A power cable with self-removing snow function

A power cable, functional technology, applied in the field of power cables with self-snow removal function, can solve problems such as damaged insulation layer, fire, insulation layer damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

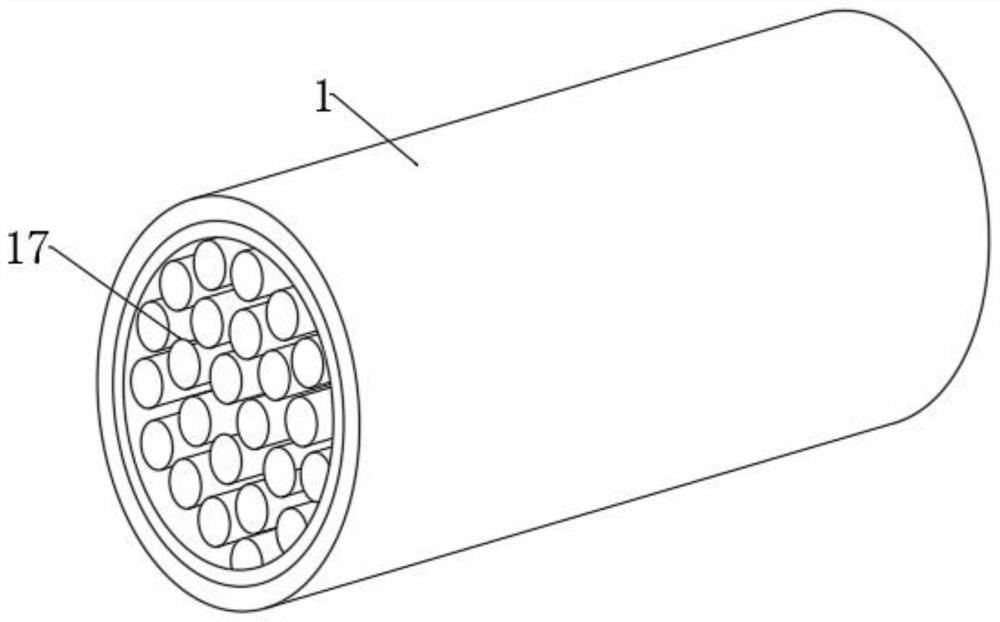

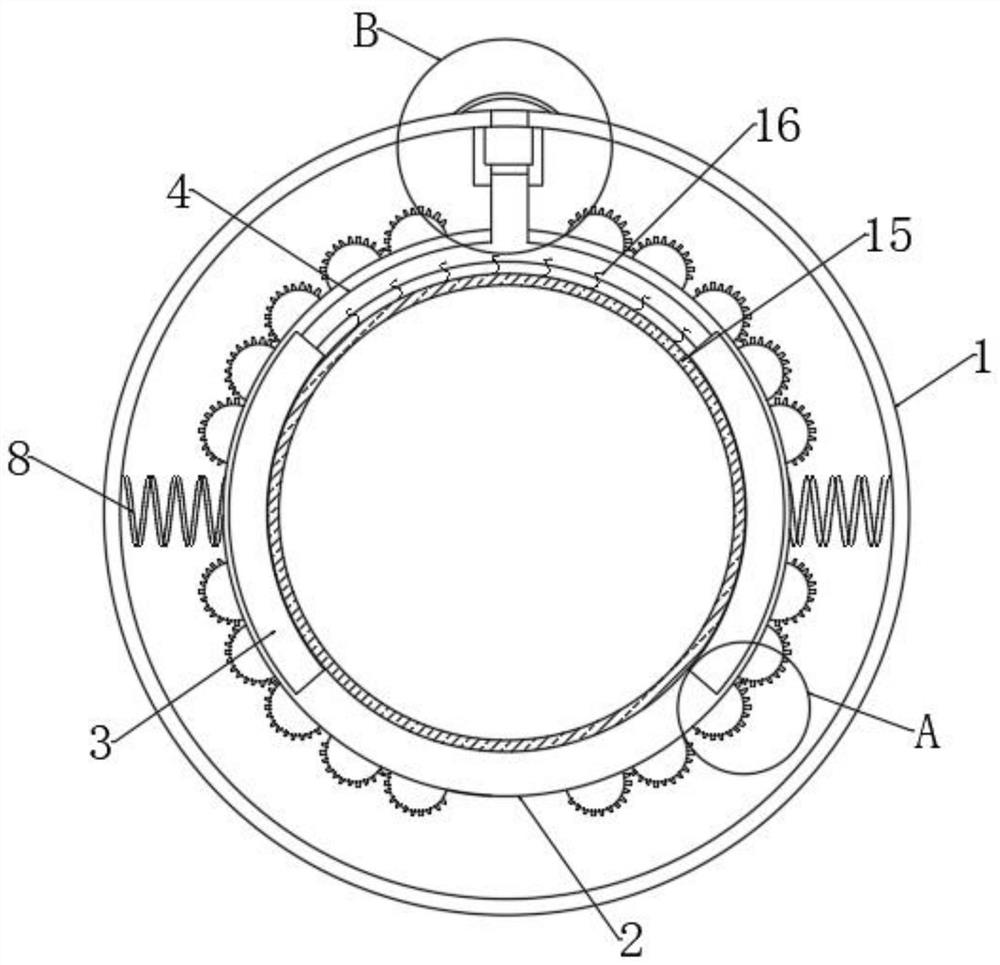

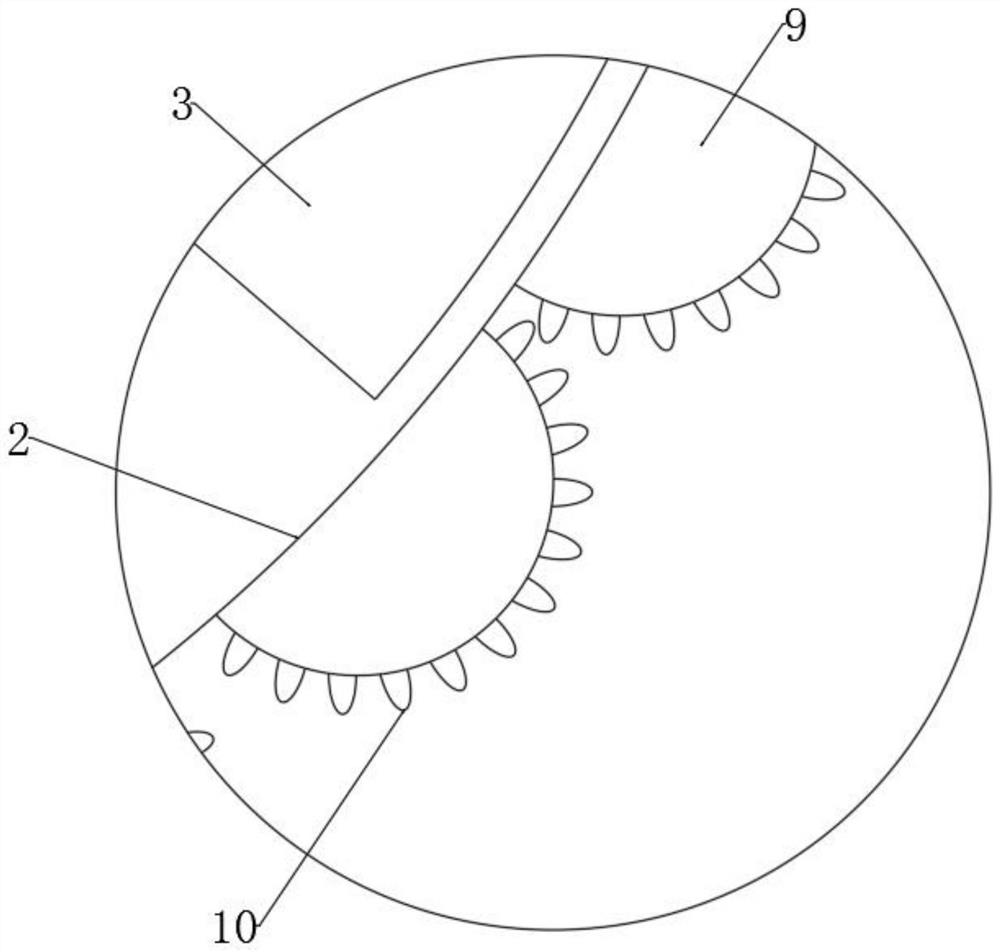

[0040] see Figure 1-6 , a power cable with self-snow removal function, including a cable duct 1, a rubber collar 2 is provided on the inner wall of the cable duct 1, and two symmetrical airbags 3 are embedded in the inner wall of the rubber collar 2, and one end of the airbag 3 is inserted inside One end of the circulation pipe 4 is provided, the other end of the circulation pipe 4 is fixedly connected to one end of the fixed pipe 5, the fixed pipe 5 is located in the cable duct 1, and the other end of the fixed pipe 5 is fixedly connected to one end of the limit support plate 6, and the limit support The other end of the plate 6 is in contact with the inner wall of the cable duct 1, and one end of the limit support plate 6 is embedded with a breathable film 7, and the breathable film 7 is in contact with the fixed pipe 5, and two symmetrical The deformation collar 8 is fixedly connected to the outside of the rubber collar 2 with a plurality of evenly distributed ball bags 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com