A sampling device for geological structure exploration

A sampling device and geological structure technology, applied in the direction of sampling devices, etc., can solve the problems of too many on-site tools, inconvenient use, and easy to throw on the surrounding staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

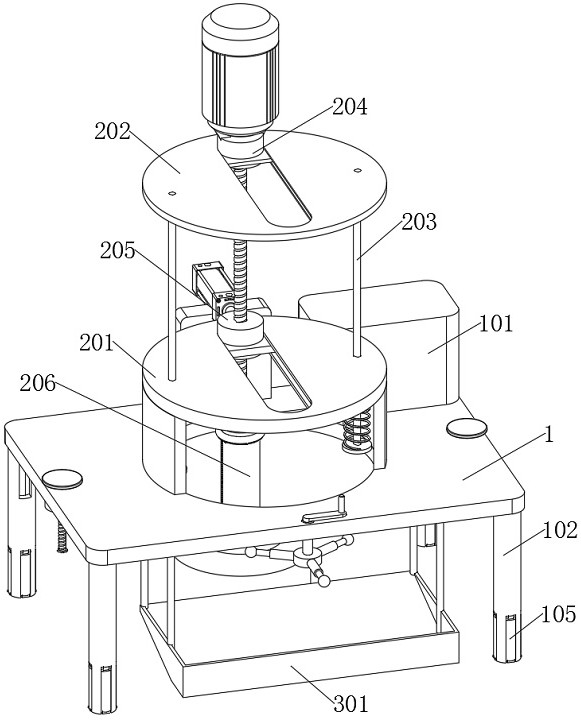

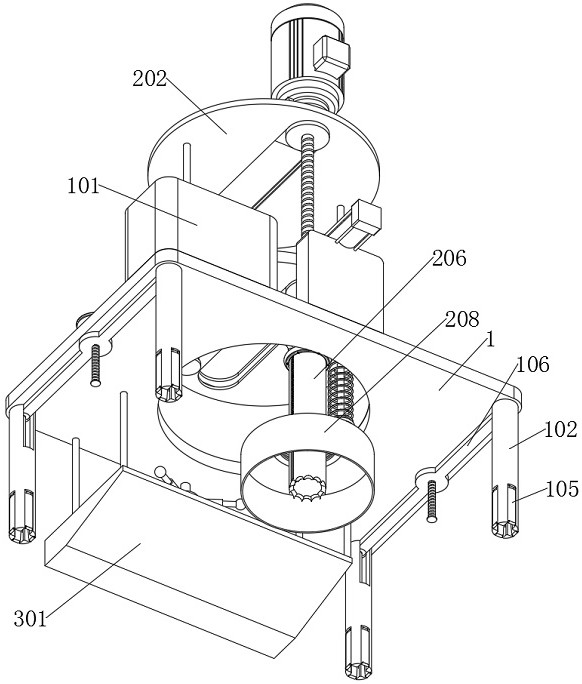

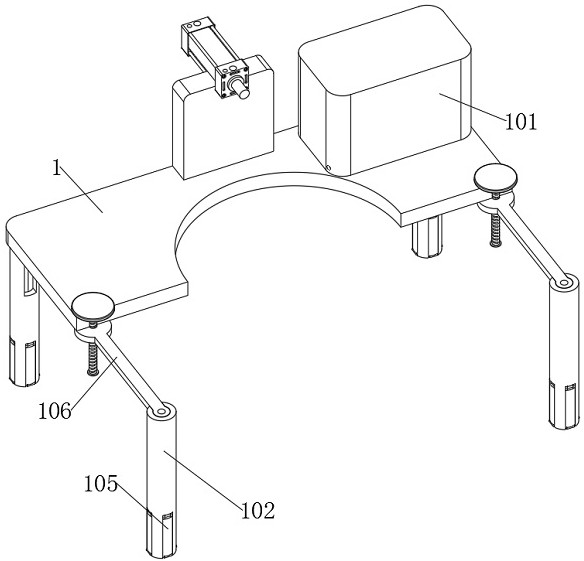

[0039] Example: please refer to Figure 1 to Figure 8 :

[0040] The present invention provides a sampling device for geological structure survey, comprising: a main body 1, the main body 1 is a rectangular plate-like structure, and a cylinder is installed on the rear side of the top of the main body 1 through a connecting plate, and the middle position of the top of the main body 1 is provided with a cylinder Slotting, the slot is a circular structure, and the top of the main body 1 is installed with a rotating assembly 2; the rotating assembly 2, the rotating assembly 2 includes a carrier plate 201, and a support plate is installed at the bottom of the carrier plate 201, and the bottom of the support plate is installed on the The top of the main body 1 and the support plates at the bottom of the carrier plate 201 are located on both sides of the groove on the top of the main body 1 , and the top of the carrier plate 201 is provided with a chute;

[0041] like figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com