Side pulling and ejection device and injection mold

An ejector and injection mold technology, applied in the field of molds, can solve the problems of increasing installation difficulty, increasing mold design costs, and the inability of molded products to fall off automatically, and achieve the effect of accelerating the falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

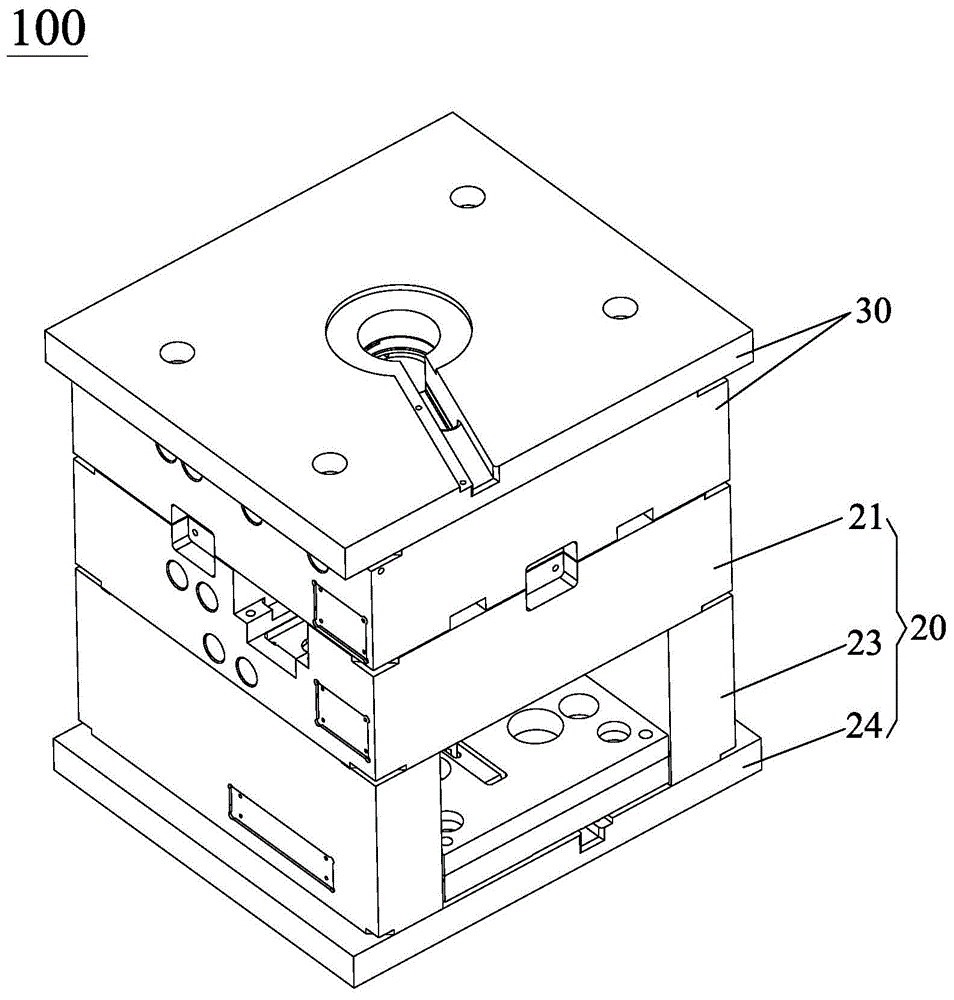

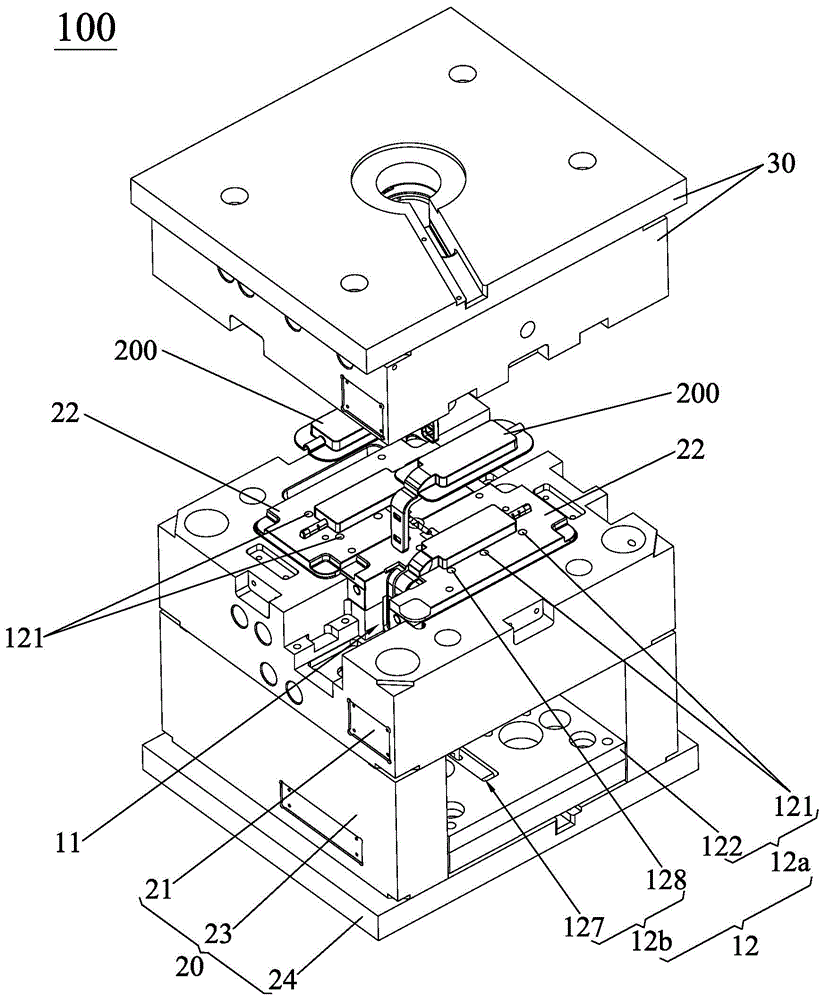

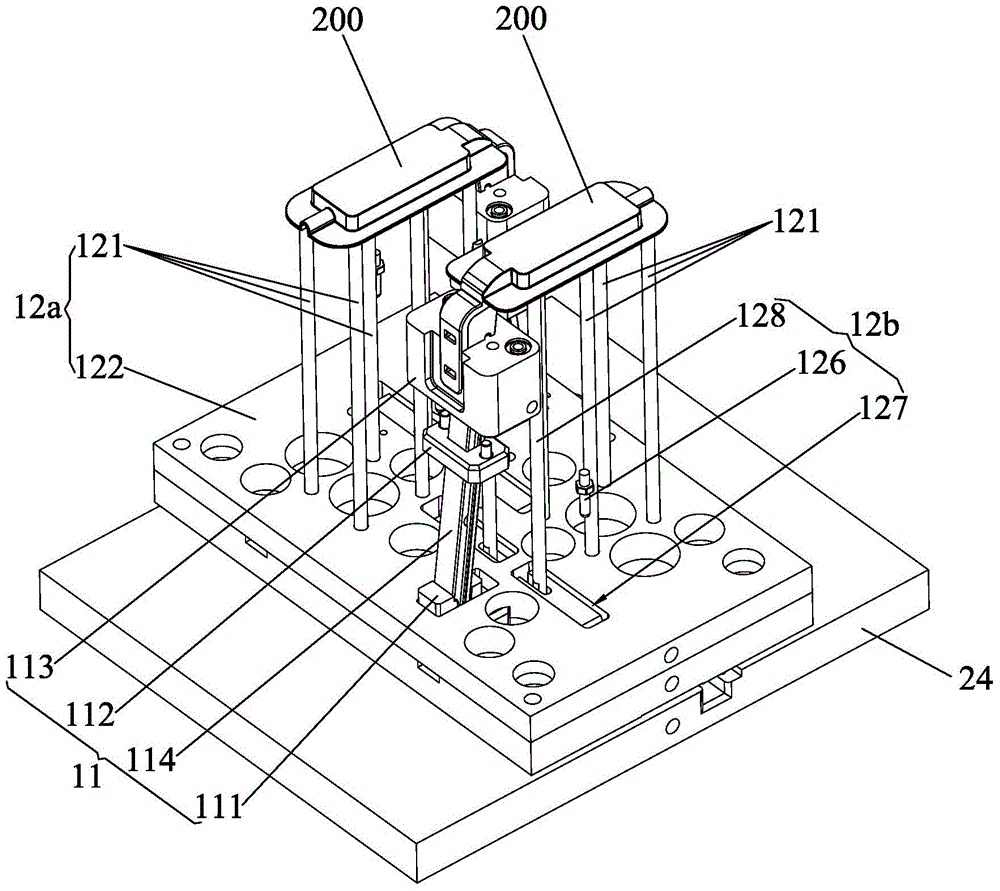

[0025] see Figure 1 to Figure 5 , the injection mold 100 of the present invention includes a movable mold 20 , a fixed mold 30 and a side ejector device 10 . The movable mold 20 and the fixed mold 30 form a molding cavity (not shown in the figure), so that the molten plastic is cooled in the molding cavity to form the desired molded product 200 . Specifically, in the present embodiment, the movable mold 20 comprises a base 24, a support block 23, a movable mold core 22 and a movable mold core fixing plate 21, and the support block 23 is along the mold opening direction (such as figure 2 In the direction from bottom to top) respectively installed on the corresponding two sides of the base 24 (such as figure 2 the left and right sides of the middle base 24), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com