Rotary tool turret special for NC turning and milling center and rotation method

A technology of CNC center and rotary turret, applied in the direction of tool holders, etc., can solve the problems of difficult replacement of tool handles, easy loosening of tool handles, easy deflection, and up and down movement of turrets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

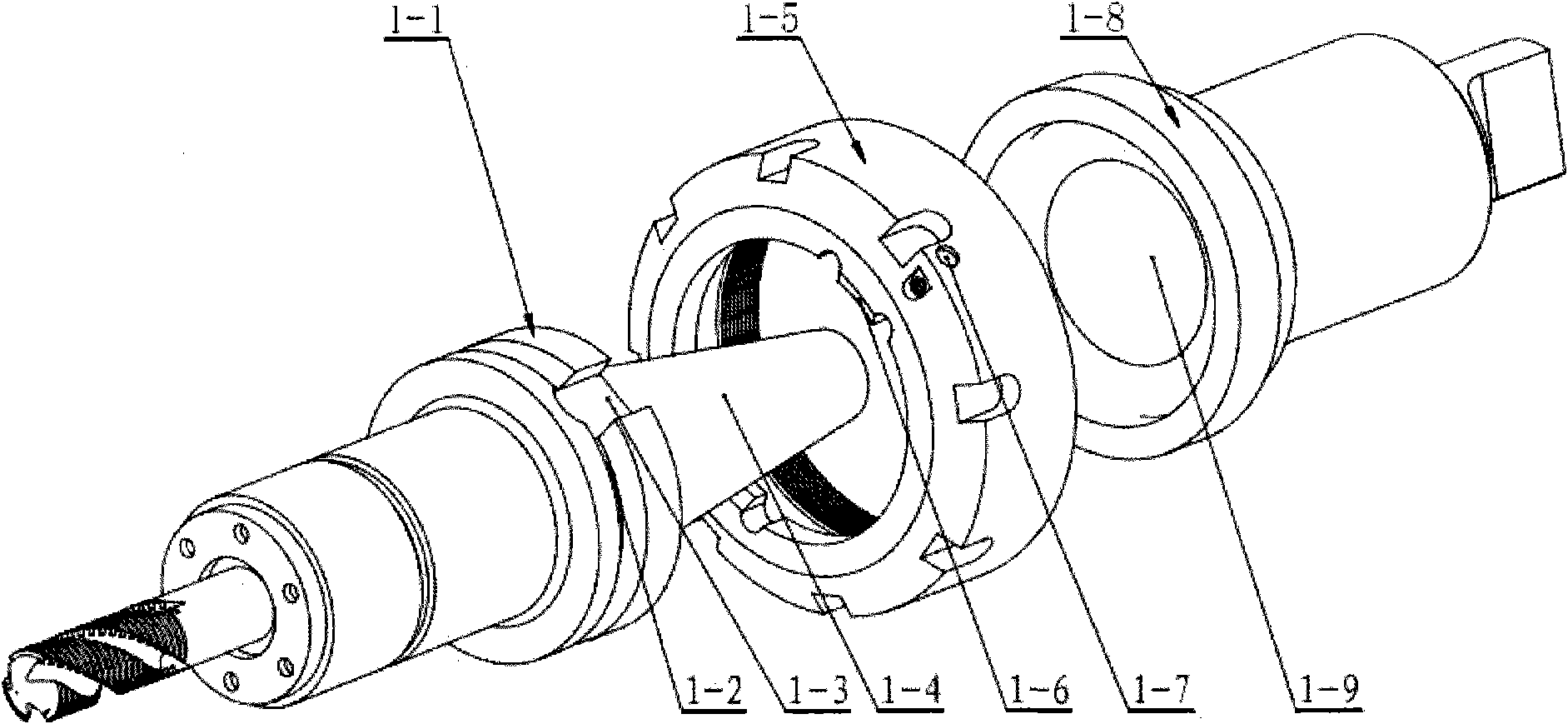

[0021] Embodiment 1: see attached Figure 1 to Figure 5 . It includes Dota ( Figure 5-1 ), the guide seat in the turret ( Figure 4-4 ) indirectly fastened to the base ( Figure 5-4 ), a round hole is opened on the normal surface of the guide seat ( Figure 4-3 ), so that the main shaft drive shaft ( Figure 4-2 ) is connected to the transmission, and the outer circular surface of the guide seat has a glyph guide groove ( Figure 4-5 ), the distance between the upper and lower ends is symmetrical to the center of the circular hole on the normal plane. One-shaped flat head handle seat ( figure 1 -8) The tail is formed into an inline flat head and is located in the inline guide groove in the guide seat. The inline flat head handle seat cooperates with the inline guide groove on the guide seat and rotates along the guide seat. wear plate ( Figure 4 -6) It is built into the inline guide groove of the guide seat and the wear-resistant sheet is located on the left side a...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, the rotation method of the special rotary turret of the turning and milling CNC center, when the turret is rotating, it drives the inline flat head tool handle seat ( figure 1 -8) With the guide seat inline guide groove ( Figure 4-5 ) for a 360-degree circular rotation, and after the turret rotates at a specific angle, the flat head at the end of the flat head handle seat is transferred into the flat groove of the main shaft drive shaft ( Pic 4-1 ) after anastomosis, the main shaft drive shaft is driven by the servo motor ( Figure 4-2 ) rotation, so that the flat-shaped flat head handle seat is rotated, and at this time, the V-shaped groove handle ( Picture 1-1 ) and tools to process the parts.

Embodiment 3

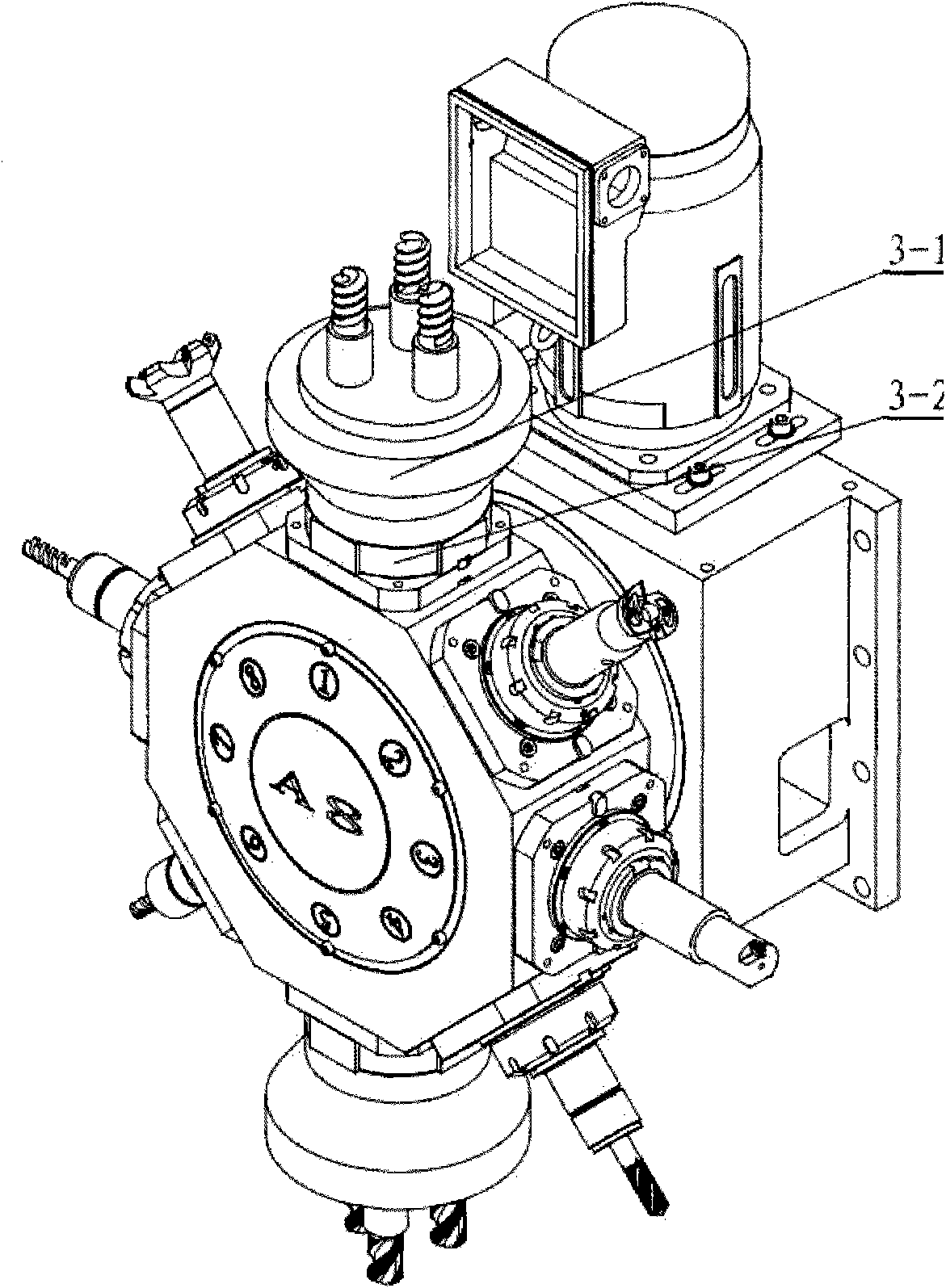

[0027] Embodiment 3: On the basis of Embodiment 1, a kind of turret rotating structure, it comprises turret, and described turret rotates and adopts three-plate clutch structure and is divided by indexing ring A ( Figure 5-3 ), indexing tooth plate B ( Figure 5-2 ), indexing tooth disc C ( Figure 5-5 ) and friction plate ( Figure 5 -6) composition, the indexing tooth plate A is fastened on the turret ( Figure 5-1 ), the index ring C is fastened to the base ( Figure 5-4 ), the indexing toothed disc B can be used for piston movement, the gears of the indexing toothed disc A and the indexing toothed disc C are aligned, and the indexing toothed disc B performs the toothing of the indexing toothed disc A and the indexing toothed disc C snap lock, servo motor and worm ( Figure 5 -9) and drive the worm wheel through the worm ( Figure 5 -7) rotation, the worm gear is installed on the cylindrical helical gear shaft ( Figure 5 -8), the outer circular helical gear of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com