Carbon washing groove and production method of low-ash-content water purification activated carbon

A production method and carbon tank technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of simple production process, high ash content of activated carbon, less effective micropores, etc., and achieve good taste, well-developed micropores, The effect of high iodine adsorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

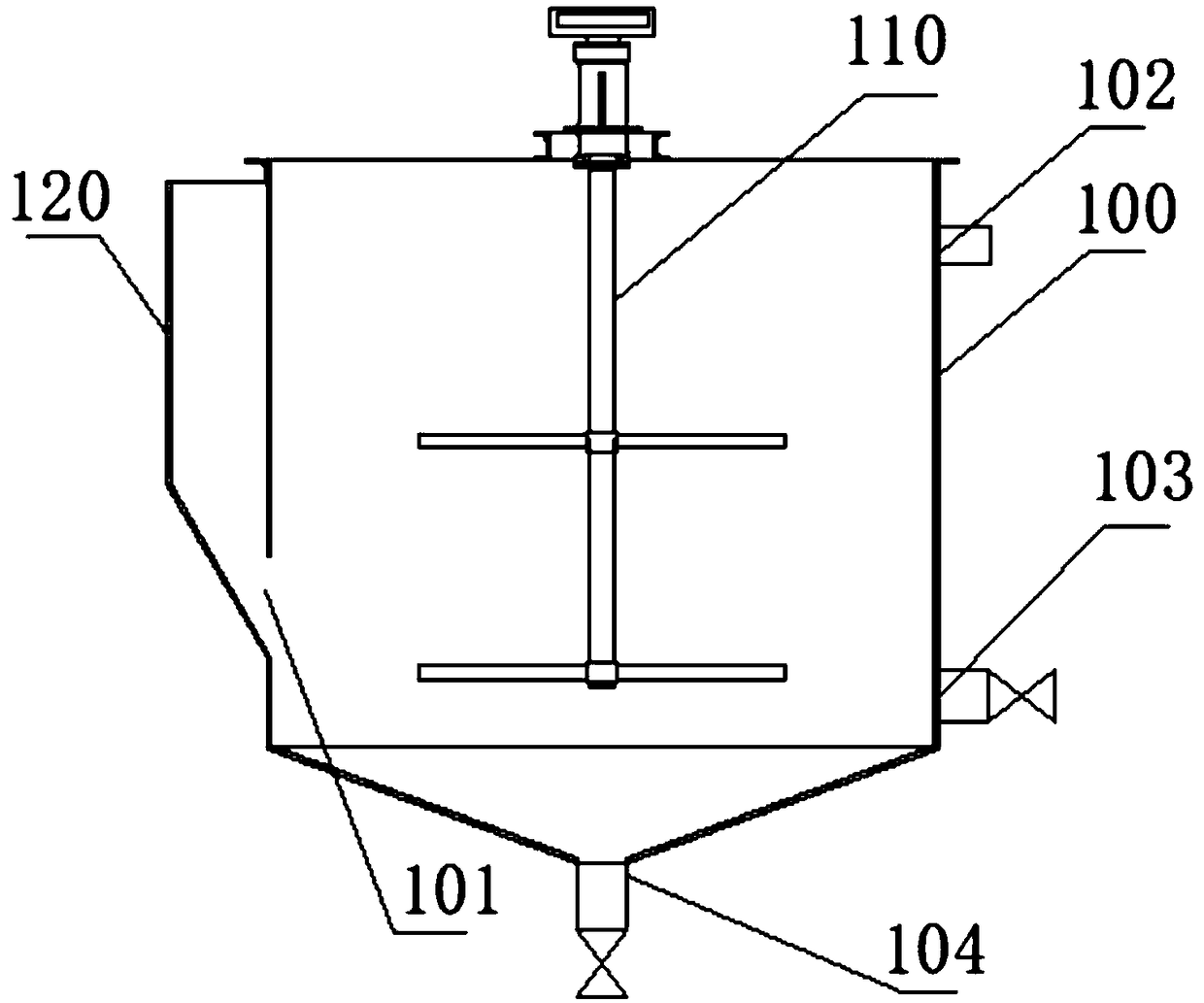

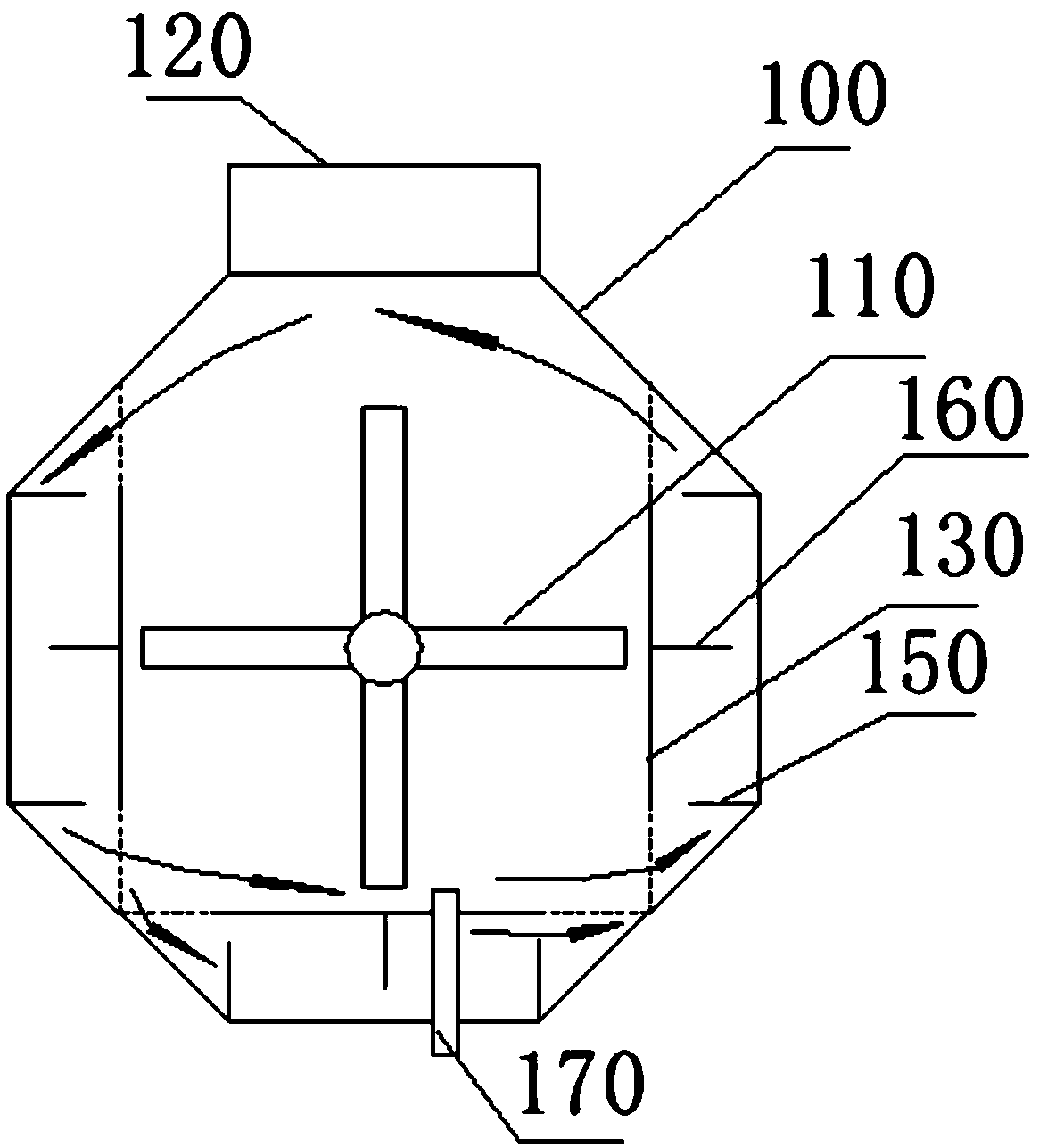

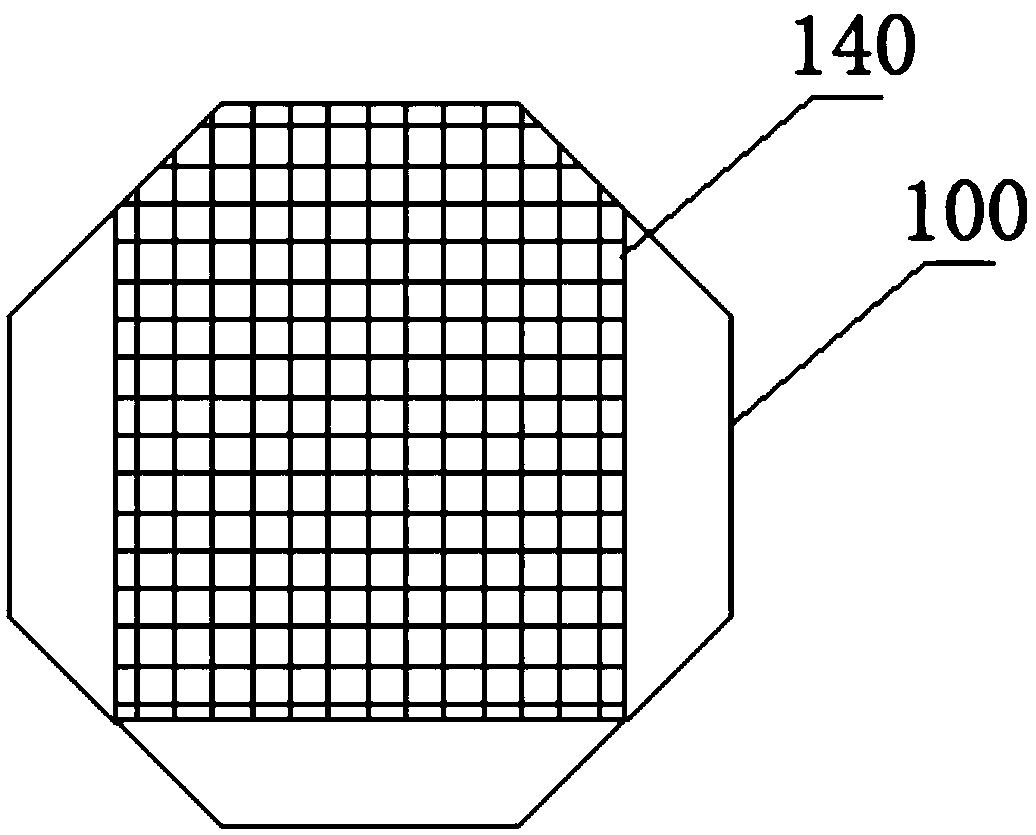

[0048] Such as Figure 1 to Figure 3 As shown, the present invention provides charcoal washing tank, comprising:

[0049] The tank body 100 is provided with a feed inlet 101, a water inlet 102, a slurry outlet 103 and a sand outlet 104, the sand outlet 104 is located below the slurry outlet 103; the slurry outlet 103 and the sand outlet 104 are respectively provided with a discharge Material valve and sand discharge valve.

[0050] A stirring device 110 is arranged in the tank body 100 .

[0051] The charcoal washing tank provided by this solution, when in use, first introduces water into the tank body 100, and then introduces crushed materials into the tank body 100 through the feed port 101. During the stirring process of the stirring device 110, the materials follow the water flow Tumbling, rubbing and scrubbing the materials against each other, and rubbing and scrubbing with the inner wall of the tank body 100 and the blades. After elutriation, the sand particles sink to...

Embodiment 2

[0076] Such as Figures 1 to 3 As shown, the present invention provides charcoal washing tank, comprising:

[0077] The tank body 100 is provided with a feed inlet 101, a water inlet 102, a slurry outlet 103 and a sand outlet 104, the sand outlet 104 is located below the slurry outlet 103; the slurry outlet 103 and the sand outlet 104 are respectively provided with a discharge Material valve and sand discharge valve.

[0078] A stirring device 110 is arranged in the tank body 100 .

[0079] The charcoal washing tank provided by this solution, when in use, first introduces water into the tank body 100, and then introduces crushed materials into the tank body 100 through the feed port 101. During the stirring process of the stirring device 110, the materials follow the water flow Tumbling, rubbing and scrubbing the materials against each other, and rubbing and scrubbing with the inner wall of the tank body 100 and the blades. After elutriation, the sand particles sink to the b...

Embodiment 3

[0104] Such as Figures 1 to 3 As shown, the present invention provides charcoal washing tank, comprising:

[0105] The tank body 100 is provided with a feed inlet 101, a water inlet 102, a slurry outlet 103 and a sand outlet 104, the sand outlet 104 is located below the slurry outlet 103; the slurry outlet 103 and the sand outlet 104 are respectively provided with a discharge Material valve and sand discharge valve.

[0106] A stirring device 110 is arranged in the tank body 100 .

[0107] The charcoal washing tank provided by this solution, when in use, first introduces water into the tank body 100, and then introduces crushed materials into the tank body 100 through the feed port 101. During the stirring process of the stirring device 110, the materials follow the water flow Tumbling, rubbing and scrubbing the materials against each other, and rubbing and scrubbing with the inner wall of the tank body 100 and the blades. After elutriation, the sand particles sink to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com