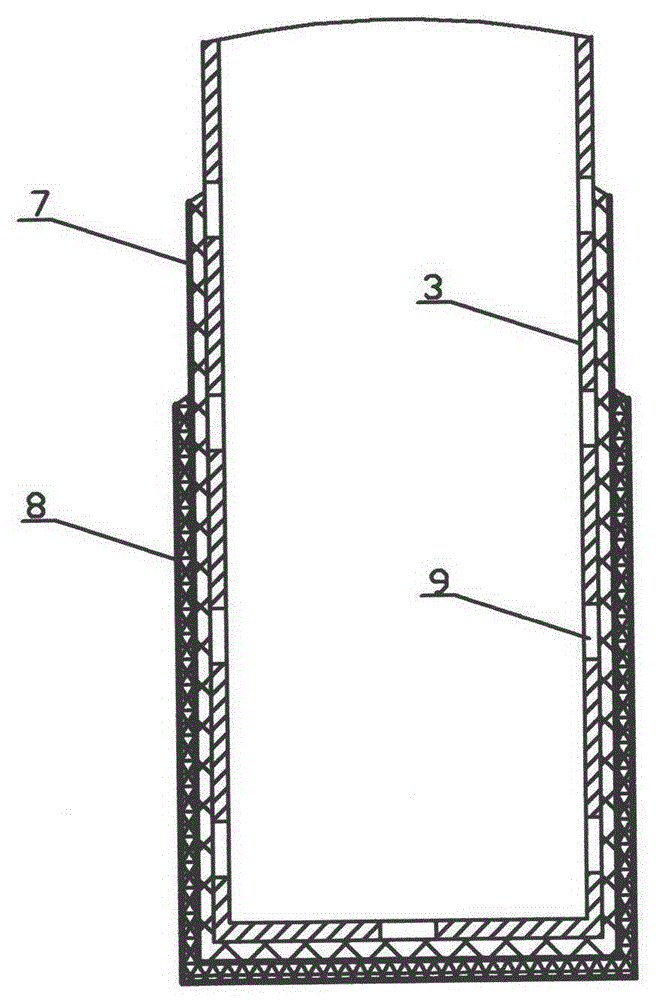

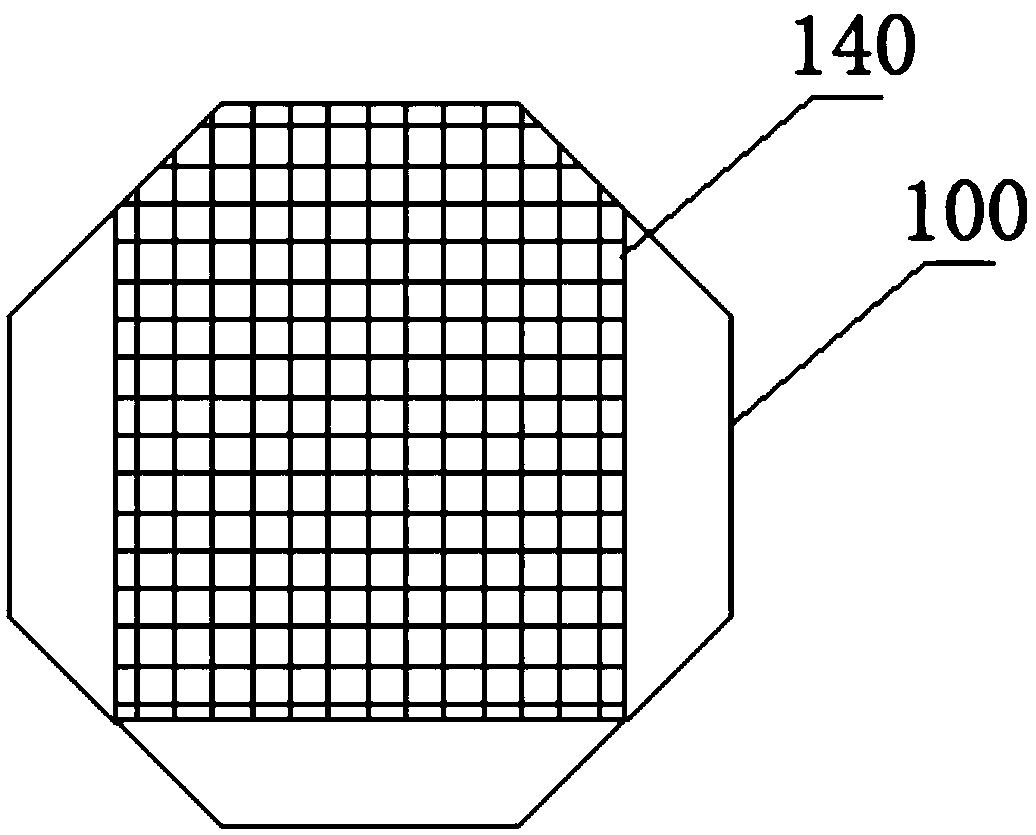

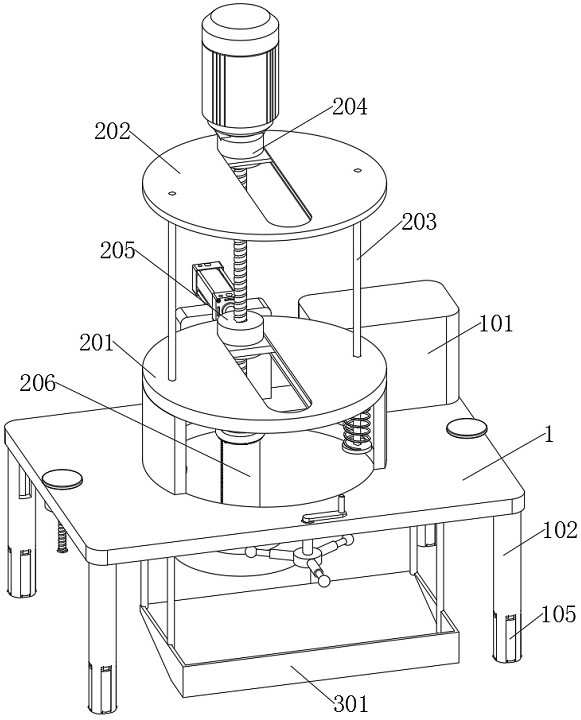

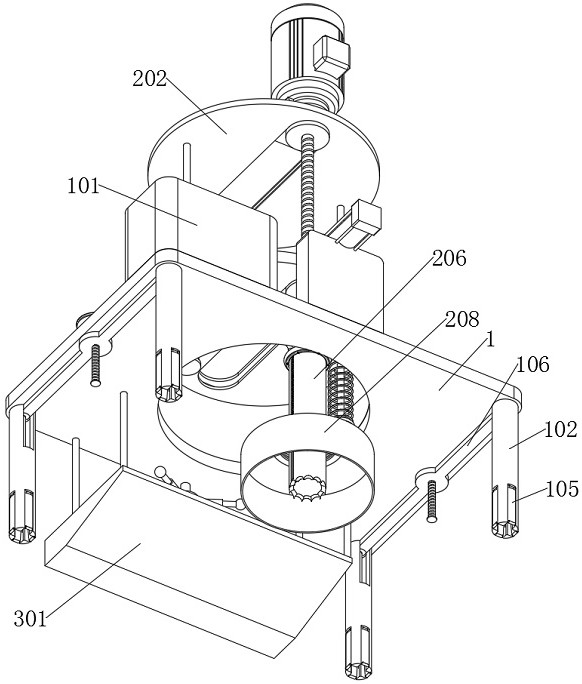

Tubular concentration device

ActiveCN104056479AQuick and complete sheddingExtend your lifeStationary filtering element filtersSludgePapermaking

The invention relates to a tubular concentration device in the manufacturing field of papermaking, brewing and sludge treatment industrial equipment. The tubular concentration device comprises a base and a cylinder, wherein a feed hole and a discharge hole are formed in the cylinder; filter pipes are arranged in the cylinder; the upper parts of the filter pipes are communicated with straight pipes; filtrate outlets, gas inlets and vibrators are arranged on the straight pipes; the outer surface of each filter pipe is coated with a screen which is further sleeved with a filter bag; the straight pipes are elastically connected with the upper end surface of the cylinder; or every 2-50 straight pipes are connected in parallel to form a group, each group is provided with one vibrator, and the filtrate outlets and the gas inlets of the straight pipes are gathered as one; when in use, each filter pipe is subjected to cake removal in turn while other filter pipes work normally; the feed hole is continuously opened, and the discharge hole is opened for discharging once at an interval of certain time; since the upper parts of the straight pipes are connected with the vibrators and provided with the gas inlets, vibration as well as blowing is performed in cake removal, and the drop speed of filter cakes is increased; the outer surface of each filter pipe is coated with the screen and the filter bag to form a porous filter layer with certain thickness, the concentration filtration is smooth and the service life of the filter bag is long.

Owner:杭州安永环保科技有限公司

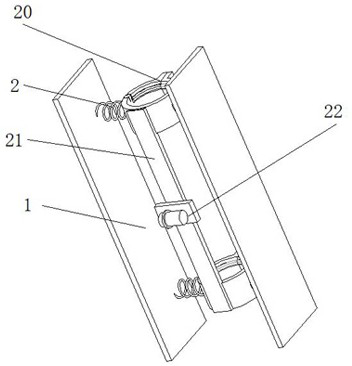

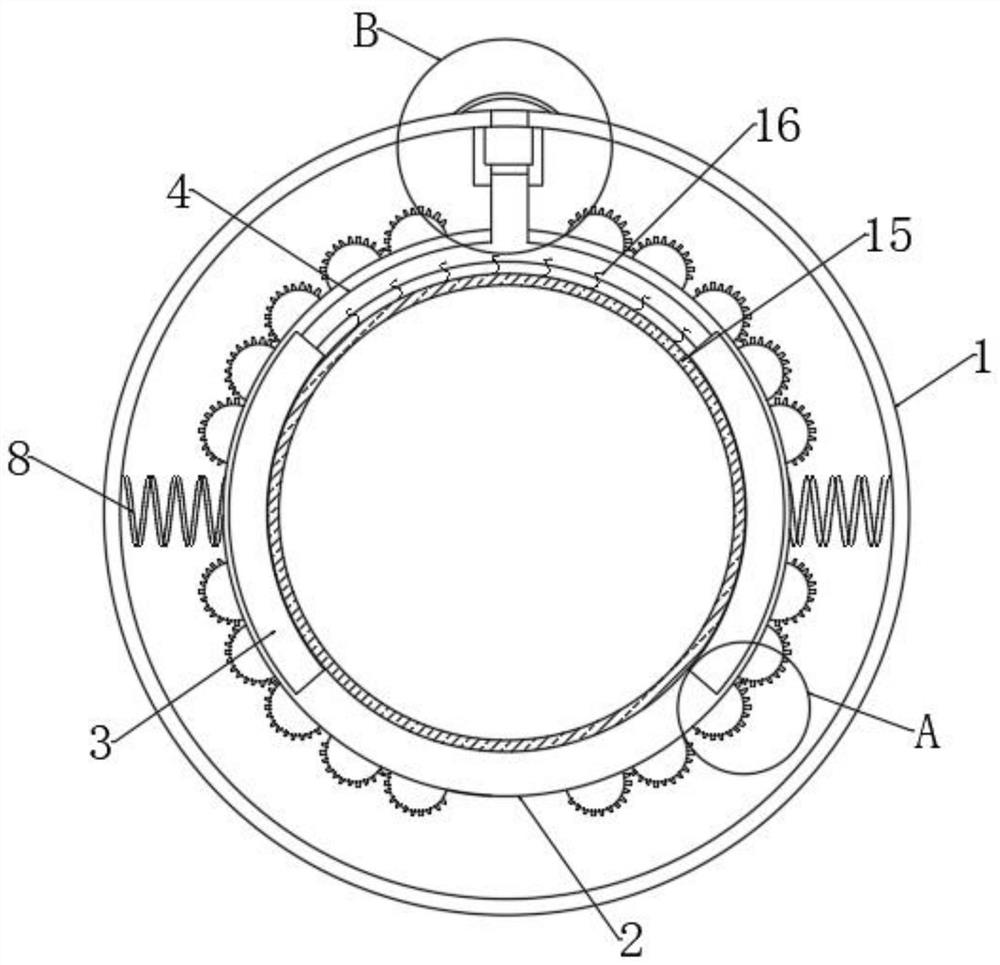

An ultrafiltration membrane self-cleaning device

ActiveCN113559719BImprove cleaning efficiencyImprove cleaning qualityUltrafiltrationMicro bubbleWater storage tank

The invention discloses an ultrafiltration membrane self-cleaning device, which relates to the technical field of water purification; specifically, it includes a filter cartridge holder, an ultrafiltration membrane filter cartridge and a water storage tank, and the inside of the filter cartridge holder is fixedly installed with multiple groups springs, and a filter cartridge fixture is installed between each group of springs, and the ultrafiltration membrane filter cartridge is fixedly installed between two adjacent filter cartridge fixtures, and the top of the ultrafiltration membrane filter cartridge is installed with a raw water inlet pipe, And the other end of the raw water inlet pipe is equipped with a water inlet three-way solenoid valve. In the present invention, the purified water in the water storage tank is introduced into the ultrafiltration membrane filter cartridge to backwash the ultrafiltration membrane, wherein the purified water in the water storage tank contains air bubbles introduced by the air pump, and the micro bubbles are used to impact and burst in the ultrafiltration membrane , to effectively improve the cleaning of dirt and impurities on the surface of the ultrafiltration membrane. At the same time, the ultrafiltration membrane filter cartridge is driven to vibrate during backwashing, and the vibration is used to speed up the speed of dirt shedding, thereby improving the efficiency and quality of ultrafiltration membrane cleaning.

Owner:迈博瑞生物膜技术(南通)有限公司

Peeling machine with water tank

InactiveCN108040619AImprove peeling efficiencyGood peeling effectThreshersAgricultural engineeringWater tanks

The invention discloses a peeling machine with a water tank. The machine comprises a rack, a supporting rack, a bearing plate, a cutting unit, a baffle unit, a water tank unit, a bearing plate unit and a roller-type conveying line unit. The rack is provided with a first air cylinder; the supporting rack is fixedly arranged on the top surface of the rack and comprises a baseplate and a pair of sideplates which are symmetrically arranged at the two side edges of the baseplate, and a containing area is defined by the baseplate and the side plates; the bearing plate is aslant arranged in the containing area of the supporting rack; the cutting unit is located above the bearing plate; the baffle unit is located at a discharging port side of the lower end of the bearing plate; the water tank unit is arranged on the top surface of the rack and located at one side of the supporting rack; the bearing plate unit is arranged in the containing area of the supporting rack and used for bearing cornears on the bearing plate to the water tank unit; the roller-type conveying line unit is arranged below the rack. According to the peeling machine with the water tank, the efficiency and effect of peeling the corn ears can be effectively improved.

Owner:SUZHOU JIAMING MACHINERY MFG

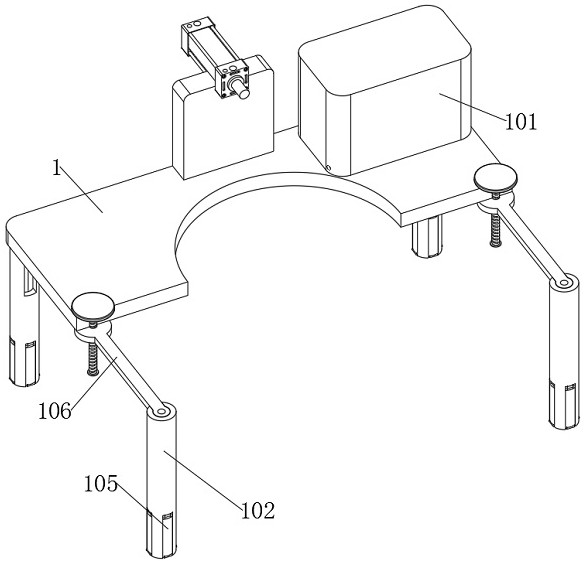

Sampling device for geological structure exploration

ActiveCN114646497AEasy accessPreventing Situations That Fall On StaffWithdrawing sample devicesDrill holeMining engineering

The invention provides a sampling device for geological structure survey, and relates to the technical field of geological survey sampling equipment.The sampling device comprises a main body, the main body is of a rectangular plate-shaped structure, an air cylinder is installed on the rear side of the top of the main body through a connecting plate, and an open groove is formed in the middle of the top of the main body and is of a circular structure; a rotating assembly is mounted at the top of the main body; the rotating assembly comprises a carrier plate, supporting plates are installed at the bottom of the carrier plate, the bottoms of the supporting plates are installed at the top of the main body, the supporting plates at the bottom of the carrier plate are located on the two sides of the open groove in the top of the main body, and a sliding groove is formed in the top of the carrier plate; and the material taking mechanism is mounted at the bottom of the main body. The protective cover moves along with the movement of the rotating part, so that the protective cover is placed on the ground to protect the periphery of the drilled hole, and the problems that when an existing sampling device is used, a drill bit needs to be cooled by spraying water flow, and the water flow is easily thrown to surrounding workers under the driving of the drill bit are solved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

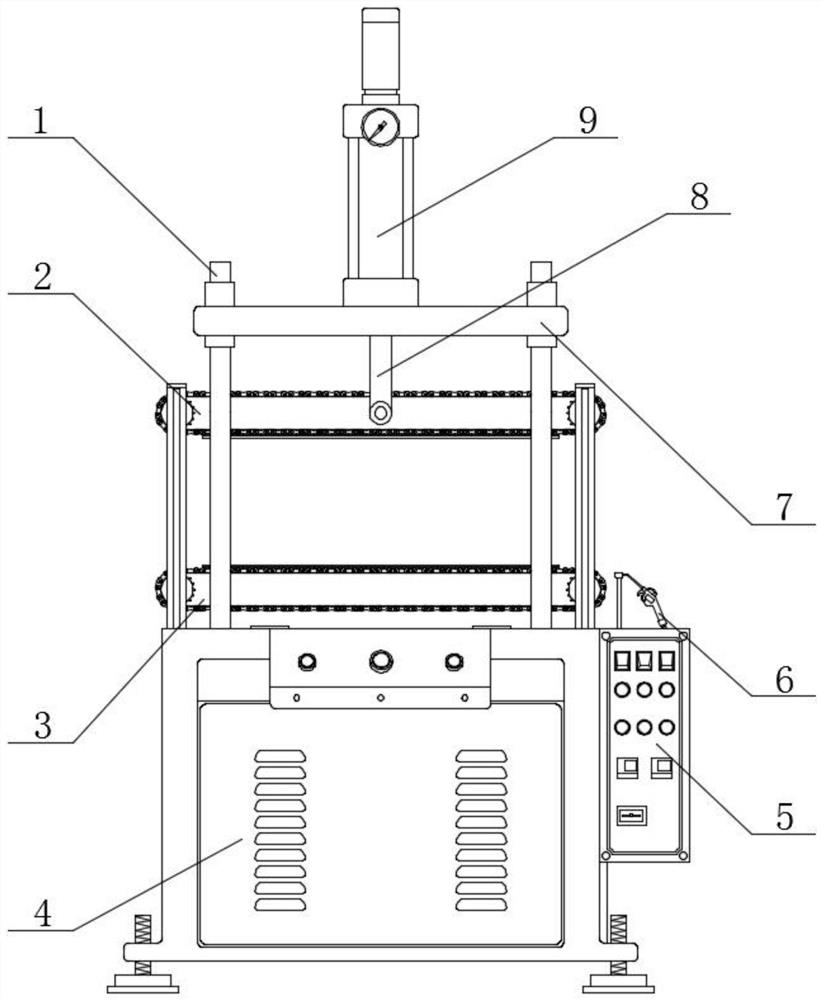

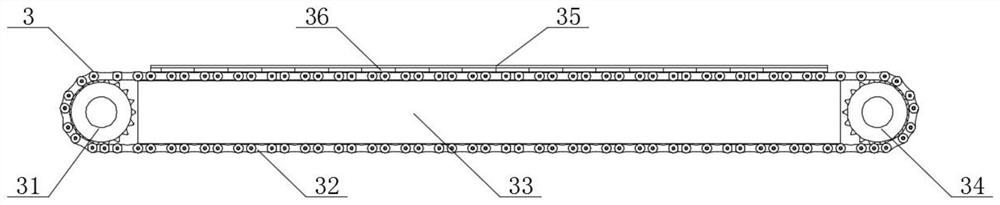

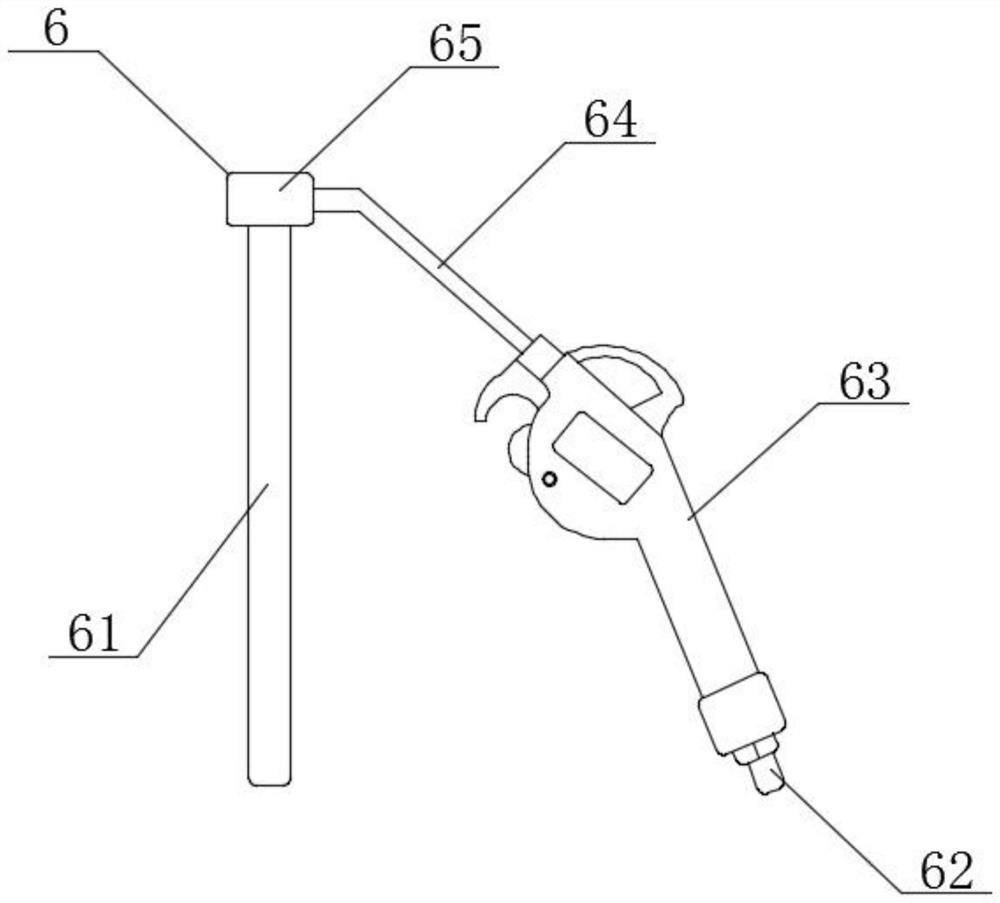

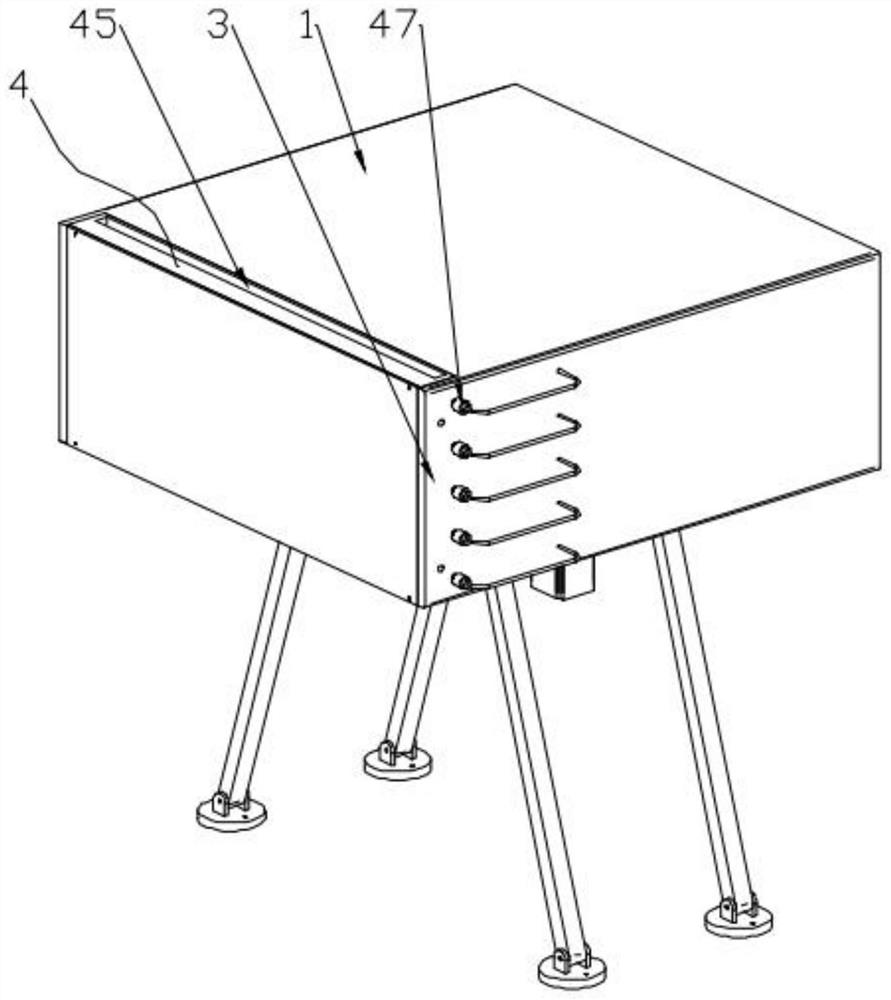

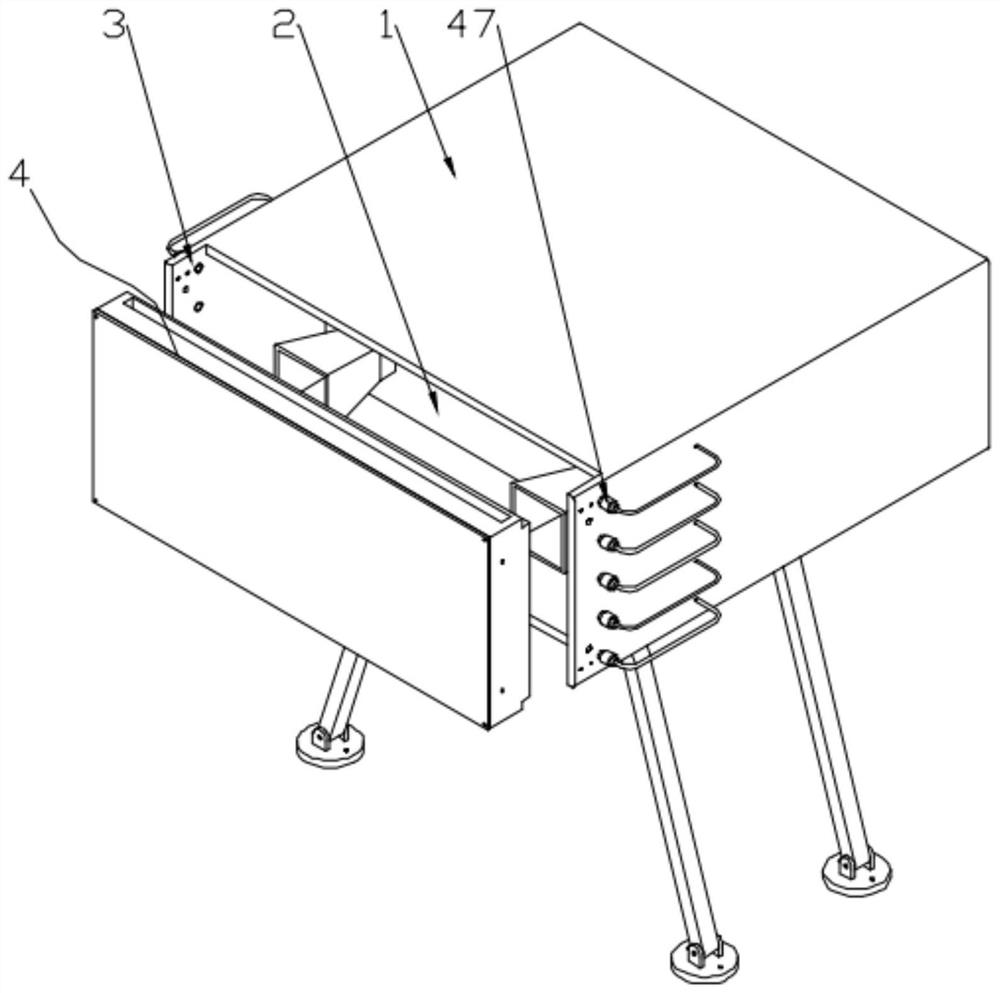

Novel anti-adhesion rubber forming machine

The invention provides a novel anti-adhesion rubber forming machine. A control box is fixedly connected to the right end face of a cabinet in a welded mode, a falling device is connected to the upperend face of the control box, a supporting rod is connected to the upper end face of a lower extrusion device, and the lower extrusion device is connected to the position, on the upper end face of thecabinet, of the middle of the supporting rod. According to the novel anti-adhesion rubber forming machine, the lower extrusion device composed of a power wheel, a rotating chain, a supporting plate, atransmission wheel, a shaping soft plate and a chain plate is arranged, a power motor on the surface of the power wheel can well drive the power wheel to rotate, the rotating power wheel can well drive the transmission wheel to rotate through the rotating chain, so that the shaping soft plate and the chain plate are driven to move, the processed and formed rubber can be well extruded from the right side through an upper extrusion device and the lower extrusion device, and the part, adhered to the surface of the shaping soft plate, of the rubber is blown down through the falling device, so that an operator can conveniently collect the rubber, and meanwhile, the integrity of the rubber is guaranteed.

Owner:东莞市科盛智能装备科技有限公司

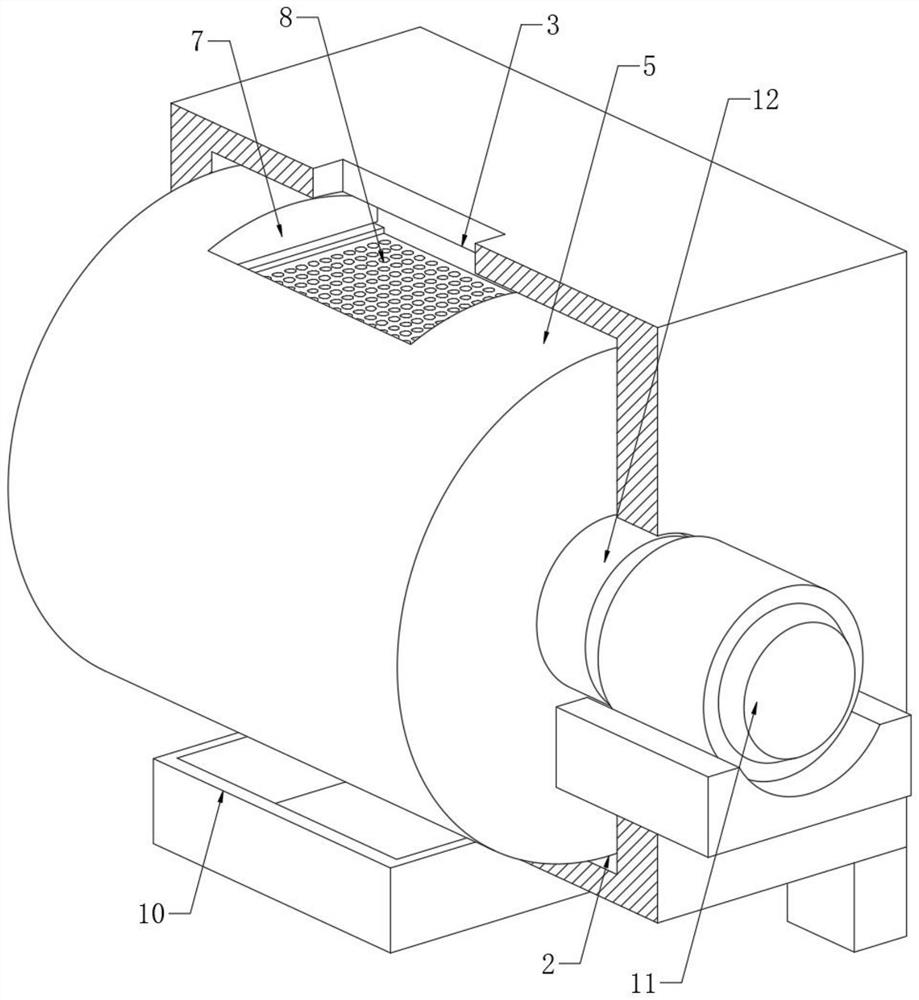

Continuous sand screening equipment for building raw material processing

ActiveCN114653579AImprove screening efficiencyEasy maintenanceSievingGas current separationArchitectural engineeringStructural engineering

The continuous sand screening equipment for building raw material processing comprises a box body, a cylindrical groove is horizontally formed in the box body, a rotating roller is coaxially and rotationally installed in the cylindrical groove, the peripheral wall of the rotating roller is in sealed sliding connection with the groove wall of the cylindrical groove, and a plurality of sand screening grooves are symmetrically formed in the peripheral wall of the rotating roller; a filter plate is horizontally arranged in each sand screening groove, a plurality of sand shaking mechanisms matched with the corresponding filter plates are arranged in the rotating roller, a material conveying hole is coaxially formed in the middle of the rotating roller in a penetrating mode, and a material conveying mechanism is arranged in the material conveying hole. According to the sand screening device, the rotating roller and the one-way bearing are arranged, the two sand screening grooves are formed in the rotating roller to be matched with the material conveying mechanism, sand is screened, meanwhile, the filter plate on the lower side can be conveniently overhauled, maintained or replaced through the access hole, operation is convenient, the sand screening device is suitable for continuous operation, and the sand screening efficiency is improved.

Owner:广东天政建设工程有限公司

Keyboard automatic disassembly cleaning machine

ActiveCN107737774BRealize fully automatic disassemblyImprove processing efficiencyCleaning using gasesSortingEngineeringConveyor belt

The invention discloses a full-automatic keyboard disassembling and cleaning machine. The machine comprises a control box, wherein a feeding device, a rotating disc device and a keycap detaching device and a keycap falling device are arranged on the table surface of the control box in sequence from one end to the other end; the feeding device comprises a feeding manipulator arranged on a first electric guide rail; a second electric guide rail is arranged between the keycap detaching device and the keycap falling device; a movable conveying manipulator is arranged on the second electric guide rail; an optical detector is arranged at the rear end of the control box; a third electric guide rail is arranged between the optical detector and the keycap falling device; the conveying manipulator is further arranged on the third electric guide rail; a conveyor belt is arranged below the optical detector; a stacking device is arranged at one end of the conveyor belt, and a dust collecting deviceand a discharging device are arranged at the other end; the discharging device comprises a fourth electric guide rail arranged above the conveyor belt; and a discharging manipulator is arranged on the fourth electric guide rail. The full-automatic keyboard disassembling and cleaning machine can realize full-automatic disassembling, cleaning and sorting of keyboards, thereby being high in automation degree and processing efficiency.

Owner:平邑县经发企业服务有限公司

Wheat threshing bar with protrusions

The invention discloses a wheat threshing bar with protrusions. The wheat threshing bar comprises a bar body and a handle. The bar body is of a cylindrical shape. A plurality of protrusions are arranged on the periphery of the bar body, and are of elastic cylindrical structures. The wheat threshing bar has the advantages that by the elastic protrusions on the periphery, threshing speed of wheat grains is greatly increased, and damages to the wheat grains are reduced.

Owner:郑福建

A sampling device for geological structure exploration

ActiveCN114646497BEasy accessPreventing Situations That Fall On StaffWithdrawing sample devicesMining engineeringGeological survey

The invention provides a sampling device for geological structure survey, which relates to the technical field of geological survey sampling equipment, and includes a main body, the main body is a rectangular plate-like structure, and a cylinder is installed on the top and rear side of the main body through a connecting plate, and the main body is There is a slot in the middle of the top, the slot is a circular structure, and a rotating component is installed on the top of the main body; the rotating component includes a carrier plate, and a support plate is installed at the bottom of the carrier plate, and the bottom of the support plate is installed on the bottom of the main body. The support plates at the top and the bottom of the carrier plate are located on both sides of the slot on the top of the main body, and the top of the carrier plate is provided with a chute; the reclaiming mechanism is installed on the bottom of the main body. The protective cover moves with the movement of the rotating parts, so that the protective cover is placed on the ground to protect the periphery of the drilled hole, which solves the problem that when the existing sampling device is used, the drill bit needs to be cooled by a jet of water, and the water flow drives the drill bit. It is easy to throw the problem on the surrounding staff.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

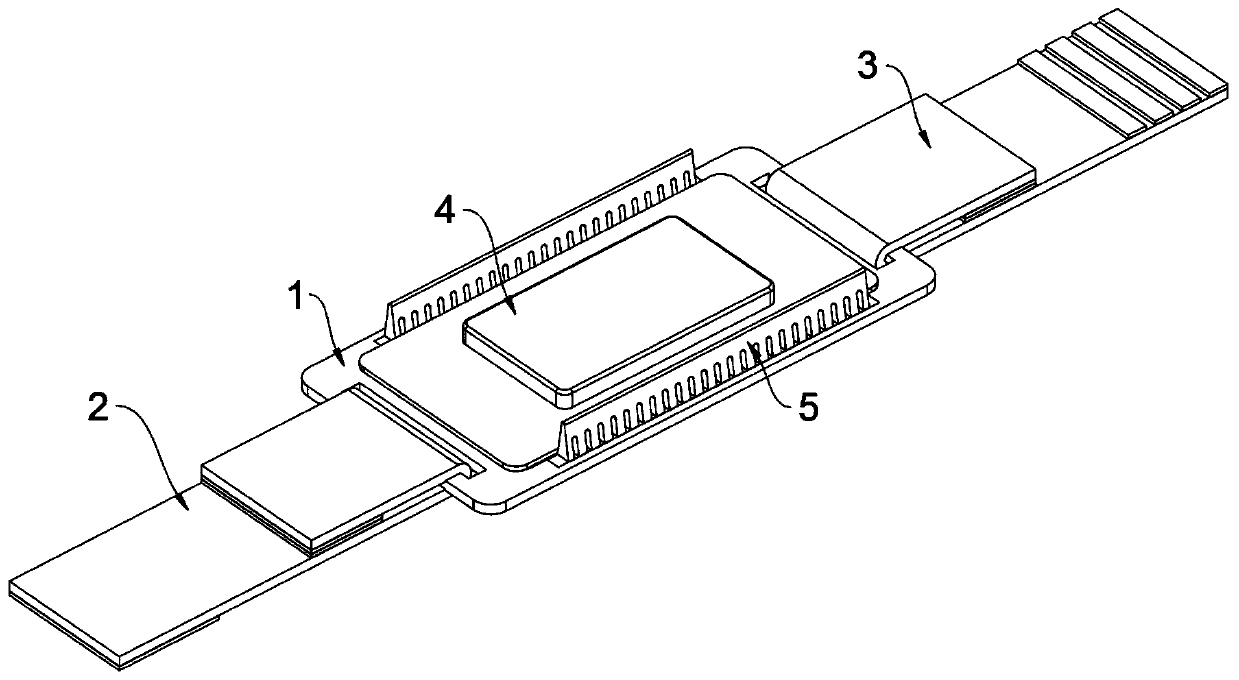

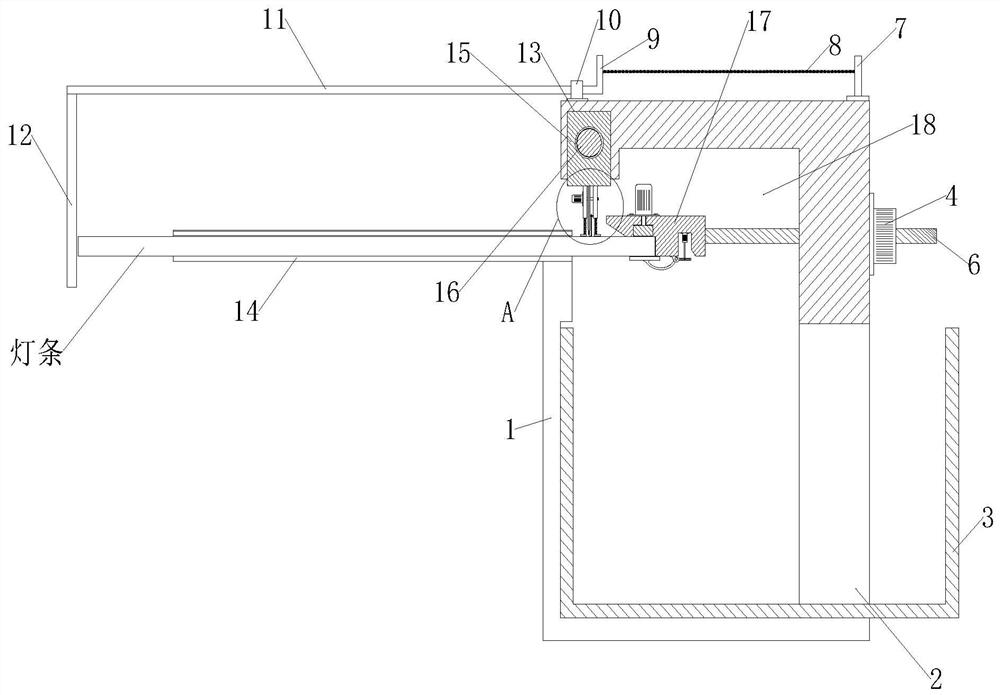

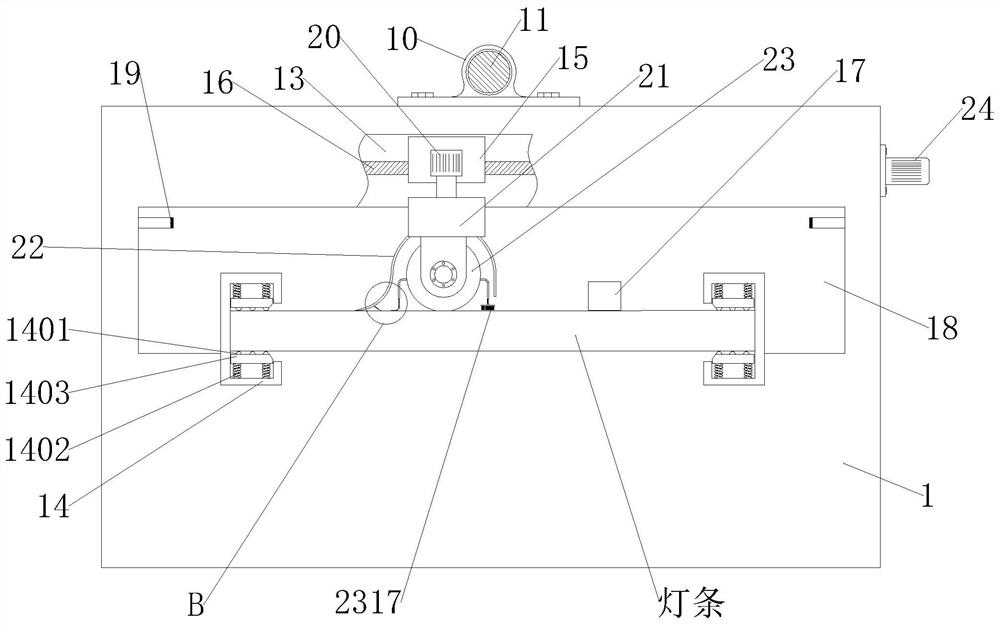

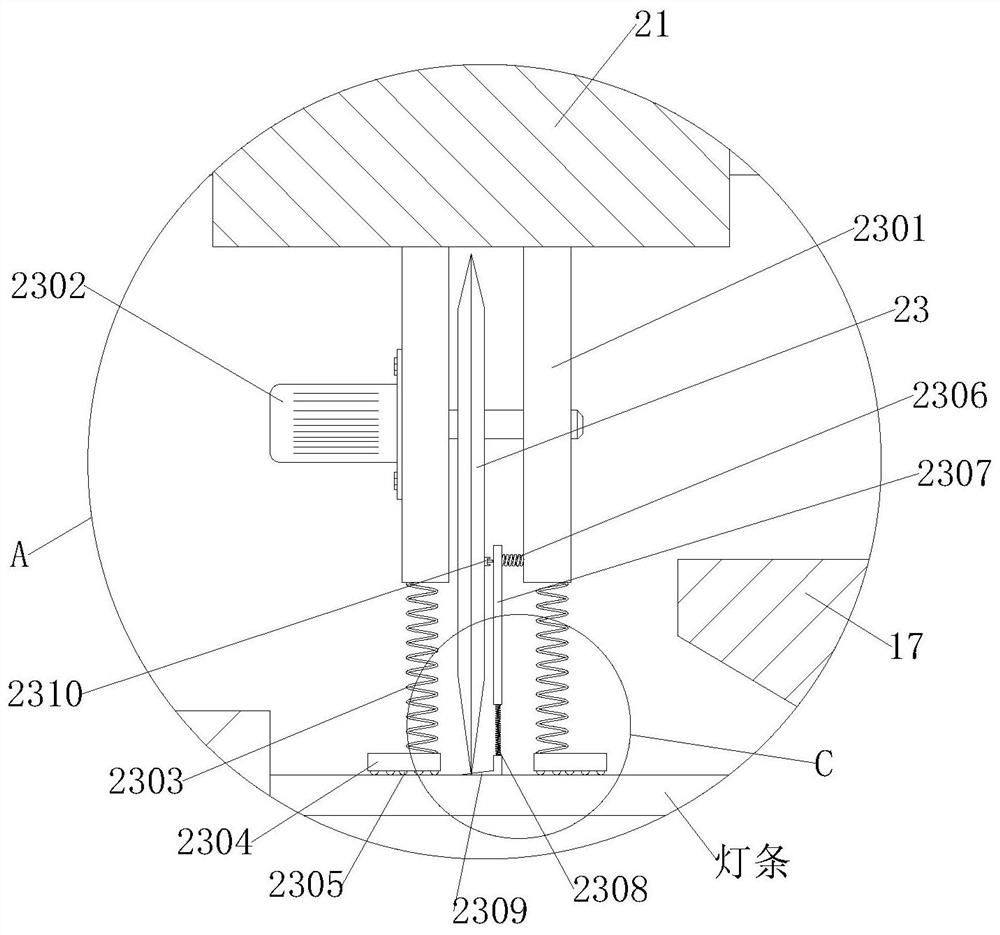

A kind of LED light strip production and processing equipment and processing method thereof

ActiveCN112372731BHigh continuous production efficiencyHigh positioning accuracyMetal working apparatusEngineeringMaterial storage

The invention provides a LED light bar production and processing equipment and a processing method thereof, and relates to the technical field of LED light bulbs. The LED light bulb production and processing process is completed by a LED light bulb production and processing device. The LED light bulb production and processing device Including a cutting machine, the cutting machine is a hollow square box in the middle, a cutting opening is opened at the left end of the cutting machine close to the top of the cutting machine, a storage slot is opened at the bottom of the right end of the cutting machine, and a storage slot is opened in the storage slot A material storage box is installed through a sliding connection; the bottom surface of the pressing foot of the present invention is equidistantly provided with several second balls with a spherical structure, so that the pressing foot rolls on the top of the light bar, reducing the pressure on the sole of the pressing foot facing the light bar Scratching on the surface, through several second balls, the pressing foot slides more smoothly on the surface of the light bar, thereby reducing the vibration on the surface of the light bar when the pressing foot slides on the surface of the light bar, and further improving the cutting accuracy of the cutting knife Spend.

Owner:金华橙果环保科技有限公司

Side ejection device and injection mold

InactiveCN104149294BSpeed up sheddingAchieve the purpose of free fallEngineeringMechanical engineering

Owner:DONGGUAN WELLMEI MOLD MFG CO LTD

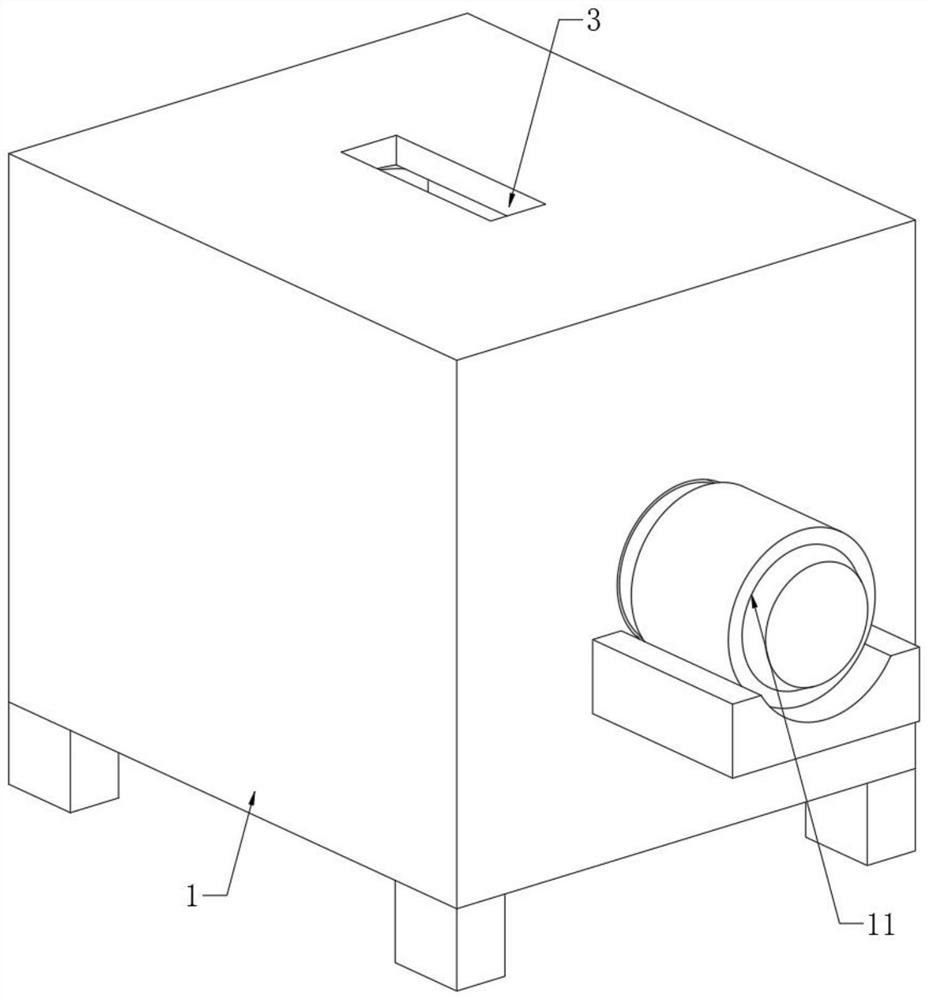

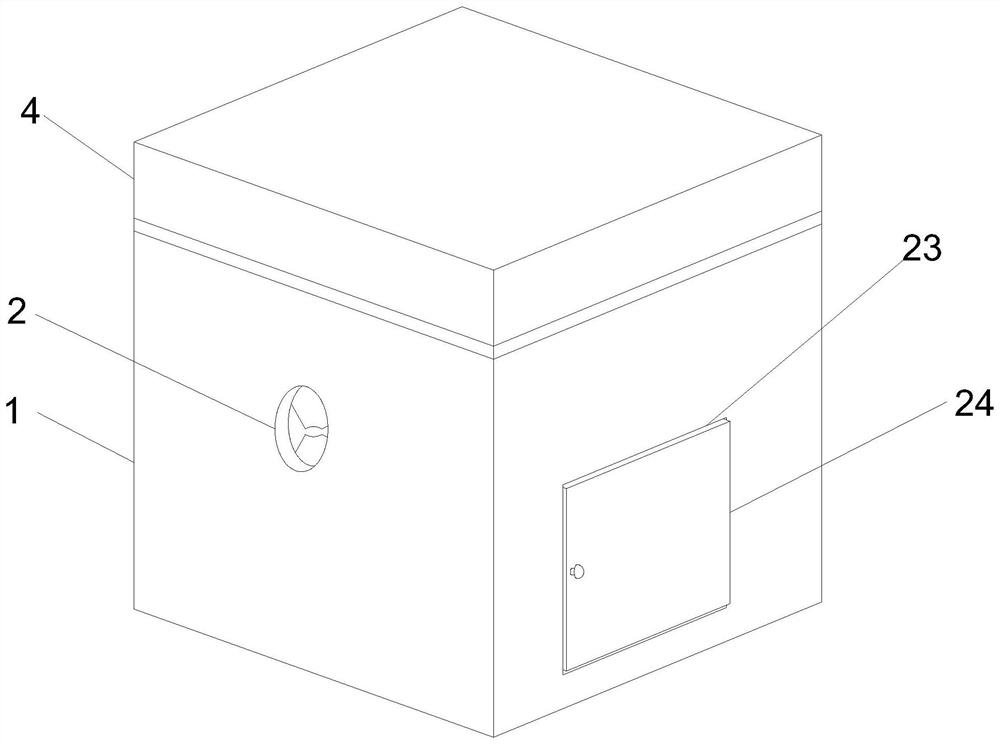

Syringe recovery treatment equipment for anesthesia department of hospital

ActiveCN112547764AImprove reprocessingFast Classification ProcessingSolid waste disposalSurgeryBiomedical engineering

The invention discloses syringe recovery treatment equipment for the anesthesia department of a hospital. The syringe recovery treatment equipment for the anesthesia department of the hospital comprises a box body, wherein a through hole is formed in the outer wall of the box body, a clamping part is installed in the box body, a buckle cover is buckled at the upper end of the box body, a needle tube separation device is installed on the buckle cover, and a partition plate is installed in the box body. By arranging the box body, a motor, a fixing rod and a clamping block, a needle cap insertedinto the through hole is limited through the needle tube limiting device, a needle tube is partially inserted into a strip-shaped opening in the fixing rod, the needle tube is wound through rotation of the motor, the curled shape of the needle tube is limited through the clamping block, the needle tube is wound and pulled out of the needle cap through rotation of the motor, and then separation forthe needle cap and the needle tube is realized; however, the motor is arranged on the buckle cover, the fixing rod is vertically arranged, the needle tube separated from the needle cap is spiral, theneedle tube falls off due to gravity and is separated from the fixing rod along with the rotation stop of the motor, and then automatic separation is realized.

Owner:JILIN UNIV

Magnetic attraction type iron sundry collector for engineering vehicle wheel protection

ActiveCN112277891ASpeed up sheddingAvoid adsorptionVehicle cleaningStructural engineeringMechanism (engineering)

The invention relates to an iron sundry collector, in particular to a magnetic attraction type iron sundry collector for engineering vehicle wheel protection. The magnetic attraction type iron sundrycollector for engineering vehicle wheel protection can continuously attract scrap iron and collect the scrap iron at the same time, and the scrap iron can be taken out conveniently. The magnetic attraction type iron sundry collector for engineering vehicle wheel protection comprises a mounting plate and supports, and the supports are connected to the two sides of the bottom of the mounting plate;and transverse plates which are connected to the side parts of the transverse plate and the bracket. Through cooperation of the conveying mechanism, the collecting mechanism and the discharging mechanism, scrap iron on the front side of an engineering vehicle tire can be automatically attracted and collected, the scrap iron can be scraped off through a scraper blade, and meanwhile the scrap iron falling speed can be increased under beating of a strip-shaped roller and the action of a scraping roller; under the action of the antimagnetic plate, irony objects can be prevented from being attracted to the front side and the rear side of the strong magnet.

Owner:莫运贵

Moulded pipe processing system for metallurgy casting

InactiveCN111889750AProcessing does not affectImprove work efficiencyFeeding apparatusPositioning apparatusGas cylinderProcess engineering

The invention relates to a moulded pipe processing system for metallurgy casting. The moulded pipe processing system for metallurgy casting comprises a workbench, a supporting mechanism and a waste clamping mechanism, wherein the workbench is mounted on existing working ground; the upper end surface of the workbench is provided with the supporting mechanism; and the middle part of the supporting mechanism is provided with the waste clamping mechanism. According to the moulded pipe processing system for metallurgy casting, the waste clamping mechanism can be adopted to firstly drill pipe wasteto be drilled, so that the lower end surface of the drilled waste pipe is supported, and therefore, pipe waste does not drop into a pipe while the pipe waste is cut off, next-step processing of the pipe is not affected, and work efficiency is improved; a gas cylinder pushes a convex table column to move downwards, so that a fan-shaped plate is pushed to support the drilled waste pipe, and therefore, the supported pipe is not liable to drop; under action of a telescopic spring, a fan-shaped plate returns to the original position, so that a ring-shaped plate pushes the pipe waste to be more simply, and the waste drop speed is also increased.

Owner:管冰倩

Incineration device for solid waste treatment

PendingCN112902172AImprove incineration efficiencyPlay a driving effectIncinerator apparatusThermodynamicsProcess engineering

The invention discloses an incineration device for solid waste treatment and relates to the technical field of solid waste incineration. The incineration device for solid waste treatment comprises an incinerator, a smoke outlet and a base, wherein the smoke outlet is formed in the top of the incinerator, the bottom of the incinerator is fixed to a heat driving cavity via a sealing spacer and is insulated with the heat driving cavity I via a sealing spacer, and the base is fixedly mounted at the bottom of the heat driving cavity I. According to the incineration device for solid waste treatment, in a paper garbage or plastic garbage combustion process, a gas in the heat driving cavity I is heated to expand, an auxiliary combustion mechanism lifts up the incinerated paper garbage or plastic garbage by the heat driving mechanism under the air pressure action generated by expansion of gas. In the lifting process, the paper garbage or plastic garbage slides off from a side surface of an auxiliary push-pull rod, such that the paper garbage or plastic garbage accumulated together is dispersed, and therefore, the incineration efficiency of the paper garbage or plastic garbage is improved.

Owner:段冬冬

A power cable with self-removing snow function

ActiveCN113595011BNot easy to wear and tearNot easy to corrodeOverhead installationApparatus for overhead lines/cablesSnowpackSnow removal

Owner:JIANGSU HUAMAI NEW MATERIAL CO LTD

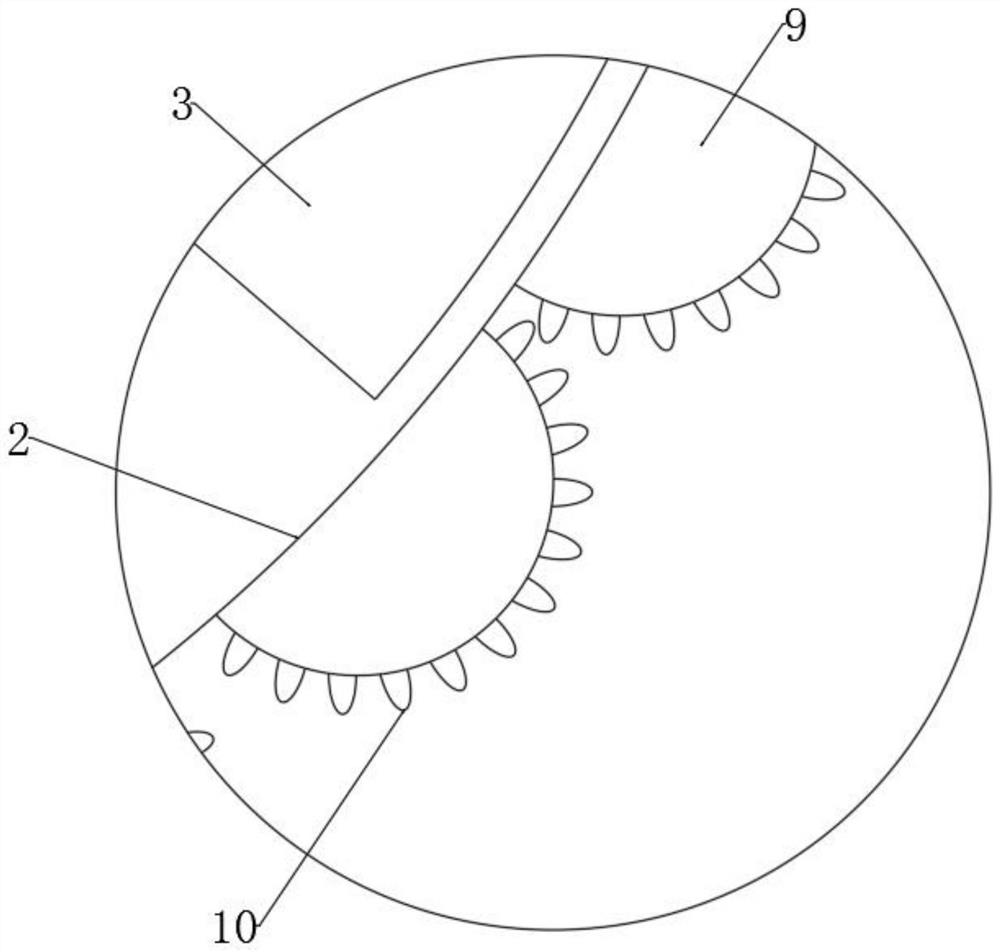

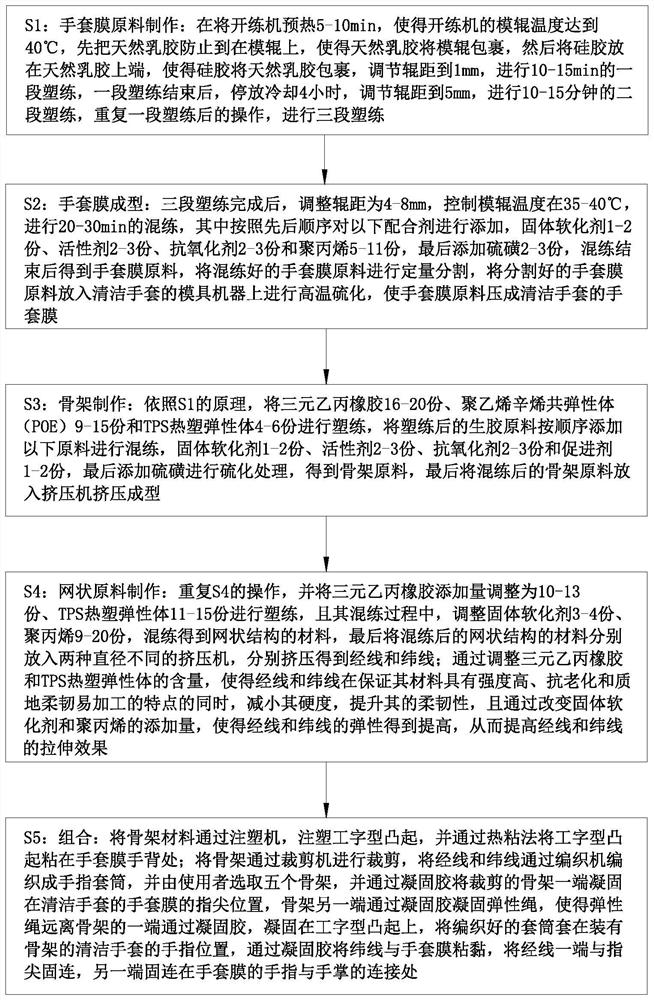

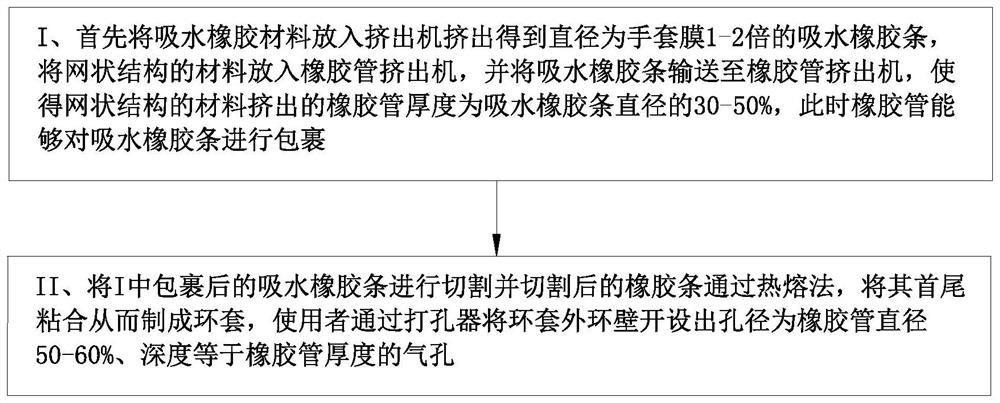

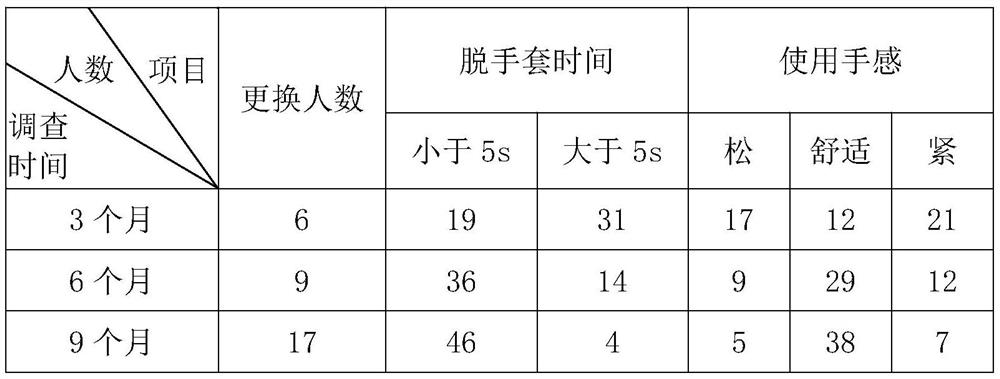

High-elasticity composite high polymer material and preparation process thereof

ActiveCN113929980ASpeed up sheddingAvoid slippery and difficult to gripDomestic articlesElastomerPolymer science

The invention relates to the technical field of high polymer materials, and in particular, relates to a high-elasticity composite high polymer material and a preparation process thereof. The high-elasticity composite high polymer material comprises 24-32 parts of natural latex, 16-28 parts of silica gel, 16-20 parts of ethylene propylene diene monomer, 9-15 parts of polyethylene octylene co-elastomer (POE), 5-11 parts of polypropylene, 4-6 parts of a TPS thermoplastic elastomer and 2-3 parts of an antioxidant; the natural latex, the silica gel and the polypropylene are made into a glove film structure of cleaning gloves; existing cleaning gloves are made of high-elasticity materials, so that the gloves are difficult to take off when the gloves are used; therefore, through the arrangement of a framework, a user can separate the gloves from the hand by pulling the framework, the situation that the outer surface of the gloves is smooth and difficult to hold due to residual dishwashing liquid on the surface of the gloves is avoided, the falling speed of the gloves is increased, the framework can rub and scrape off stains on tableware under pushing of the finger joints, and thus the practicability of the material is improved.

Owner:东莞一贝核科技有限公司

Radar device for dam body monitoring

PendingCN113687311AEfficient detectionAccurate detectionWave based measurement systemsHollow article cleaningRadarTransducer

The invention discloses a radar device for dam body monitoring, and relates to the field of radar equipment, the radar device comprises a box body and a radar host, the radar host is installed in the box body, the box body is installed on the ground by means of supporting legs arranged at the bottom of the box body, and two symmetrically arranged extension plates are integrally formed at the front end of the box body; and a baffle assembly is installed between the two extension plates and comprises a baffle body, a movable plate, a spring and an end cover, the movable plate is utilized, effective and accurate detection of the icing phenomenon can be achieved, ice blocks in the ventilation holes can be removed in time by means of a contact switch and a corresponding ultrasonic transducer, Therefore, the influence on radar monitoring is reduced.

Owner:安徽城宜防务科技有限责任公司

Processing device for building raw materials

InactiveCN113681600AReduce contentNo wasteMetal working apparatusArchitectural engineeringElectric machinery

The invention discloses a processing device for building raw materials, and relates to the technical field of building raw material processing. The processing device for the building raw materials comprises a processing table, a driving motor is fixed to the top of the processing table, an output shaft of the driving motor is fixed to one end of a processing sleeve, the other end of the processing sleeve is located at the end, away from the driving motor, of the top of the processing table, and the interior of the processing sleeve is hollowed out. According to the processing device for the building raw materials, wood can be cut and processed by arranging a cutting block on the processing sleeve, so that a wooden layer and a leather surface layer of the wood are separated, and the processing sleeve carries out rotary cutting, so that the processed wood can naturally form a cylindrical shape, and subsequent forming processing is not needed. Meanwhile, the content of the wooden layer attached to the leather surface layer is extremely low, the phenomenon of waste of the wooden layer is avoided, and the utilization rate of the wooden layer in the wood processing process is increased.

Owner:陆克义

Workpiece oil immersion device

ActiveCN107716209AAccelerate evaporationSpeed up the oil filterLiquid surface applicatorsCoatingsSprocketRust

The invention discloses a workpiece oil immersion device and relates to the field of rust prevention. The workpiece oil immersion device comprises a suspension beam, a motor, a first chain wheel and second chain wheels. The motor is arranged on the suspension beam. The first chain wheel is arranged on the motor. Suspension rods, first positioning rods, the second chain wheels and second positioning rods are sequentially arranged towards the two sides from the motor on the suspension beam. The suspension rods are hinged to the suspension beam, and the suspension rods are provided with sliding grooves and hooks. Sliding shafts are arranged in the sliding grooves, and the hooks are arranged on the lower sides of the suspension rods. The second chain wheels are coaxially fixedly provided withgears, racks are engaged with the lower sides of the gears, and the racks are rotationally connected with the sliding shafts. The second chain wheels are fixedly provided with fan blades. The first chain wheel is engaged with a chain, and the chain is engaged with the second chain wheels. The two ends of the chain are fixedly connected with oil barrels, oil holes are formed in the lower sides of the oil barrels, and the oil holes communicate with each other through a hose. Net pockets are arranged in the oil barrels, rope sleeves are arranged at opening portions of the net pockets, the rope sleeves are arranged outside the oil barrels, and the rope sleeves can be hooked by the hooks. By means of the workpiece oil immersion device, air can be blown towards the interiors of the oil barrels for accelerating oil filtering, the efficiency is improved, the net pockets are hooked out of the barrels automatically after oil filtering is over, the structure is simple, and operation is simplified.

Owner:重庆达小丰机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com