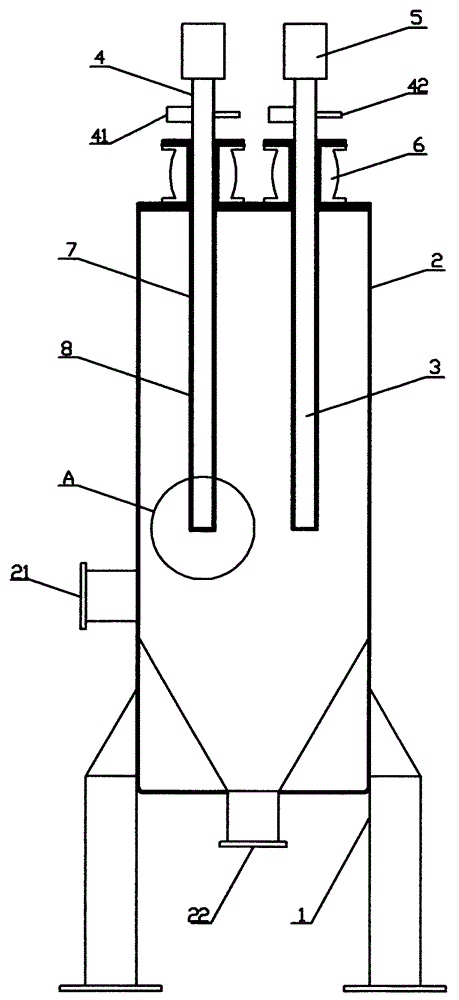

A tubular concentration device

A thickening device and tube-type technology, which is applied in the fields of sludge treatment industrial equipment manufacturing, brewing, and papermaking, can solve the problems of heavy maintenance workload, reduced work efficiency, and pressure difference, and achieve short replacement time and long life of filter bags The effect of prolonging and increasing the filtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

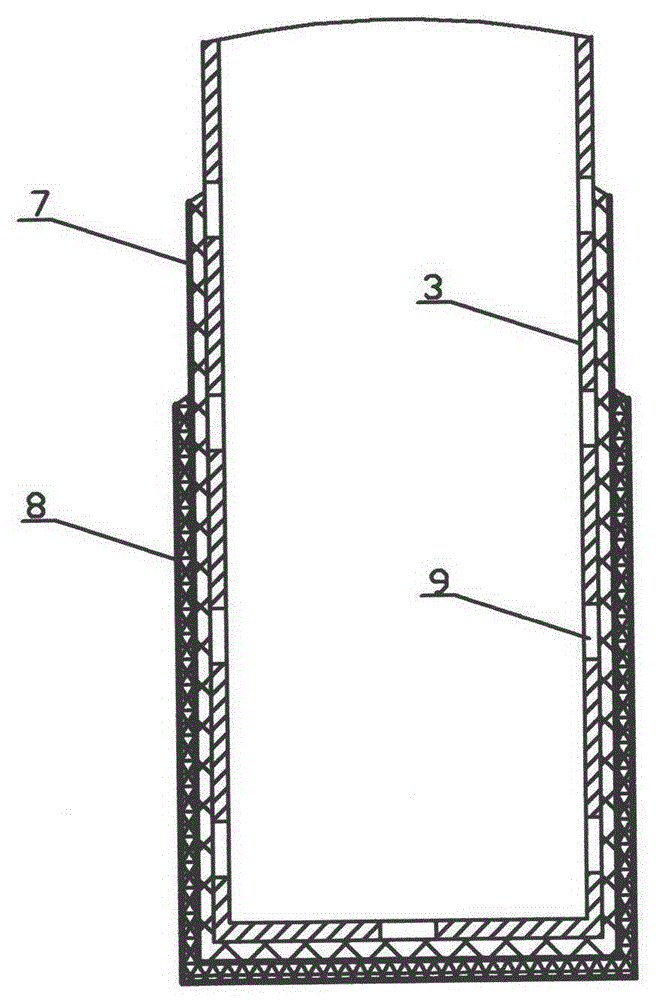

Method used

Image

Examples

example 1

[0036] Example 1: The new line of Guangdong Huiyun Titanium Industry Co., Ltd. has an annual output of 35,000 tons of titanium dioxide. It was originally equipped with seven 600-square-meter box-type filter presses to produce sludge with a solid content of about 45%, and then add water to make solid The mud with a content of about 25% enters the high-pressure sludge dryer. The project investment is about 12 million yuan, and the annual operating cost is about 6 million yuan. However, the investment of the device of the present invention is only 3.6 million yuan, and the annual operating cost is less than 1 million yuan. Bring huge economic benefits to the enterprise.

example 2

[0037] Example 2: Guangxi Pingguo Lily Chemical uses a common shell and tube filter to concentrate titanium dioxide wastewater. Since the wastewater contains a small amount of ferric hydroxide colloid, the filter cake formed on the surface of the filter tube with gypsum in the wastewater is very viscous. Relying on the filtrate to carry out negative pressure recoil can not be flushed at all, which seriously affects the filtration. In addition, there is no diversion layer outside the filter tube, only the filter cloth at the through hole of the filter tube can filter, and the area without openings accounts for as much as 65% of the total surface area of the filter tube, so more than 60% of the filter cloth does not filter effect, this also greatly affects the filtering and concentrating effect, so it is necessary to adopt 6 sets of tubular filters with an investment of more than 4 million yuan and an annual operating cost of more than 1.2 million yuan, while using the device o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com